Carbon fiber hub spoke

A carbon fiber and spoke technology, which is applied in the field of carbon fiber automobile hub spokes, can solve problems such as failure to meet locking requirements, installation balance problems, and screw hole wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

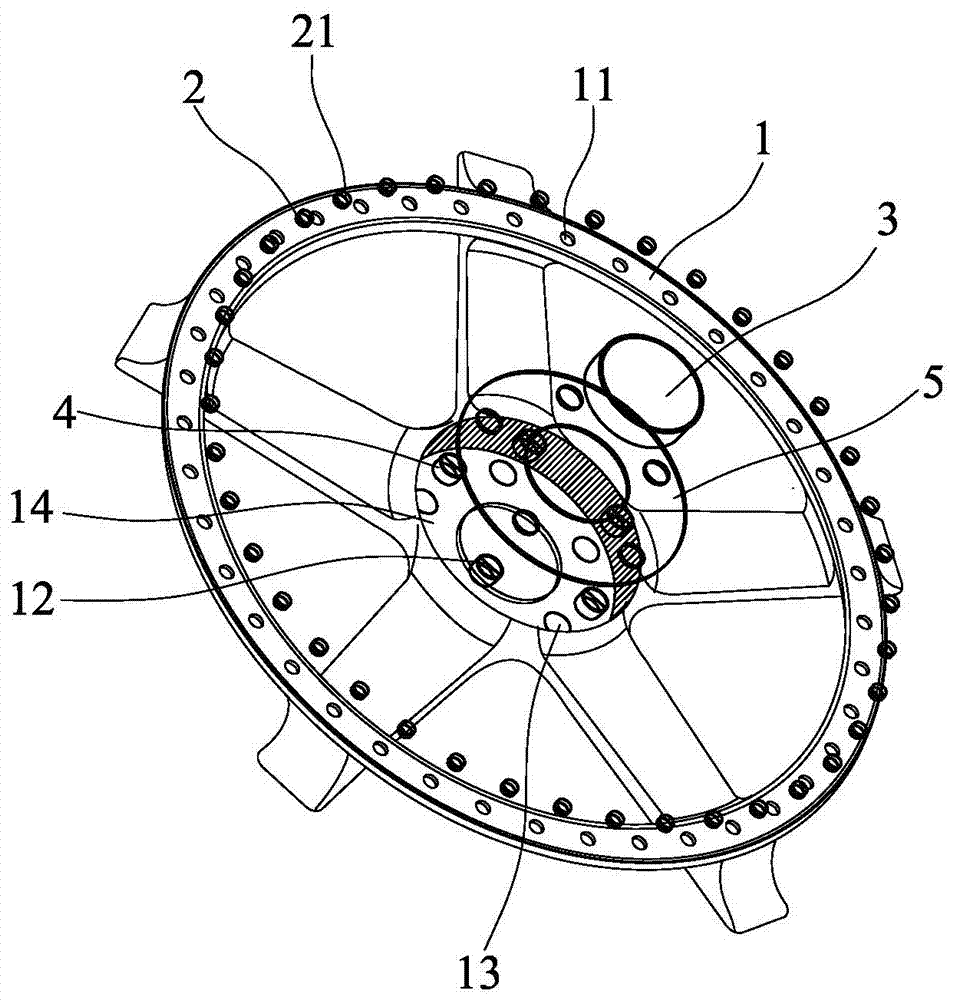

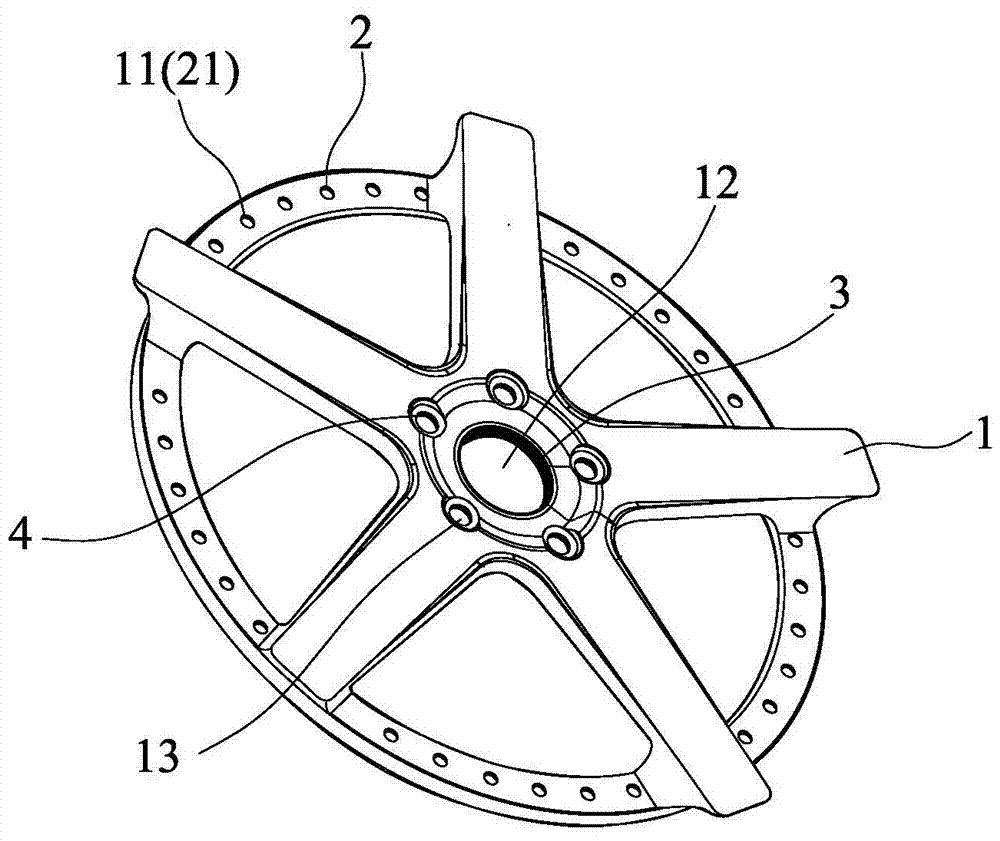

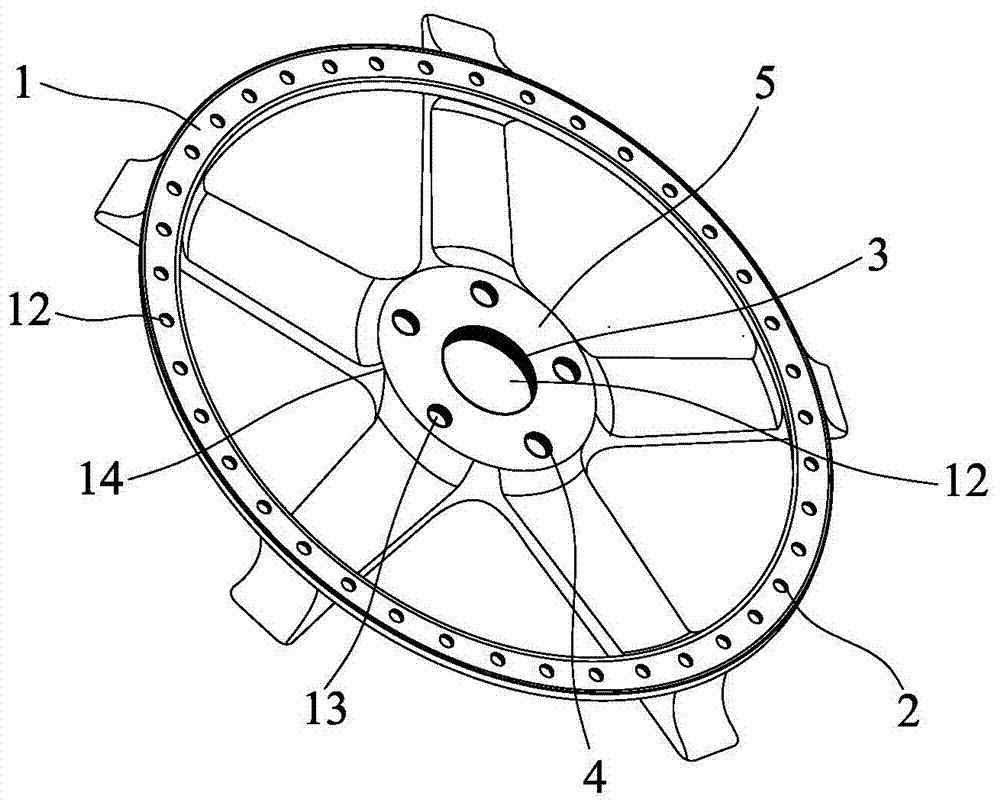

[0028] like Figure 1 to Figure 7 As shown, the present invention discloses a carbon fiber hub spoke, the hub spoke has a spoke body 1, the spoke body 1 is made of carbon fiber material, and the spoke body 1 is provided with a plurality of rim A (such as Figure 4 ) locked reserved assembly holes 11, each reserved assembly hole 11 is respectively provided with a metal piece 2 with an assembly hole 21, the center of the spoke body 1 has a reserved center for matching with the hub (not shown in the figure) Holes 12, a metal assembly ring 3 is fitted in the reserved central hole 12, and the outer ring of the spoke body 1 is also provided with a plurality of reserved lockholes 13 that are locked with the hub of the wheel shaft, each reserved A metal ring 4 is respectively fixed in the lock hole 13, and a metal she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com