Adhesive tape wear resistance testing machine

A wear-resistant test, adhesive tape technology, applied in the direction of wear-resistant test, measuring device, instrument, etc., can solve the problems of insufficient sealing, no tape, anti-corrosion failure, etc., and achieve the effect of low cost, reliable use and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

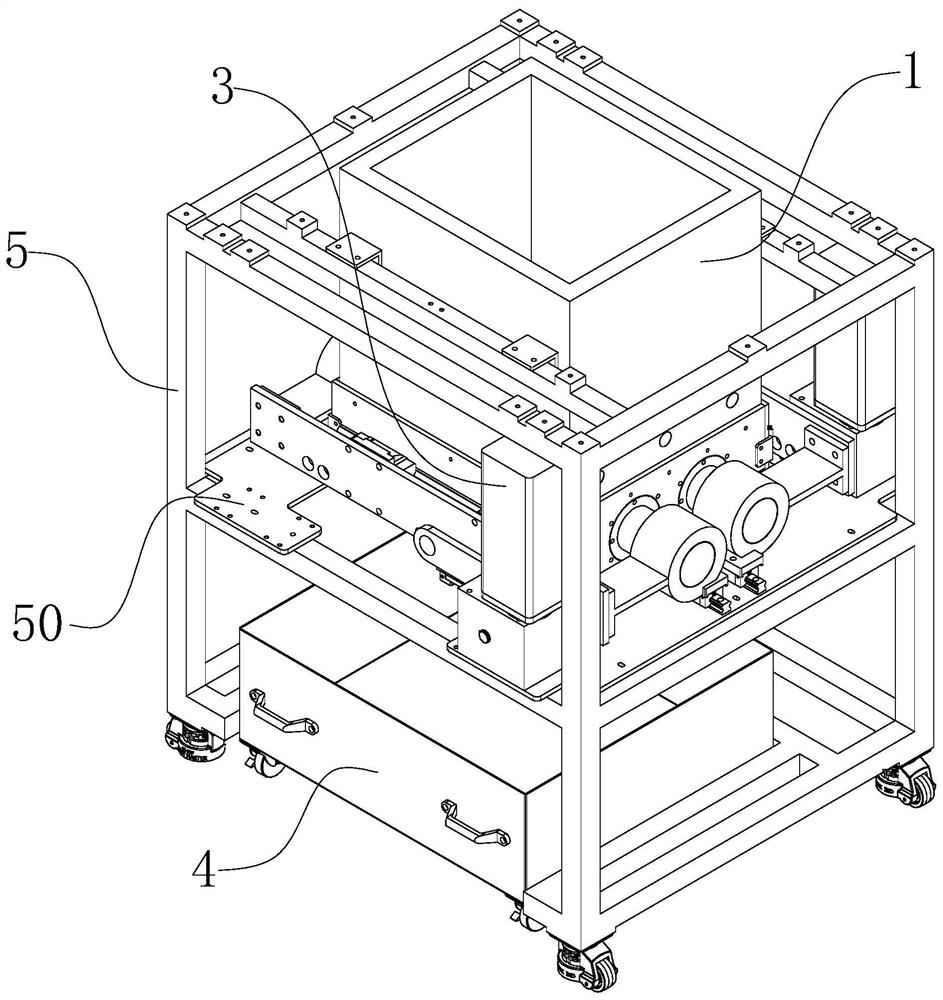

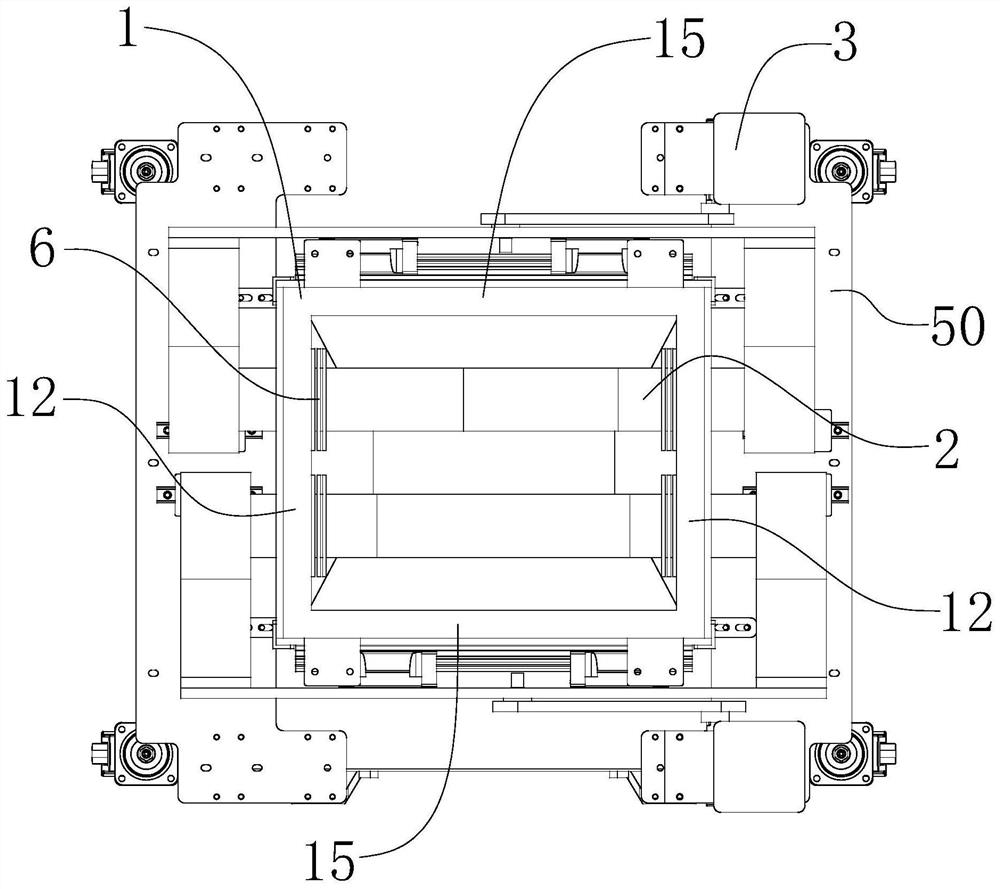

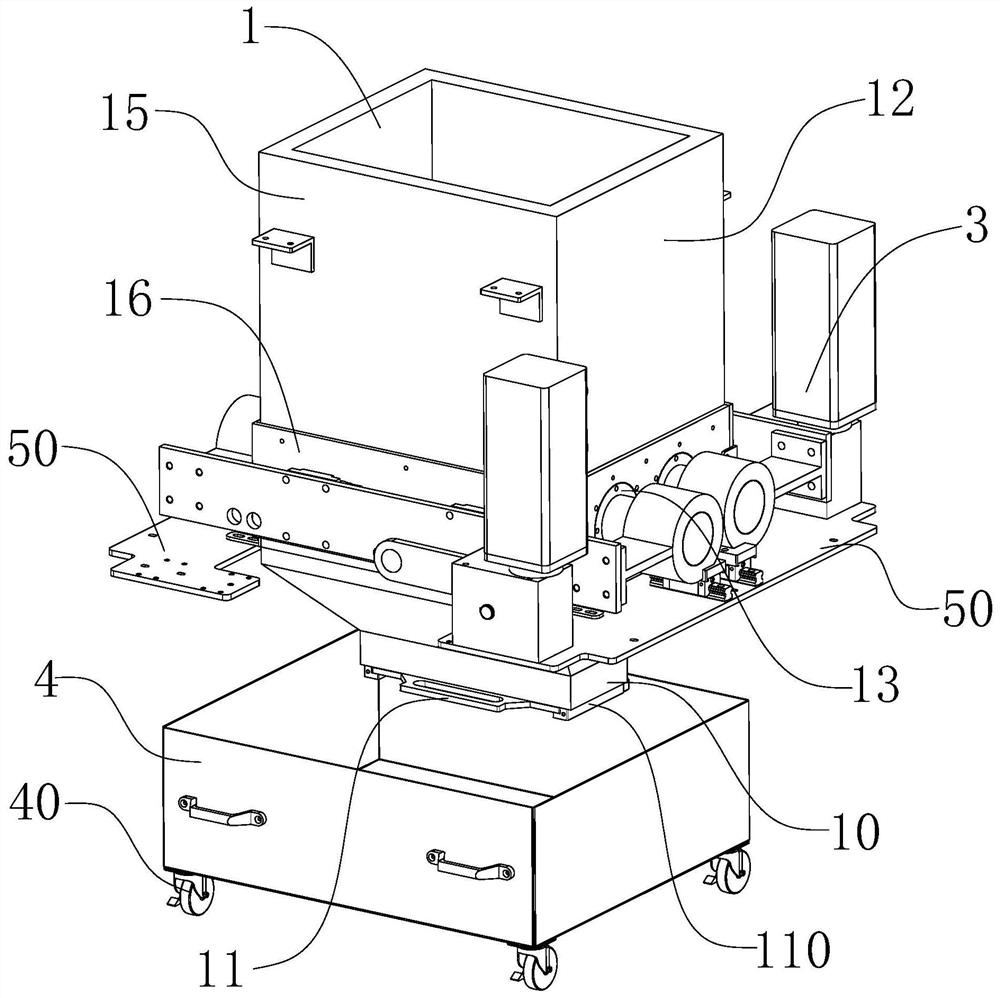

[0030] Such as figure 1 and figure 2 As shown, the belt abrasion tester corresponding to a preferred embodiment of the present invention includes a box body 1 containing a friction medium, a test carrier 2 located in the box body 1, and a drive test carrier 2 to reciprocate drive unit 3.

[0031] The box body 1 is used to hold the friction medium. The friction medium can be made of different materials according to the environment in which the tape is used, for example, it can be solid particles such as sand, soil, gravel and mixtures thereof. The test carrier 2 is in contact with the friction medium, which may be fully or partially buried in the friction medium. The surface of the test carrier 2 is wrapped with adhesive tape. After the driving device 3 drives the test carrier 2 to reciprocate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com