A better performance vertical rotary cutting machine assembly line

A technology of rotary cutting machine and assembly line, which is used in the manufacture of thin wood chips, manufacturing tools, wood processing appliances, etc., can solve the problems of waste of raw materials, intermittent thin wood, and poor quality, and achieve the effect of improving the quality of rotary cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

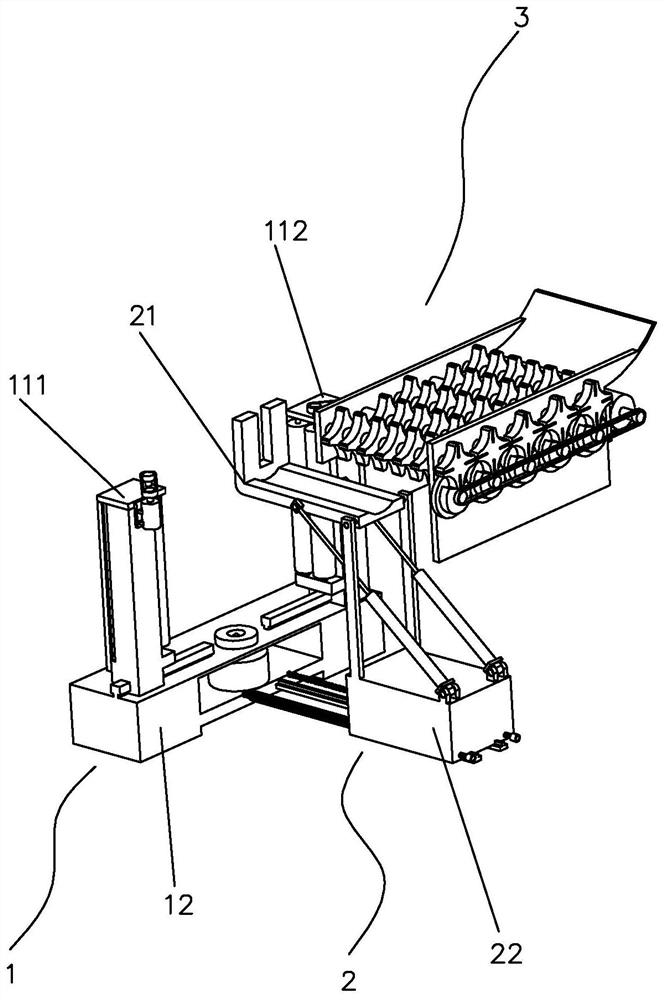

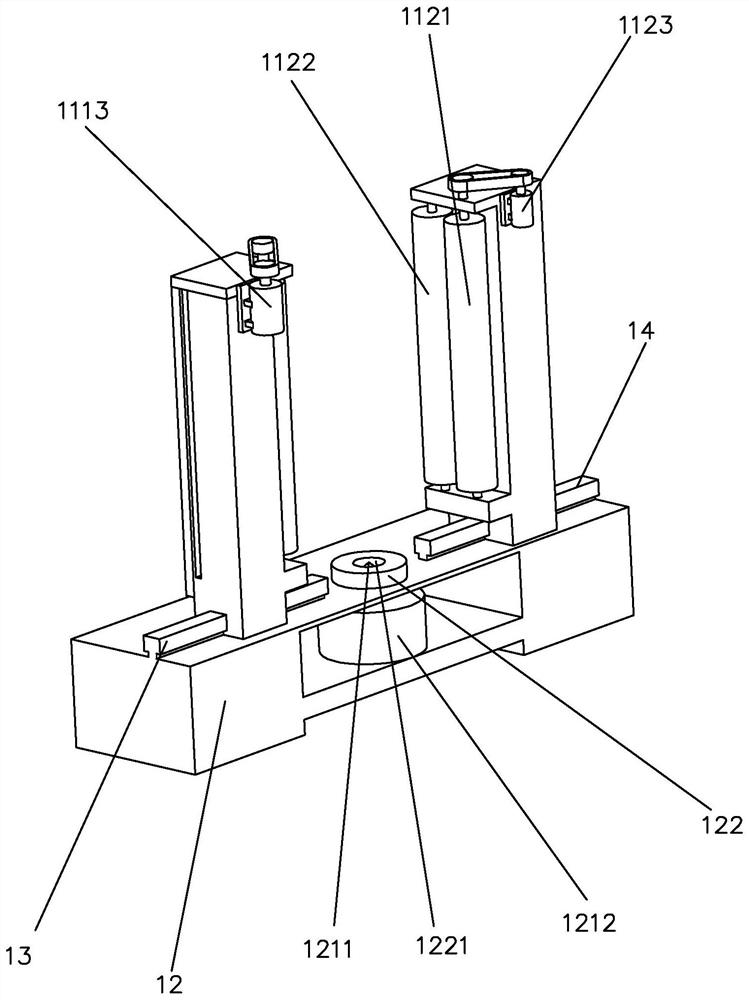

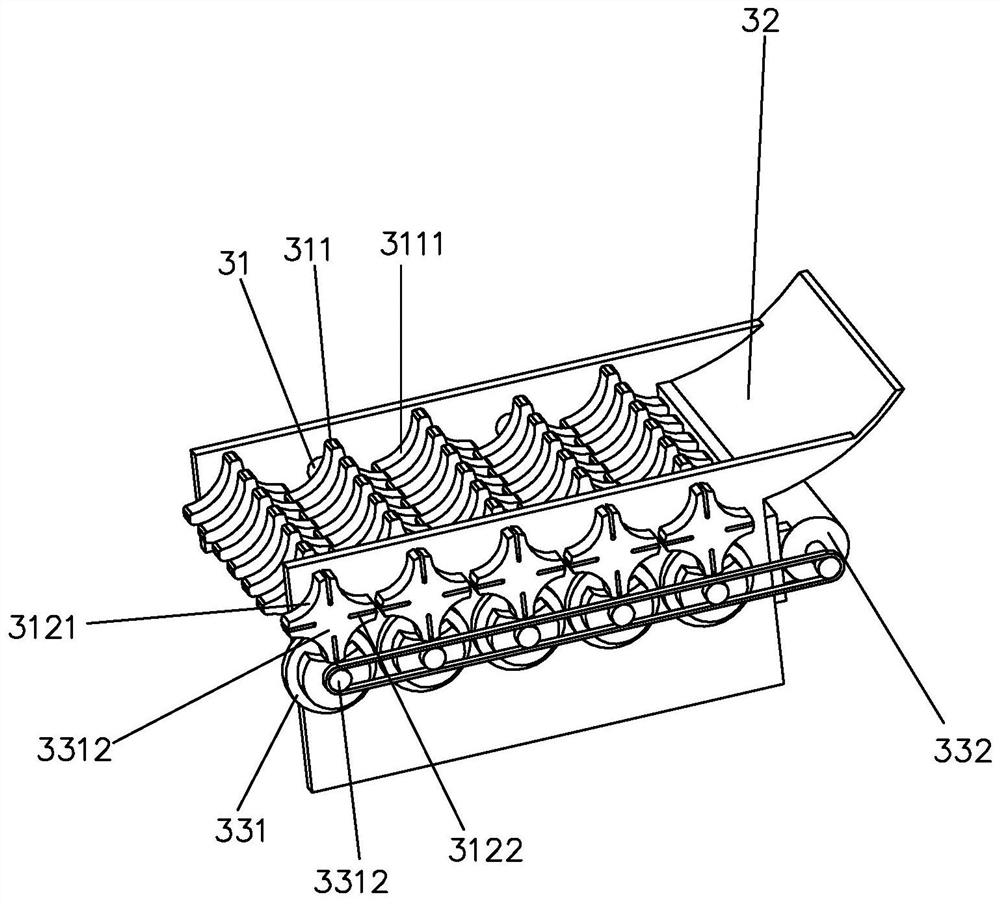

[0031] Such as Figure 1-5As shown, a vertical rotary cutting machine assembly line with better performance includes a rotary cutting device 1 for centering and rotary cutting of round logs, and a transport device for transporting round logs to rotary cutting device 1; rotary cutting device 1 includes a vertical rotary cutting mechanism 11 that keeps logs in a vertical state for cutting; the transport device includes a transport body located upstream and a transport overturning mechanism 2 located downstream; the transport overturning mechanism 2 includes an overturning carrier for carrying logs 21, an inversion bearing base 22 that is rotatably connected to the inversion carrier 21, an inversion drive mechanism 23 that drives the inversion carrier 21 to overturn, and a horizontal drive mechanism 24 that drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com