Vibration prevention device for new energy battery assembly

A battery assembly and new energy technology, applied in battery pack components, electrical components, circuits, etc., can solve the problems of limited shock absorption, no shock absorption, and lack of shock absorption functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

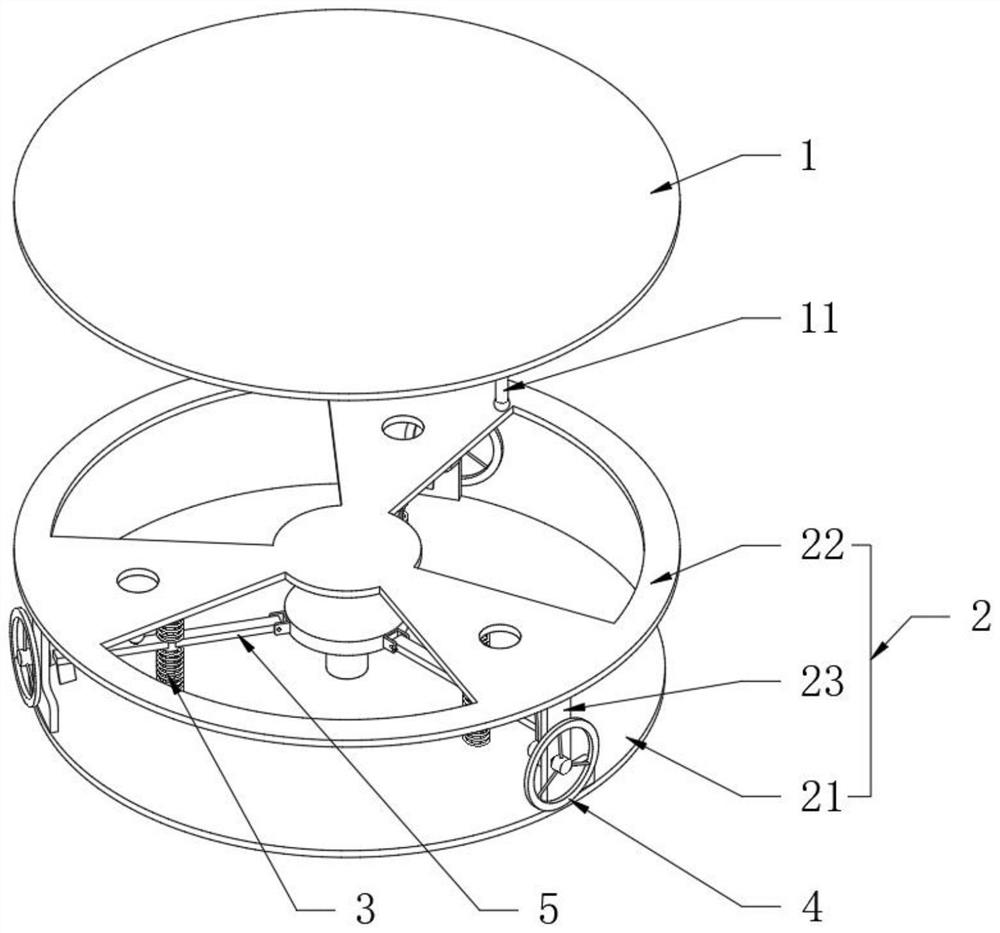

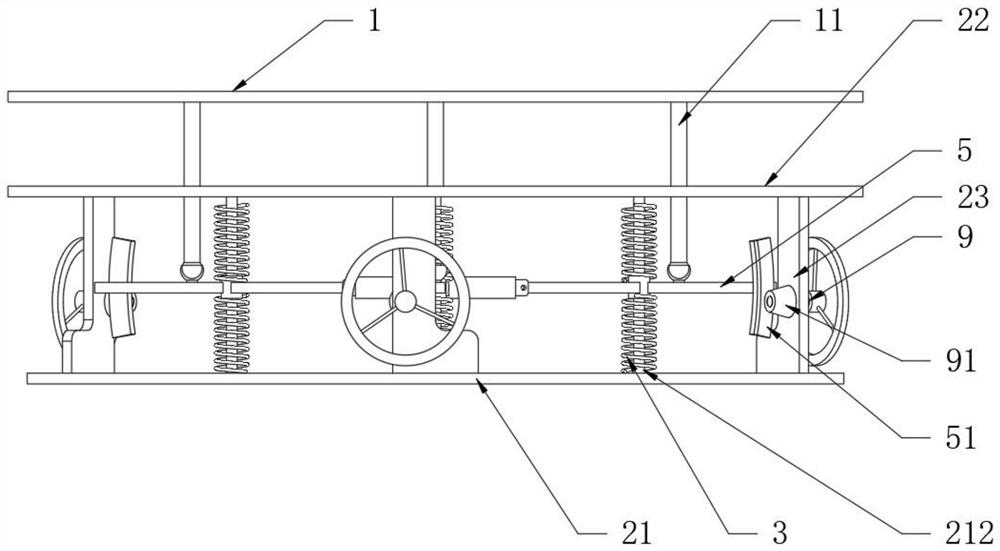

[0032] see Figure 1-3 , a shock-absorbing device for new energy battery components, including a battery mounting plate 1, a supporting device 2, a spring 3, a flywheel disc 4 and a connecting rod 5, the battery mounting plate 1 is used for fixing and installing the battery and its components, and the supporting device 2 It is used to be installed on the automobile and plays the role of support and positioning; the support device 2 is provided with a lower circular plate 21 and an upper circular plate 22 located on the upper part of the lower circular plate 21 and distributed through the axis center, and the lower surface wall of the upper circular plate 22 And near the outer periphery, three support plates 23 evenly distributed in the circumferential direction are fixedly connected with the lower circular plate 21. One side of the flywheel disc 4 is fixedly provided with a connecting shaft 9 at the center of the disc, and one end of the connecting shaft 9 runs through the supp...

Embodiment 2

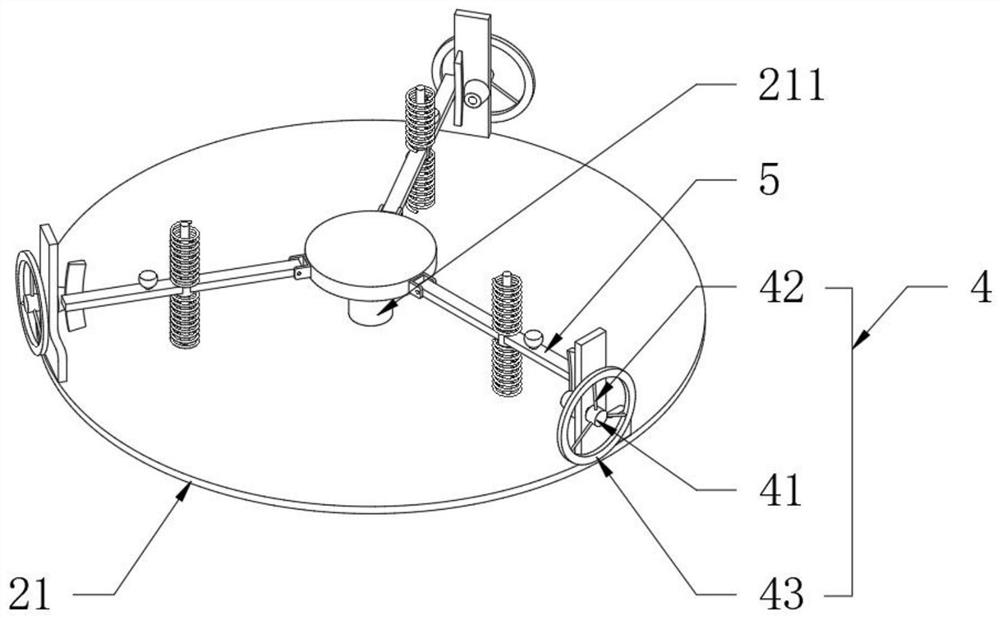

[0034] see image 3 with Figure 4, and the difference from Embodiment 1 is that the flywheel disc 4 is provided with an inner shaft 41, a fixed shaft 42 and an annular plate 43 sequentially along the radial direction from inside to outside, and the outer wall of the inner shaft 41 passes through the inner surface of the fixed shaft 42 and the annular plate 43 The wall is fixedly connected, and one side of the annular plate 43 is detachably connected with an annular counterweight plate 6. Specifically, one side of the annular plate 43 and one side of both sides of the annular counterweight plate 6 are fixedly provided with permanent magnet rings 102. When increasing the buffer strength, the inertial resistance of the flywheel disc 4 rotation can be improved by increasing the ring-shaped counterweight plate 6. If the rotational inertial resistance of the flywheel disc 4 is small, the battery mounting plate 1 is prone to tilt for smaller vibrations, and it is also There will be...

Embodiment 3

[0036] see Figure 4 The difference from Embodiment 2 is that the number of fixed shafts 42 is three and is evenly distributed in the circumferential direction, the axis of the fixed shaft 42 is perpendicular to the axis of the connecting shaft 9, and the fixed shaft 42 is sleeved with a weight sleeve 7 and a spring 2. 8. The counterweight sleeve 7 is located on one side of the inner shaft 41. When the flywheel disc 4 accelerates and rotates to a certain speed, the counterweight sleeve 7 slides radially outward by the centrifugal force generated by its own weight and compresses the spring 2. 8, the counterweight The radius of gyration of the cover 7 increases, thereby dynamically increasing the rotational inertial resistance of the flywheel disc 4, thereby impelling the flywheel disc 4 to rotate and decelerate in one direction. When the external shock source disappears, the flywheel disc 4 can be accelerated to a static state. Furthermore, the battery mounting plate 1 is stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com