Icing wind tunnel anti-icing and deicing test method and system

A test method and test system technology, applied in the field of anti-icing and deicing test methods and systems in icing wind tunnels, can solve problems such as easy icing or overflow ice, difficulty in setting periodic control laws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

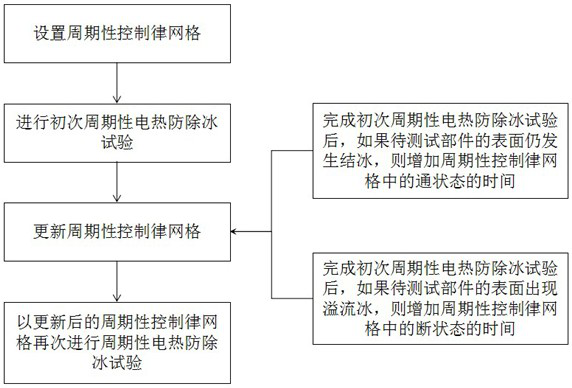

[0057] Such as Figure 4 Shown is a kind of icing wind tunnel anti-deicing test method provided by the embodiment of the present invention, which comprises the following steps:

[0058] Set up a periodic control law mesh;

[0059] Carry out the initial periodic electric heating anti-icing test;

[0060] Update the periodic control law grid according to the following conditions to obtain the updated periodic control law grid: after the initial periodic electrothermal anti-icing test, if the surface of the component to be tested still freezes, add the periodic control law grid time in the on-state in the grid; after completing the initial periodic electrothermal anti-icing test, if overflow ice appears on the surface of the component to be tested, increase the time in the off-state in the periodic control law grid;

[0061] The periodic electrothermal anti-icing test is carried out again with the updated periodic control law grid.

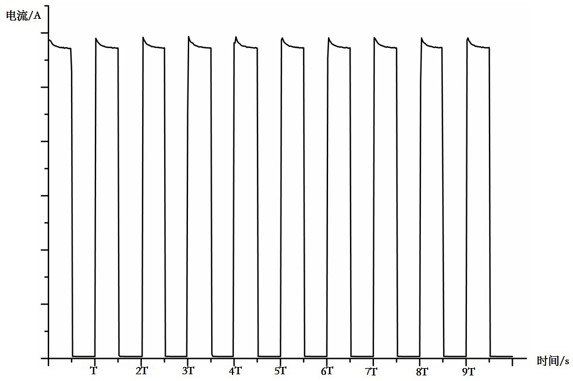

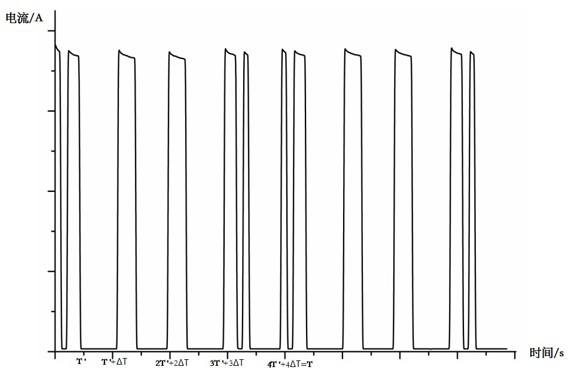

[0062] In the embodiment of the present inv...

Embodiment 2

[0074] Embodiment 2 of the present invention provides an icing wind tunnel anti-icing test system, which includes a periodic control law grid setting module and a periodic control law grid updating module, wherein:

[0075] The periodic control law grid setting module is used to set the periodic control law grid;

[0076] The periodic control law grid update module is used to update the periodic control law grid according to the following conditions after the initial periodic electrothermal anti-icing test to obtain the updated periodic control law grid: the initial periodic electrothermal anti-icing test is completed After the test, if ice still occurs on the surface of the component to be tested, increase the time of the on-state in the periodic control law grid; after completing the initial periodic electrothermal anti-icing test, if there is overflow ice on the surface of the component to be tested, Then increase the off-state time in the periodic control law mesh.

[0077]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com