Device and method for identifying surface defects of metal wire

A metal wire and defect technology, which is applied in the field of devices for identifying surface defects of metal wires, can solve the problems of easy scratches, high labor costs, and difficulty in identifying defects and sampling coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

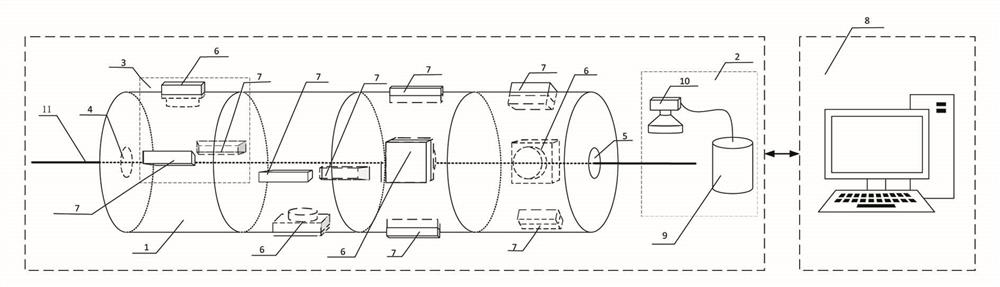

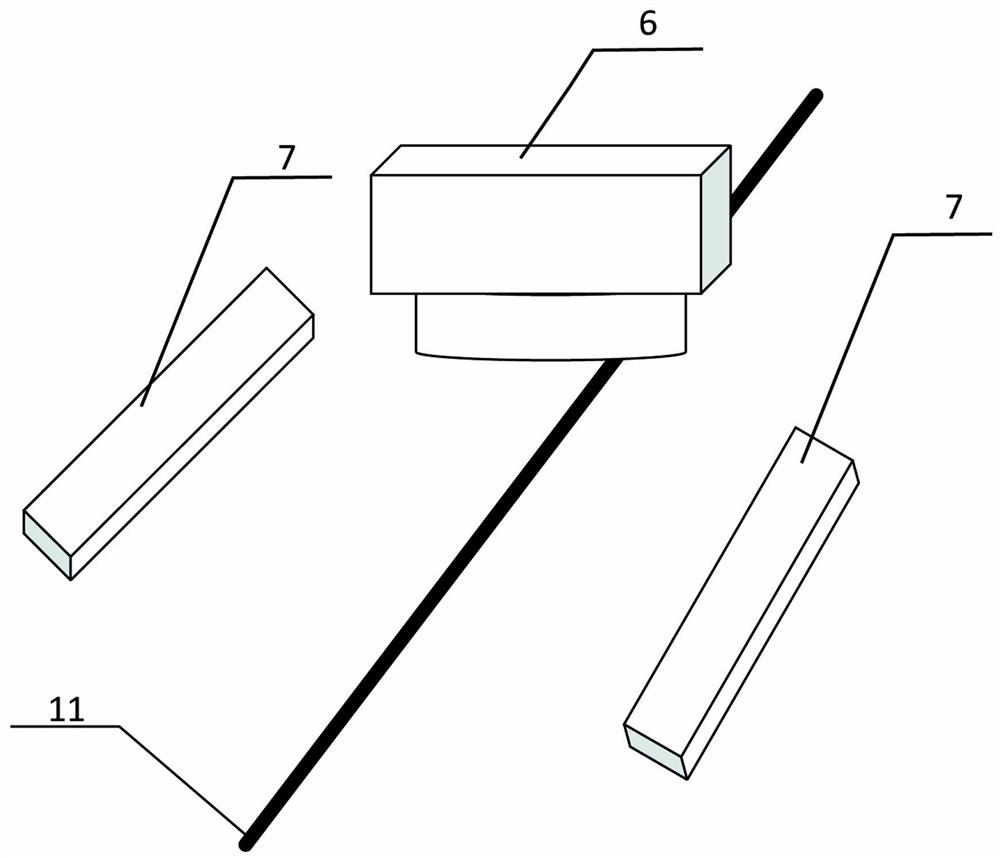

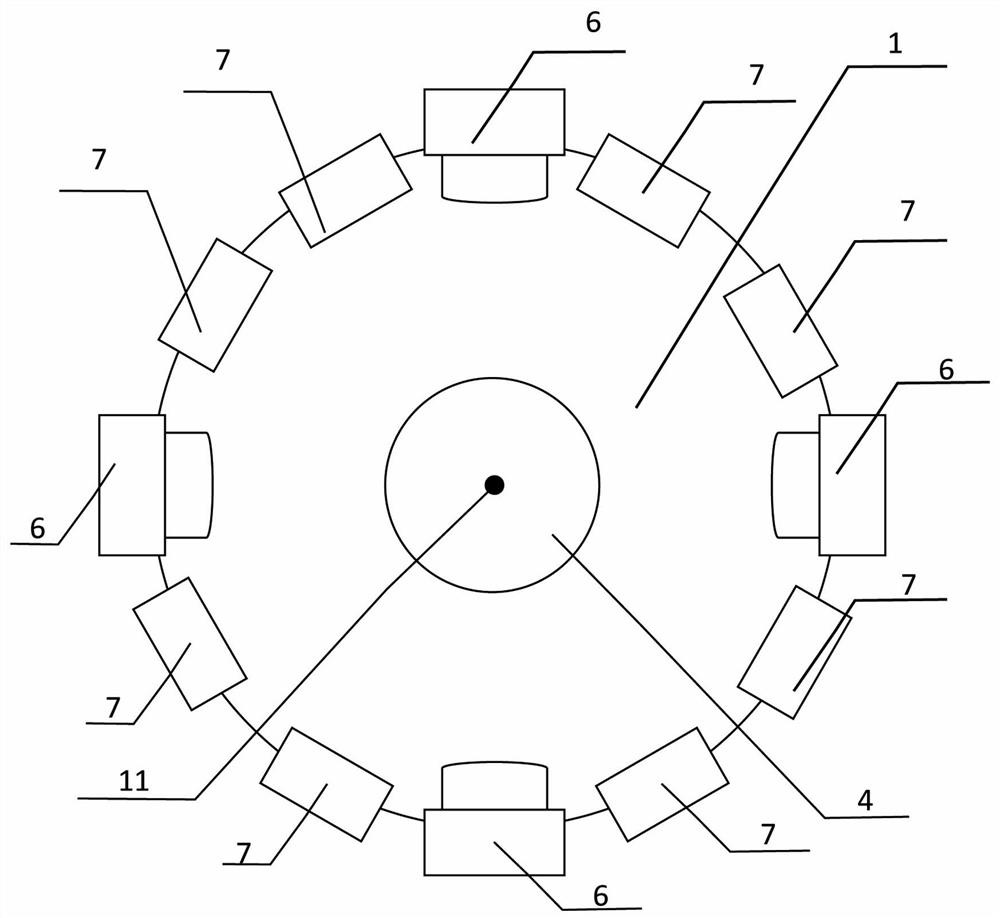

[0042] Reference figure 1 , 3 5. A device for identifying defects on the surface of a metal wire, comprising a cavity 1 with closed ends connected to a control terminal 8 and a marking unit 2, and a set of image capture is provided on the inner wall of the cavity 1 In unit 3, one end surface of the cavity 1 is provided with a first through hole 4, and the other end of the cavity 1 is provided with a second through hole 5, and the metal wire 11 enters the cavity 1 through the first through hole 4 and passes through the Two through holes 5 pass through, the marking unit 2 is located near the second through hole 5 where the metal wire 11 passes through the cavity 1, and the image acquisition unit 3 provided on the inner wall of the cavity 1 is connected to the control terminal 8.

[0043] The inner wall of the cavity 1 is coated with the same color, the color of the color is selected according to the highlighting degree of the surface defects of the metal wire 11 of different materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com