Steel sheet

A steel plate, high-quality technology, applied to the field of steel plates containing a high concentration of Mn, can solve problems such as difficulty in ensuring sufficient weldability, restrictions on the use of structural members, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

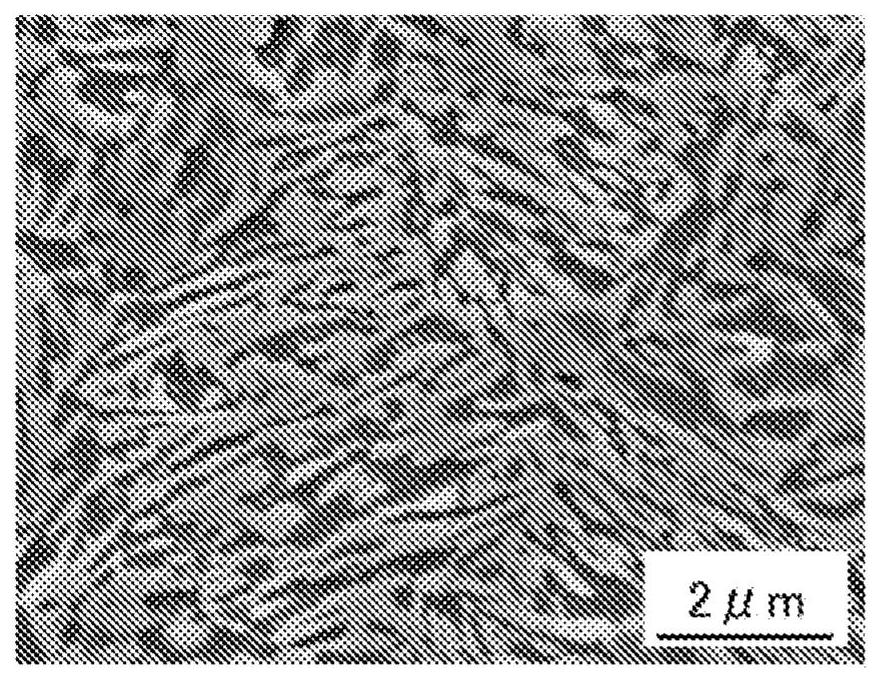

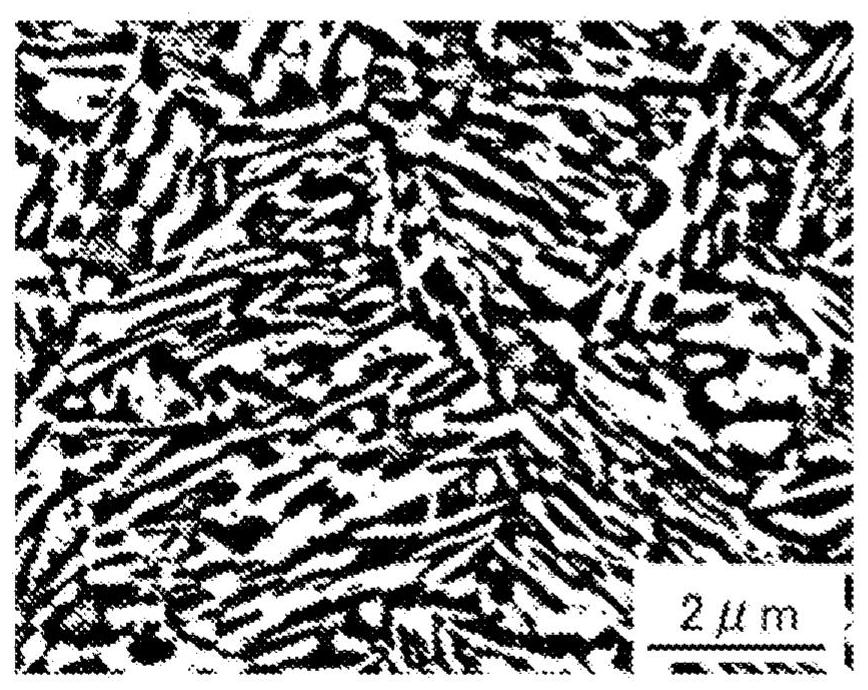

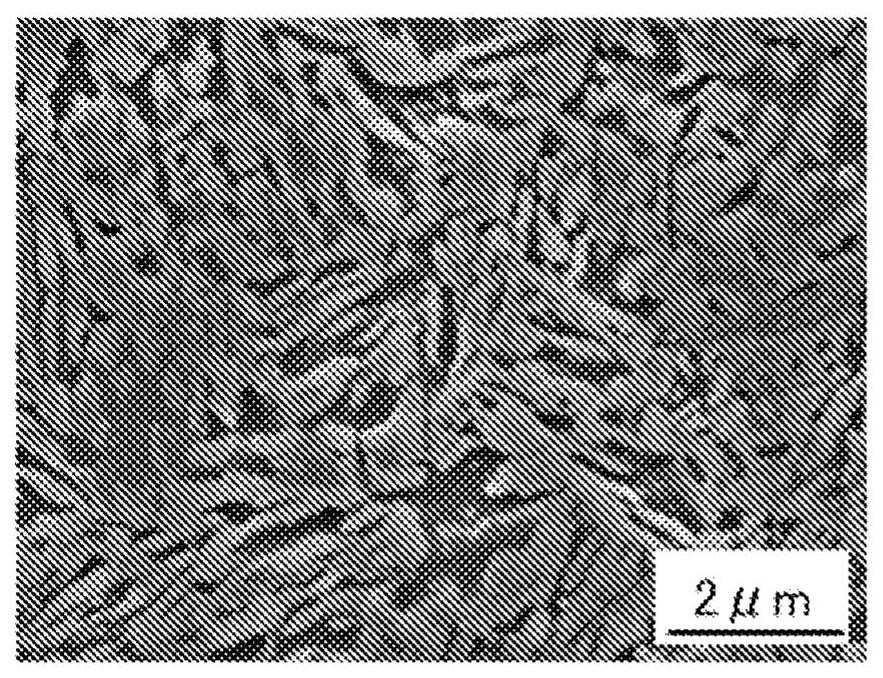

Image

Examples

Embodiment

[0191] The steel plate of this application is demonstrated more concretely with reference to an example. However, the following examples are examples of the steel sheets of the present application, and the steel sheets of the present application are not limited to the aspects of the following examples.

[0192] 1. Manufacture of steel plates for evaluation

[0193] Steels having the chemical compositions shown in Table 1 were melted in a converter and continuously cast to obtain 245 mm thick slabs.

[0194] Table 1

[0195]

[0196] The down arrow in Table 1 means the same as the previous column.

[0197] The obtained slabs were hot-rolled under the conditions shown in Table 2 to produce hot-rolled steel sheets with a thickness of 2.6 mm. Next, the obtained hot-rolled steel sheets were pickled and cold-rolled at the cold-rolling ratios shown in Table 2 to produce cold-rolled steel sheets with various thicknesses shown in Table 2.

[0198] Table 2

[0199]

[0200]Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com