Variable-diameter floating ice channel

A channel and ice floe technology, applied in measurement devices, instruments, fluid dynamics tests, etc., can solve problems such as the difficulty of simulating ice density, the influence of ship model ice breaking rotation load test results, and the error of test simulation environment. , to achieve the effect of improving the efficiency of the pool test, changing the density of floating ice, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

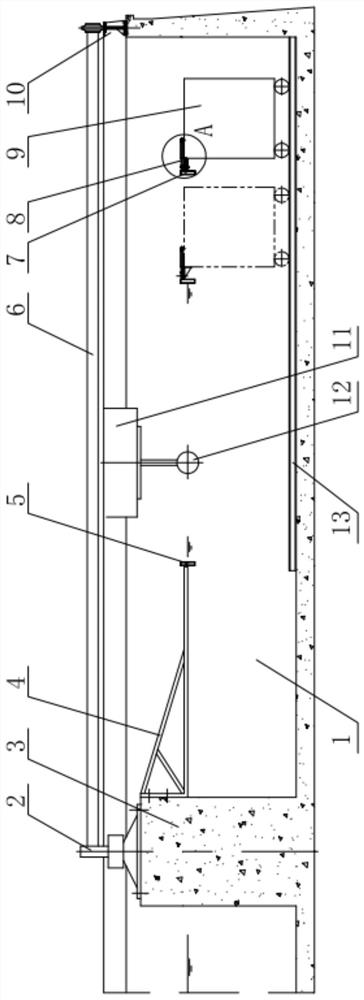

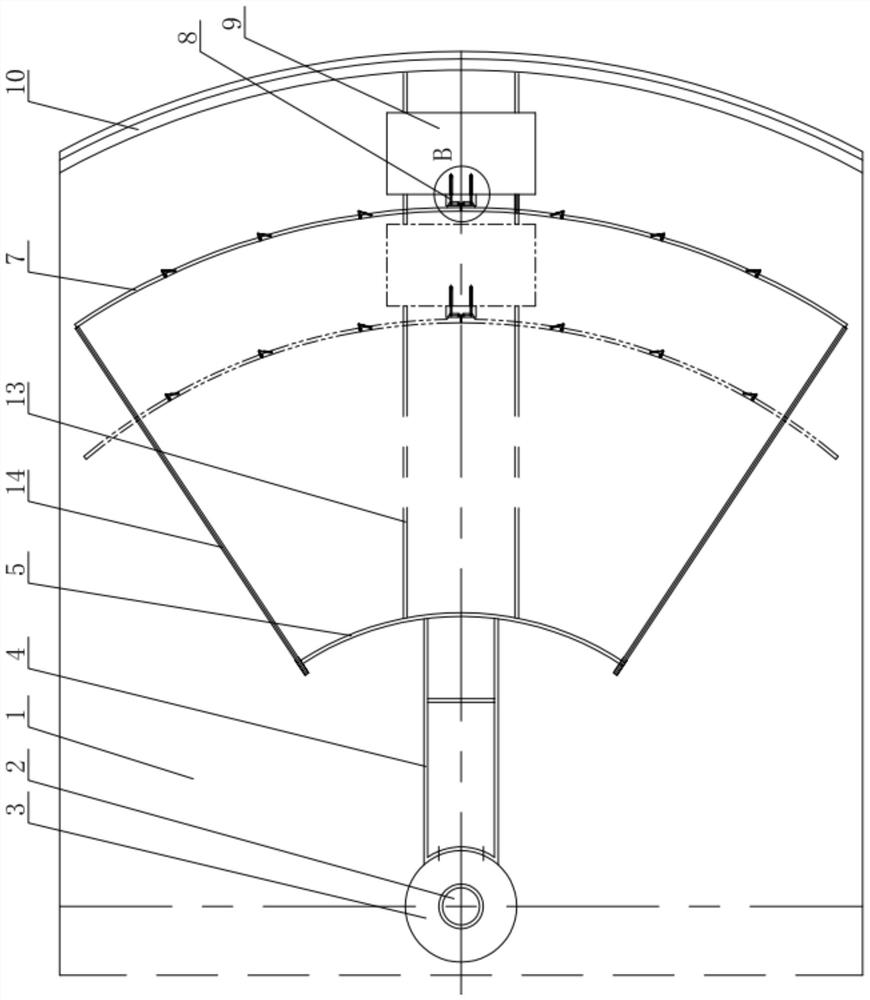

[0044] The outer channel 7 is composed of an odd number of small channels 71 , and a small channel 71 located in the middle is installed on the mobile trolley 9 , and the adjacent small channels 71 are connected by a diameter reducing mechanism 1 72 in rotation.

Embodiment 2

[0046] The outer channel 7 is composed of an even number of small channels 71, and the two small channels 71 located in the middle are respectively connected to the mobile trolley 9 through the diameter reducing mechanism 28; the even number of small channels 71 are symmetrical along the outer channel 7 The wires are divided into two groups, and the adjacent small grooves 71 in each group are connected by rotation through a diameter reducing mechanism one 72 .

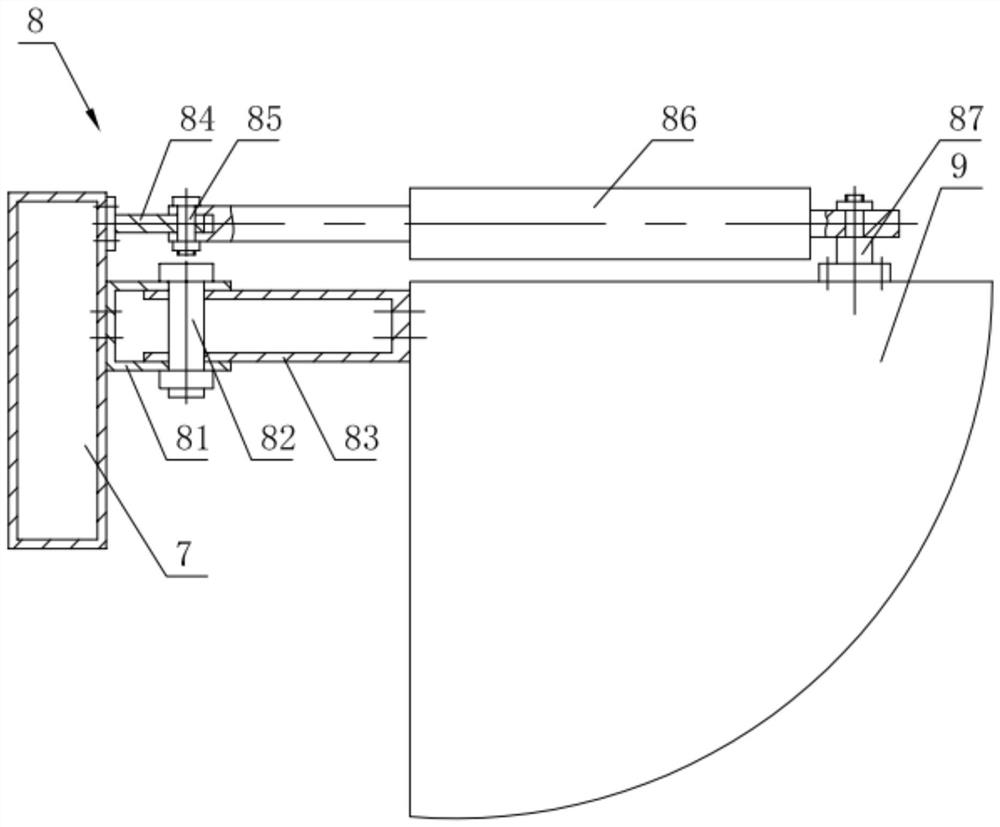

[0047] Such as figure 2 with Figure 4 As shown, the structure of the single set of reducing mechanism 2 8 is as follows: it includes electric cylinder 1 86, the tail end of electric cylinder 1 86 is rotated and installed on the mobile trolley 9 through the rotating shaft 1 87, and the output end of electric cylinder 1 86 is rotated and installed in the small channel The outer wall of 71; the outer wall of the small channel 71 extends outwards with a lug 84, and the lug 84 is rotationally connected with the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com