Double-layer anti-corrosion treatment equipment applied to carbon steel plates in environmental protection industry

A technology for anti-corrosion treatment and steel plate, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of increasing coating difficulty, increasing production cost, reducing efficiency, etc., achieving increased coating difficulty, reducing production cost, The effect of reducing the burden on workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

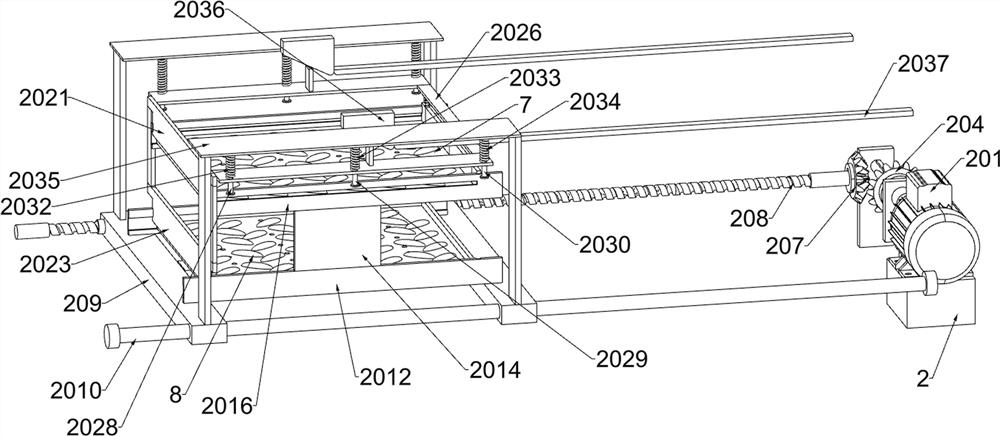

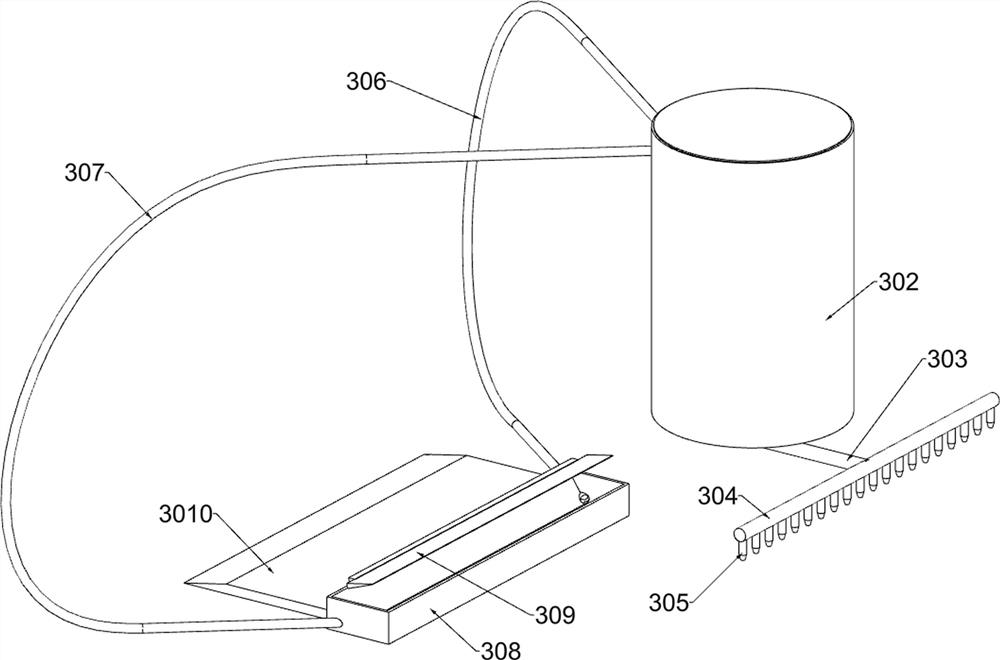

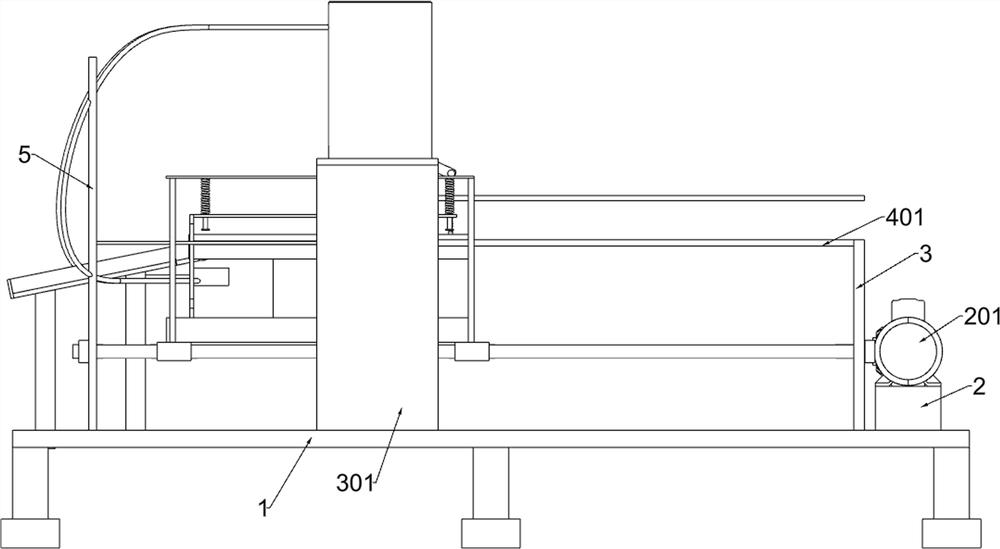

[0035] A double-layer anticorrosion treatment equipment for carbon steel plates in the environmental protection industry, such as Figure 1-3 As shown, it includes a fixed frame 1, a fixed block 2, a first vertical plate 3, a second vertical plate 4, a third vertical plate 5, a fourth vertical plate 6, a first simulated embossed carbon steel plate 7, a second simulated rolled Spliced carbon steel plate 8, fixed conveying component and resin adding and cleaning component; fixed frame 1 is fixedly connected with fixed block 2; one side of fixed frame 1 is fixedly connected with first vertical plate 3 and second vertical plate 4 at the same time; fixed frame 1 The other side is fixedly connected with the third vertical plate 5 and the fourth vertical plate 6 at the same time; the upper part of the fixed frame 1 is provided with the first simulated embossed carbon steel plate 7 and the second simulated embossed carbon steel plate 8 respectively fixed and The fixed conveying asse...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap