Hot-dip galvanized steel sheet and alloyed hot-dip galvanized steel sheet

A hot-dip galvanized steel sheet and hot-dip galvanized steel technology are applied in the fields of high-strength hot-dip galvanized steel sheet, high-strength alloyed hot-dip galvanized steel sheet, and high-strength alloyed hot-dip galvanized steel sheet, which can solve the problem of high-strength hot-dip galvanized steel sheet. Problems such as difficulty in chemical conversion, etc., to achieve the effects of excellent impact absorption, excellent press formability, high yield strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

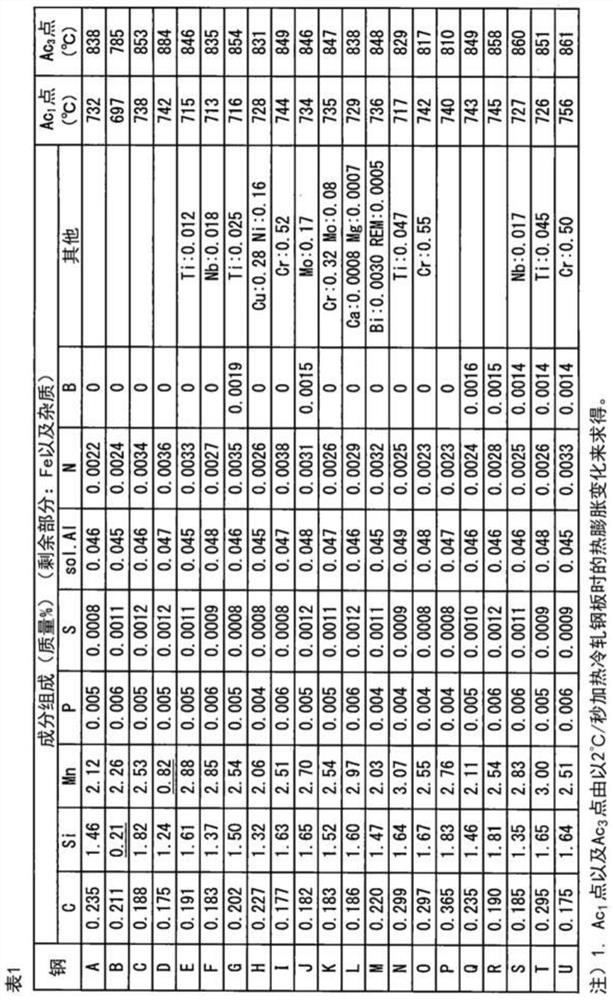

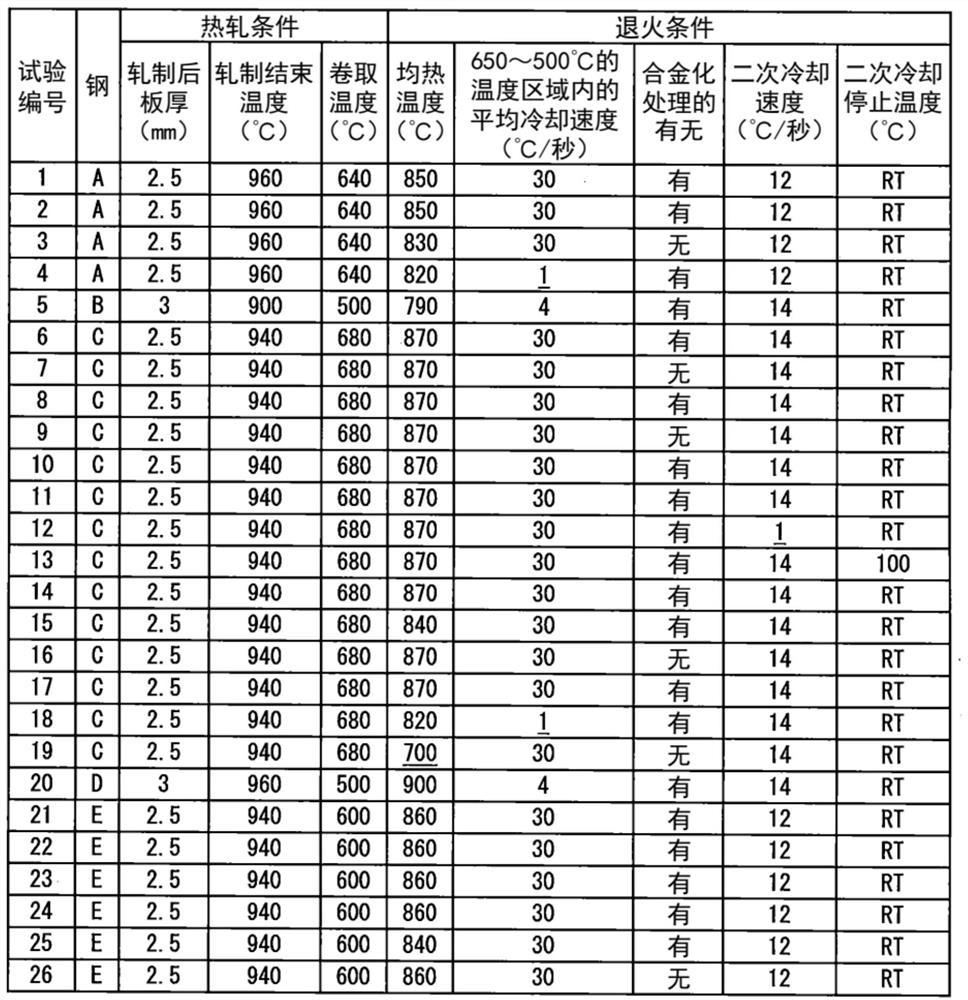

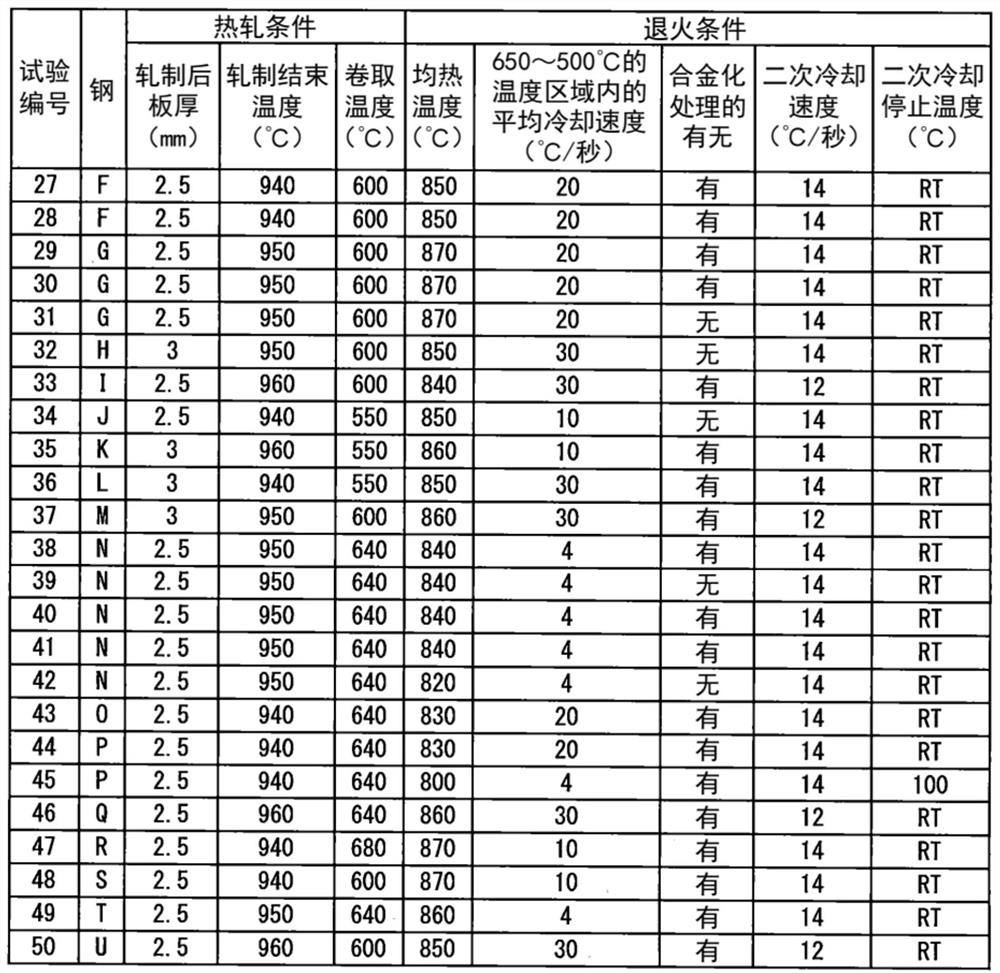

[0201] Molten steel was cast using a vacuum melting furnace, and steels A to U having the component compositions shown in Table 1 were produced. Ac in Table 1 1 point and Ac 3 The points are obtained from thermal expansion changes when the cold-rolled steel sheets of steels A to P are heated at 2°C / sec. Steels A to U were heated to 1200° C. and kept for 60 minutes, and then hot rolled under the hot rolling conditions shown in Tables 2-1 and 2-2.

[0202]

[0203] Specifically, in Ar 3 Steels A to U were subjected to 10-pass rolling in the temperature range above the temperature point to obtain hot-rolled steel sheets with a thickness of 2.5 to 3.0 mm. After hot rolling, the hot-rolled steel plate is cooled to 500-680°C by spraying water, the cooling end temperature is set as the coiling temperature, and the hot-rolled steel plate is loaded into the electric heating furnace kept at the coiling temperature, and kept After 60 minutes, the hot-rolled steel sheet was furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com