A kind of rice and wheat collecting and distributing device and method

A distributor, rice and wheat technology, applied in the field of agricultural machinery research, can solve the problem that the outlet of the distributor cannot be closed randomly, so as to improve the operation performance, reduce the probability of blockage, and reduce the effect of air pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

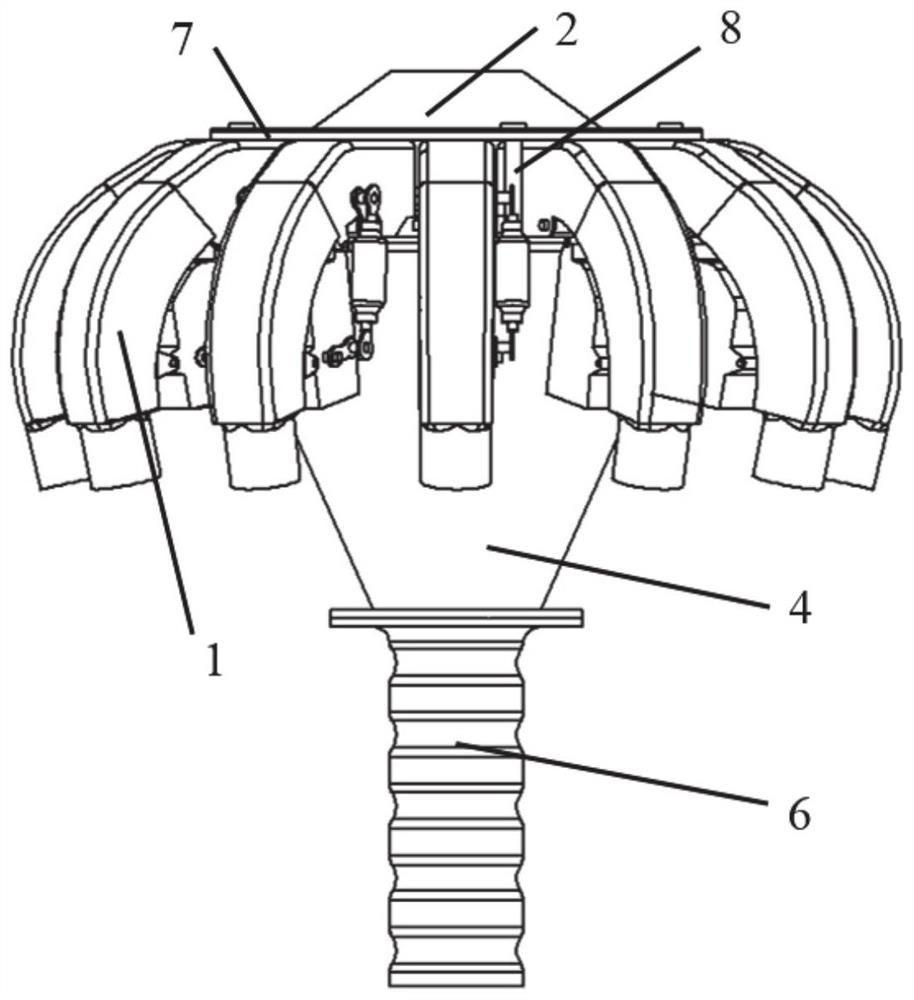

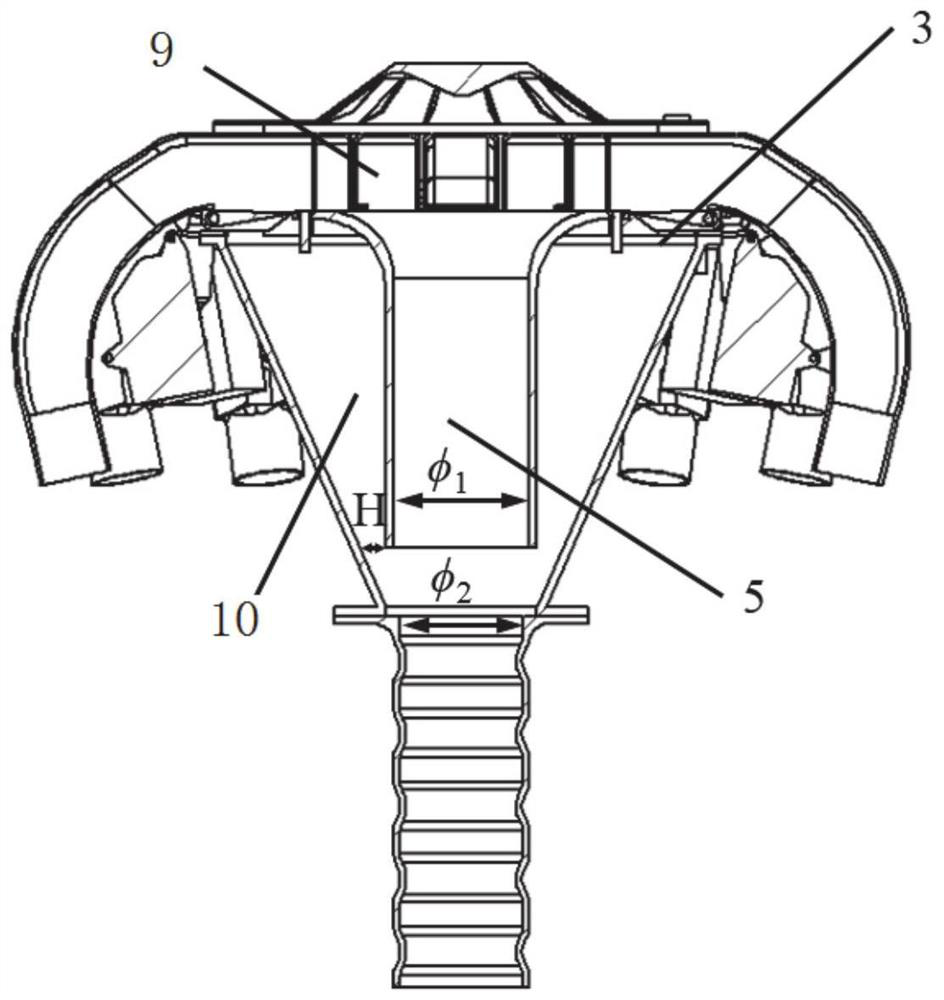

[0037] This embodiment provides a kind of rice and wheat collecting and distributing device, such as Figure 1-Figure 2 As shown, it includes an outlet unit 1, a cover plate 2, a tapered pipe 4, a straight pipe 5, a corrugated pipe 6, and a chassis 3. There are multiple outlet units 1, which are detachably connected to the cover plate 2. The outlet unit 1 is evenly arranged in a ring shape on the edge of the chassis 3 , the chassis 3 is installed concentrically with the tapered pipe 4 and the straight pipe 5 , and the bellows 6 is detachably connected with the tapered pipe 4 .

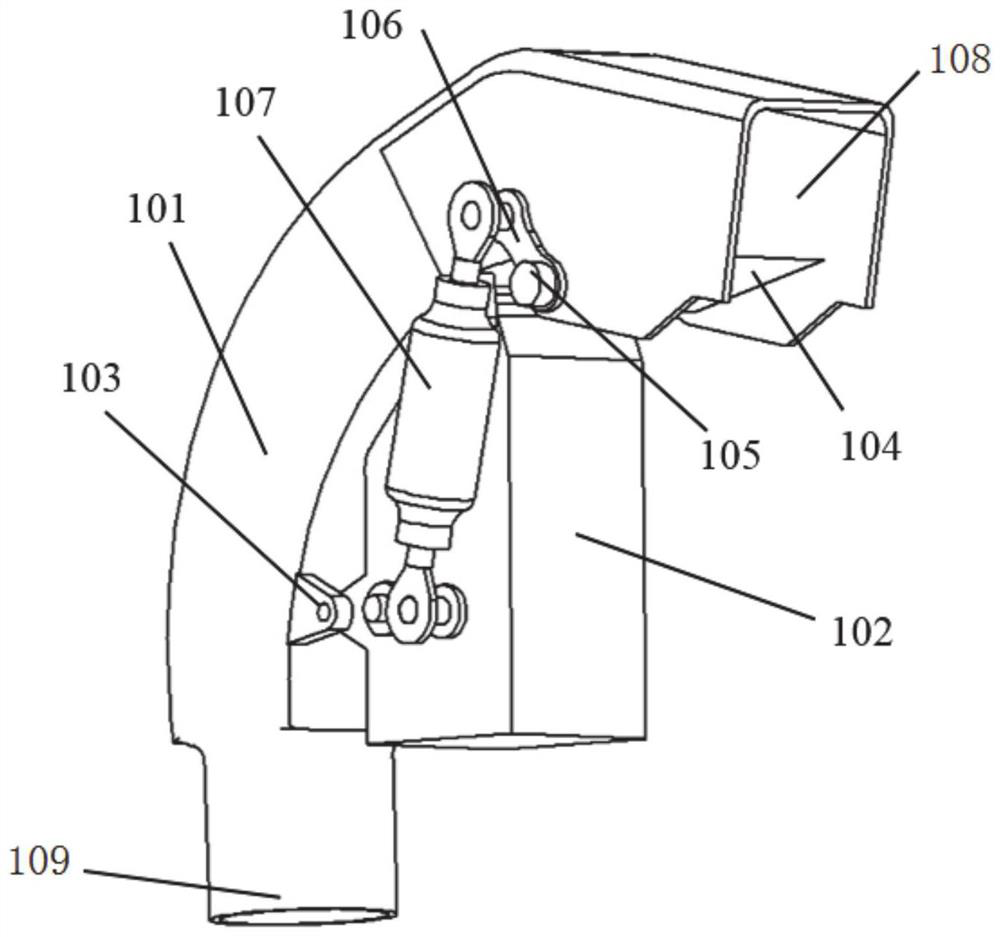

[0038] Specifically, an upper connecting plate 7 is installed on the top of the outlet unit 1, and the cover plate 2 is installed on the top 7 of the upper connecting plate, and is fixed together with the upper connecting plate 7, the outlet unit 1 and the chassis 3 through the first pin 8 . The outlet unit 1 , the chassis 3 , the upper connection plate 7 and the cover plate 2 form a distribution cham...

Embodiment 2

[0048] This embodiment provides a control method for the rice and wheat collecting and distributing device, including:

[0049] The positive pressure airflow passes through the bellows 6, and the airflow and the mixture of rice and wheat seeds are sent to the distribution chamber 9 through the straight pipe 5, and the rice and wheat seeds rise to contact with the cover plate 2, and the separation effect of the conical protrusion 201 and the partition 202 forms a uniform The seed flow enters the inlet 108 of the corresponding outlet unit 1, and the valve 104 is in an open state at this moment.

[0050] When a row of outlet cells 1 needs to be closed, the controller controls the motor 102 to rotate clockwise 90°, and the connecting rod 107 moves down to drive the valve 104 to rotate counterclockwise. block.

[0051] The blocked seeds fall into the return chamber 10 through the hole 301 of the bottom plate 3, and fall to the lower end surface of the straight pipe 5 under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com