Tightening chain fixing mechanism

A fixing mechanism and fixing seat technology, which is applied in the direction of friction clamping detachable fasteners, connecting components, supporting machines, etc., can solve the problems of limited installation space of fixed brackets, insufficient tightening force, fixed installation length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

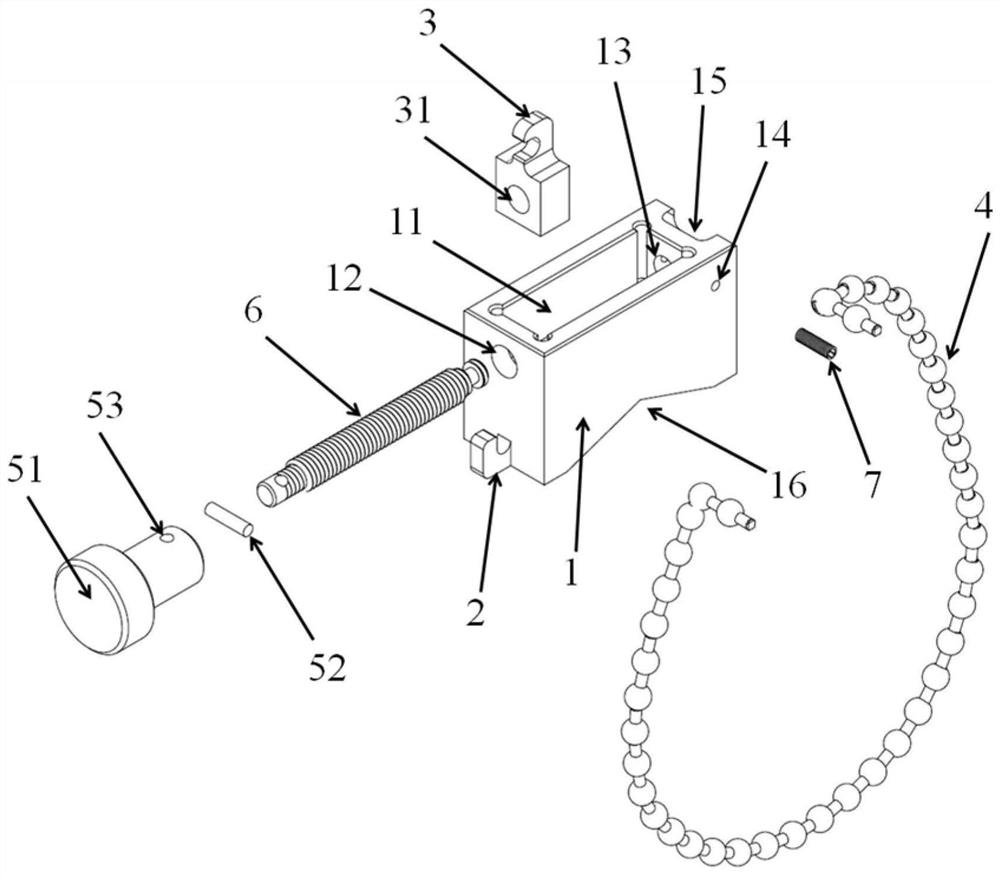

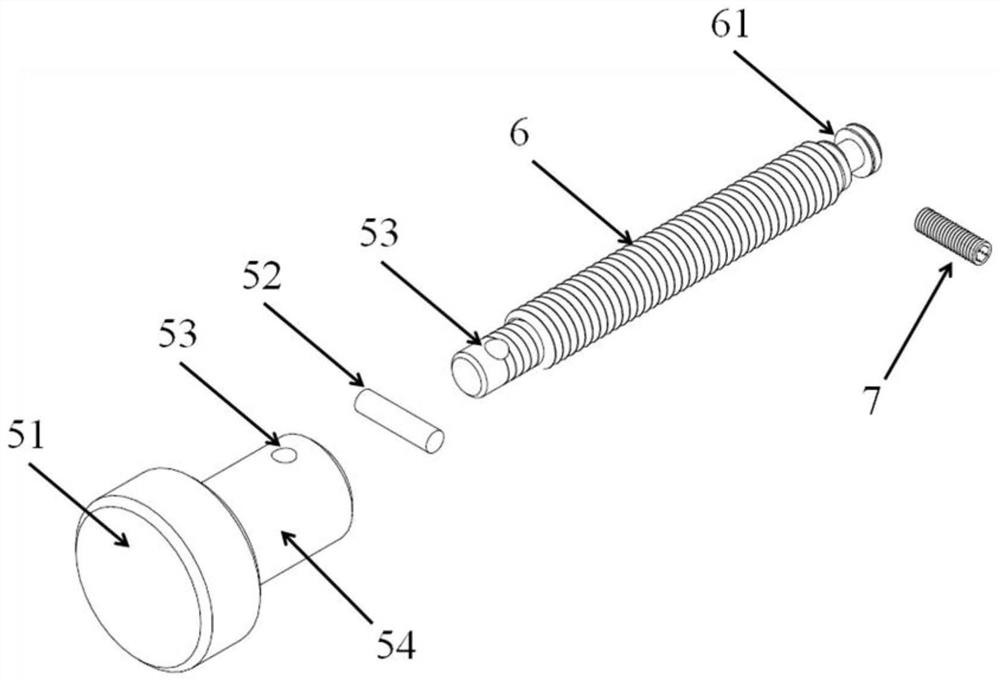

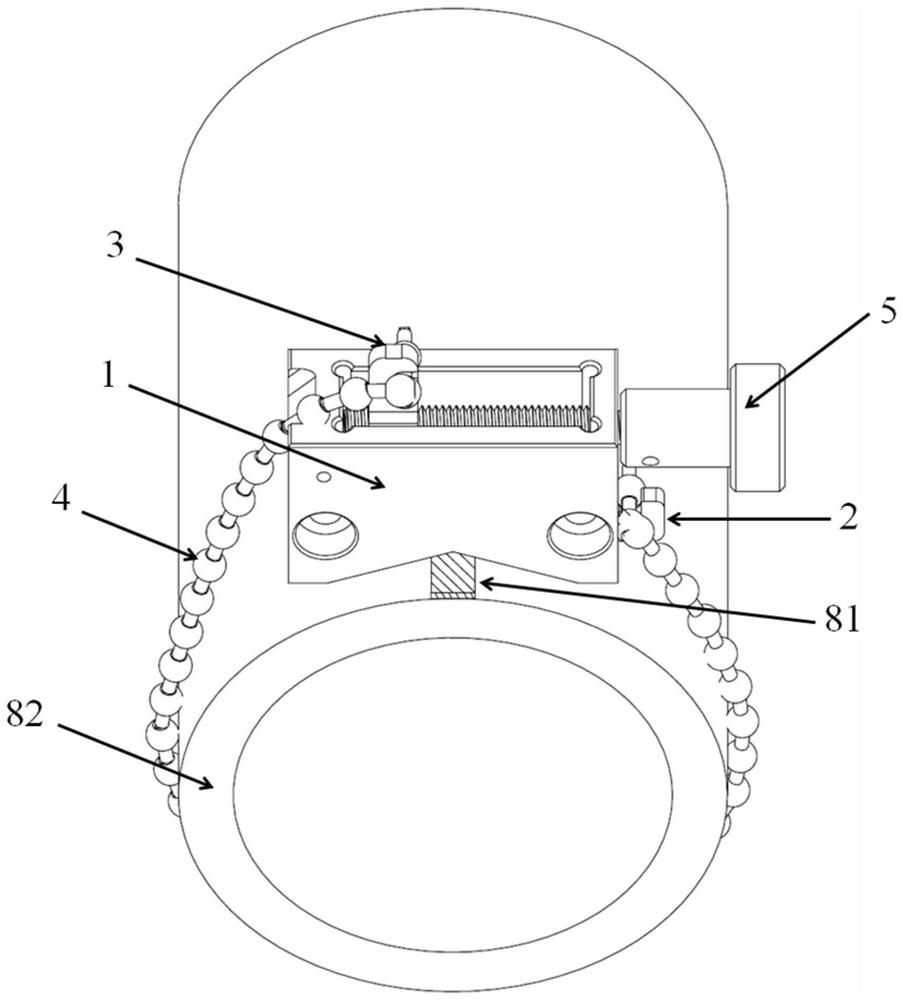

[0024] like Figure 1 to Figure 3 As shown, a tightening chain fixing mechanism of the present invention includes a fixed seat 1, a fixed hook 2, a movable hook 3, a tightening chain 4, a driving part 5, and a directional rod 6, and the fixed hook 2 is fixedly connected to the fixed On the seat 1, the fixed seat 1 is provided with a guide groove 11, the directional rod 6 is arranged in the guide groove 11, the movable hook 3 is connected on the directional rod 6, one end of the tightening chain 4 is stuck on the fixed hook 2, and the other One end is stuck on the movable hook 3 after bypassing the object to be fixed, the driving part 5 is connected to the directional rod 6 and drives the movable hook 3 to move along the guide groove 11 through the directional rod 6, and the movable hook 3 is close to the fixed hook 2 The direction of moving makes tightening chain 4 taut.

[0025] The tightening chain fixing mechanism includes a directional rod limit post 7, a directional rod ...

Embodiment 2

[0032] like Figure 1 to Figure 3 As shown, on the basis of the first embodiment, a guide rail can be provided in the guide groove 11, and the movable hook 3 is first slidably connected to the guide rail. The threaded hole 31 is cooperatively connected with the movable hook 3, and the rotating screw rod drives the movable hook 3 to move directionally along the guide rail. The design of the guide rail allows the movable hook 3 to move on the directional track of the guide rail, which is also a kind of positioning for the movable hook. When assembling, the screw rod is directly screwed into the threaded hole 31 of the movable hook 3 and fixed in the guide groove within 11.

[0033] As another embodiment, the guide groove 11 can also be entirely replaced with a guide rail structure. There is a movable hook 3 on the guide rail, and a screw rod passes through the middle of the movable hook 3. Rotating the screw rod realizes the orientation of the movable hook 3 along the guide rail....

Embodiment 3

[0035] On the basis of Embodiments 1 and 2, the driving part 5 can be replaced by a cylinder or a hydraulic cylinder, and the positioning rod 6 can be replaced by a cylinder connecting rod or a hydraulic cylinder connecting rod. The cylinder drives the movable hook 3 along the guide through the cylinder connecting rod. The groove 11 moves in a direction, or the hydraulic cylinder drives the movable hook 3 to move in a direction along the guide groove 11 through the connecting rod of the hydraulic cylinder. Cooperating with the guide groove 11 or the guide rail, the directional movement of the movable hook 3 is directly driven by the cylinder or hydraulic cylinder, and the tension of the tightening chain 4 can also be well controlled, and it can be used with automation equipment or realize remote electronic control.

[0036] The driving mechanism, positioning rod 6, and guide groove 11 of the present invention are not limited to the schemes described, as long as the structure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com