Oil coating device

An oiling device and oiling technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of increasing production costs, waste of grease, and artificial influence on the application efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

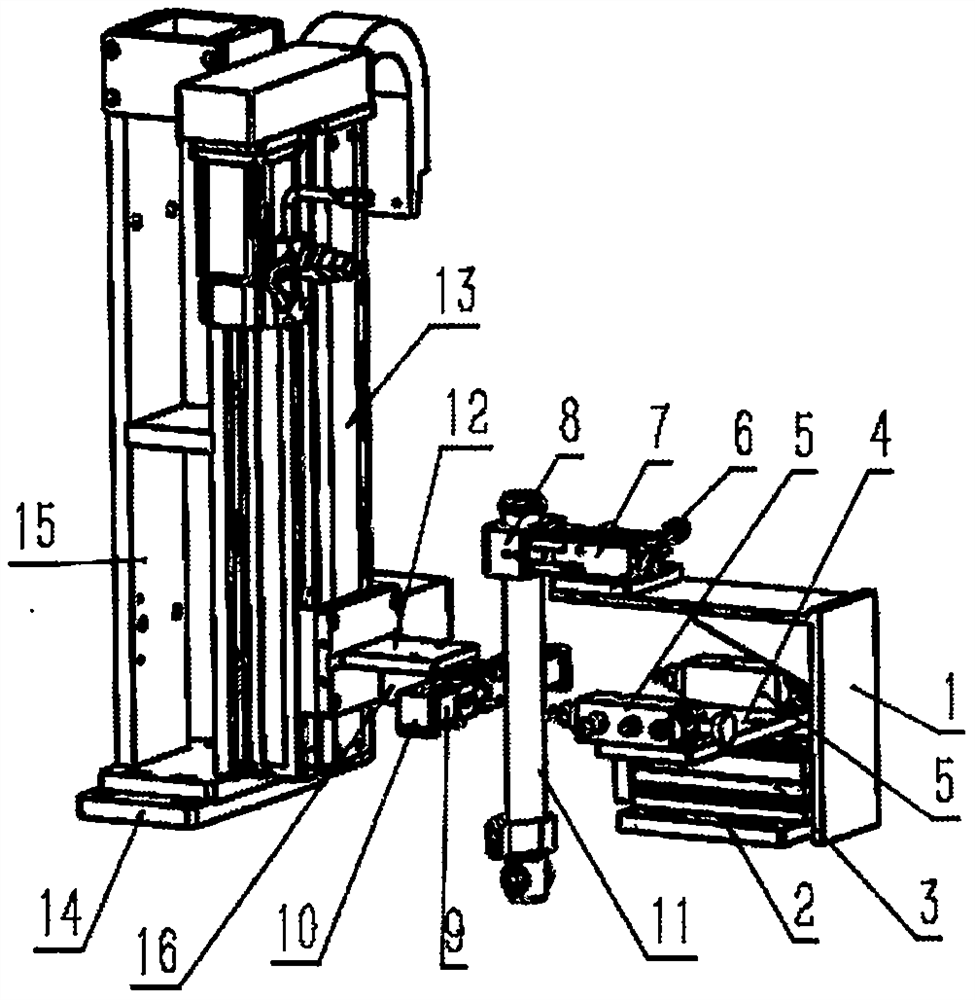

[0021] The following drawings and specific embodiments describe the present invention in further detail.

[0022] The present invention firstly provides an oiling device, comprising:

[0023] The lifting oiling module includes a lifting module and an oiling sponge, and the oiling sponge is driven by the lifting module to oil the surface of the workpiece to be oiled;

[0024] a workpiece clamping module receives and fixes the workpiece;

[0025] The spraying module, driven by the driving device, sprays grease on the surface of the oiled sponge.

[0026] In the embodiment provided by the present invention, the specific structure and specific oiling method of the oiling device, the lifting module, the workpiece clamping module and The spraying modules are placed sequentially on the automated assembly line (not shown in the figure), and the electrical signals are connected between each component and the transfer device / manipulator on the automated assembly line to realize automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com