A multi-gap gear-rotor system test platform

A gear rotor and test platform technology, applied in vibration testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of high manufacturing requirements, high cost, errors, etc., and achieve low processing cost and strong practicability. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

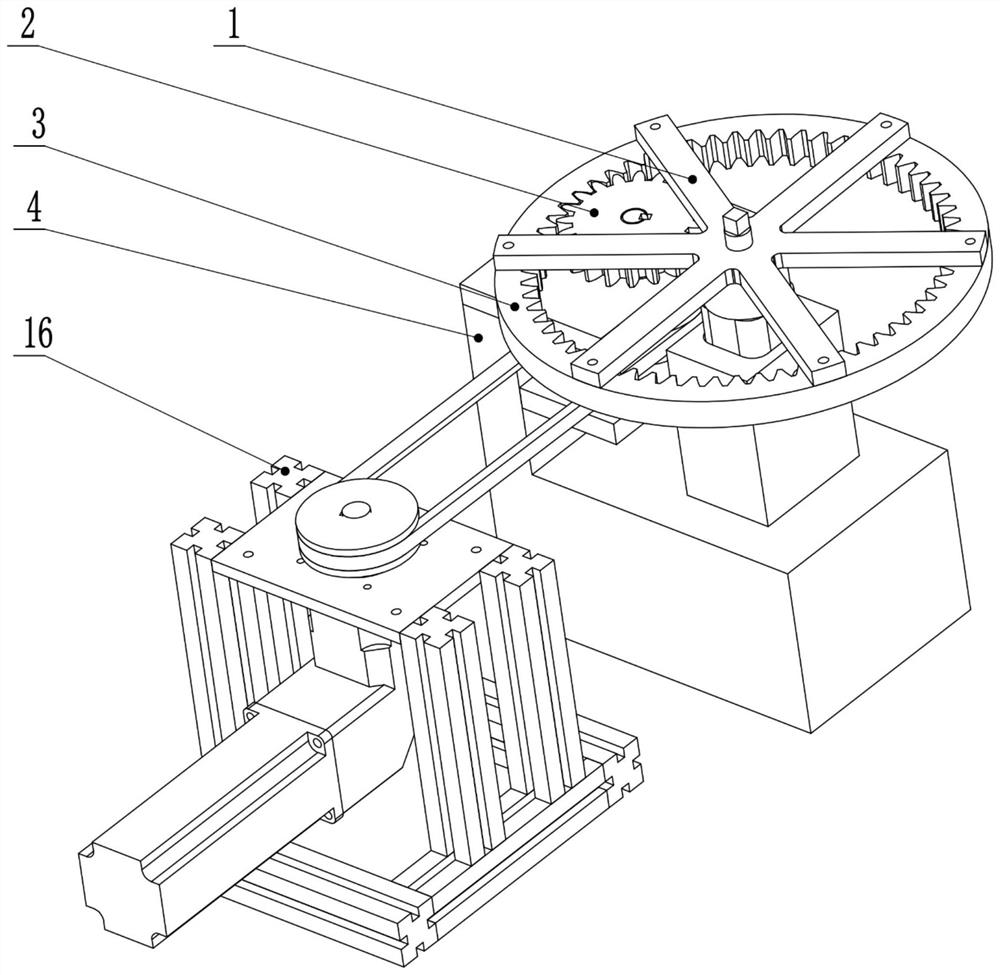

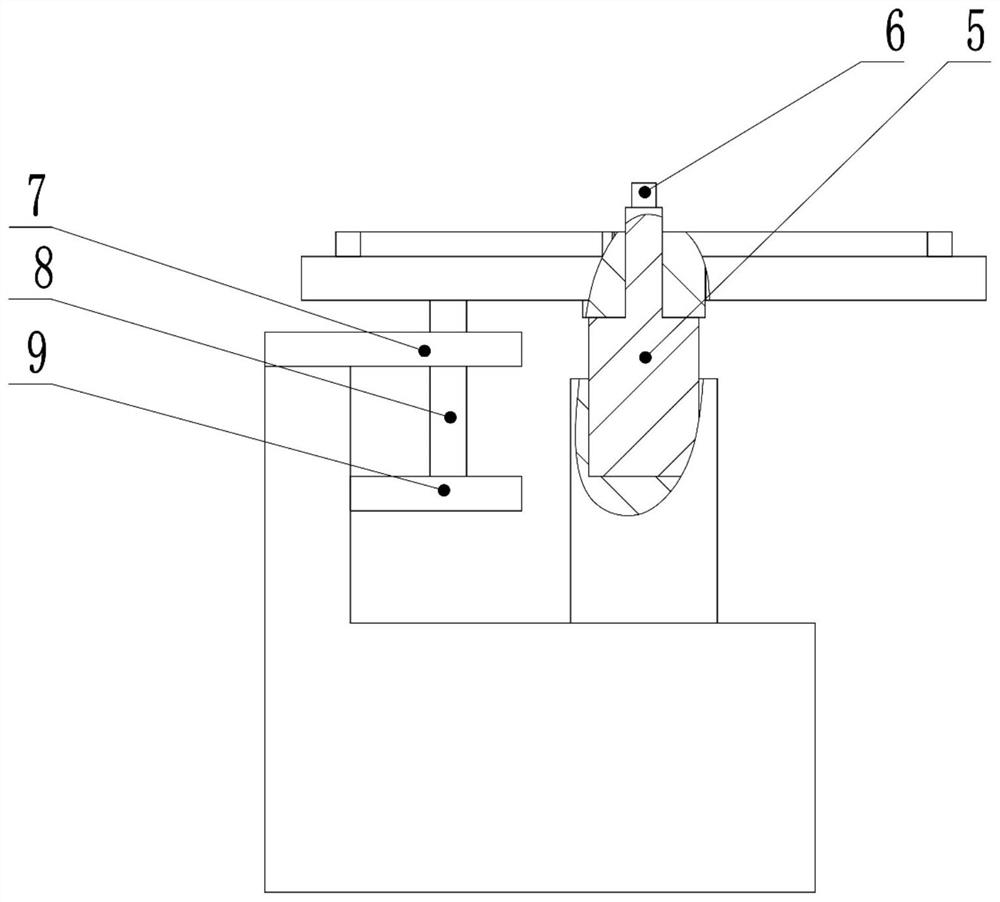

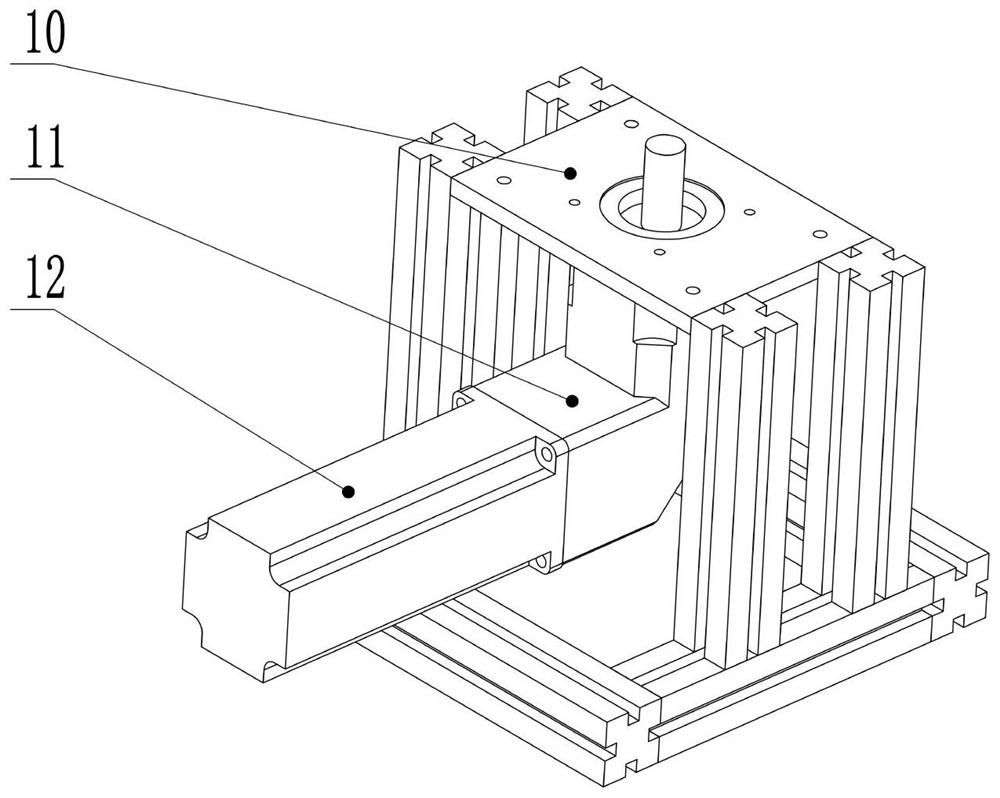

[0044] This embodiment provides a multi-gap internal gear rotor system test platform (see Figure 1-4 , referred to as test platform), including internal gear rotor test bench, driving device and transmission mechanism; said internal gear rotor test bench includes workbench base 4, driven gear frame support block 5, driven gear frame 1, Driven gear 3, upper bearing plate 7, lower bearing plate 9, driving gear shaft 8, driving gear 2 and triaxial acceleration sensor 6;

[0045] The workbench base 4 is L-shaped (see Figure 5 ), the L-shaped horizontal surface is provided with a mounting column for installing the driven gear frame support block, and the upper end of the mounting column is provided with a groove; on the L-shaped vertical surface, the driving gear shaft is fixed by the upper and lower bearing plates; The lower part of the supporting block of the driven gear frame has a shape matching the groove of the mounting column, and is fixed in the groove, and the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com