Spraying-free plastic, forming device for production and forming method

A molding device and spray-free technology, applied in the field of plastic molding, can solve the problem of inconvenient removal of finished products, and achieve the effects of simultaneous mold separation, high efficiency, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

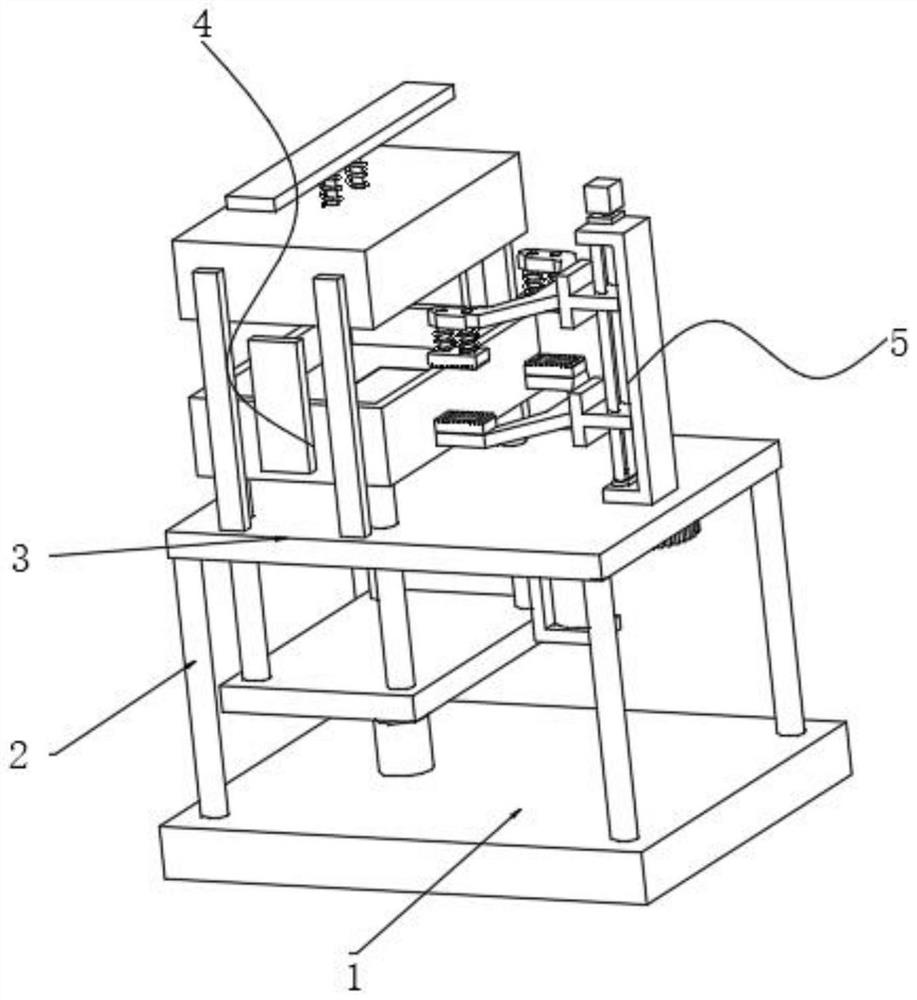

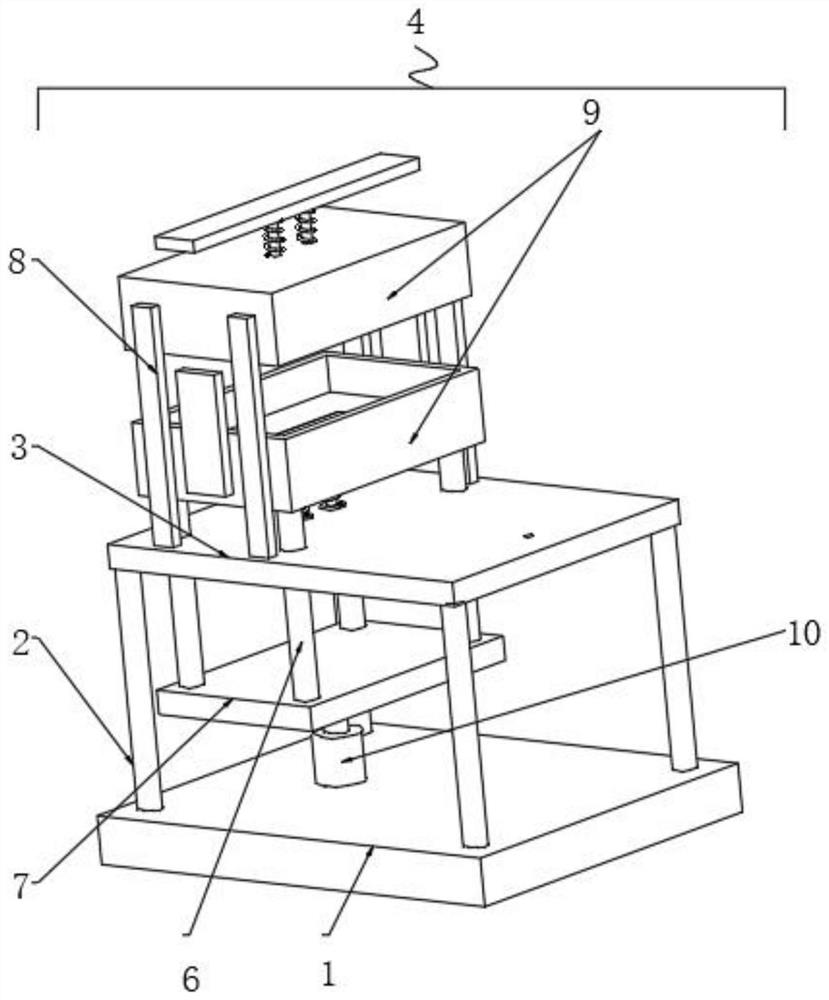

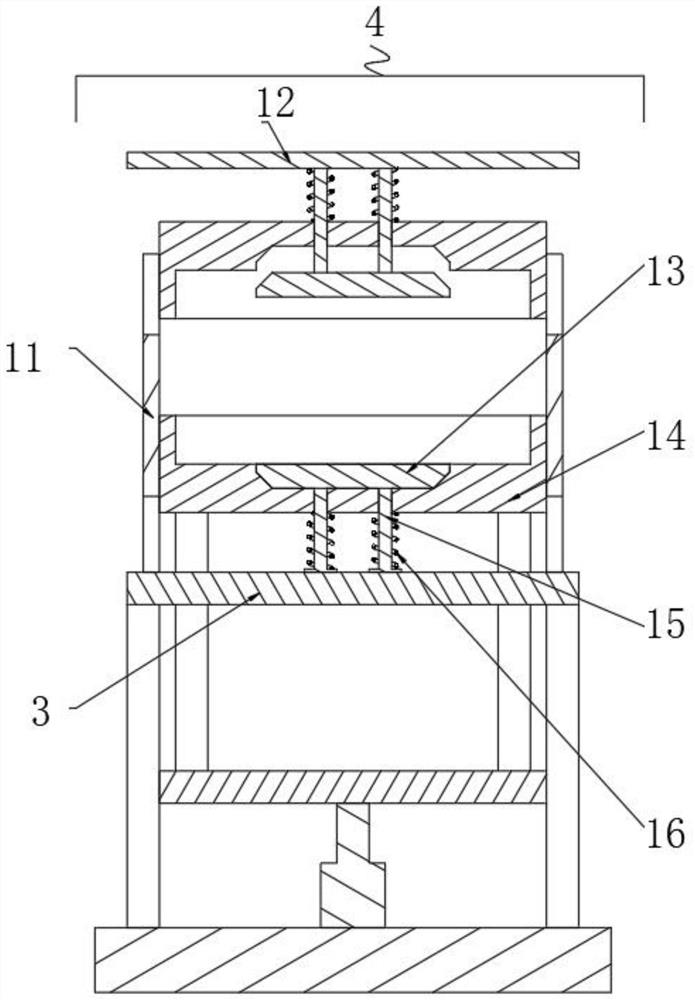

[0038] A molding device for spray-free plastic production, such as Figure 1-5As shown, it includes a base 1, the top of the base 1 is connected with a support base 3 through a pillar 2, and the top of the support base 3 is provided with an automatic mode release forming mechanism 4, and the automatic mode release forming mechanism 4 includes two groups of pairs The half-mold assembly 9 placed, the half-mold assembly 9 includes a stripper plate 13 and a half-mold main body 14, the stripping plate 13 is slidably connected to the inner wall of the half-mold main body 14 by two slide bars 15, and the The half-mold main body 14 is provided with an accommodating groove conforming to the shape of the stripping plate 13, and the outer wall of the slide bar two 15 is provided with a spring one 16, and the half-mold main body 14 at the bottom is slidably connected to the four slide bar one 6 The inner wall of the support seat 3, the half-mould main body 14 at the top is fixed on the to...

Embodiment 2

[0043] A molding device for spray-free plastic production, such as figure 1 , 5 , 6, in order to solve the problem of automatic reclaiming; the present embodiment makes the following improvements on the basis of embodiment 1: the top outer wall of the base 1 is also provided with a retrieving mechanism 5, and the retrieving mechanism 5 includes two The slider 21 and the driving assembly for driving the two sliders 21, the inner walls of the two sliders 21 are fixed with telescopic rods 26 by bolts, and the telescopic ends of the telescopic rods 26 are fixed with "V"-shaped jaws by bolts 22, the outer wall of one of the "V"-shaped jaws 22 is fixed with two splints 25 by bolts, and the outer wall of the other "V"-shaped jaw 22 is slidably connected with two other splints 25 through a slide bar three 23 , the outer wall of the sliding rod three 23 is provided with a spring two 24 .

[0044] In order to solve the clamping problem, such as Figure 4 As shown, the drive assembly ...

Embodiment 3

[0049] A spray-free plastic, which is a spray-free plastic processed by a molding device for spray-free plastic production in Embodiment 1 and Example 2, and is composed of the following weight ratio components: ABS resin 30-60 parts AS resin 15- 20 parts of metal powder 3-10 parts of mineral powder 3-15 parts of foaming agent 1-3 parts; toughening agent 0.5-1.5 parts; dispersant 0.5-3 parts of antioxidant 0.1-1 part of sulfur black 1-2 parts of high gloss 0.5-2 parts of toner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com