Water inlet pipeline filtering device for tower crane spraying machine

A technology of a tower crane sprayer and a filter device, applied in the field of sprayers, can solve the problems of reducing the spray range effect of the spray head, affecting the dust reduction treatment effect of the construction site, and difficult to disassemble the spray head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

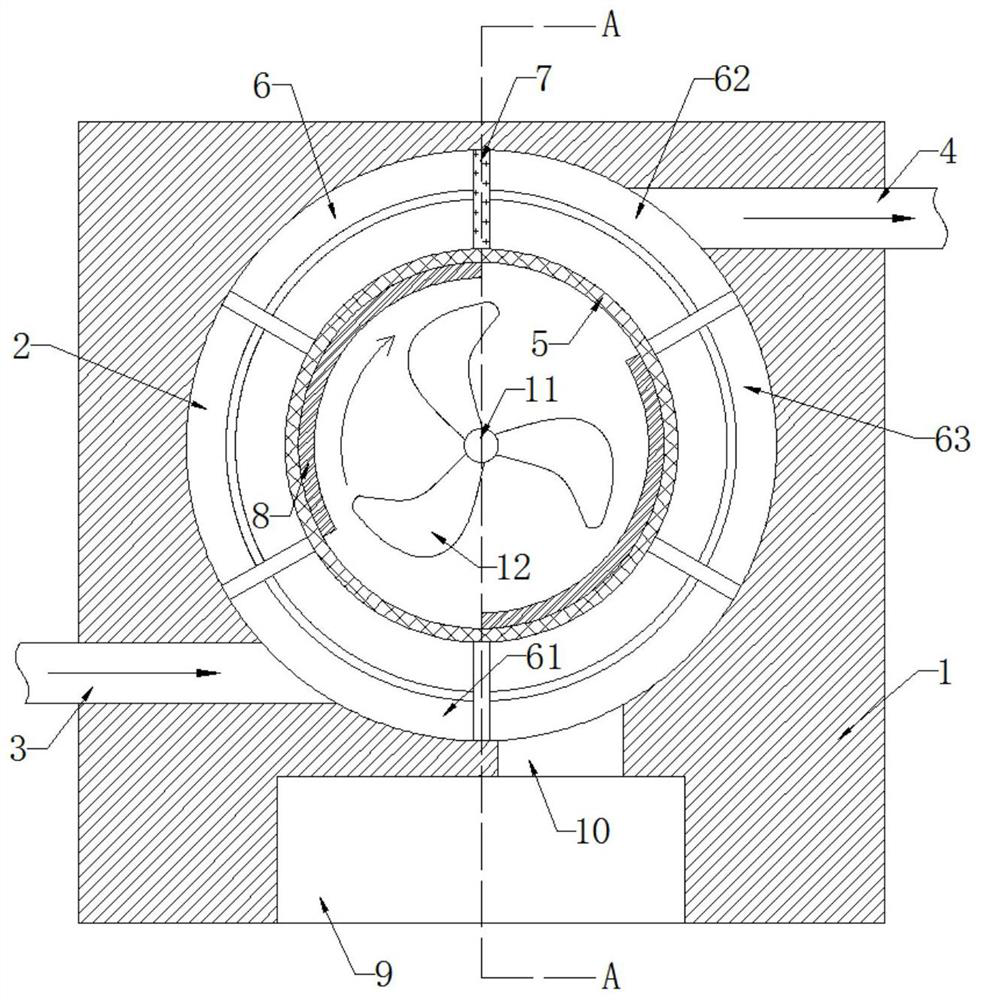

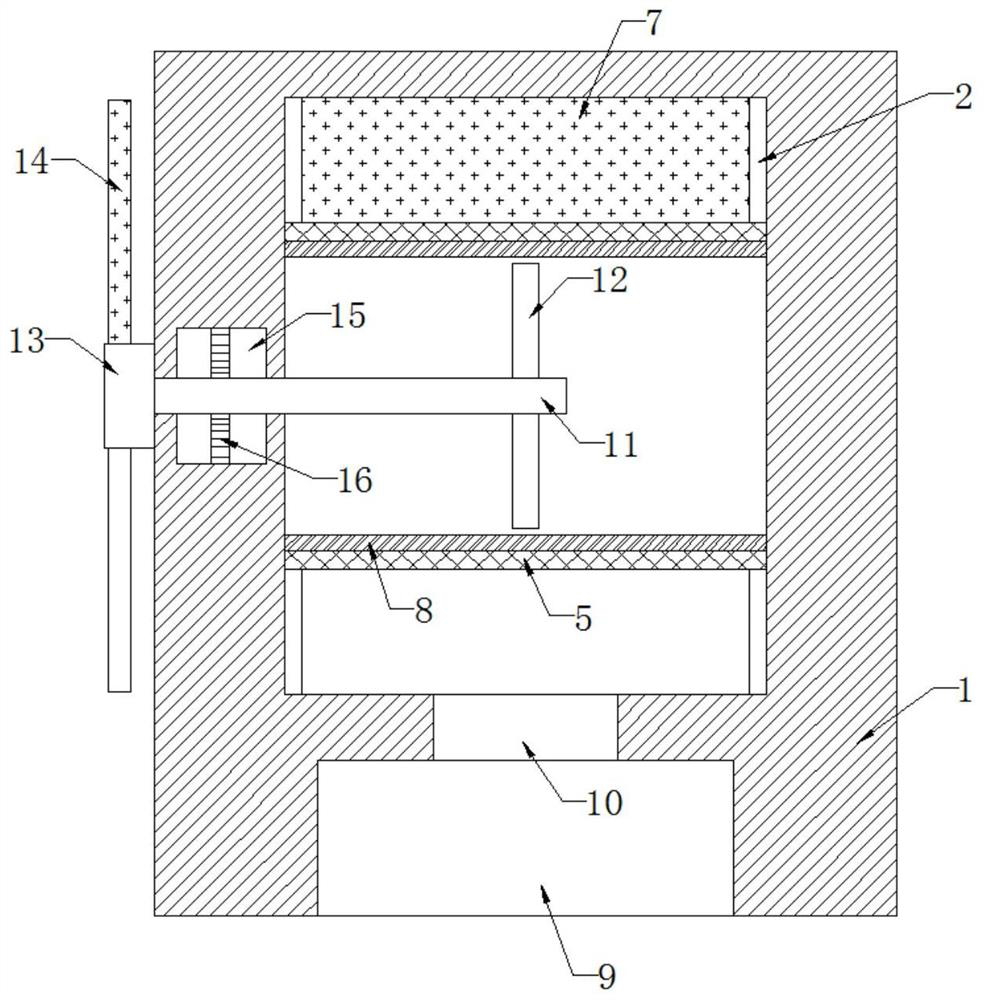

[0019] refer to Figure 1-2 , a water inlet pipe filter device for a tower crane spray machine, comprising a housing 1, a circular chamber 2 is opened in the housing 1, a water inlet pipe 3 is connected below the inner wall of the circular chamber 2, and a water inlet pipe 3 is connected above the inner wall of the circular chamber 2 The water outlet pipe 4, further, the water inlet pipe 3 and the circulating water recovery system, the circulating water recovery system is the prior art, and will not be repeated here, the water outlet pipe 4 is connected to the water inlet pipe in the sprayer, and the inner wall of the circular cavity 2 is fixed Connected with an annular filter screen 5, the annular filter screen 5 and the inner wall of the circular cavity 2 form an annular cavity 6, and the inner wall of the annular cavity 6 is sealed and slidably connected with a plurality of scrapers 7, and the plurality of scrapers 7 are fixedly connected by connecting rods, wherein One scr...

Embodiment 2

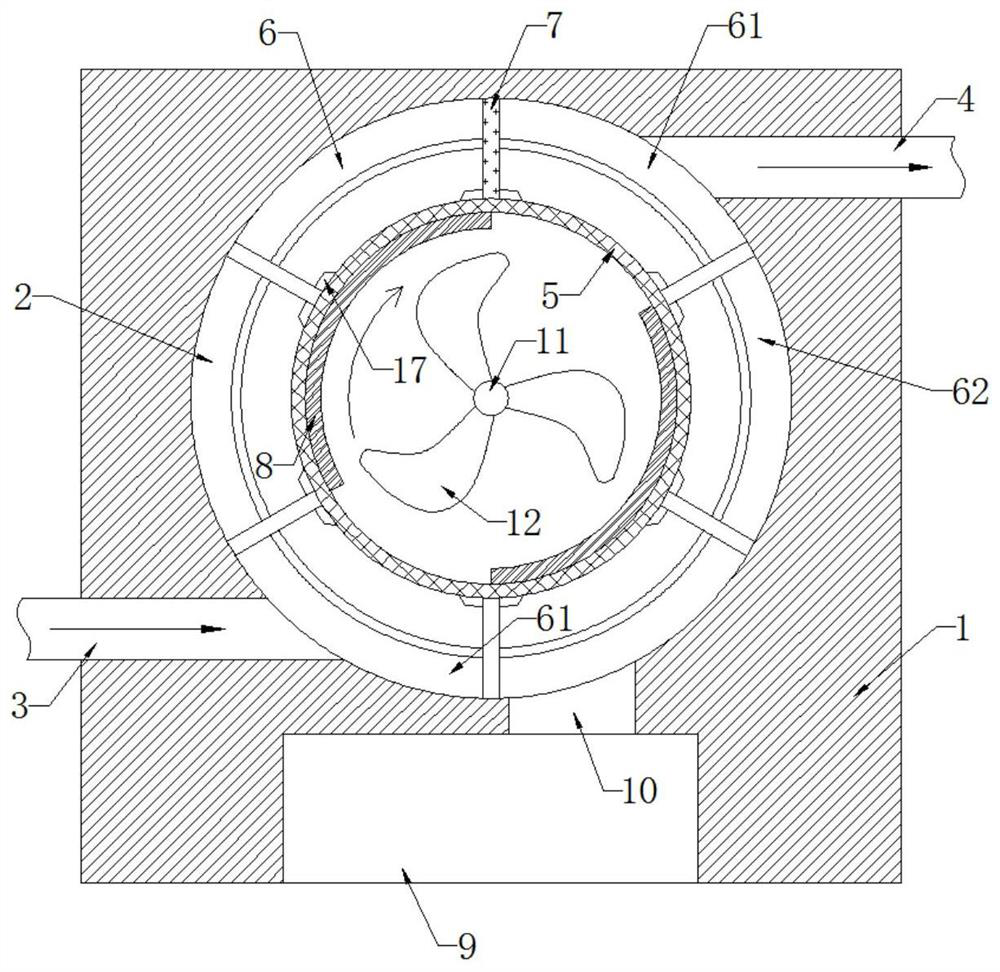

[0025] refer to image 3 , and the difference from Embodiment 1 is that one end of a plurality of scrapers 7 is fixedly connected with a scraper 17 attached to the side wall of the annular filter screen 5 .

[0026] In this embodiment, when the impeller 14 drives the scraper 7 to rotate on the inner wall of the annular cavity 6, the scraper 17 fixedly connected to the side wall of the scraper 7 can scrape off the impurities adhered to the annular filter screen 5, and the annular The filter screen 5 is further cleaned to prevent the impurities adhering to the annular filter screen 5 from clogging the mesh holes and affecting the entry of water flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com