Solvent-free compound machine scraping mechanism for PET packaging bag production

A solvent-free compound machine and packaging bag technology, which is applied in the field of PET packaging bag production, can solve the problems of difficult to scrape the packaging bag, deviation of the packaging bag adhesion, and debonding of the glued material, so as to increase the scraping area, The effect of preventing excessive displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

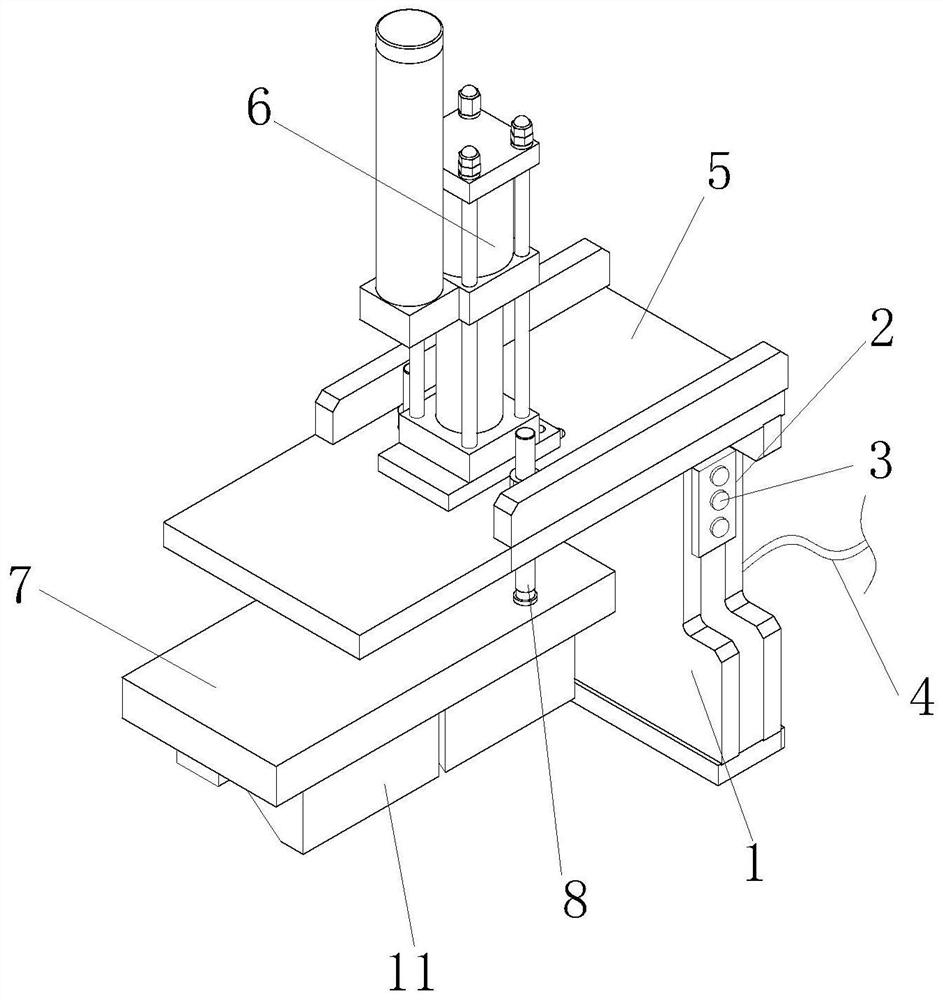

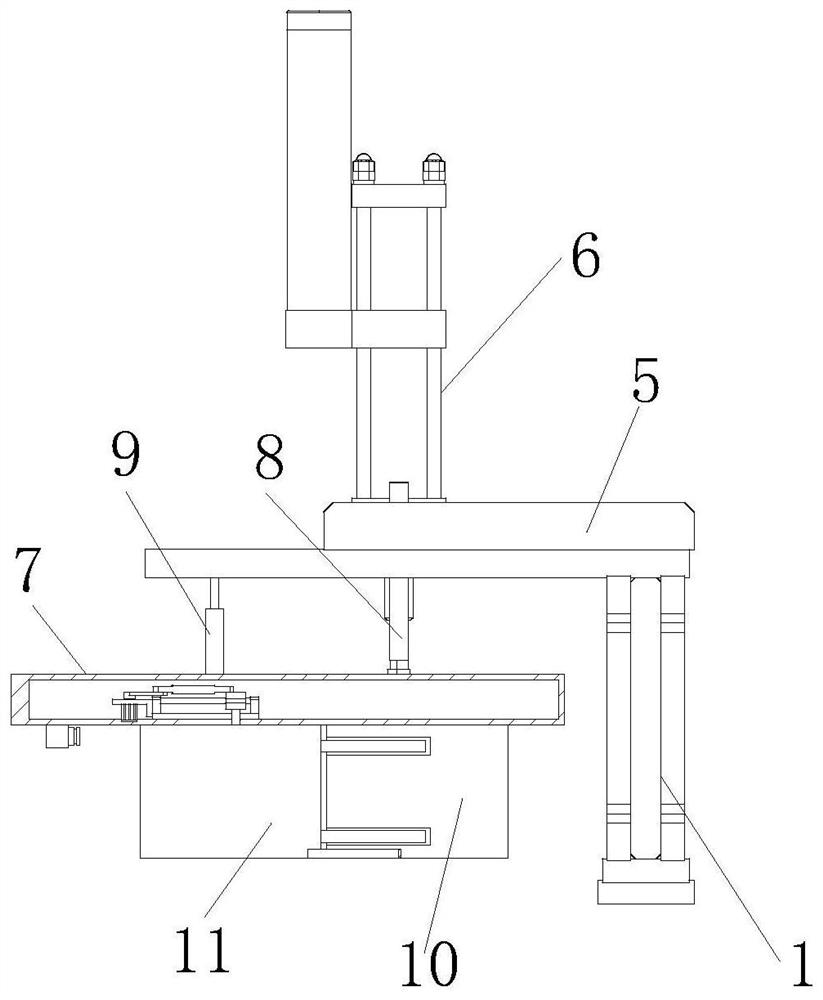

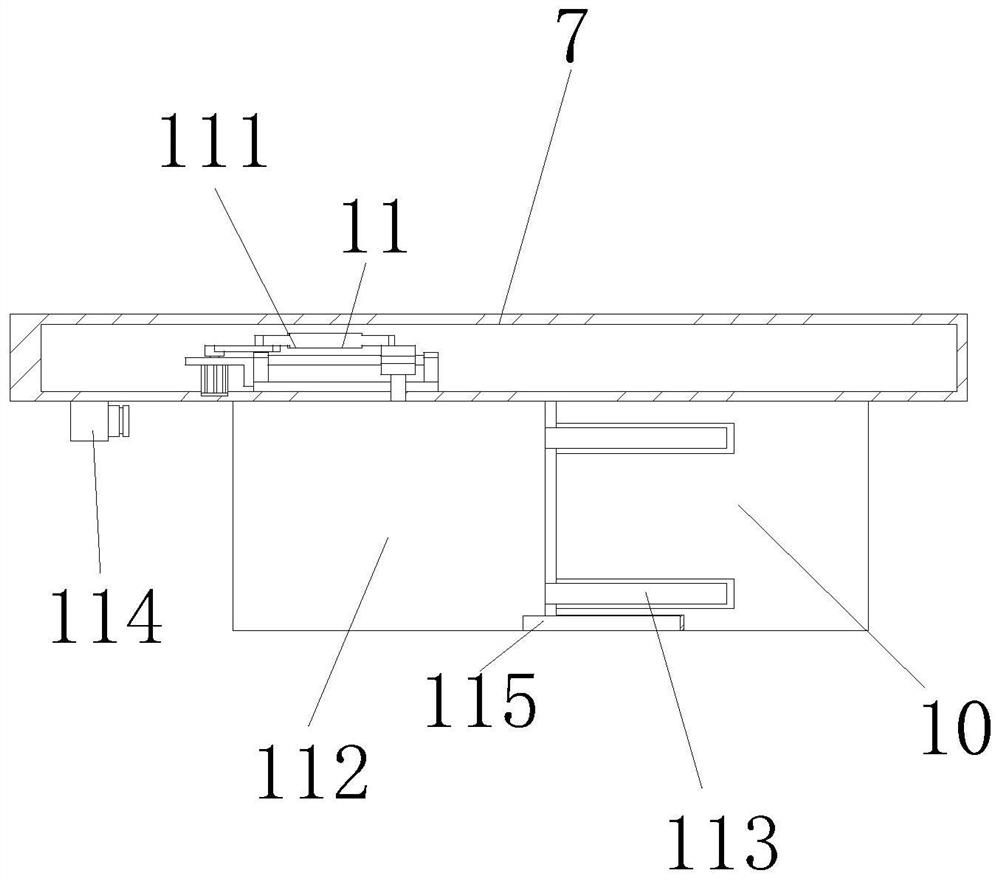

[0029] see figure 1 and figure 2 , the present invention provides a solvent-free composite machine scraping mechanism for PET packaging bag production through improvement, including a support rod 1, a support plate 5, an electric push rod 6, a connecting plate 7, a first scraper 10 and a movement adjustment mechanism 11. The right end of the support rod 1 is provided with a control panel 2, the front end of the control panel 2 is equipped with a button 3, the rear end of the support rod 1 is fixed with a power wire 4, the top of the support rod 1 is welded and fixed to the support plate 5, and the mobile adjustment mechanism 11 is installed and fixed on the Inside the connection plate 7, the support plate 5 is locked and fixed with the bottom of the electric push rod 6 by screws, the output end of the electric push rod 6 is fixedly connected to the top of the connection plate 7, and the left and right sides of the upper end of the connection plate 7 are oppositely provided wi...

Embodiment 2

[0034] The present invention provides a solvent-free composite machine scraping mechanism for PET packaging bag production through improvement. The connecting plate 7 is in the shape of a cuboid with an internal cavity, which is beneficial to install and fix the reciprocating swing mechanism 111. The sliding platen 115 It is in the shape of a cuboid, and the sliding pressing plate 115 slides and cooperates with the lower left end of the first scraper 10, which is beneficial to scrape the packaging bag flat.

[0035] The present invention provides a solvent-free composite machine scraping mechanism for PET packaging bag production through improvement, and its working principle is as follows;

[0036] First, before use, place the scraping mechanism of the solvent-free compound machine for PET packaging bag production horizontally, so that the support rod 1 can fix and support the mechanism;

[0037] Second, when in use, connect the external power supply through the power lead 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com