Skin-friendly breathable double-layer velvet cotton fabric and preparation method thereof

A velvet cotton and double-layer technology, applied in the field of materials, can solve problems such as skin-friendly properties and poor air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention also provides a method for preparing a skin-friendly and breathable double-layer velvet cotton fabric, comprising the following steps:

[0039] Step 301, blending modified cotton fibers and mulberry silk to form a modified cotton layer.

[0040] Step 302, weaving the modified polyester fibers as warp and weft yarns to form a modified polyester layer.

[0041] Step 303, using an adhesive to bond the modified cotton layer and the modified polyester layer together to obtain the skin-friendly and breathable double-layer velvet cotton fabric.

[0042] In the embodiment of the present invention, the adhesive may be water-based glue, for example, JL-8261 water-based self-adhesive, JL-606 dry-type water-based laminating adhesive, and the like.

Embodiment 1

[0045] The skin-friendly and breathable double-layer velvet cotton fabric in the present embodiment is prepared by the following method:

[0046] Prepare the modified cotton layer: freeze-dry the cotton fiber and pulverize it, disperse the pulverized cotton fiber in cobalt hydroxide / sulfolane solution, react at 80°C for 1 hour, cool, filter, wash 3 times and then freeze-dry to obtain Modified cotton fibers;

[0047] The modified cotton fiber and mulberry silk are used for blending to form a modified cotton layer.

[0048] Preparation of modified polyester layer: polyester is used as raw material, sliced, dried, and melted to obtain a melt; the melt is mixed with sodium dihydrogen phosphate for blending and spinning, and post-processed to obtain a polyester copolymer modified with surface micropores. Blended fibers; the temperature of blended spinning is controlled at 280°C, and the pressure is 7MPa;

[0049] The polyester blended fiber modified by surface micropores was immers...

Embodiment 2

[0054] The skin-friendly and breathable double-layer velvet cotton fabric in the present embodiment is prepared by the following method:

[0055] Prepare the modified cotton layer: freeze-dry the cotton fiber and pulverize it, disperse the pulverized cotton fiber in cobalt hydroxide / sulfolane solution, react at 90°C for 1 hour, cool, filter, wash twice and freeze-dry to obtain Modified cotton fibers;

[0056] The modified cotton fiber and mulberry silk are used for blending to form a modified cotton layer.

[0057] Preparation of modified polyester layer: polyester is used as raw material, sliced, dried, and melted to obtain a molten liquid; mixed with sodium dihydrogen phosphate and potassium dihydrogen phosphate in the molten liquid for blending and spinning, and post-processing to obtain micropores on the surface Modified polyester blended fiber; the temperature of the blended spinning is controlled at 290°C, and the pressure is 6MPa;

[0058] The polyester blended fiber ...

PUM

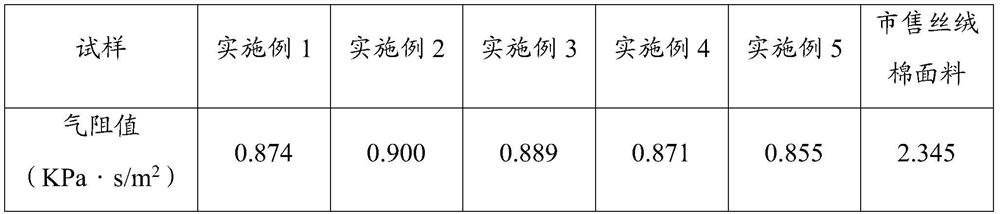

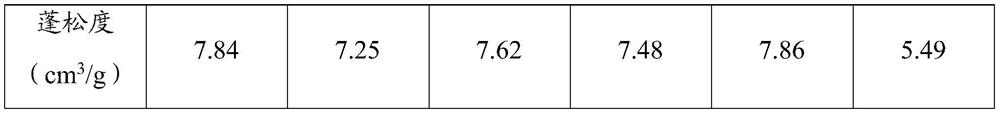

| Property | Measurement | Unit |

|---|---|---|

| Loft | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap