Heat-dissipating bracket forming die for main board of industrial camera

A heat dissipation bracket and industrial camera technology, applied in the field of industrial camera production, can solve problems such as deformation and damage of ribs 110, difficult demoulding, etc., and achieve the effect of avoiding deformation and damage of ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

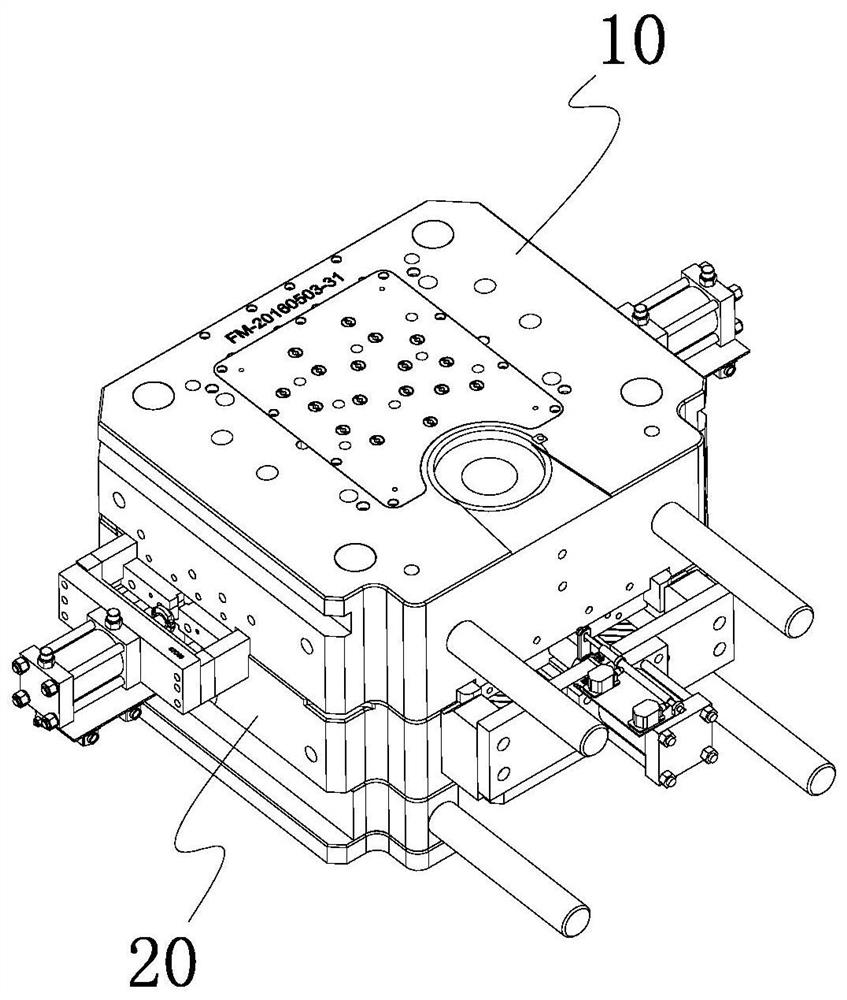

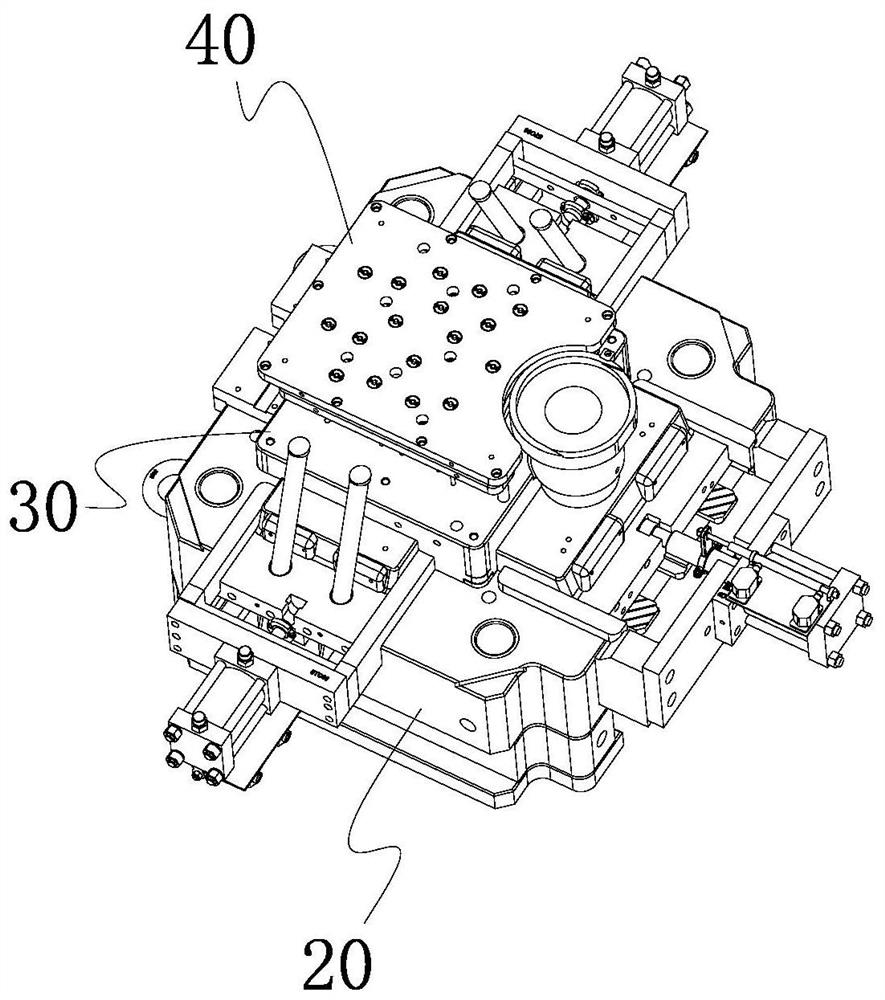

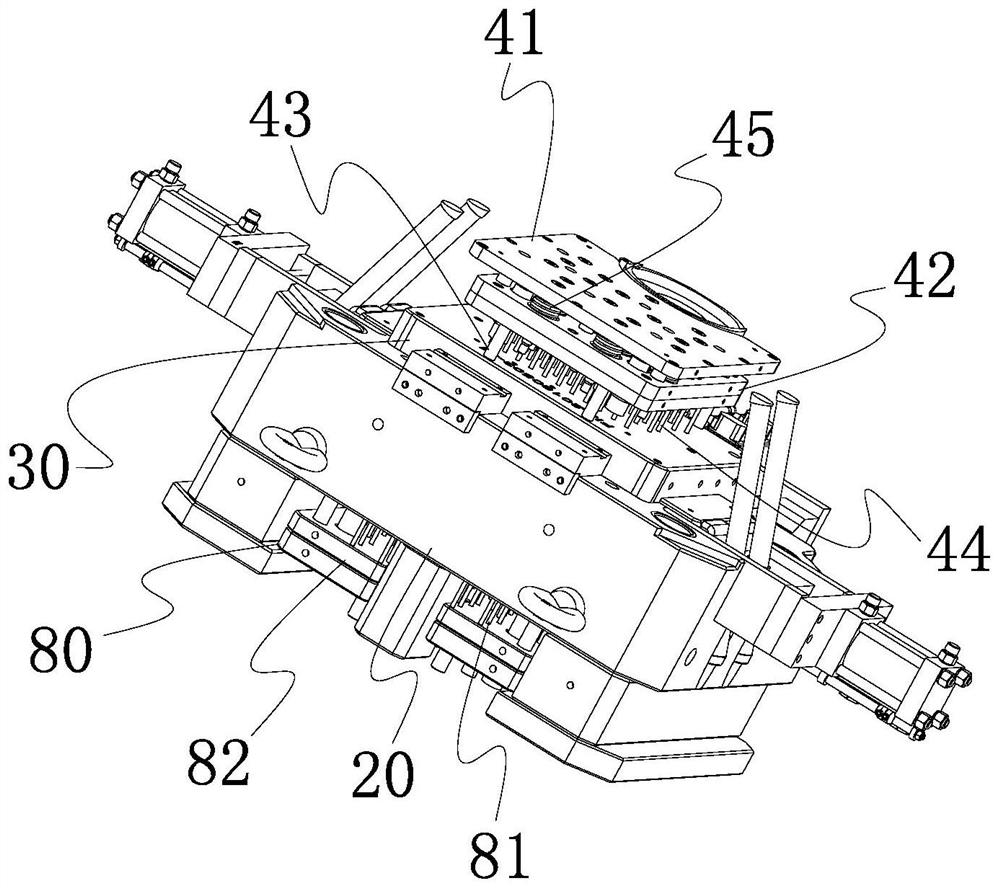

[0022] Please refer to Figure 1 to Figure 6 , The industrial camera mainboard heat dissipation bracket forming mold provided by the present invention includes an upper mold base 10, a lower mold base 20, an upper mold 30, an upper mold demoulding assembly 40, a lower mold 50 and a lower mold demoulding assembly 80.

[0023] The upper mold base 10 is arranged opposite to the lower mold base 20 , the upper mold base 30 is arranged on the bottom surface of the upper mold base 10 towards the lower mold base 20 , and the lower mold 50 is arranged on the upper surface of the lower mold base 20 towards the upper mold base 10 .

[0024] The upper mold release assembly 40 includes an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com