A stamping die for automobile sheet metal parts

A technology for automobile sheet metal parts and stamping dies, which is applied in the directions of forming tools, manufacturing tools, metal processing, etc., can solve problems such as affecting the taking of sheet metal parts, mold damage, affecting accuracy, etc., to reduce impact time and facilitate handling. The effect of removing and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

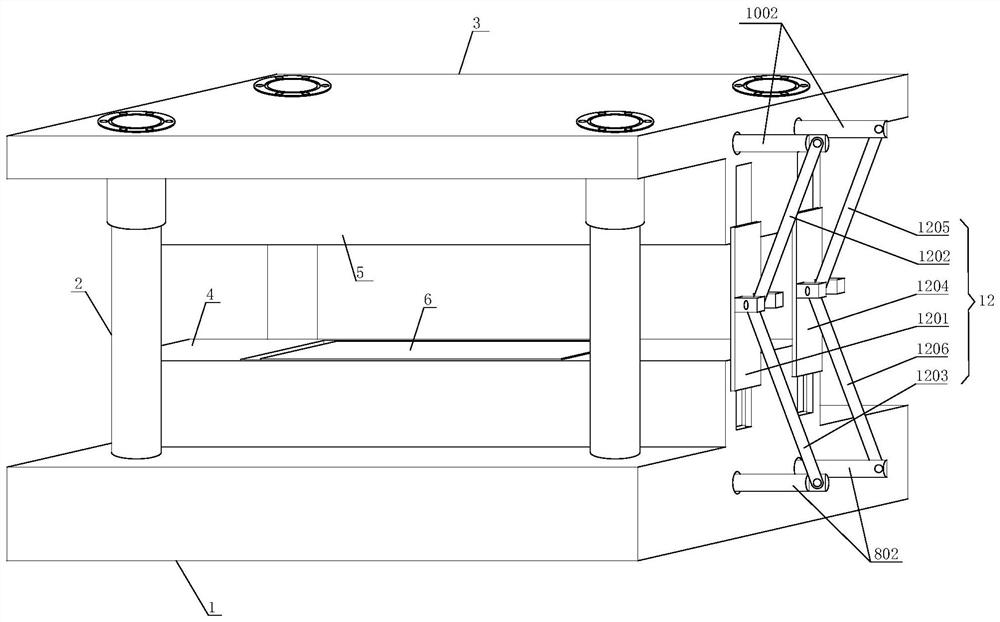

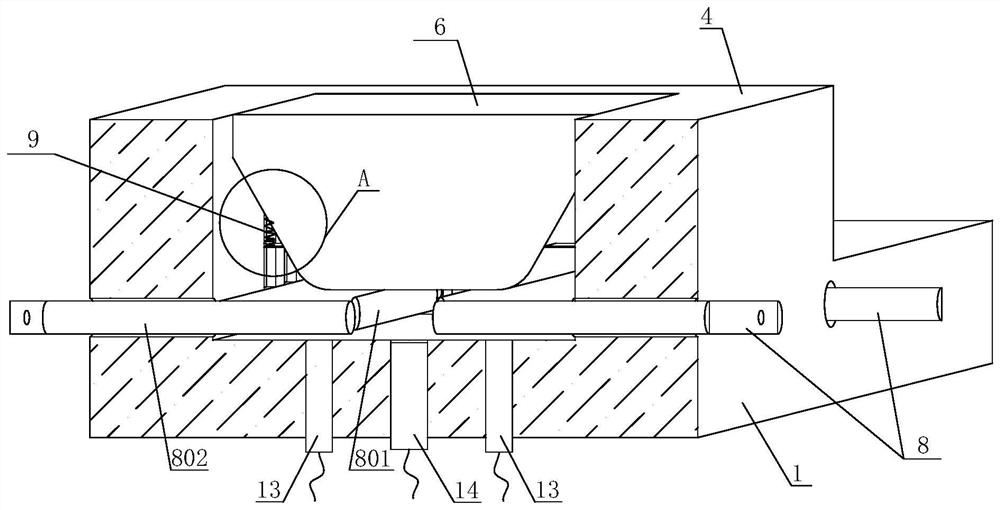

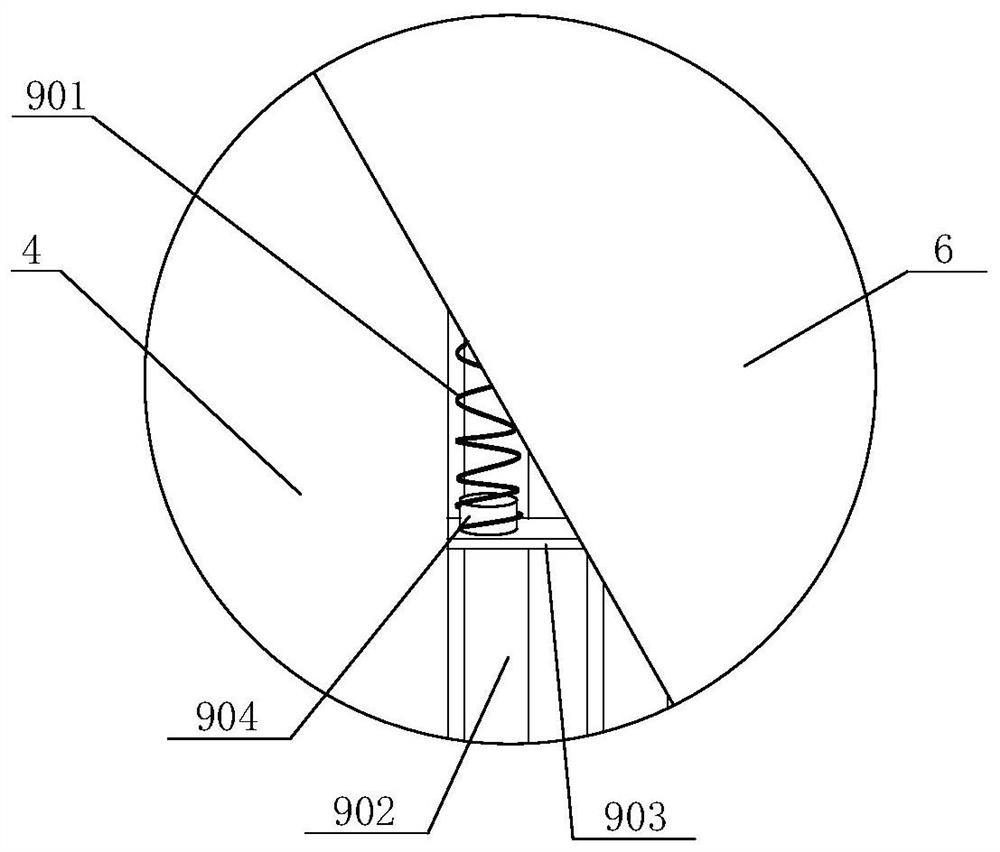

[0039] Such as figure 1 As shown, this embodiment provides a stamping die for automobile sheet metal parts, including: a lower mold base 1, a guide post guide sleeve 2, an upper mold base 3, a load-bearing platform 4, an impact table 5, a concave mold 6 and a punch 7 , the upper mold base 1 and the lower mold base 3 are flexibly connected through the guide post and guide sleeve 2, the load-bearing table 4 is installed on the lower mold base 1, and the impact table 5 is installed on the On the upper die base 3, the die 6 can be moved up and down and installed in the load-bearing platform 4, and the position corresponding to the die 6 on the lower die base 1 is provided with a dynamic support for the die 6. The die supporting mechanism 8, the die retracting mechanism 9 for driving the die 6 to retract between the bearing table 4 and the die 6 is provided; the punch 7 can be moved up and down and installed on the In the impact table 5, a punch support mechanism 10 that can dynam...

Embodiment 2

[0050] Such as figure 1 As shown, the present embodiment provides a stamping method for stamping dies of automobile sheet metal parts, comprising the following steps:

[0051] Position the sheet metal original on the die 6;

[0052] The stamping machine drives the upper die base 3 to drive the impact table 5 and the punch 7 to go down together;

[0053] The punch 7 cooperates with the die 6 to press and form the sheet metal original to obtain a sheet metal part;

[0054] During the descending process of the upper mold base 3, the linkage mechanism 12 drives the die support mechanism 8 and the punch support mechanism 10 for linkage. When the stamping is just completed, the die support roller 801 of the die support mechanism 8 is supported At the joint position between the slope and the bottom surface of the die 6, the punch support roller 1001 of the punch support mechanism 10 is supported at the joint position between the slope and the top surface of the punch 7; at this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com