Carbon fiber wheel hub

A technology of carbon fiber and wheel hub, applied in the direction of wheels, rims, web-type wheels, etc., can solve the problems that affect the driving safety of the car, the balance of installation, and the uneven thickness of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

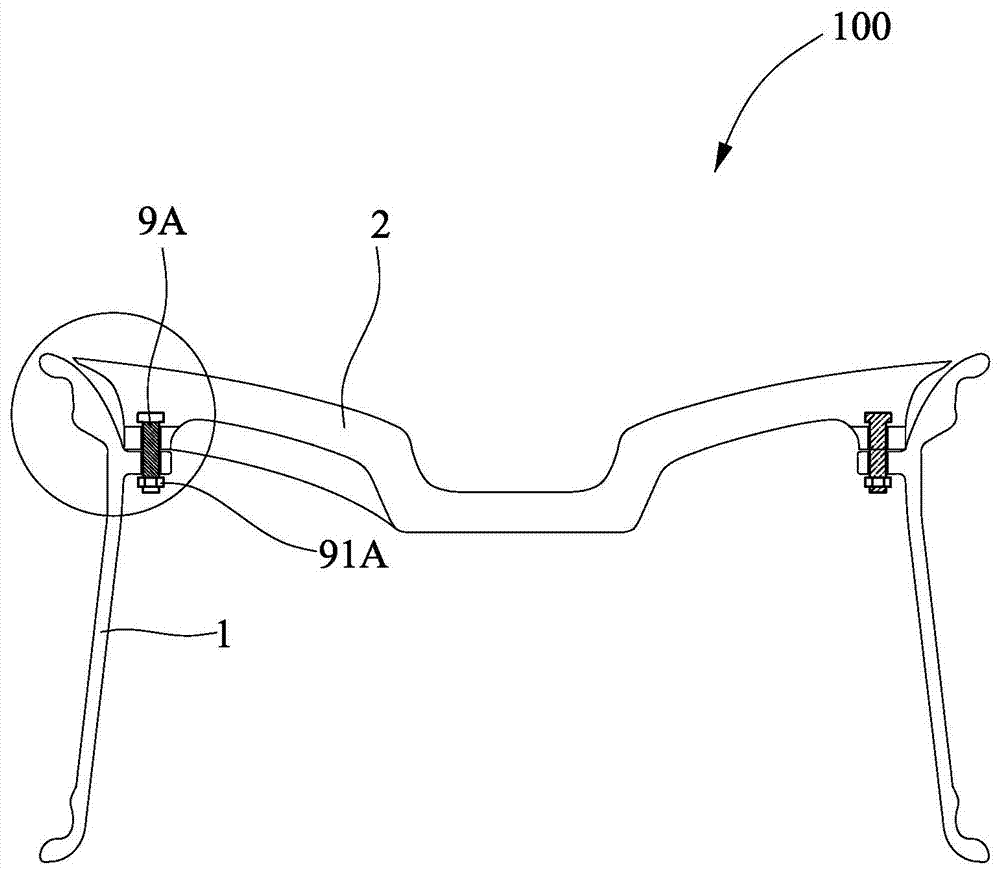

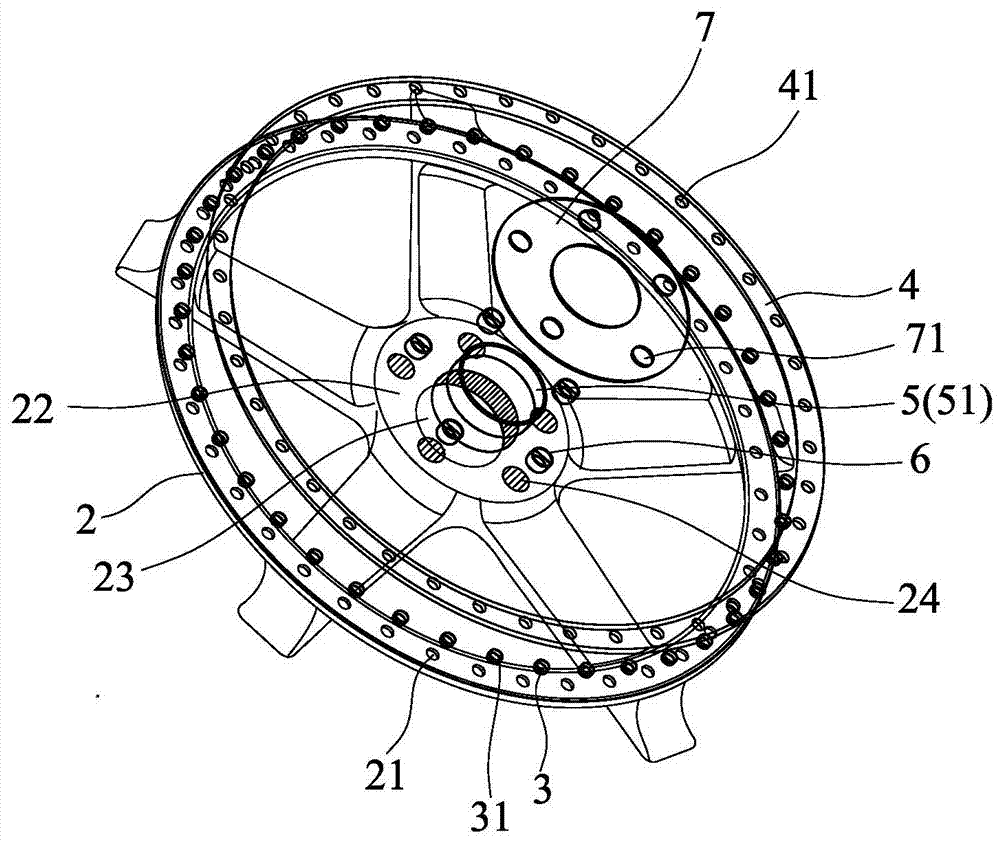

[0036] Such as Figure 1 to Figure 11 As shown, the present invention discloses a carbon fiber hub 100 , which includes a carbon fiber rim 1 and carbon fiber spokes 2 .

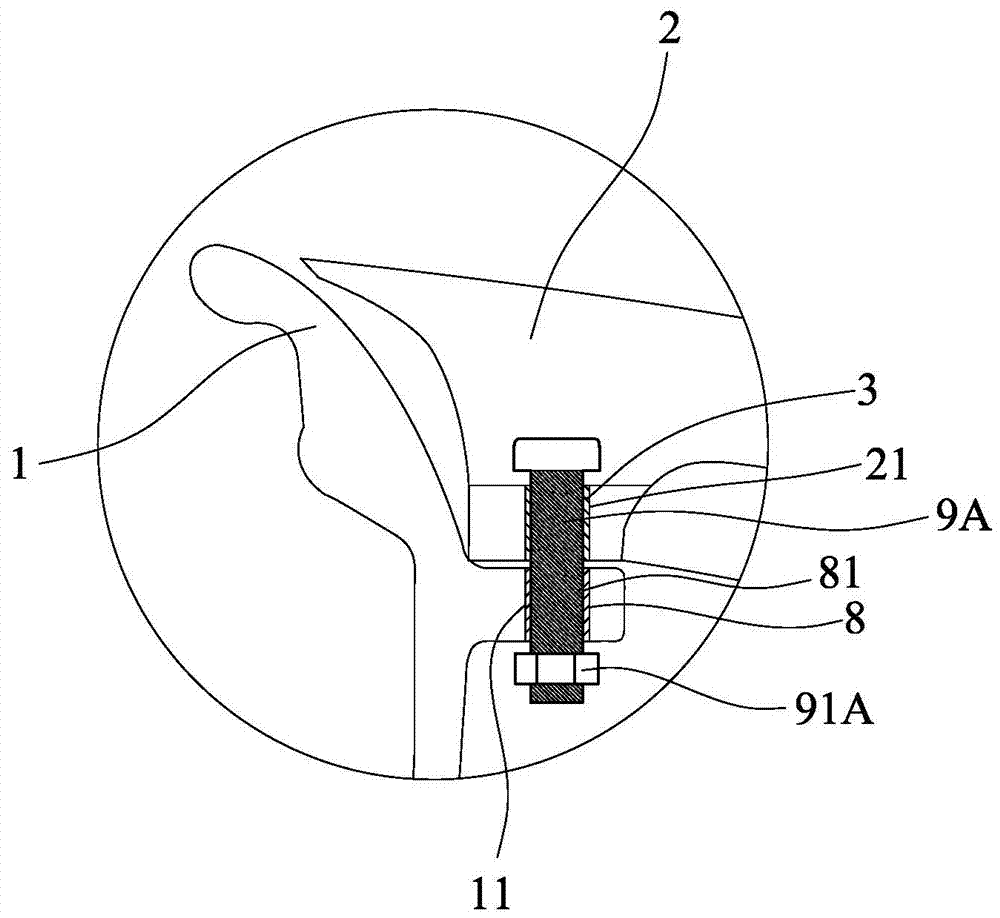

[0037] Such as figure 1 and figure 2 Shown is a sectional view and a partial enlarged view of a first preferred embodiment in which a rim 1 and spokes 2 of the present invention are assembled into a hub 100. In this embodiment, the rim 1 (such as Figure 7 and Figure 8 ) and spoke 2 (as Figure 3 to Figure 6 ) are assembled by means of external locking of bolts. The rim 1 and the spoke 2 are respectively made of carbon fiber material through mold compression molding, injection molding or 3D printing.

[0038] Such as Figure 3 to Figure 6 As shown, when the joint between the spoke 2 and the rim 1 is formed, a plurality of reserved ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com