A low-e glass manufacturing process

A processing technology and glass manufacturing technology, applied in coating, surface pretreatment, device for coating liquid on the surface, etc., can solve the problems of incomplete coating on glass surface, difficult glass surface, difficult to retain coating liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

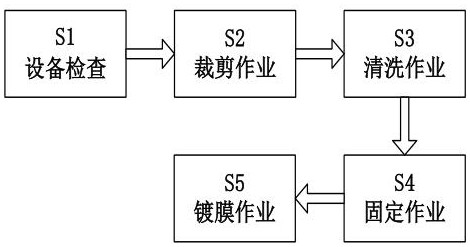

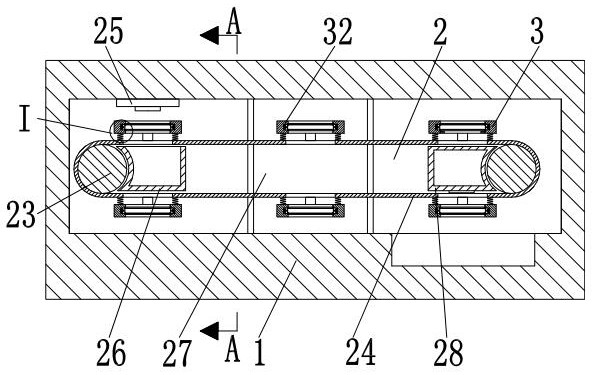

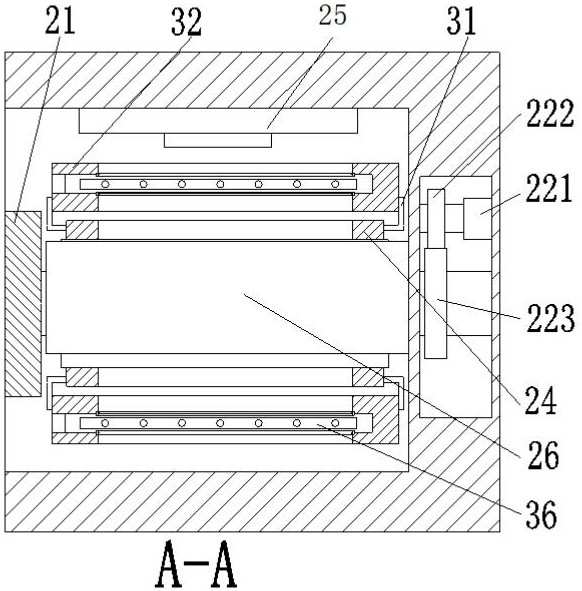

[0030] Such as Figure 1 to Figure 6 As shown, a Low-E glass manufacturing process uses a glass coating device, which includes a base frame 1, a feed coating unit 2 and a fixed limit unit 3, using the above-mentioned glass The manufacturing and processing technology of the glass by the coating device also includes the following steps:

[0031] S1. Equipment inspection: Before starting the device, conduct a routine inspection of the device;

[0032] S2. Cutting operation: cutting the glass into a fixed shape by manual or mechanical assistance;

[0033] S3. Cleaning operation: clean the glass surface with clean water to remove dust and sundries;

[0034] S4. Fixing operation: the glass is clamped and fixed by the fixed limit unit 3;

[0035] S5. C...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap