Anti-falling equipment for bridge engineering construction

A technology for bridge engineering and bridges, applied in the field of anti-fall devices for civil engineering construction, can solve the problems that the anti-fall device affects traffic, the thickness of the anti-collision wall is not large, and has potential safety hazards, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

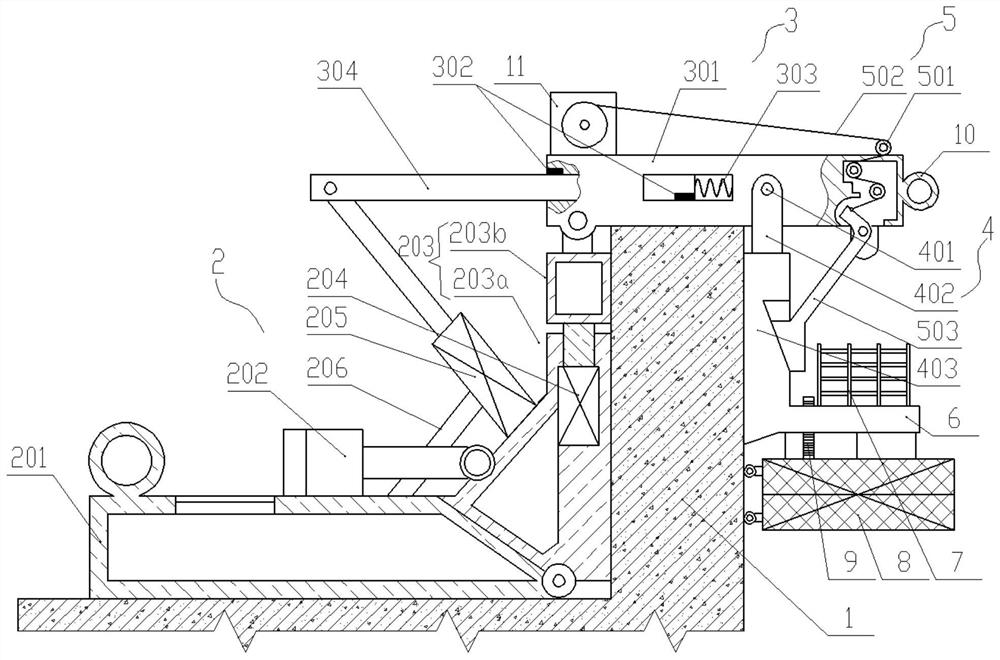

[0016] Such as figure 1 As shown, this embodiment describes a kind of anti-drop equipment for bridge engineering construction, which mainly includes an inner positioning part 2, a cantilever part 3, an outer positioning part 4 and a pressing part 5, wherein the inner positioning part 2 can tighten As for the inner surface of the anti-collision wall 1 attached to the side of the bridge, as for the area of close contact, those skilled in the art can design adaptively according to needs, and a larger area should be selected for close contact, and the effect is better. The side of the inner positioning part 2 away from the anti-collision wall 1 is fixed with a first hydraulic rod 205 obliquely upward to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com