Patents

Literature

50results about How to "Reduce air pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

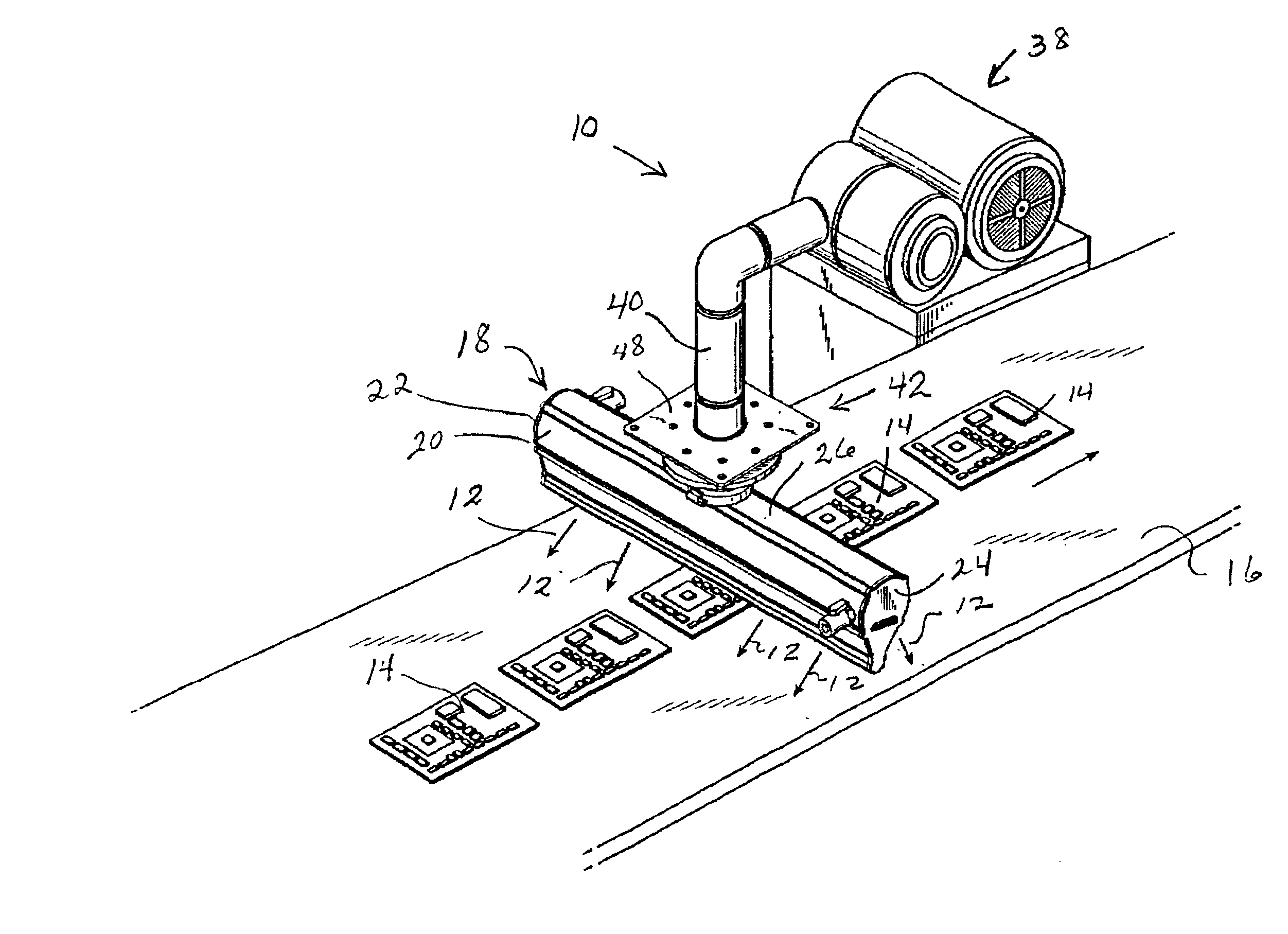

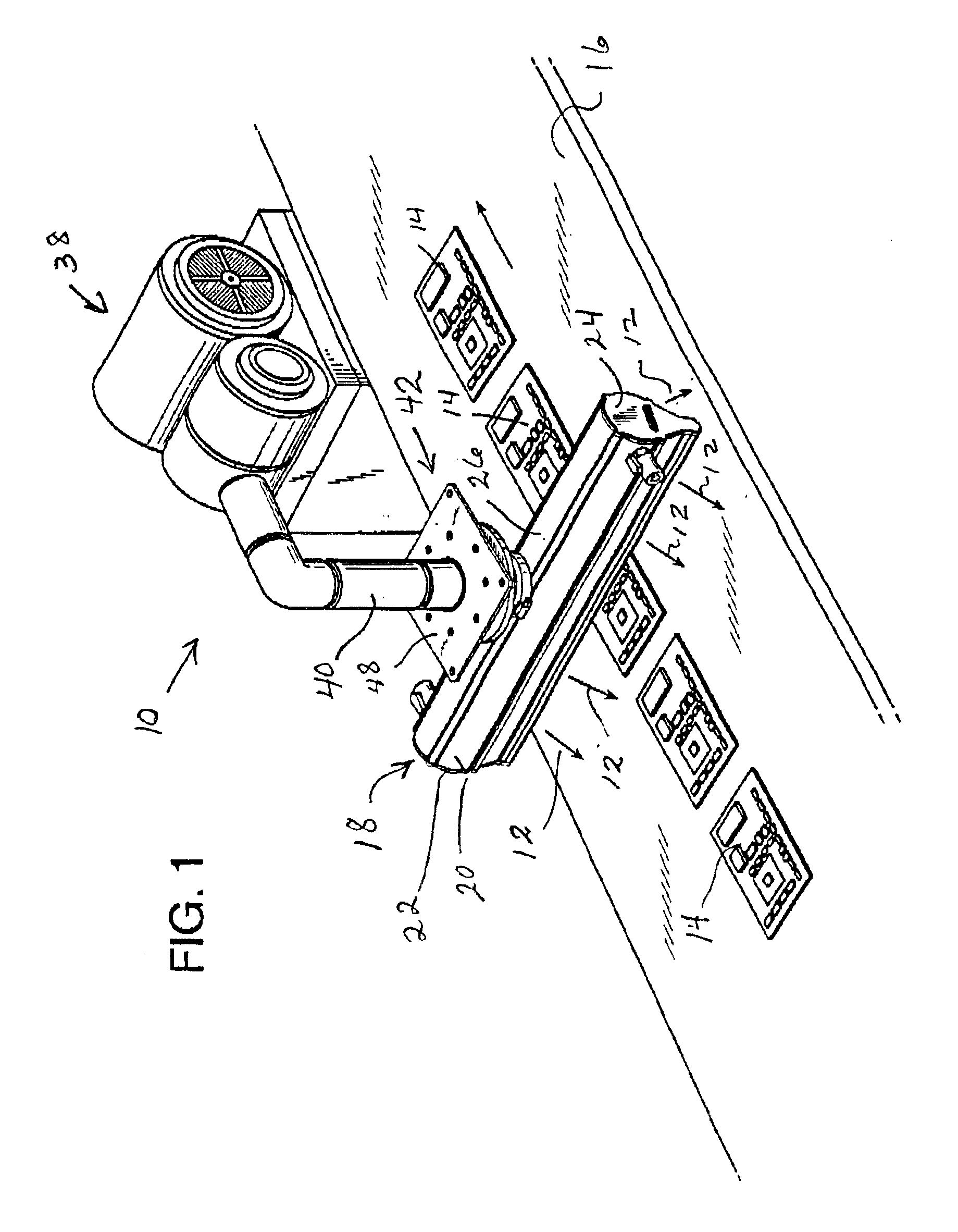

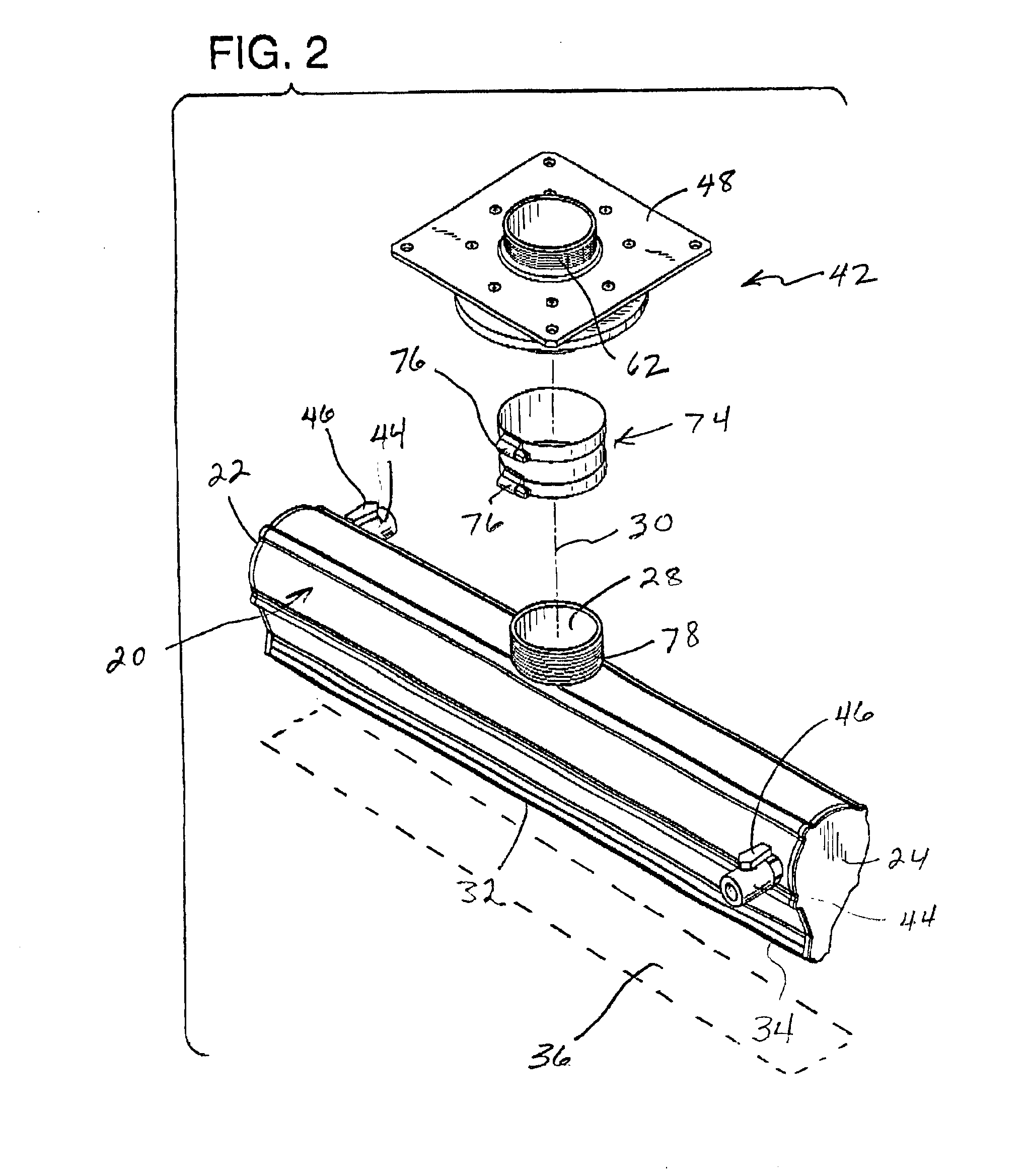

Rotatable air knife

InactiveUS6990751B2Extended stayDried or blown off more effectivelyDrying solid materials with heatDrying gas arrangementsCouplingEngineering

An air knife or air nozzle manifold for drying or blowing off passing articles moved by a conveyor system is provided with a coupling that permits rotation of the air knife or air nozzle manifold relative to the air inlet duct leading from a blower. The air knife or air nozzle manifold has opposing ends located equidistant from a longitudinal axis of rotation relative to a stationary element of the coupling. Thrust nozzles are provided at each of the opposing ends of the air knife or air nozzle manifold to deflect a certain portion of the air from the plenum chamber to provide thrusting jets of air that rotate the air knife or air nozzle manifold about the longitudinal axis. The flow of air emitted from the air knife or air nozzle manifold is thereby directed onto the passing articles from different directions as the articles move by. The efficiency of drying and blowing off the articles to be processed is thereby significantly improved.

Owner:SONIC AIR SYST

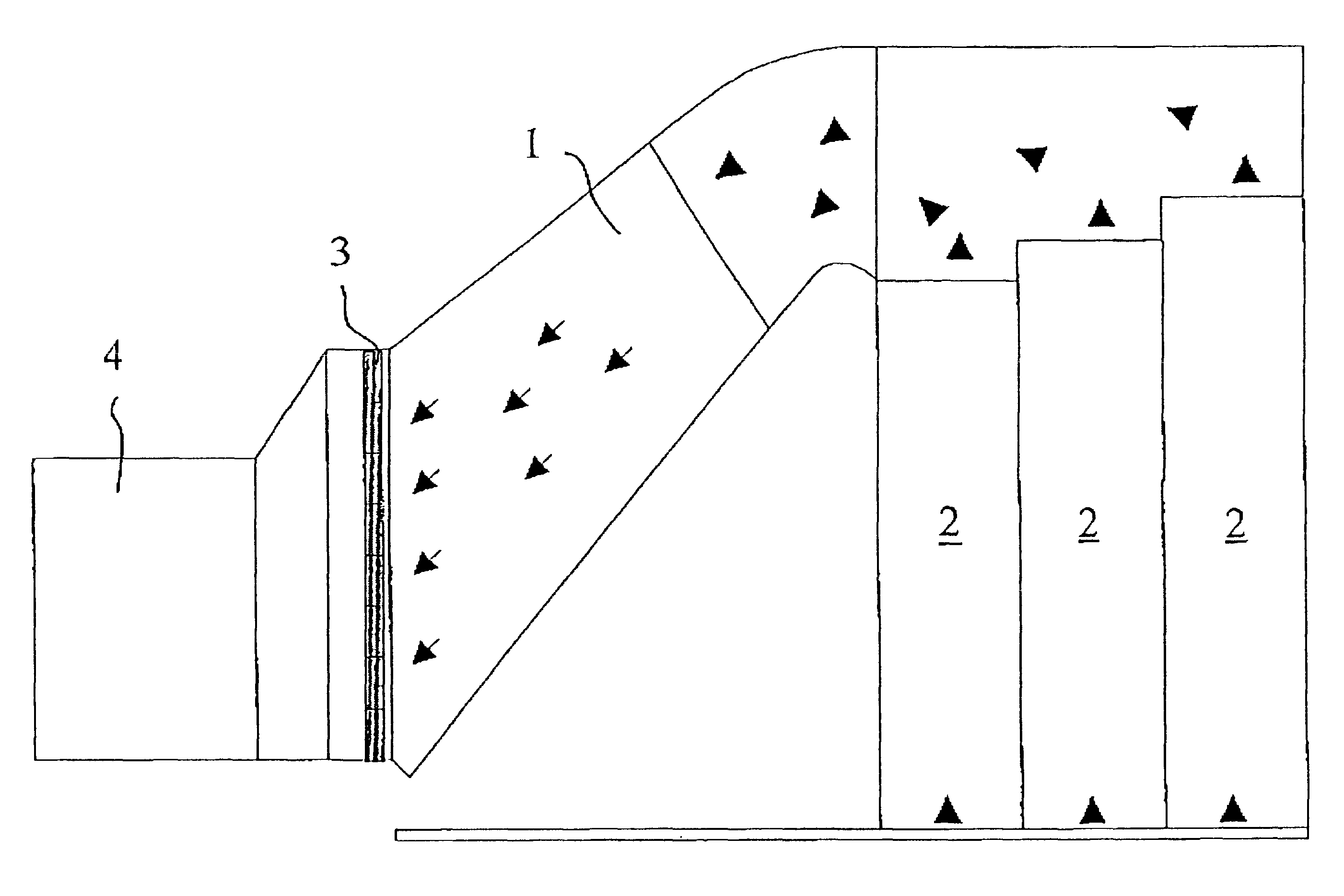

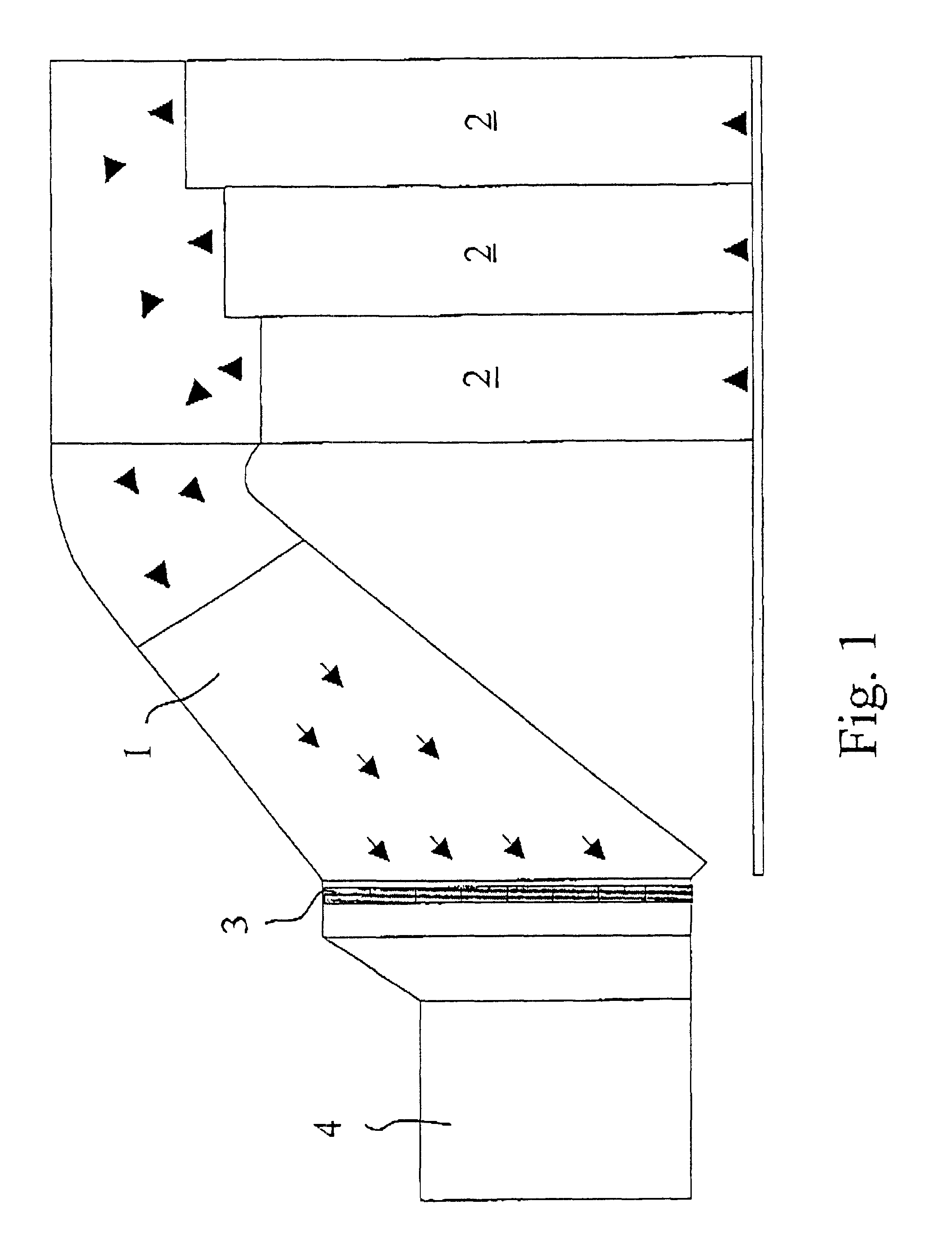

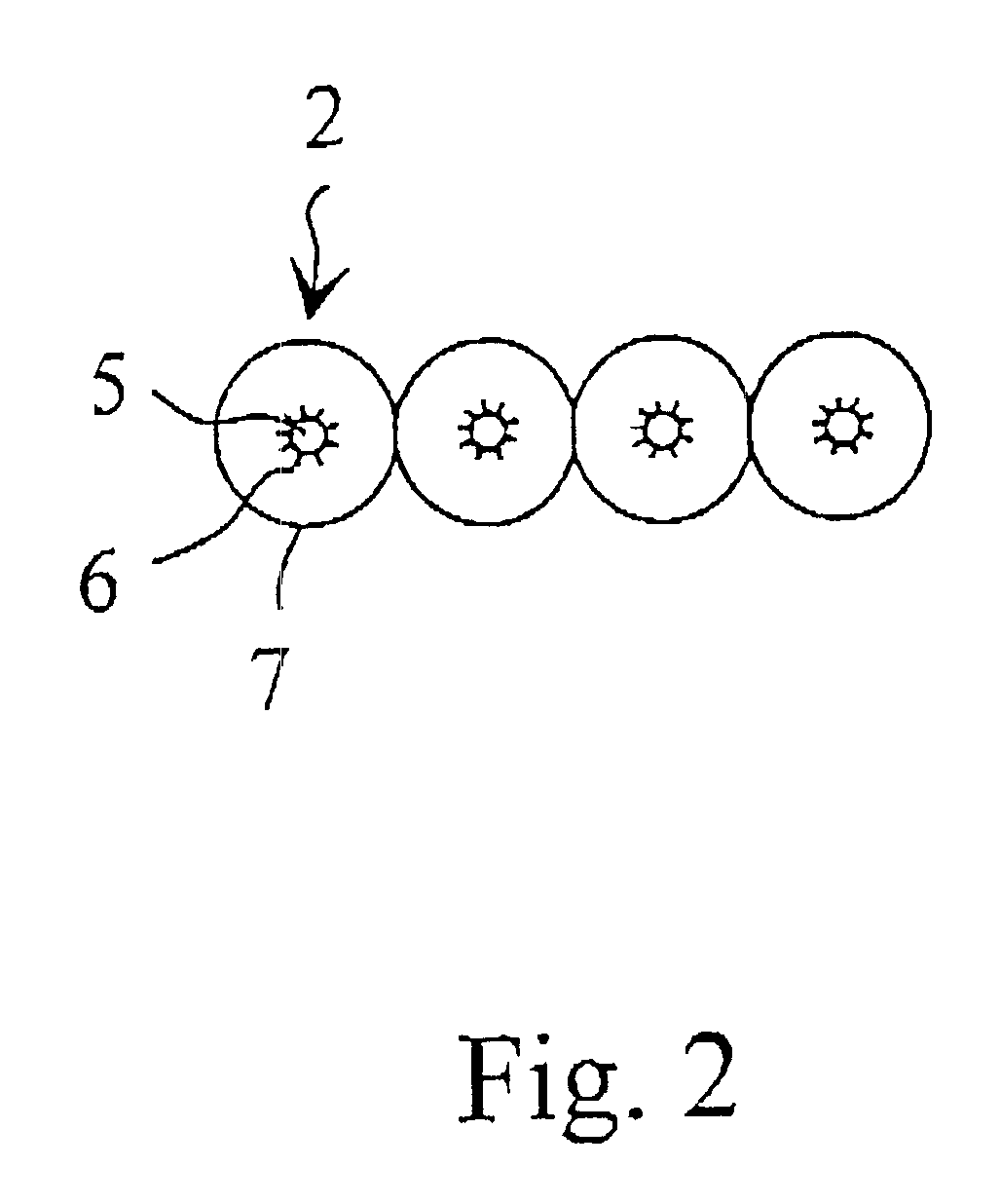

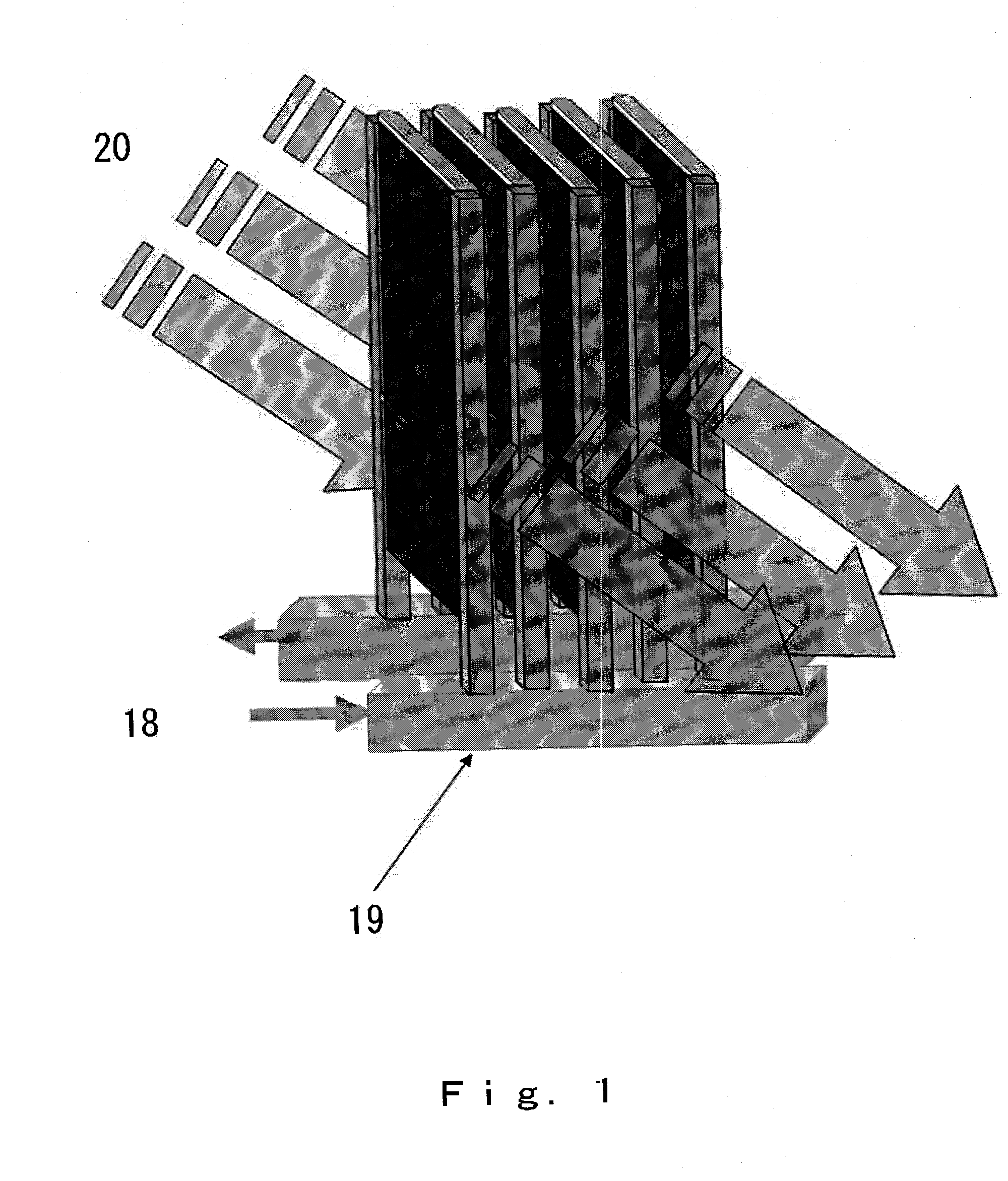

Method and arrangement for purifying the intake air of a gas turbine

InactiveUS6527829B1Increase capacityEfficient chargingAuxillary pretreatmentGas turbine plantsElectric fieldGas turbines

The present invention describes a method and an arrangement for purifying the intake air of a gas turbine of solid particles and liquid droplets. According to the invention air is taken into the system of intake air passages (1, 2, 4) of the gas turbine and the particles contained in the intake air are collected by means of at least one plate filter (3) to which a collection voltage has been connected. In order to enable and enhance collection, the air is taken into at least one charging chamber (2) arranged at a distance prior to the plate filters (3) in the flow direction of the air, where an electric field is formed between at least two electrodes (5, 7) by connecting a voltage between the electrodes which exceeds the collection voltage, whereby powerful charging of the particles and at least partial removal of the water contained in the air are effected.

Owner:FORTUM OY

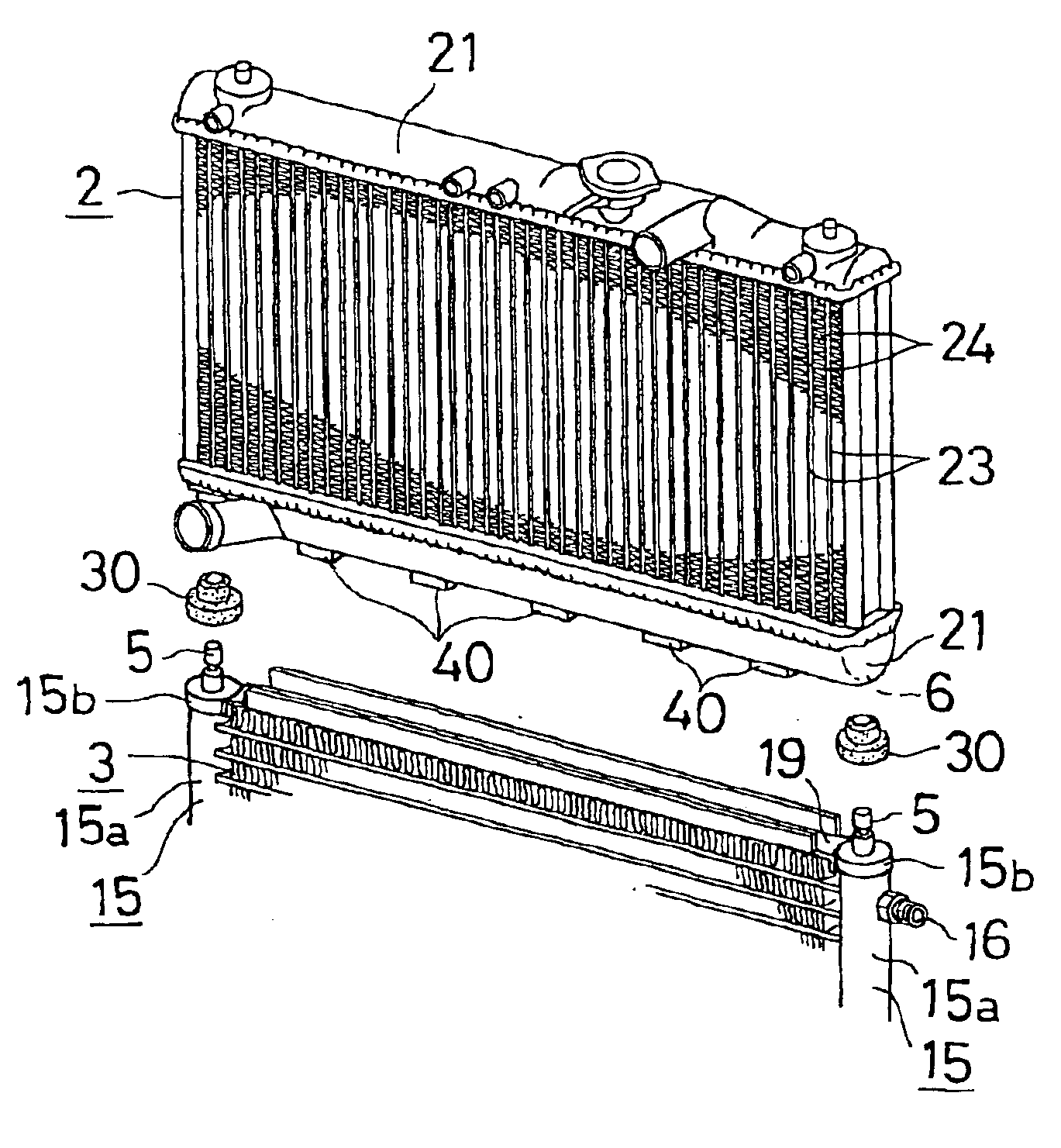

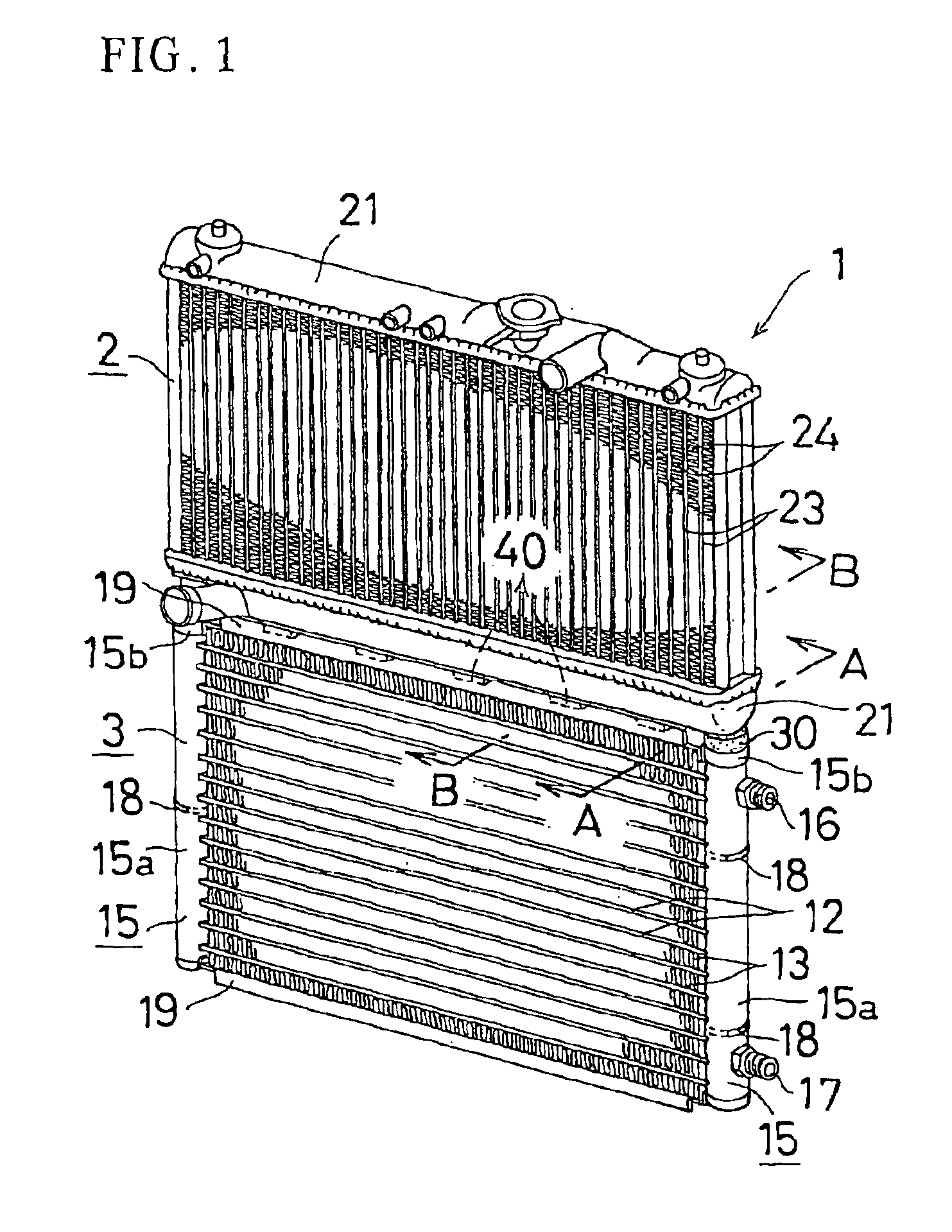

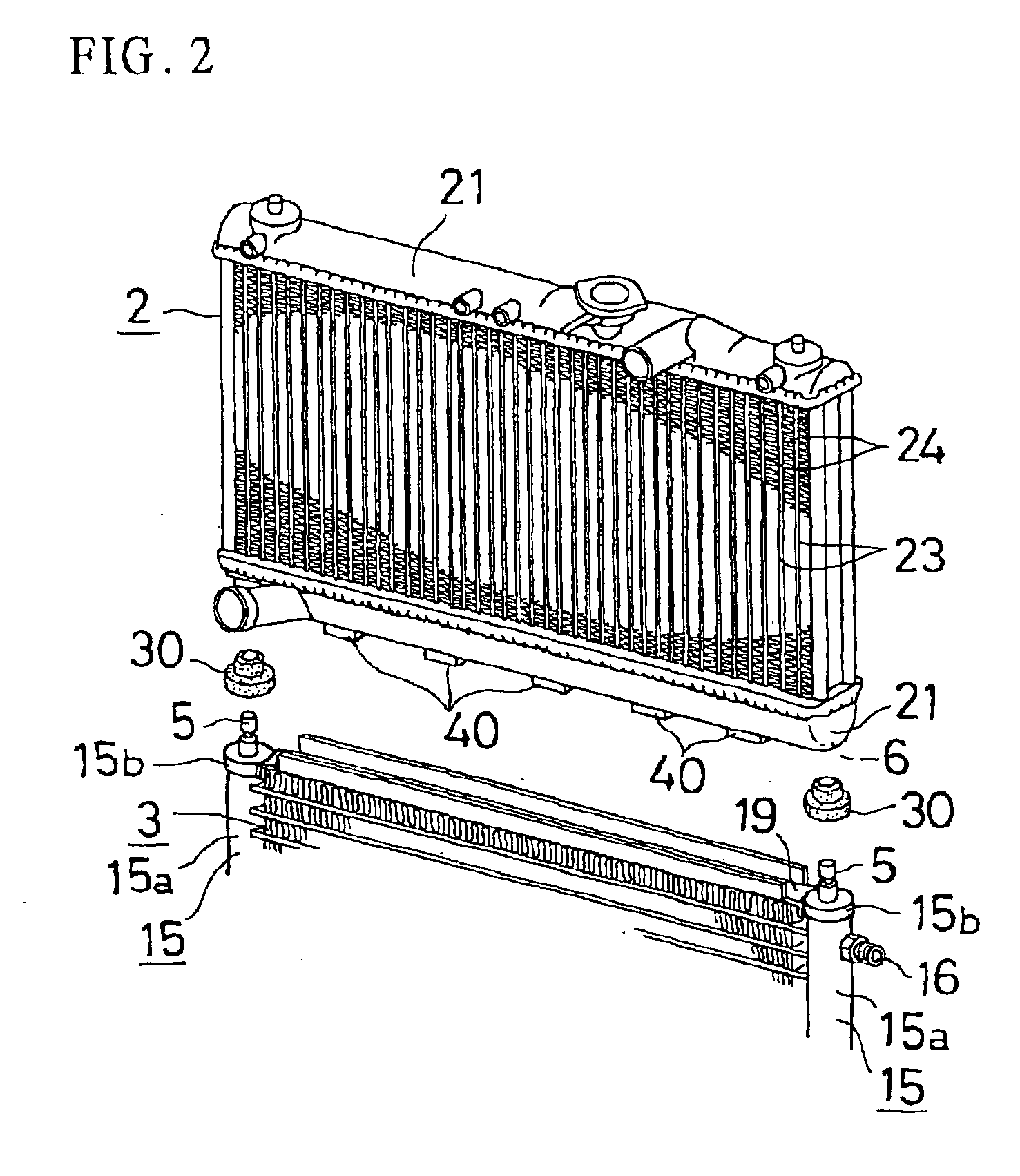

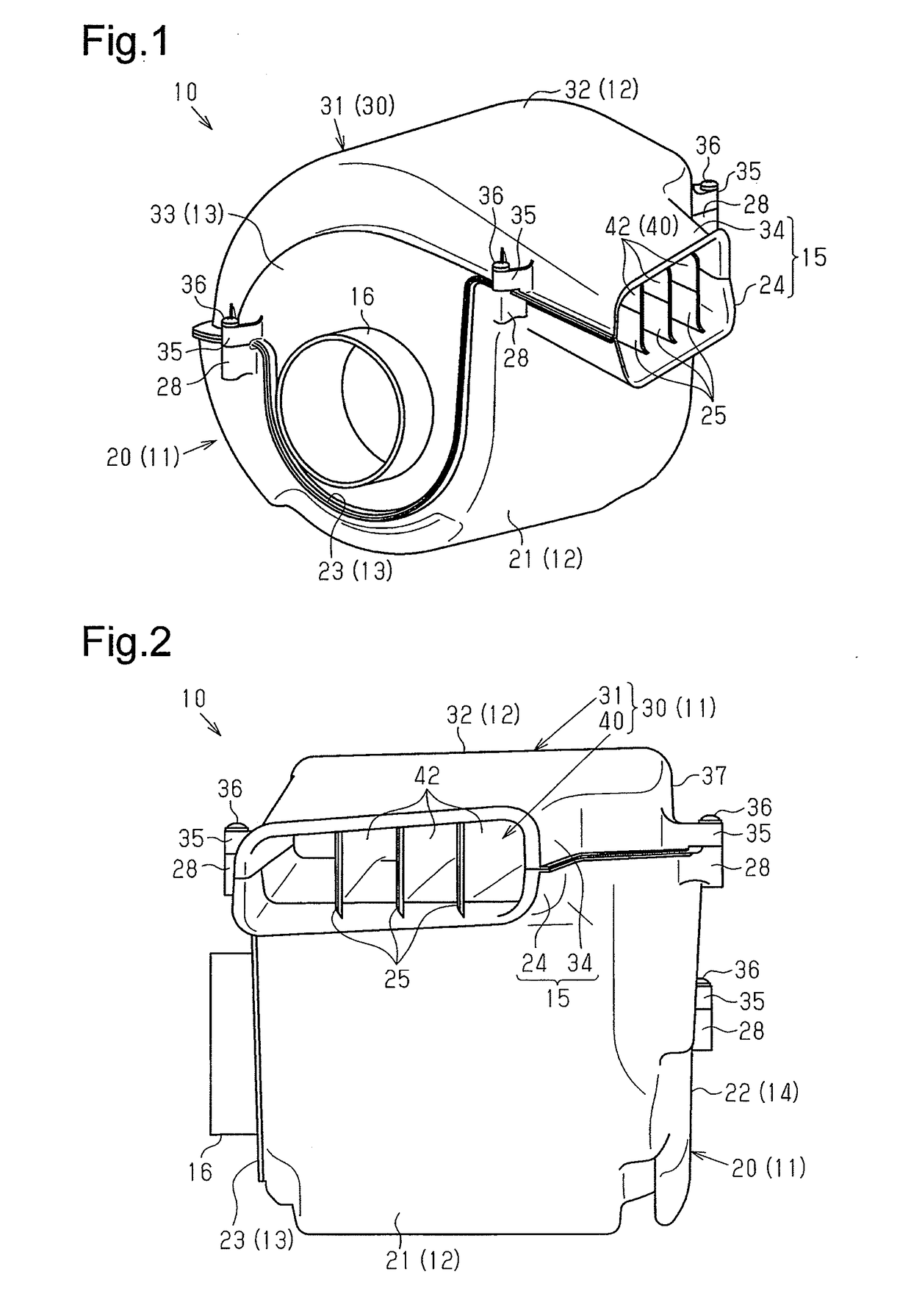

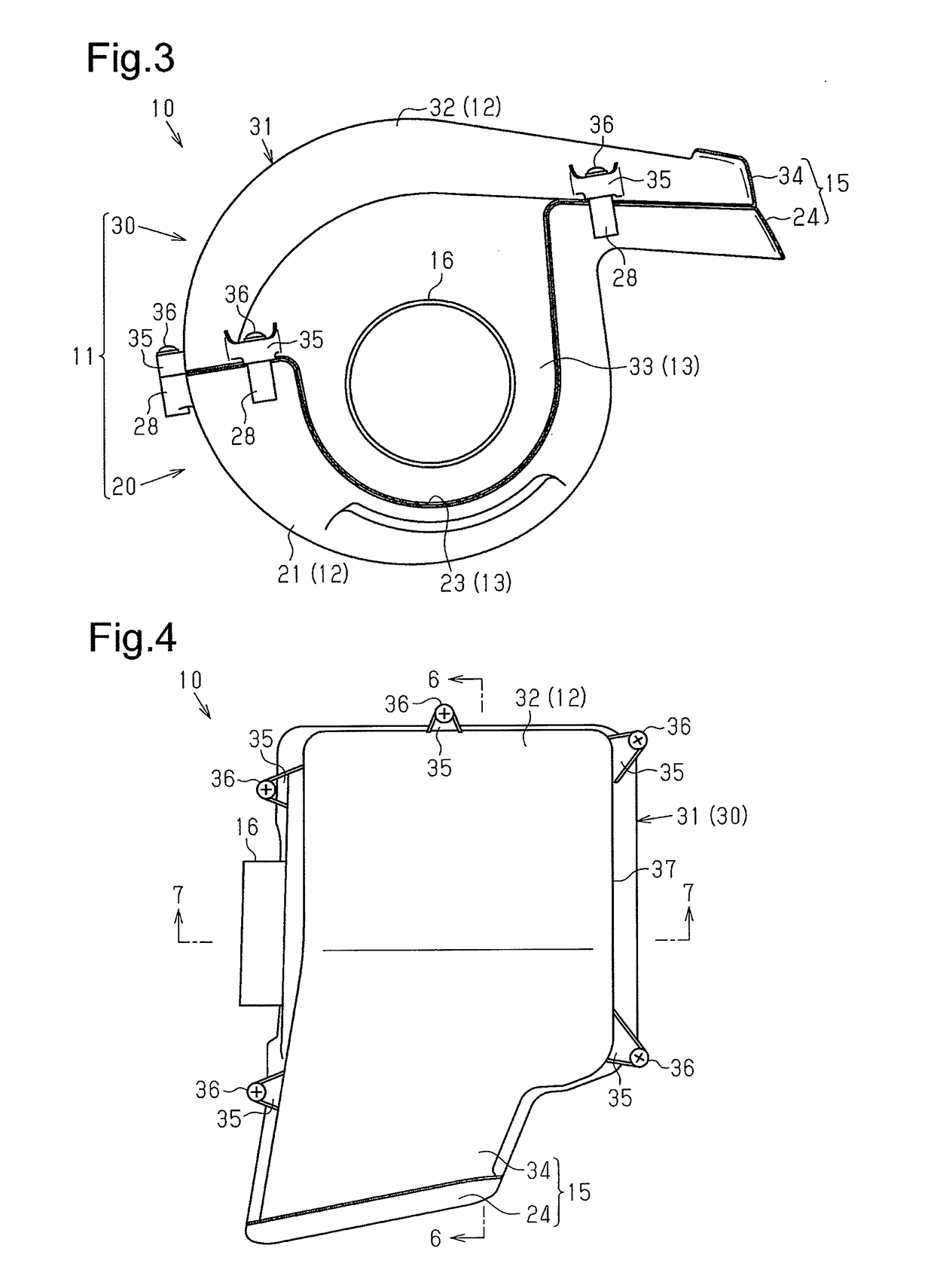

Integrated heat exchanger

InactiveUS6874570B2Easy to implementSmooth supplyAir-treating devicesRailway heating/coolingPlate heat exchangerEngineering

An integrated heat exchanger is constituted by different kinds of heat exchangers such as a radiator for use in engine-cooling systems and a condenser for use in air-conditioning systems which is low in manufacturing cost, small in thickness, easy in maintenance and / or replacement and small in air pressure loss. The heat exchanger includes a first heat exchanger (2) and a second heat exchanger (3). A fitting dented portion (6) is provided at one of a bottom surface of the first heat exchanger (2) and an upper surface of the second heat exchanger (3), and a fitting protruded portion (5) is provided at the other thereof, and wherein the fitting protruded portion (5) is fitted in the fitting dented portion (6), whereby the first heat exchanger (2) is integrally conected to the upper surface of the second heat exchanger (3).

Owner:KEIHIN THERMAL TECH CORP

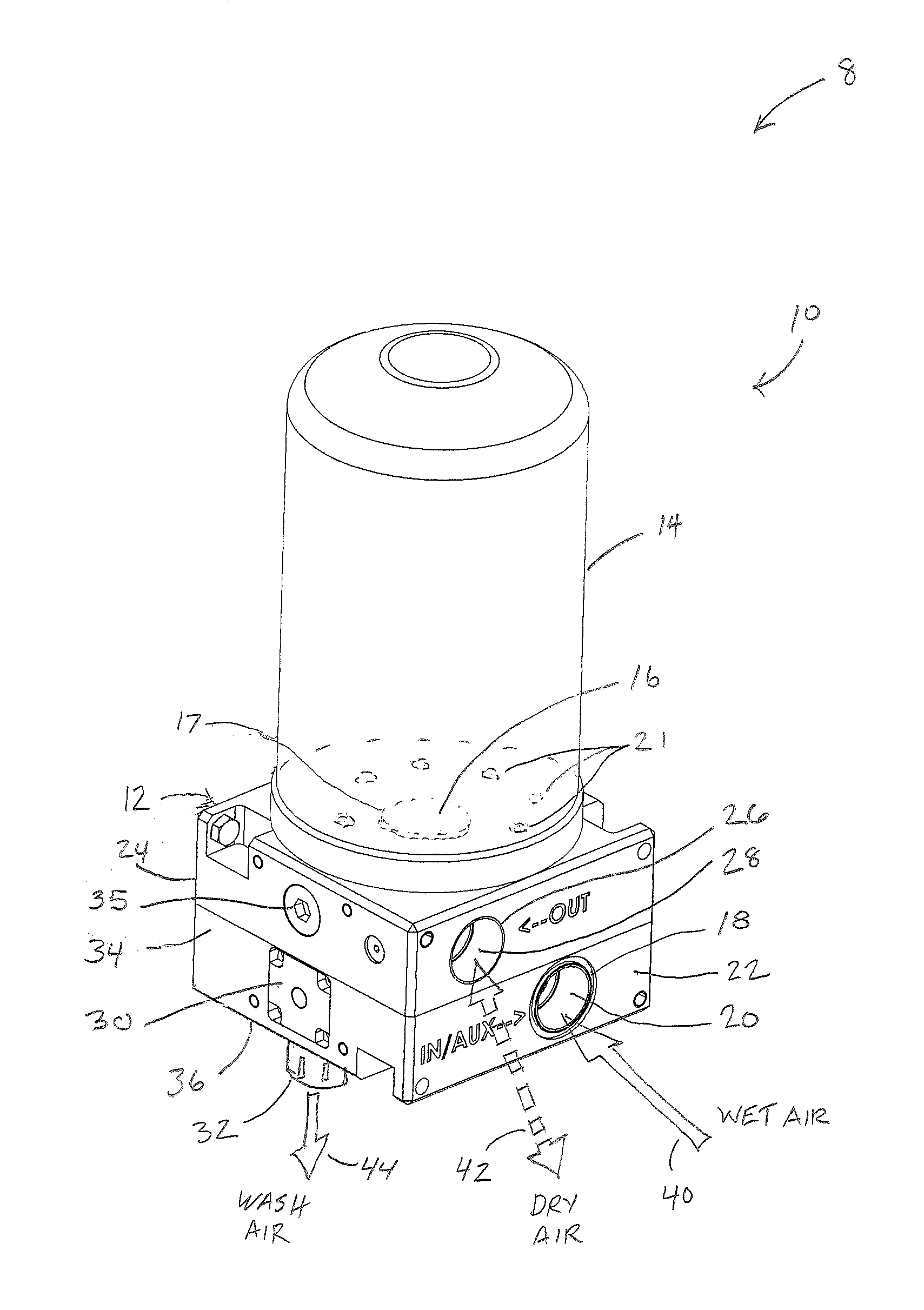

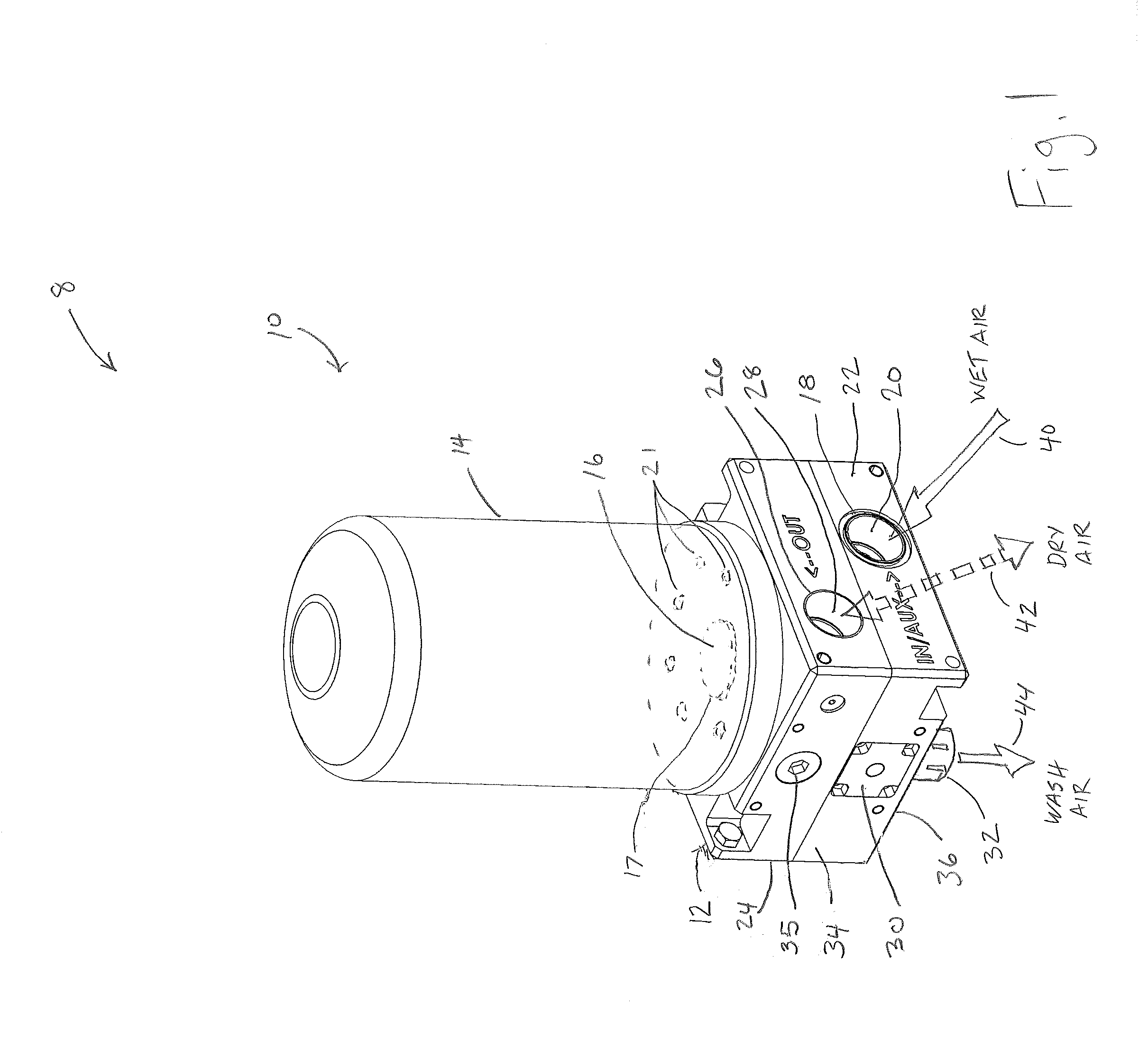

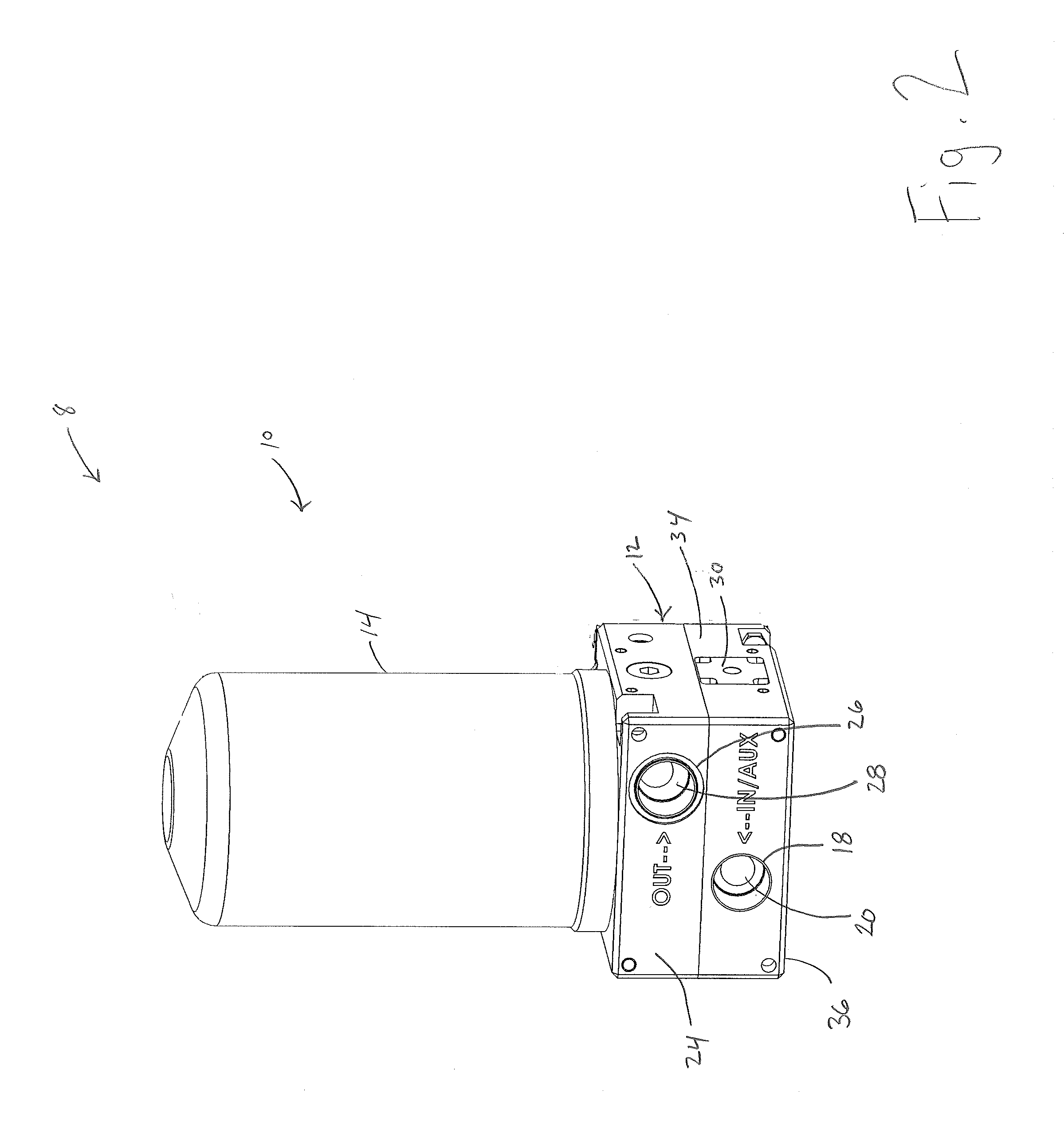

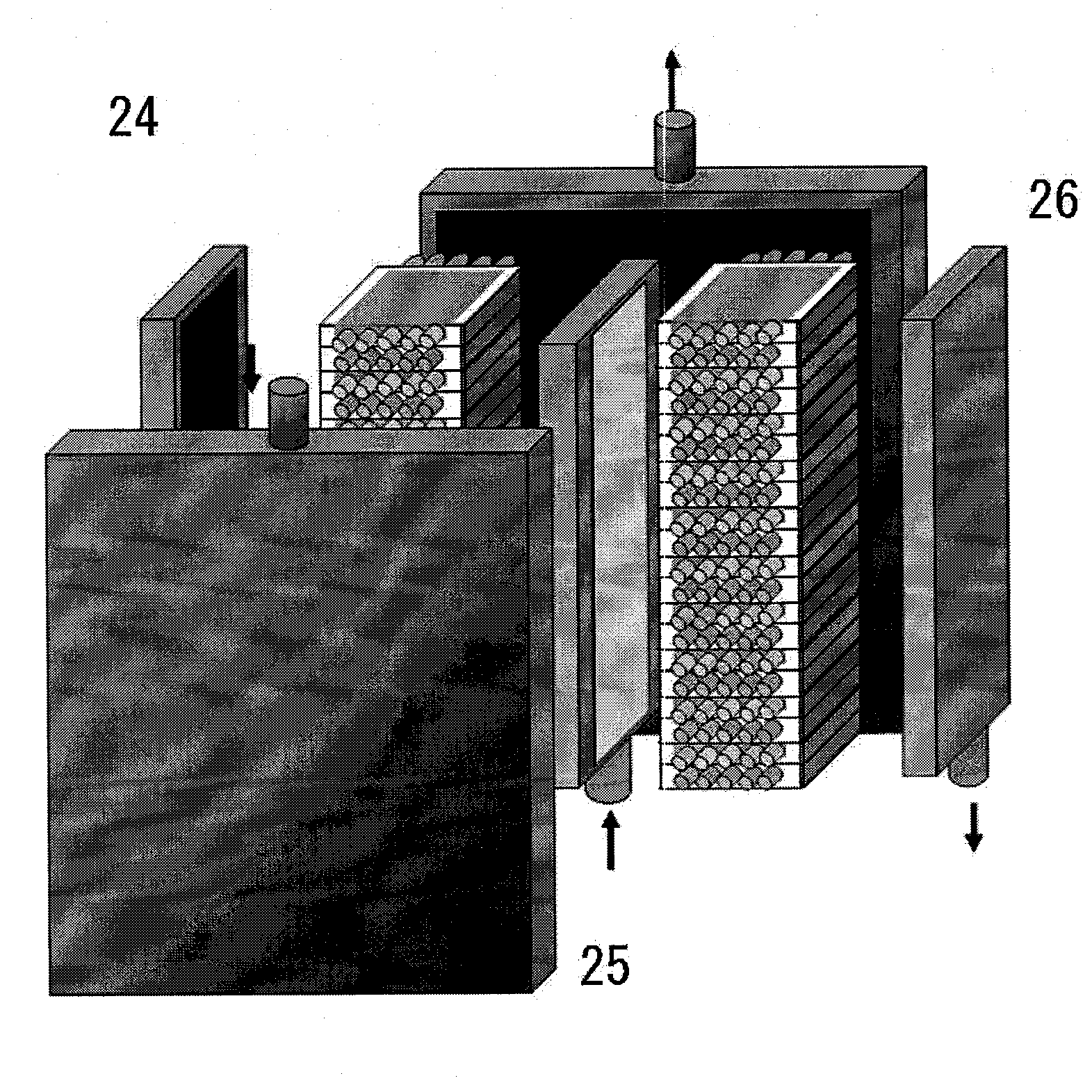

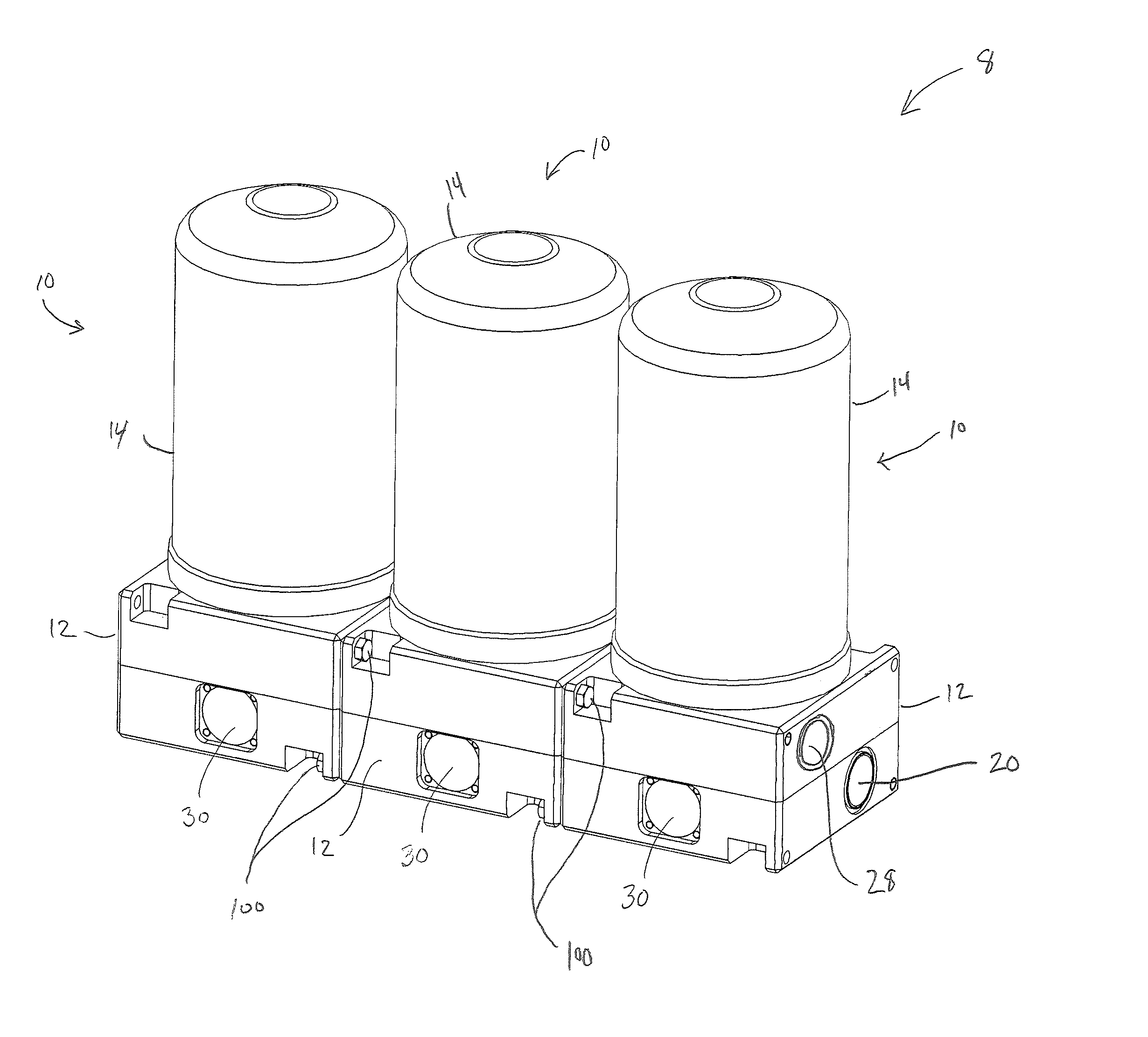

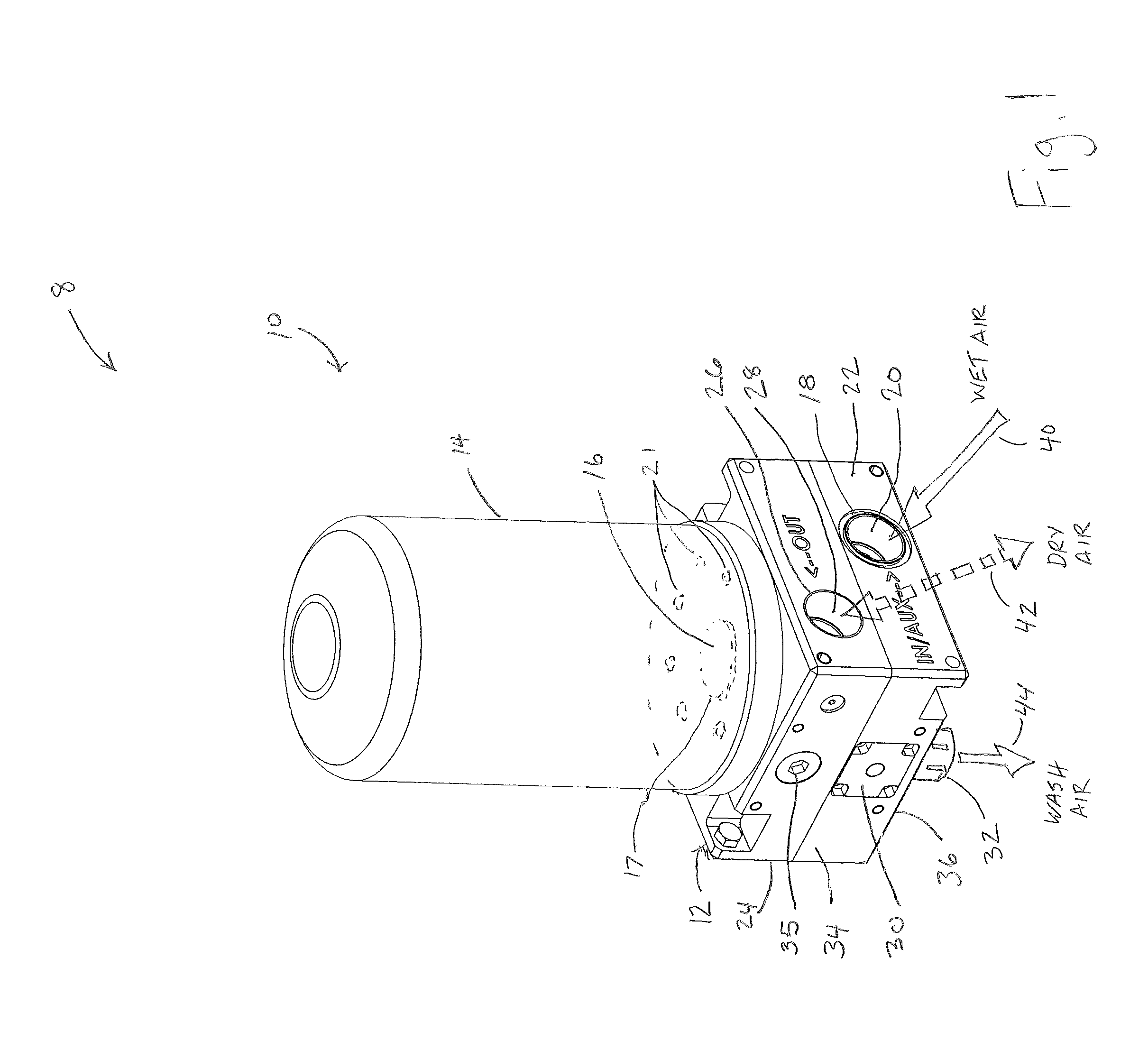

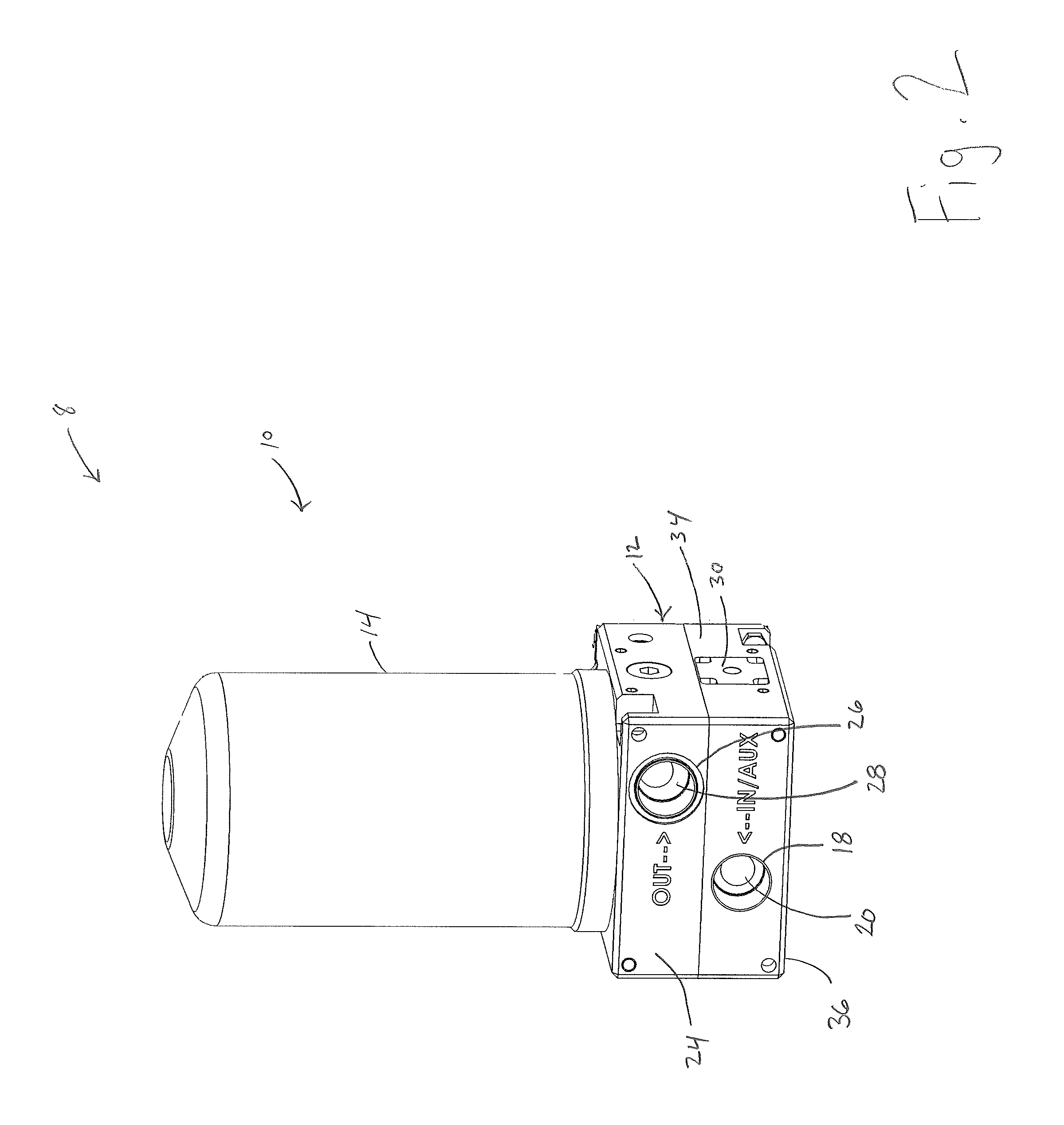

Regenerative air dryer

ActiveUS20140013956A1Simplified air pathsReduces external pipingGas treatmentIsotope separationDesiccantAir dryer

A regenerative air drying system including at least one dryer module including a housing having a inlet air passage, an outlet air passage, and a wash air passage. The air dryer system further includes a desiccant canister mounted to the housing and in communication with the inlet, outlet, and exhaust air passages, and a single controllable valve selectively moveable between a first position and a second position, wherein the single controllable valve, when in the first position, forms a supply air flow path from the inlet air passage, through the desiccant canister in a first direction, and to the outlet air passage, and when in the second position, forms a wash air path from the outlet air passage, through the desiccant canister in a direction opposite the first direction, and to the exhaust air passage.

Owner:SUBURBAN MFG

Electrochemical reactor units and modules and systems composed of them

ActiveUS20090291347A1Efficient collectionEasy to controlFinal product manufactureSolid electrolyte fuel cellsElectrochemical responseProcess engineering

The present invention is an electrochemical reactor unit in which a plurality of electrochemical reactor cells constituted by a tube are housed in a porous material body having a heat releasing function and a current collecting function, these are electrically connected in series, and a fuel manifold is mounted to the connected electrochemical reactor cells; an electrochemical reactor module that comprises a plurality of the units which are arranged in fuel supply holes, and a structure supplying air directly to the entire electrochemical reactor module; and an electrochemical reaction system in which such an electrochemical reactor module is utilized.

Owner:NAT INST OF ADVANCED IND SCI & TECH

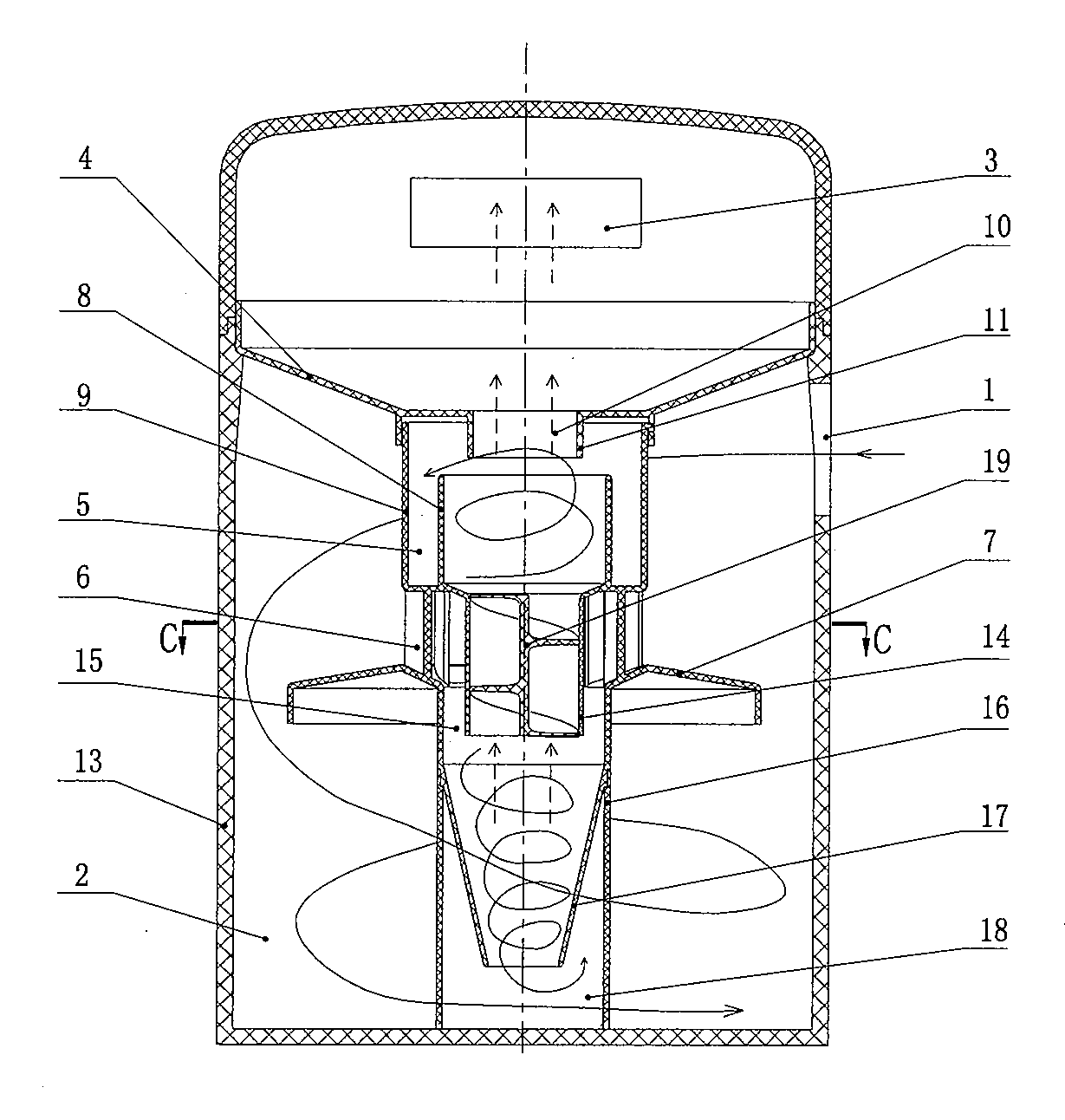

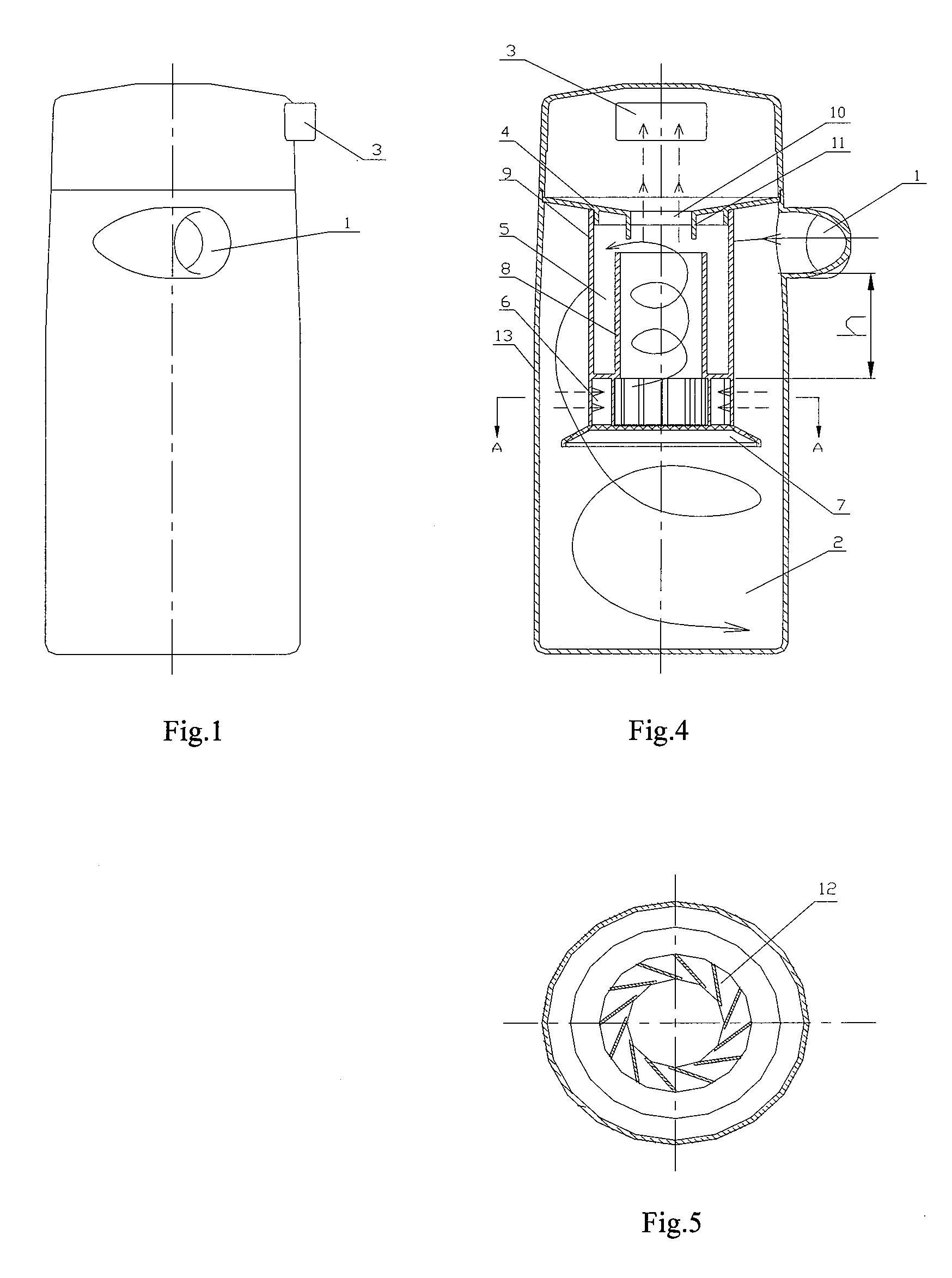

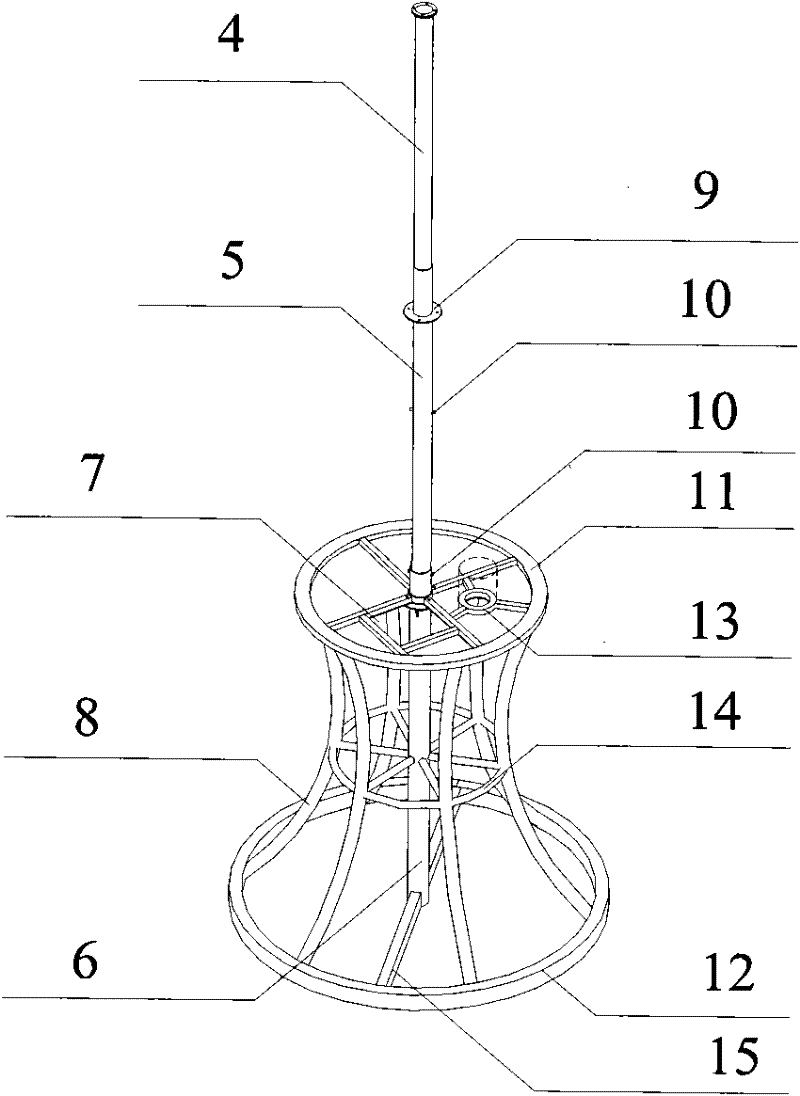

Dust Collector Cup of Fall Centrifugal Separation Type

InactiveUS20080104795A1Lower the volumeMore compact structureCleaning filter meansCombination devicesEngineeringDust collector

A dust collector cup working in the principle of fall centrifugal separation, consists of cup body (13), outlet (3) on the cup body (13), inlet (1) tangential to the circumferential wall of the cup body (13), and a separator settled in the cup body (13). The separator is composed of outlet tube (9), inlet (6) on the wall of the outlet tube (9), and the isolating shield (7) under the inlet (6) of the outlet tube (9), with the outlet tube (9) linked to the outlet (3) of the cup body (13). The fall between the horizontal positions of the lower end of inlet of the cup body (13) and the upper end of the inlet (6) of the outlet tube (9) is 0-140 mm.

Owner:WANG YUEDAN

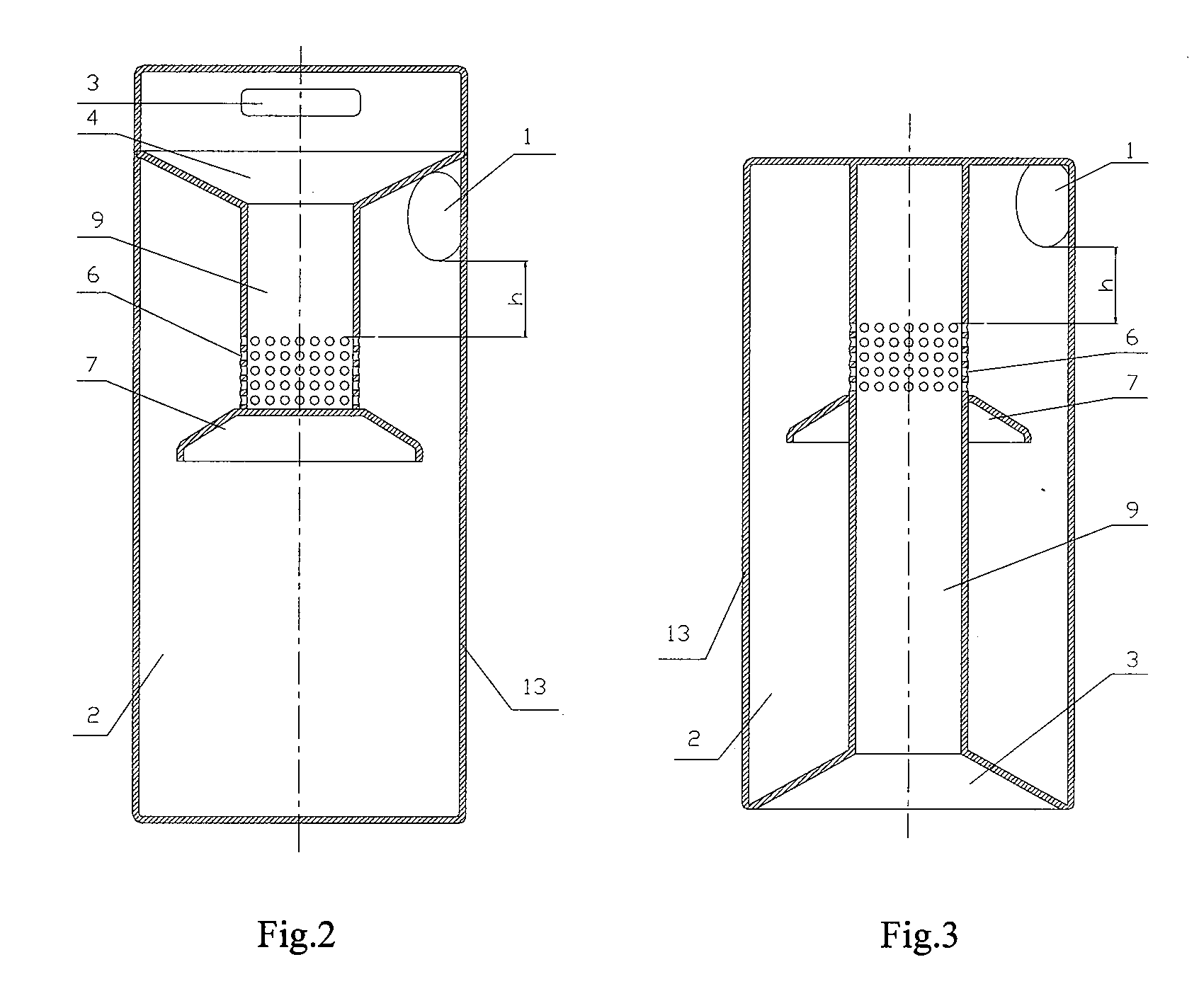

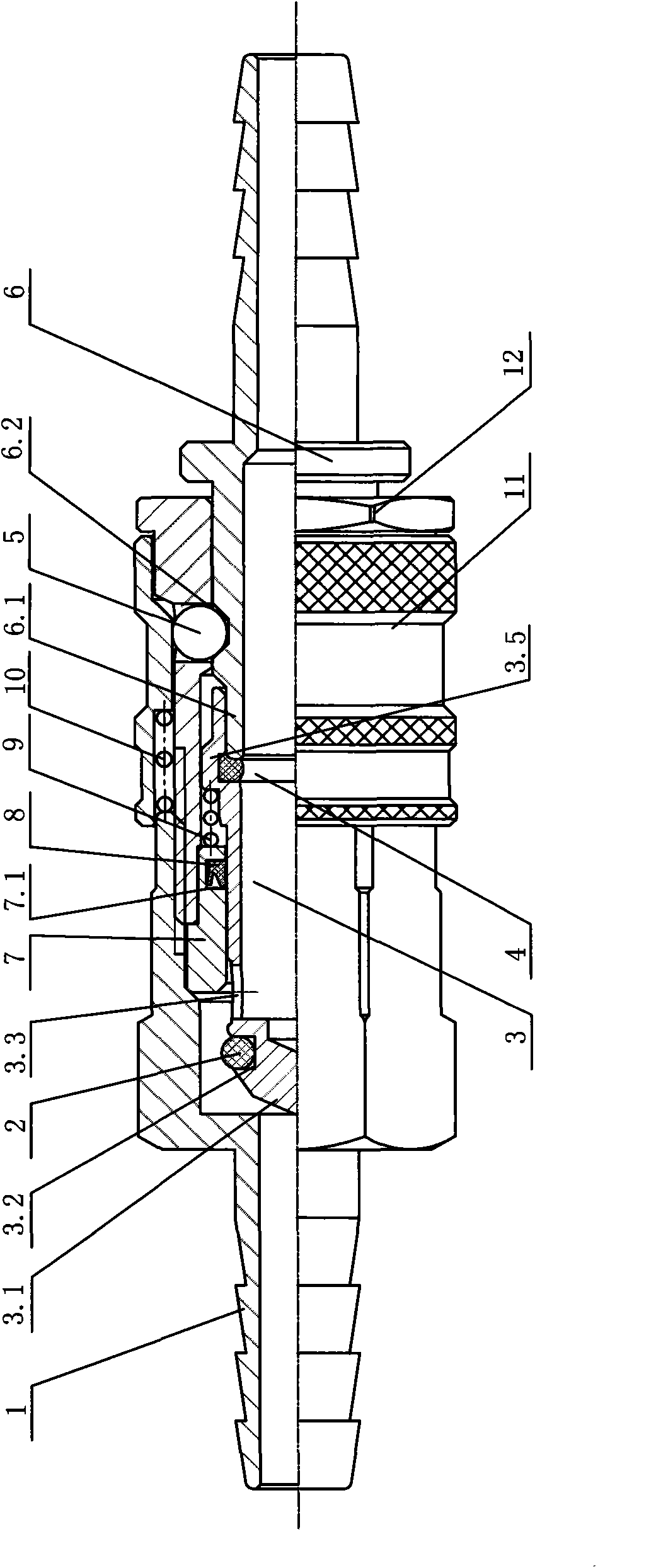

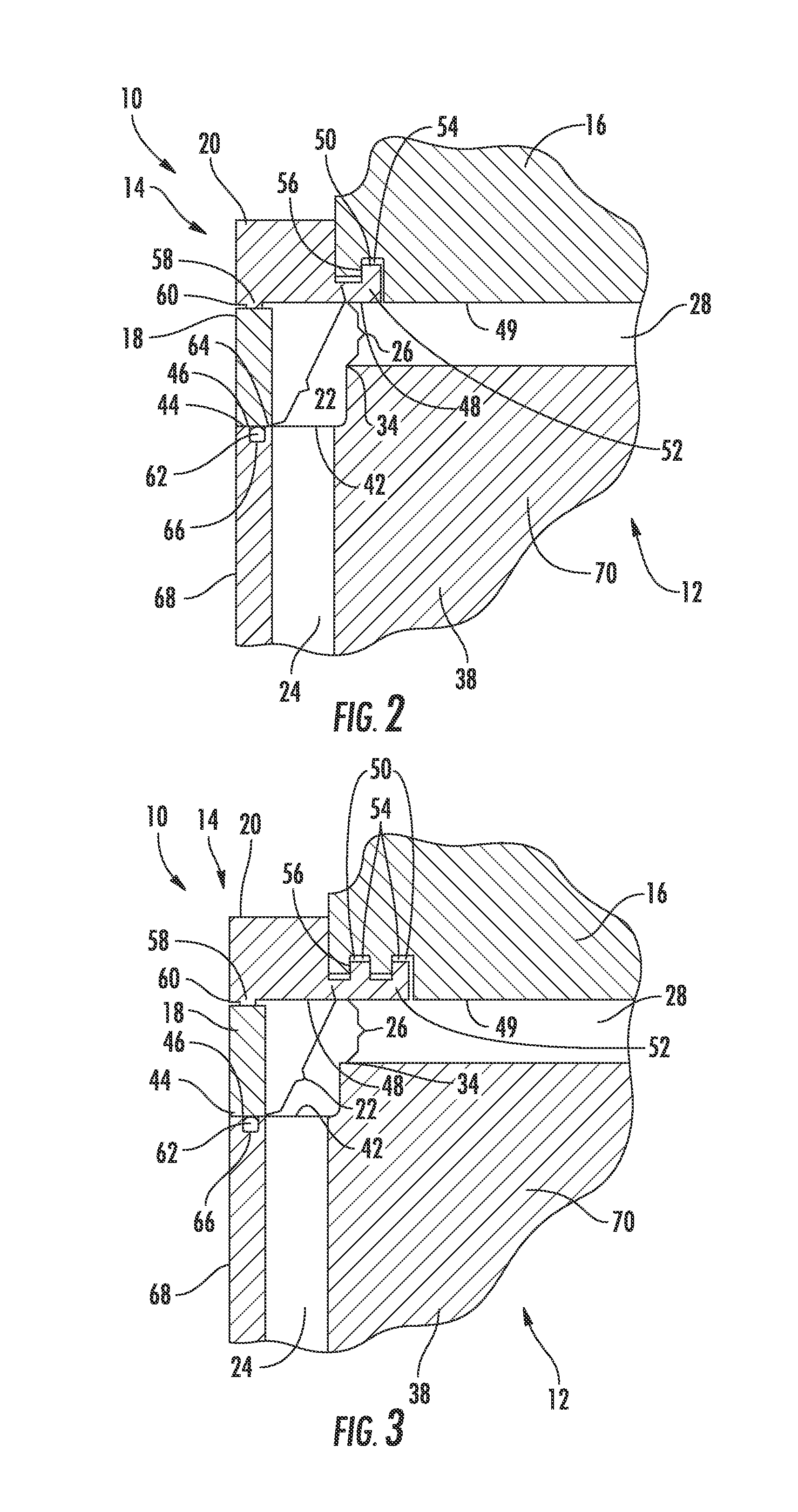

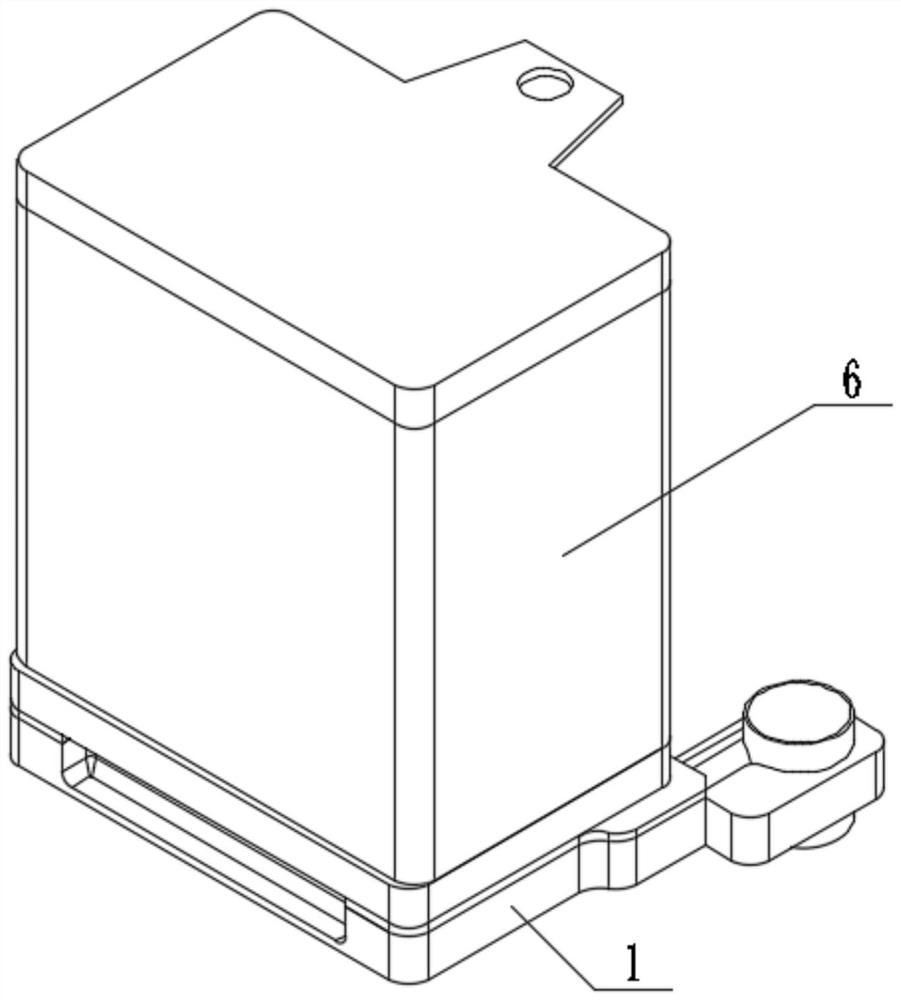

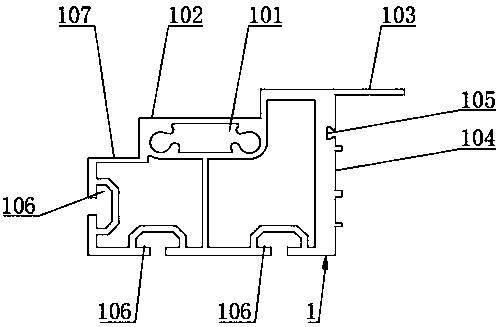

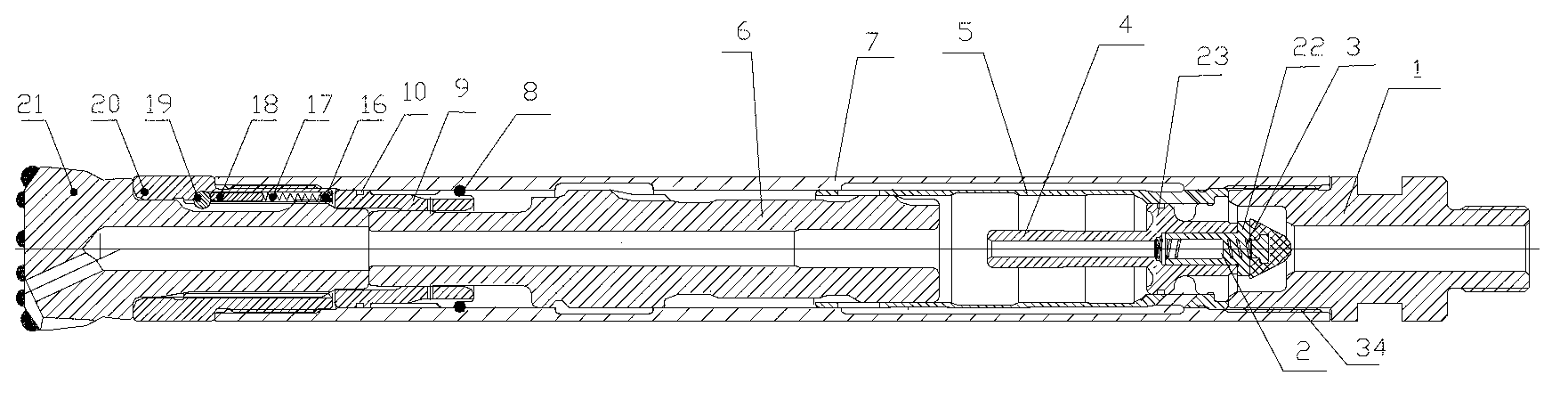

Pneumatic quick connector

InactiveCN101907210APrevent air leakageReduce air pressure lossCouplingsPneumatic pressureEngineering

The invention relates to a pneumatic quick connector which comprises a female connector connected with an air inlet pipe and a male connector connected with an air outlet pipe, wherein an air outlet end of the female connector is fixedly provided with a locking sleeve; the inner holes of the female connector and the locking sleeve are internally provided with a check valve core with an exhaust channel; an air inlet end of the male connector is communicated with the exhaust channel of the check valve core; a guide sleeve is clamped between the locking sleeve and the inner wall of the female connector; the check valve core is movably penetrated in the inner hole of the guide sleeve; a valve core spring is supported between the guide sleeve and the check valve core; the head part of the check valve core is sealed, forms a taper shape and is opposite to the air inlet direction of the female connector; the excircle of the head part of the check valve core is provided with a sealing ring slot, and an O-shaped sealing ring is embedded in the sealing ring slot; and the side wall at the front end of the check valve core is provided with an air inlet communicated with the exhaust channel of the check valve core. The invention can realize the quick on-off of an air conveyer pipeline, has a check function for preventing air leakage during turning off and also has the advantages of less loss and convenient and quick on-off operations.

Owner:楼松乔

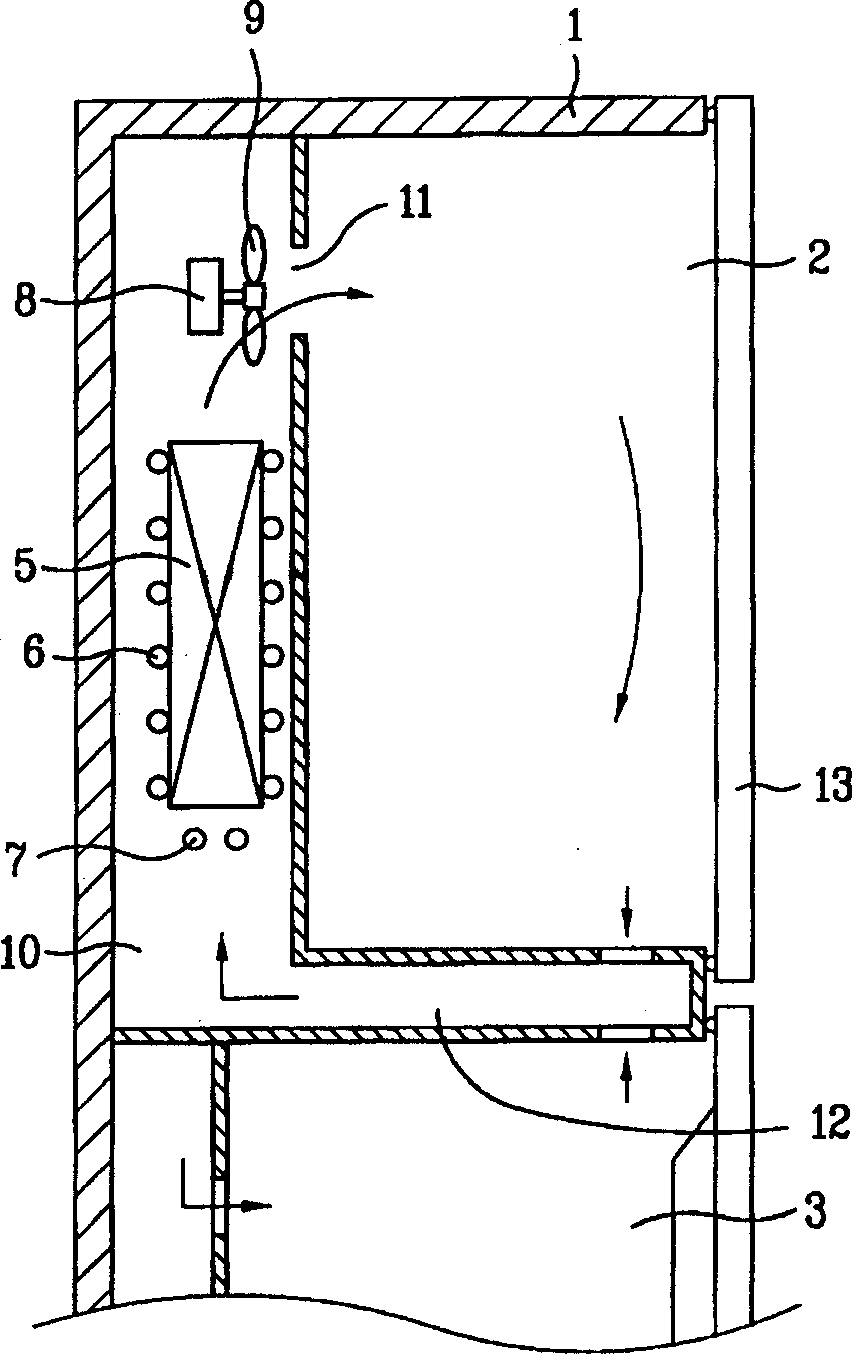

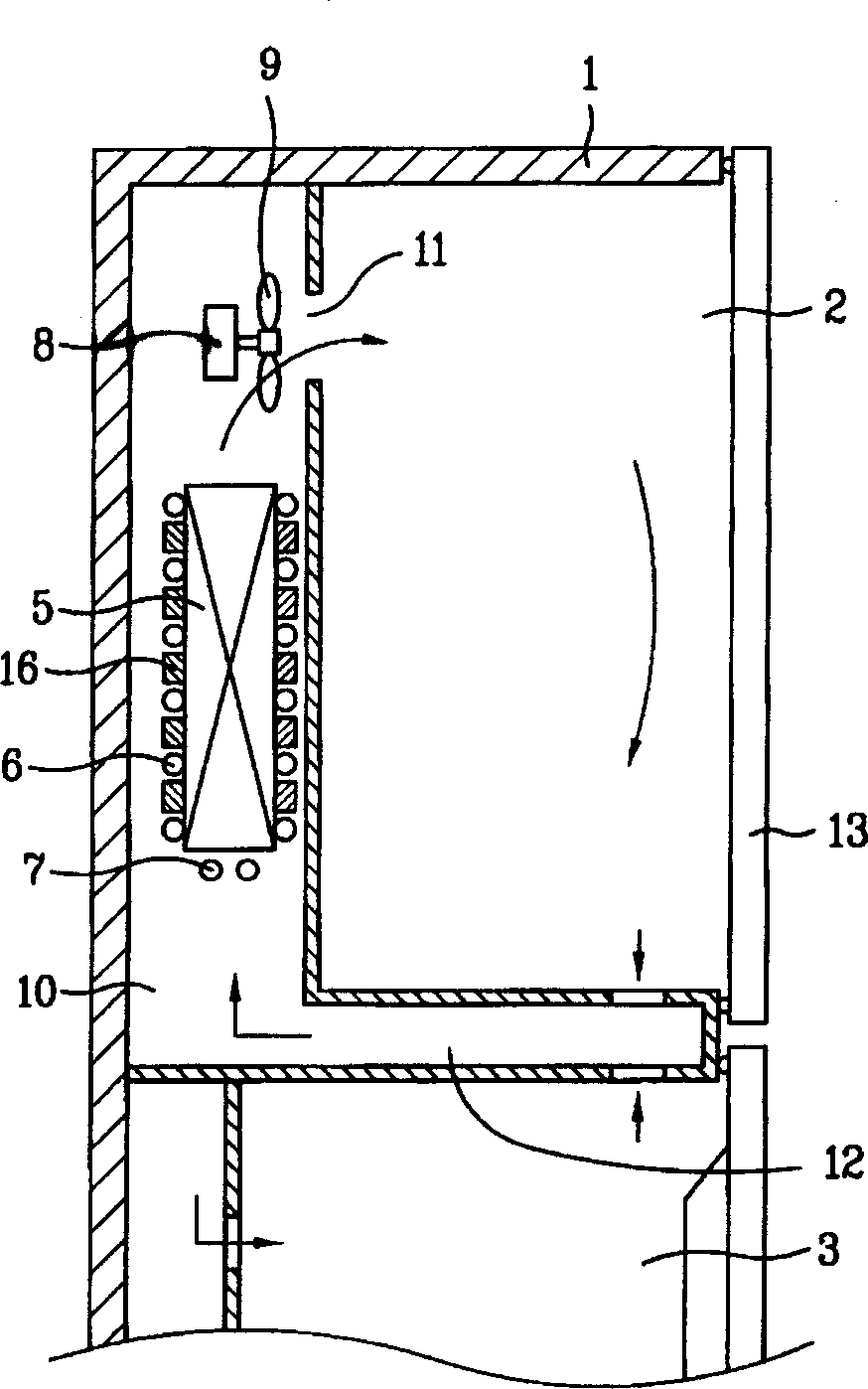

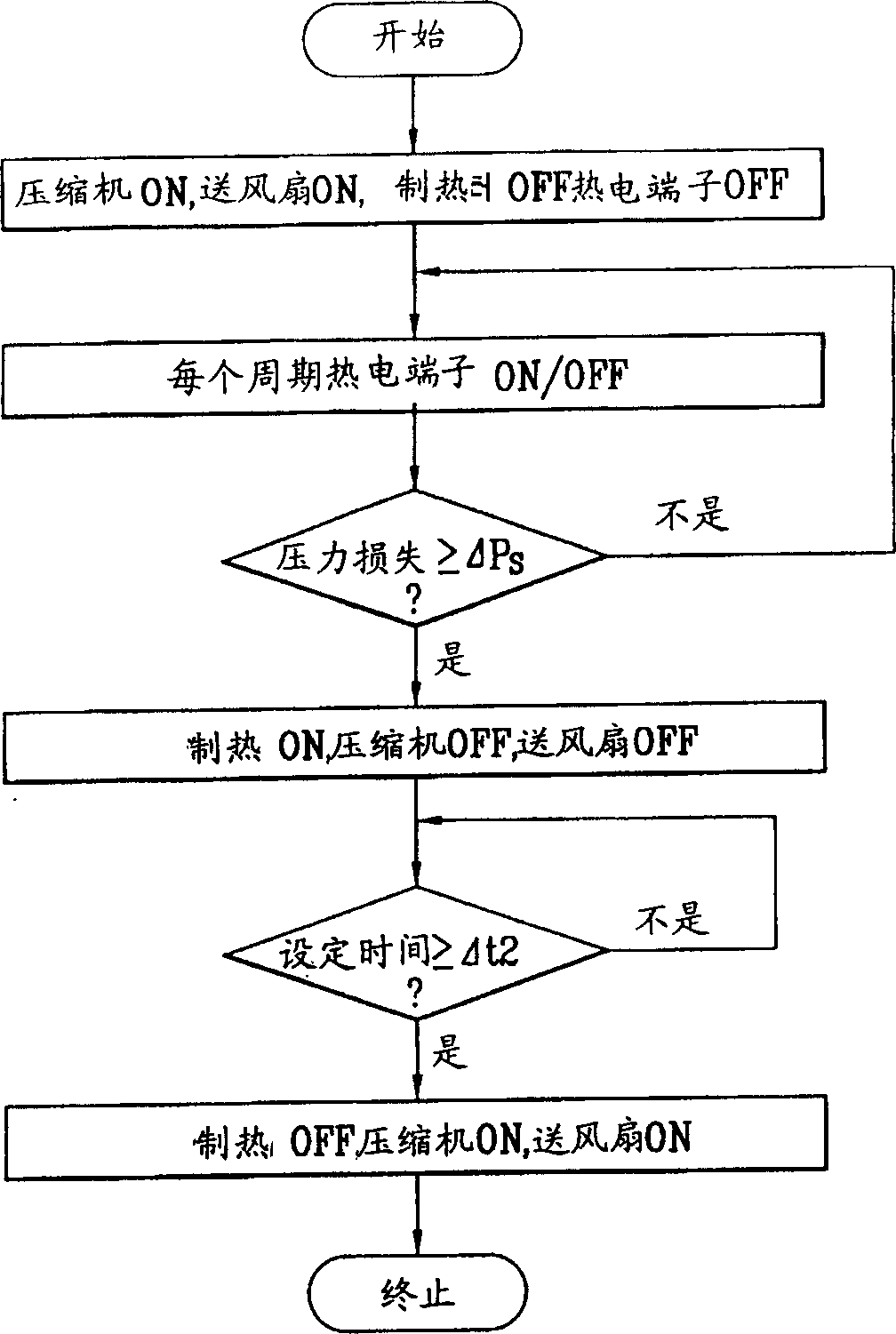

Defrosting apparatus for refrigerator and defrosting method thereof

InactiveCN1548882ASlow growth rateHigh densityLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The present invention is refrigerator heating defrosting device and method. The defrosting device includes a defrosting heater around the evaporator, an auxiliary heater and a heating body set on the evaporator for being turned on periodically. The defrosting method includes setting the defrosting heater, the auxiliary heater and the heating body; and making the heating body operate periodically and stopping the compressor and the blower for certain time after the pressure loss in the evaporator reaches set value. Compared with available technology, the present invention has longer defrosting period, short defrosting time, raised defrosting efficiency and heat exchange efficiency, and reduced power consumption.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

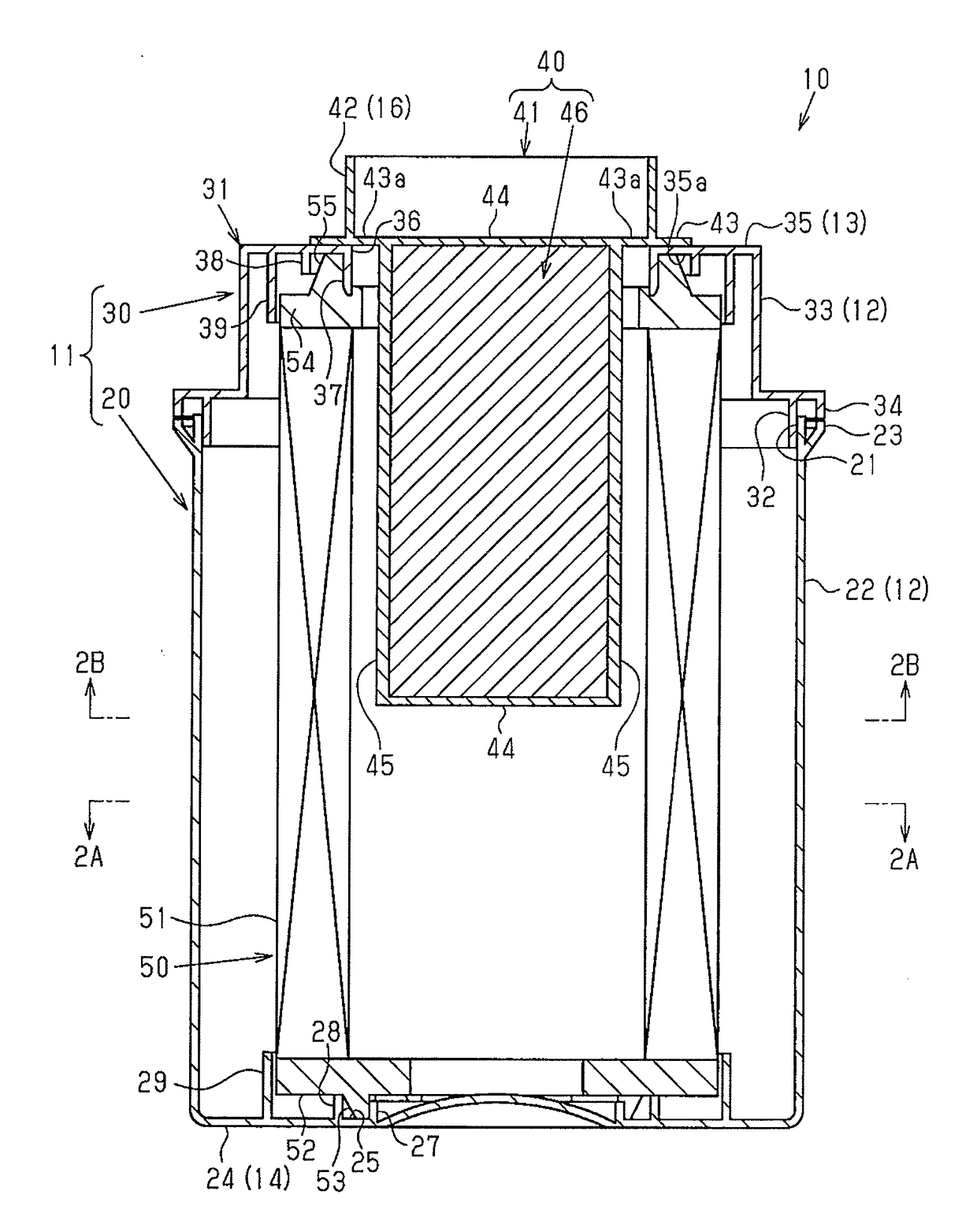

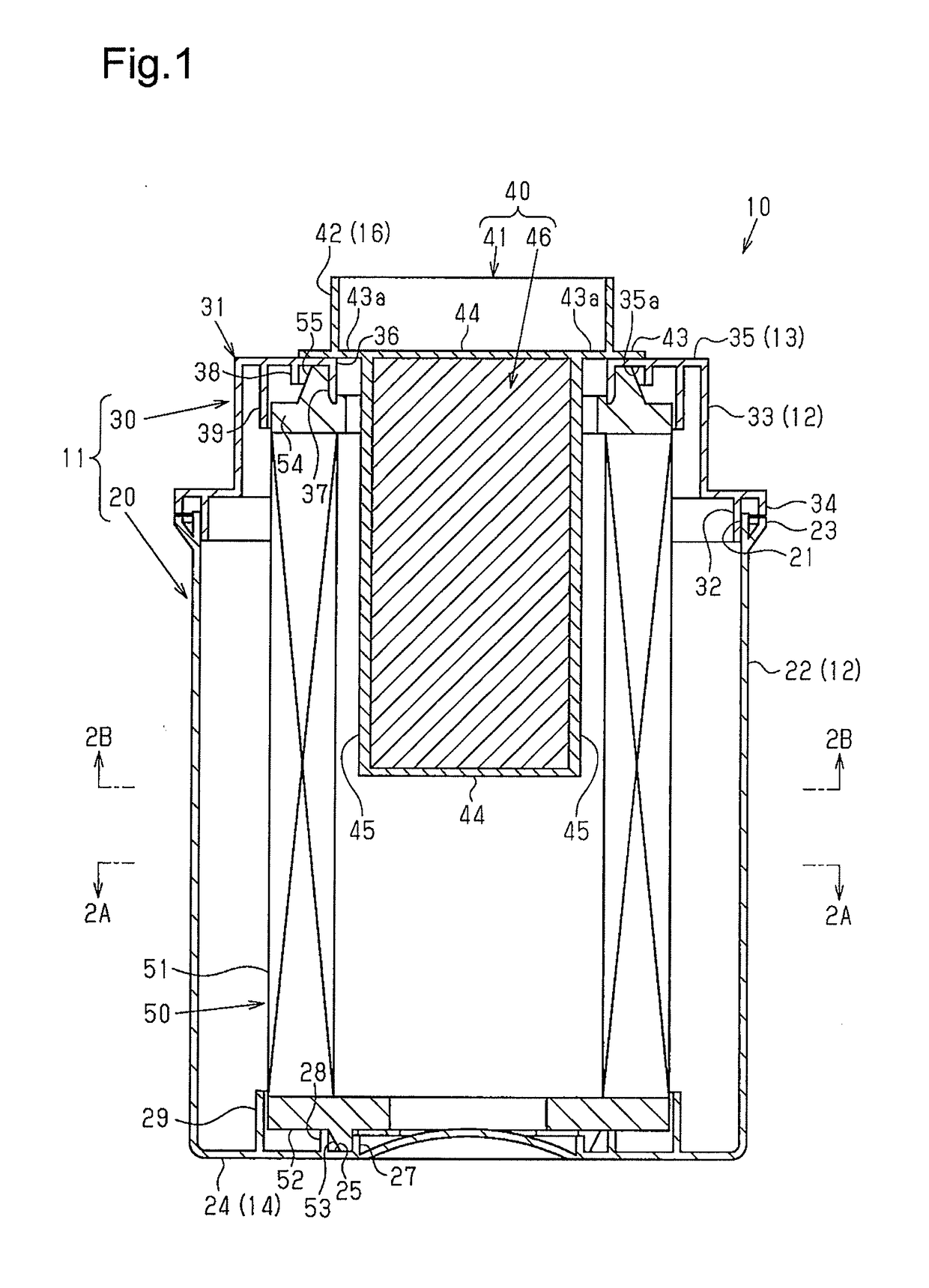

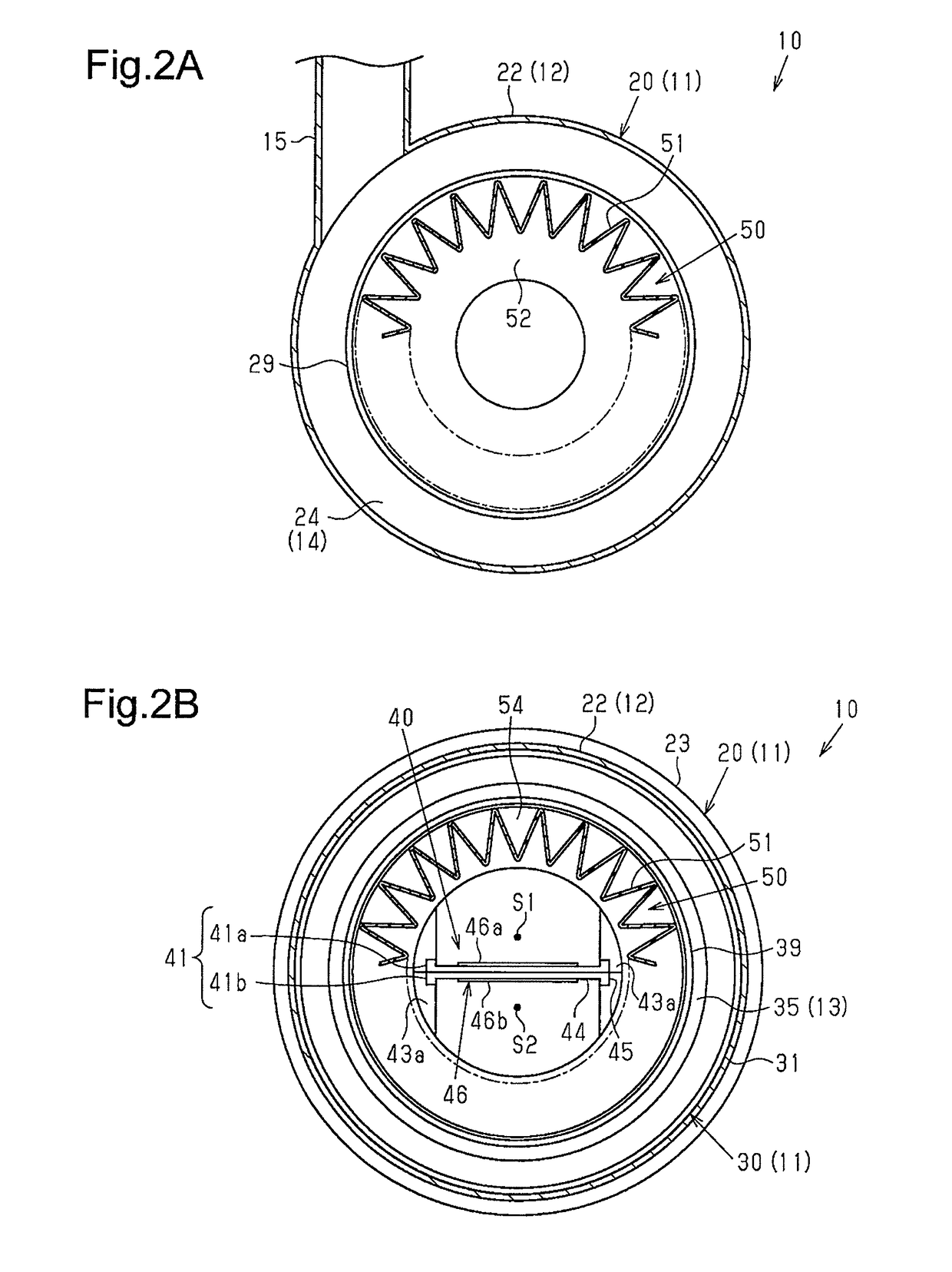

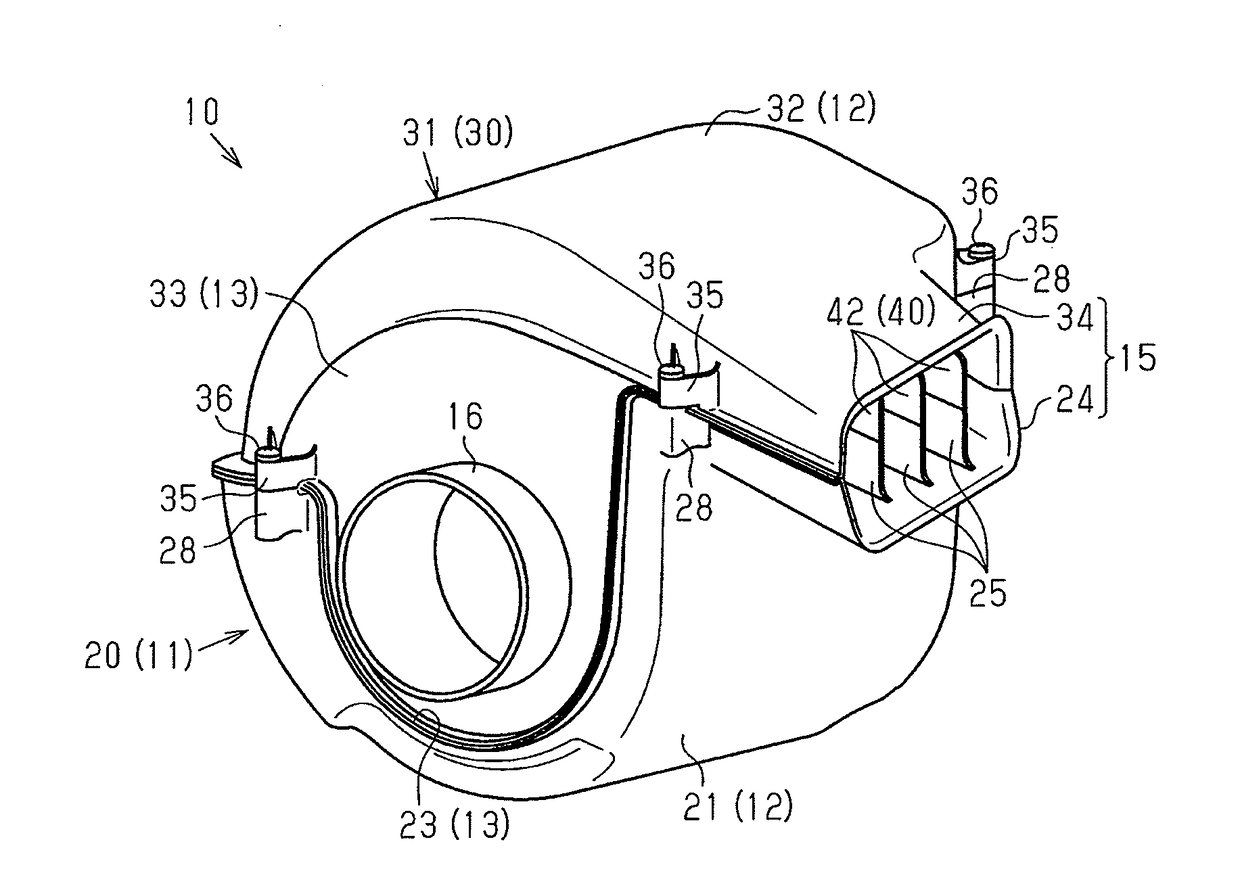

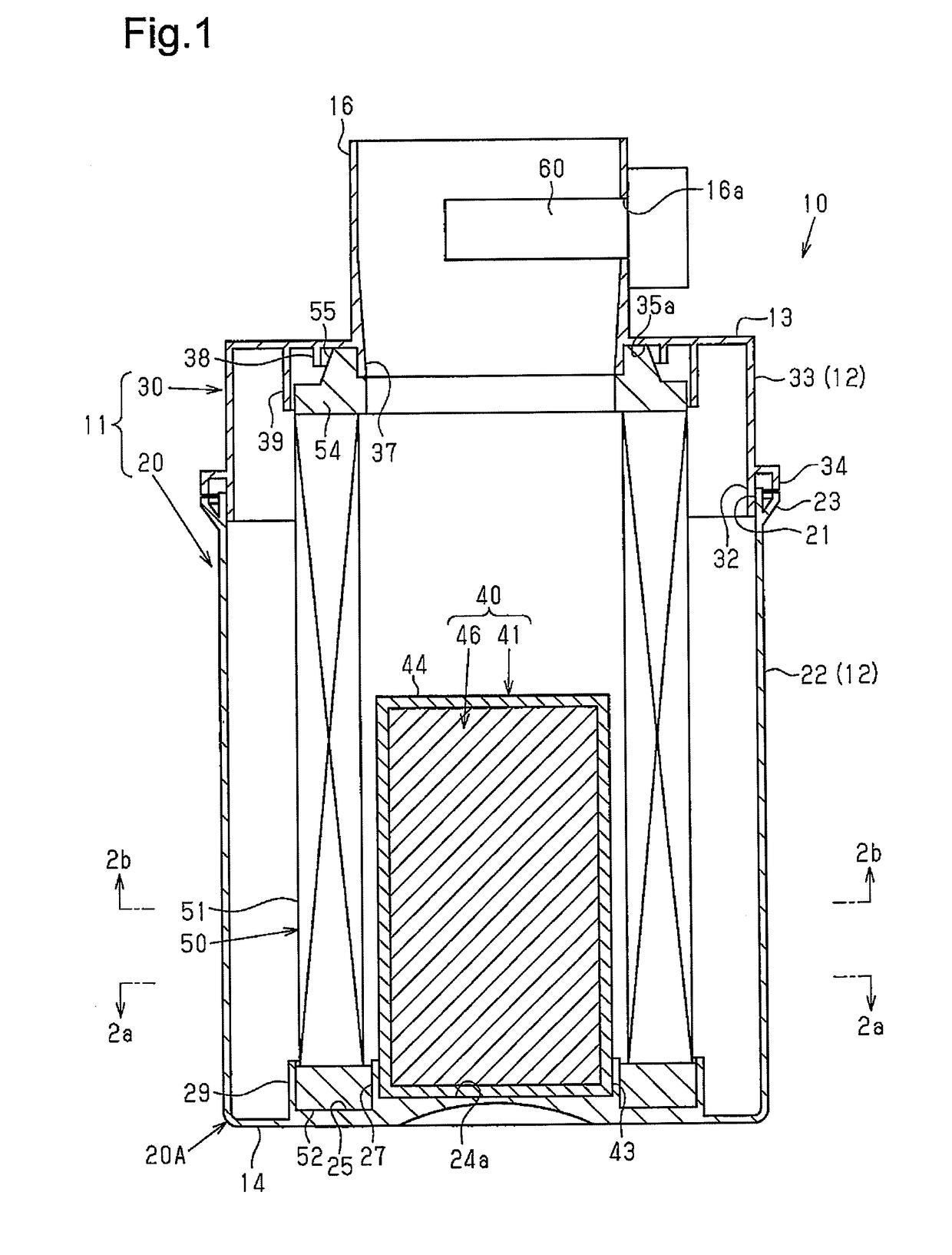

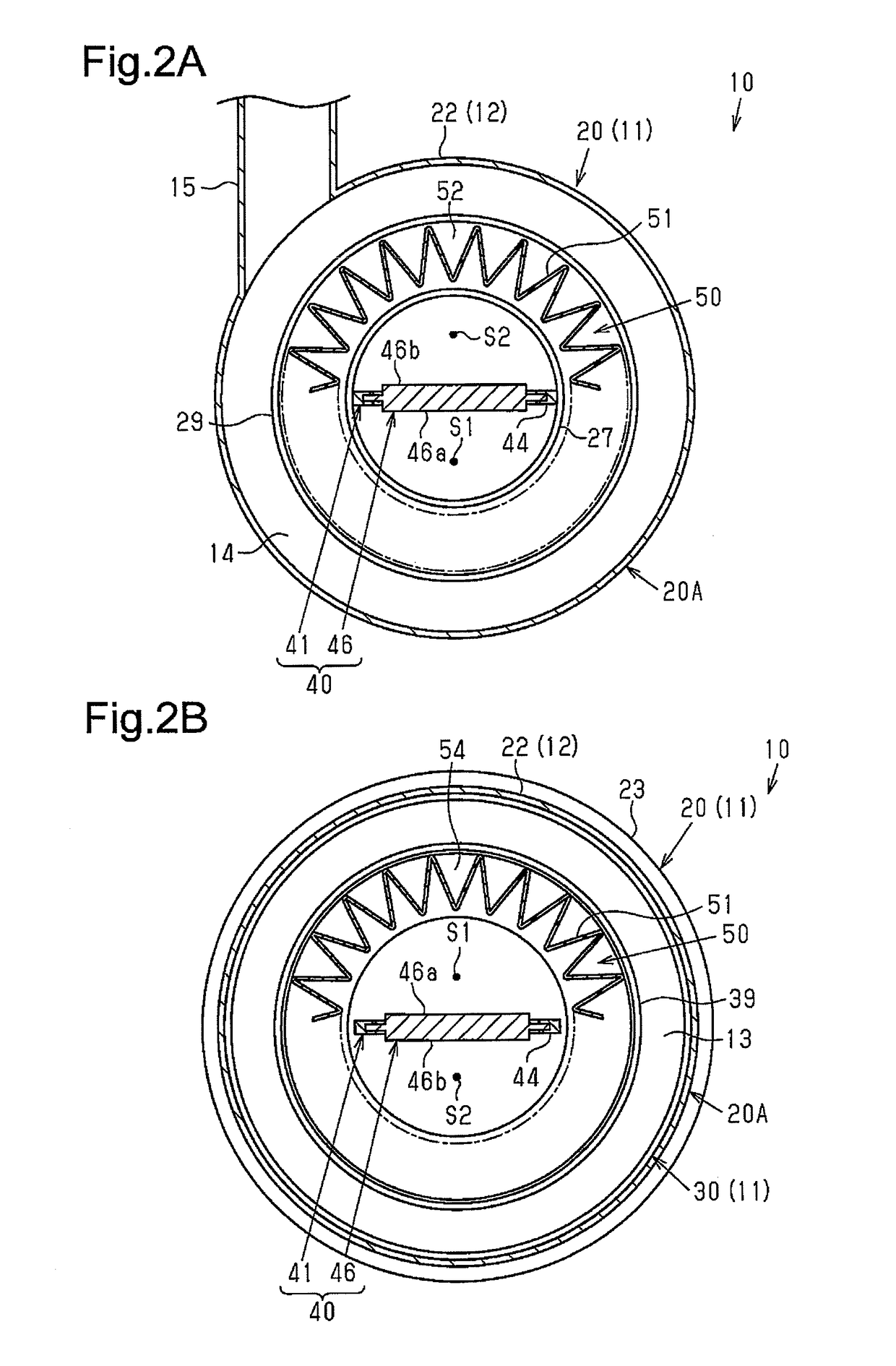

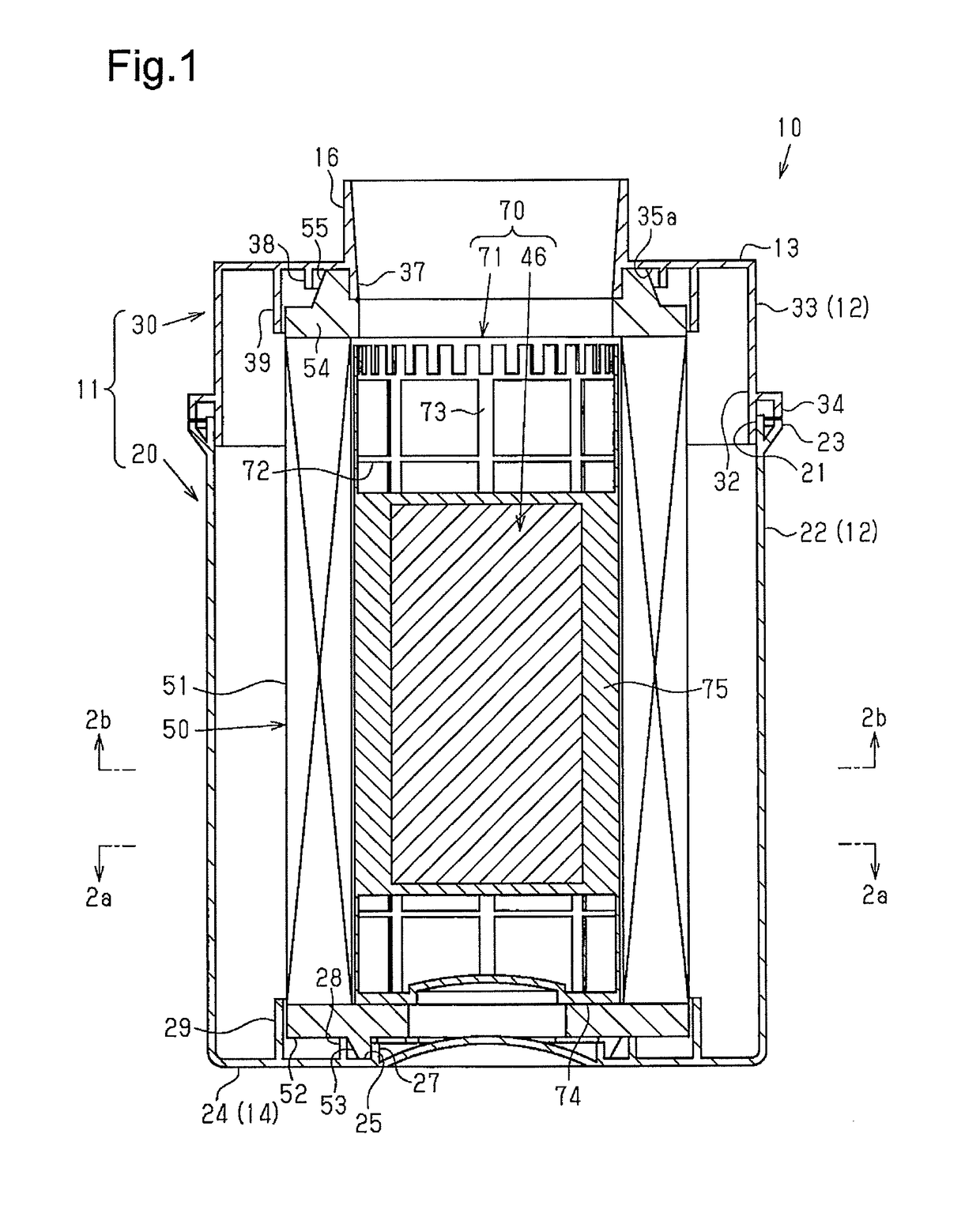

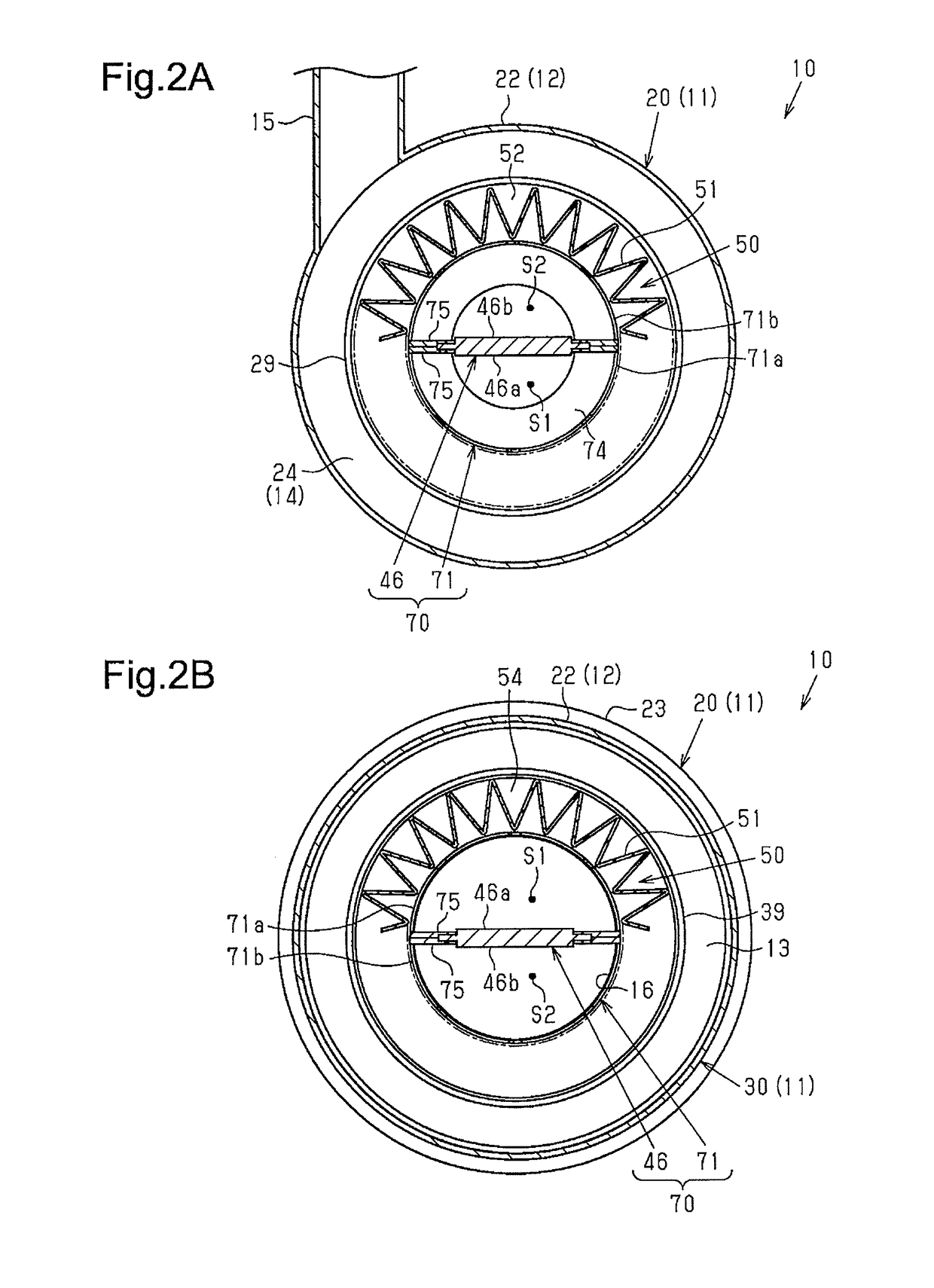

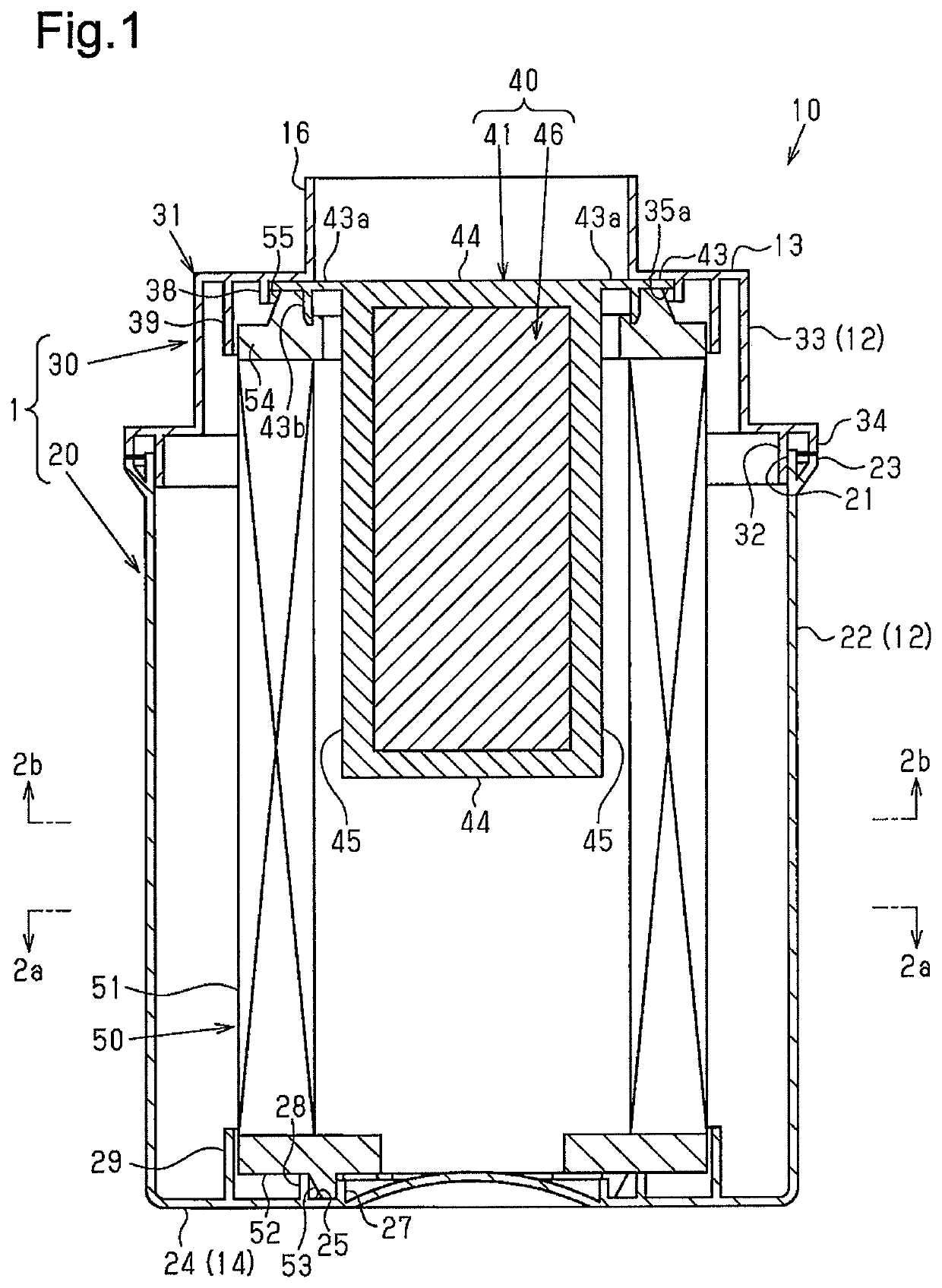

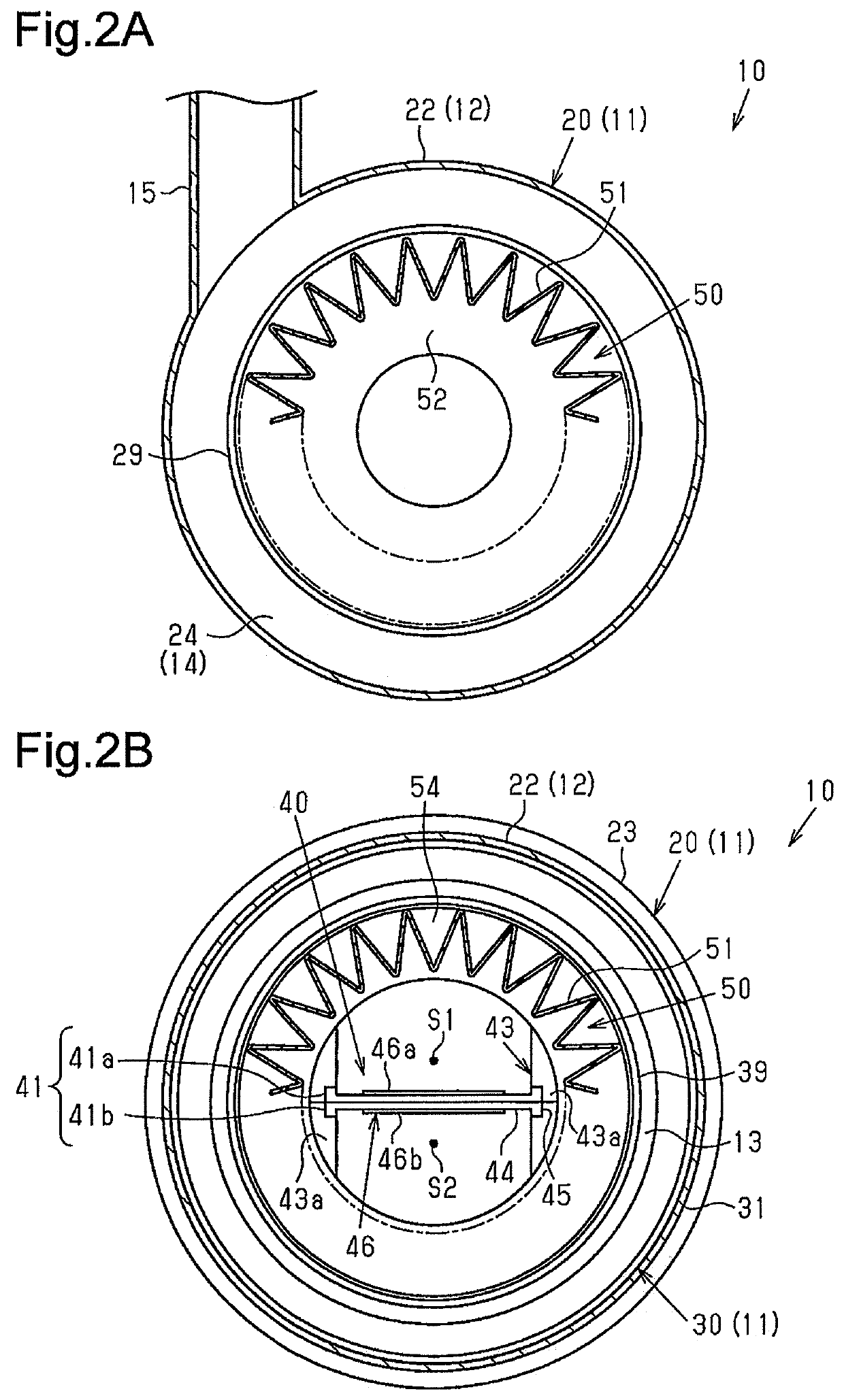

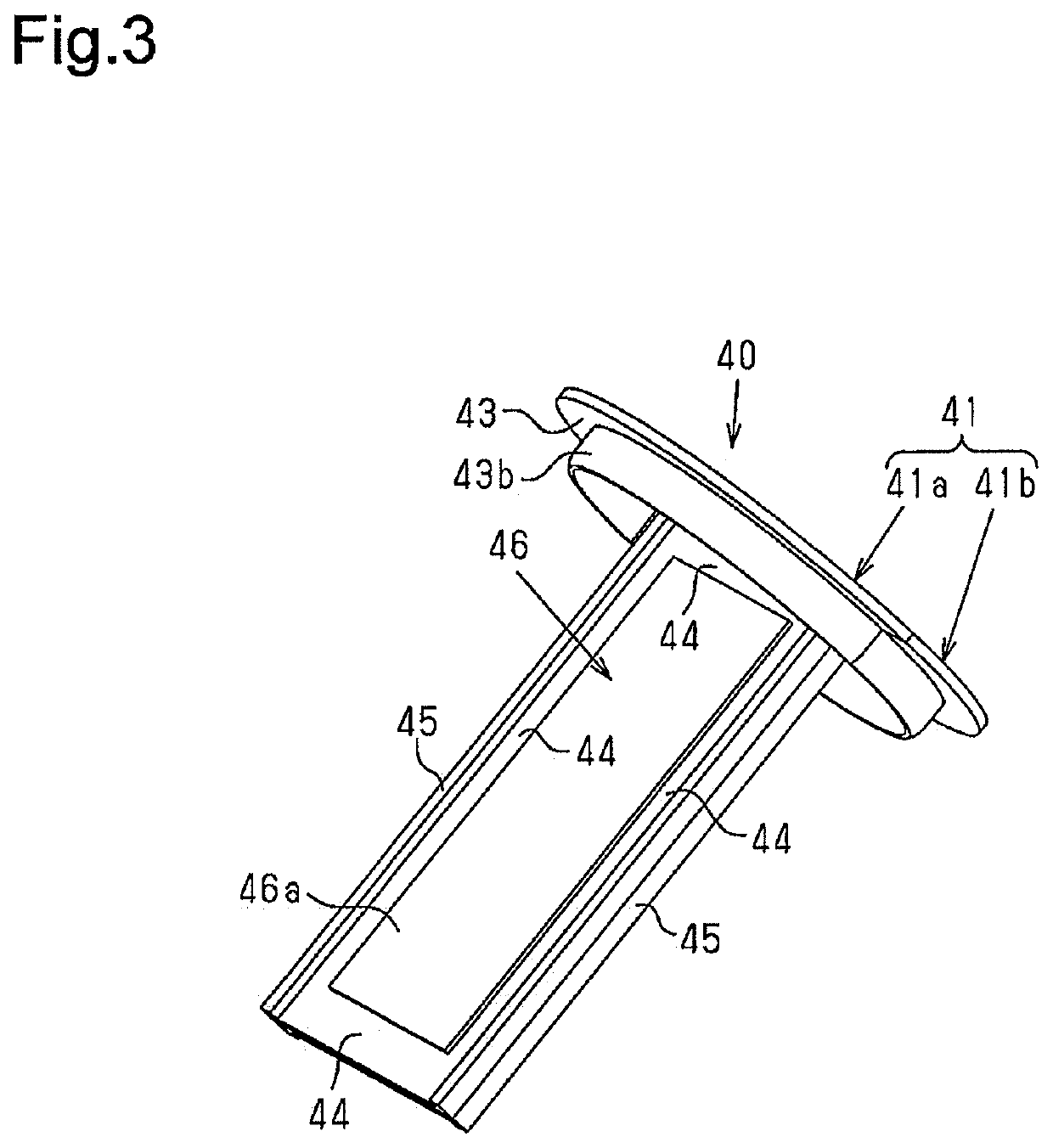

Tubular air cleaner for internal combustion engine

ActiveUS20180149119A1Increase resistanceReduce air pressure lossGas treatmentNon-fuel substance addition to fuelInternal combustion engineInternal combustion engine cooling

A tubular air cleaner for an internal combustion engine includes a tubular housing, a tubular filter element, and a planar adsorbent filter. The tubular housing includes a circumferential wall including an inlet, a top wall including an outlet, and a bottom wall opposed to the top wall. The tubular filter element is accommodated in the housing. The planar adsorbent filter is located at an inner side of the filter element to adsorb evaporated fuel of the internal combustion engine. The adsorbent filter extends in an axial direction of the filter element. The filter element includes an inner surface spaced apart from each of opposite planes of the adsorbent filter by a gap that allows air to reach the outlet without passing through the adsorbent filter.

Owner:TOYOTA BOSHOKU KK

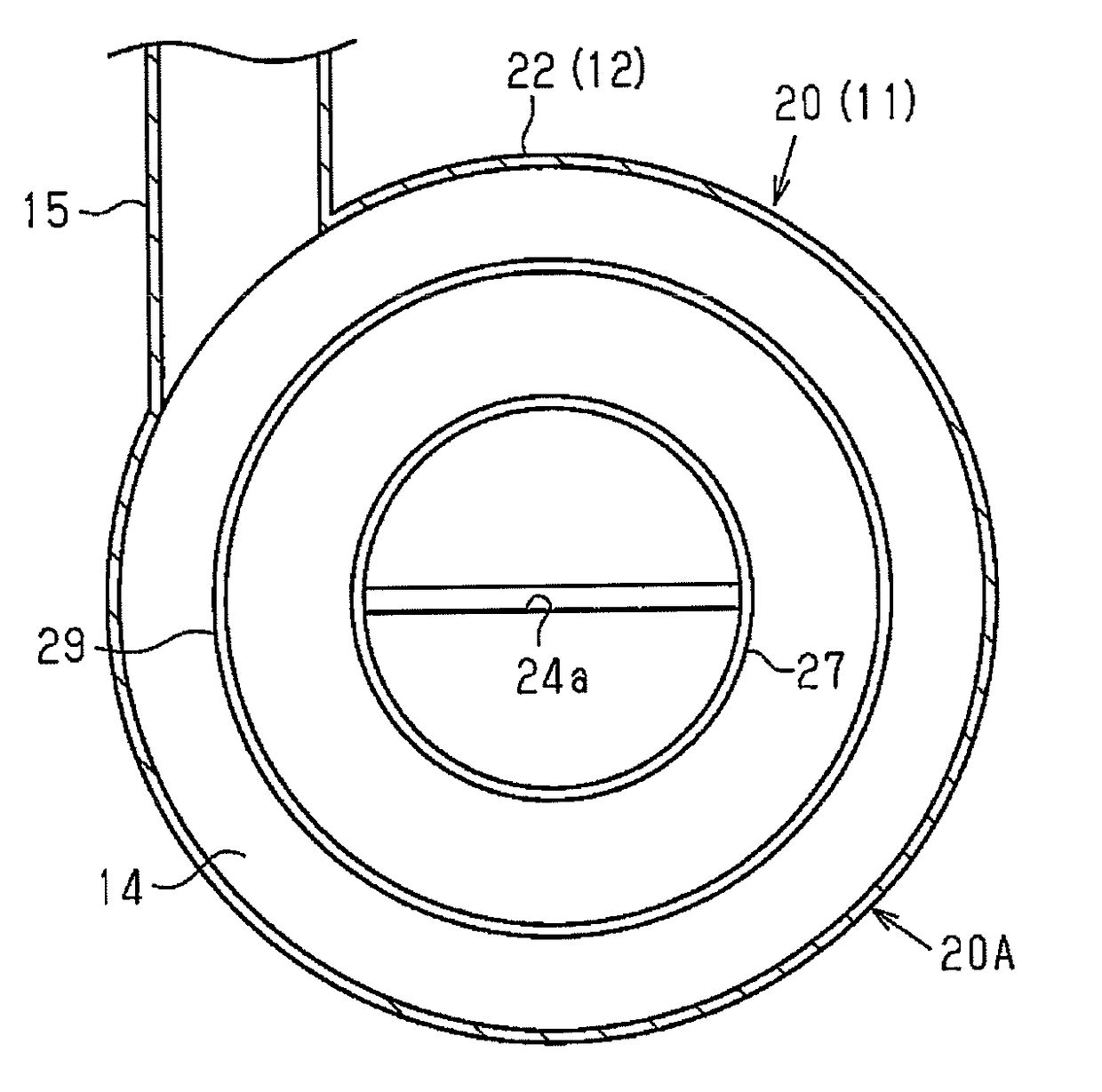

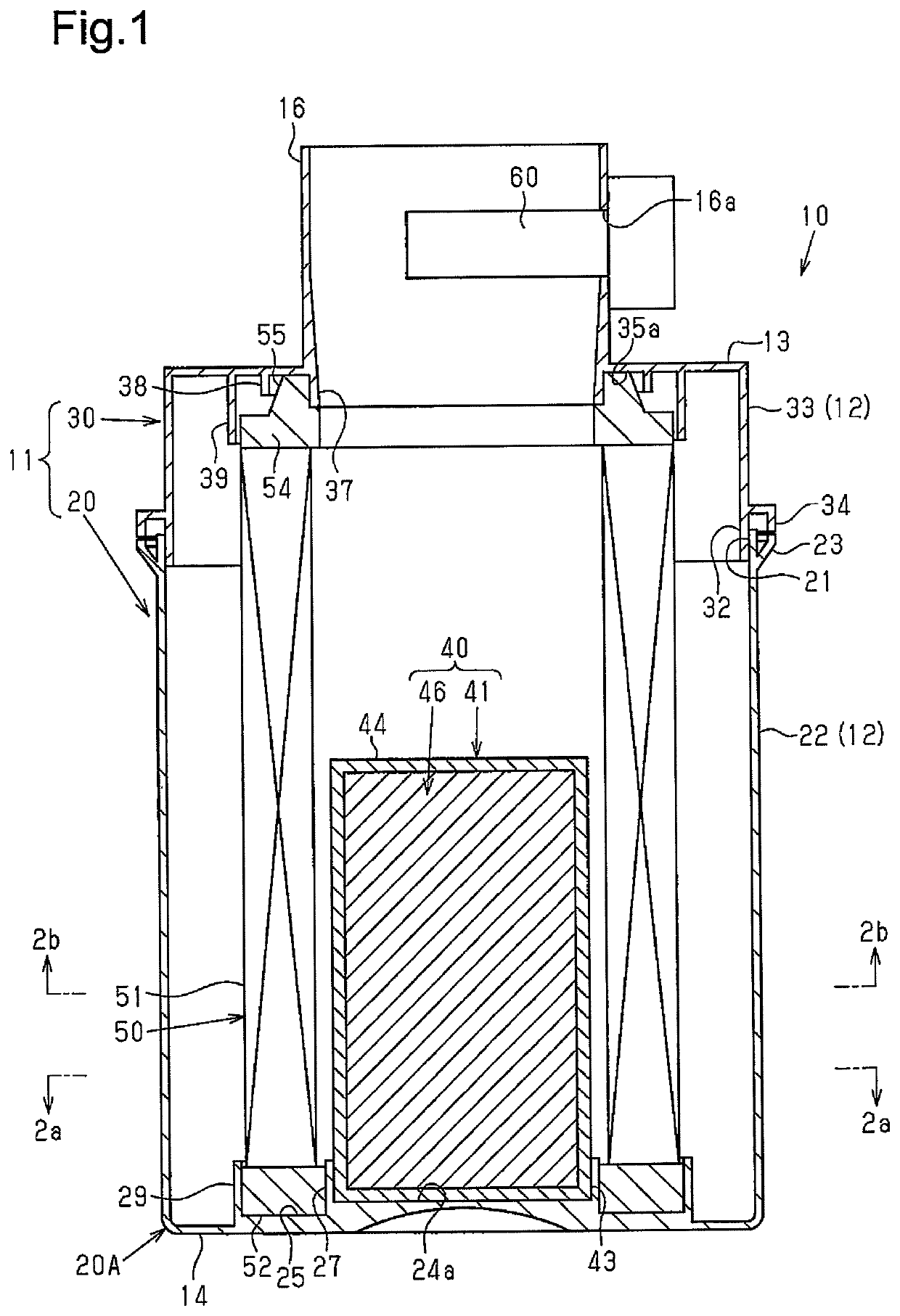

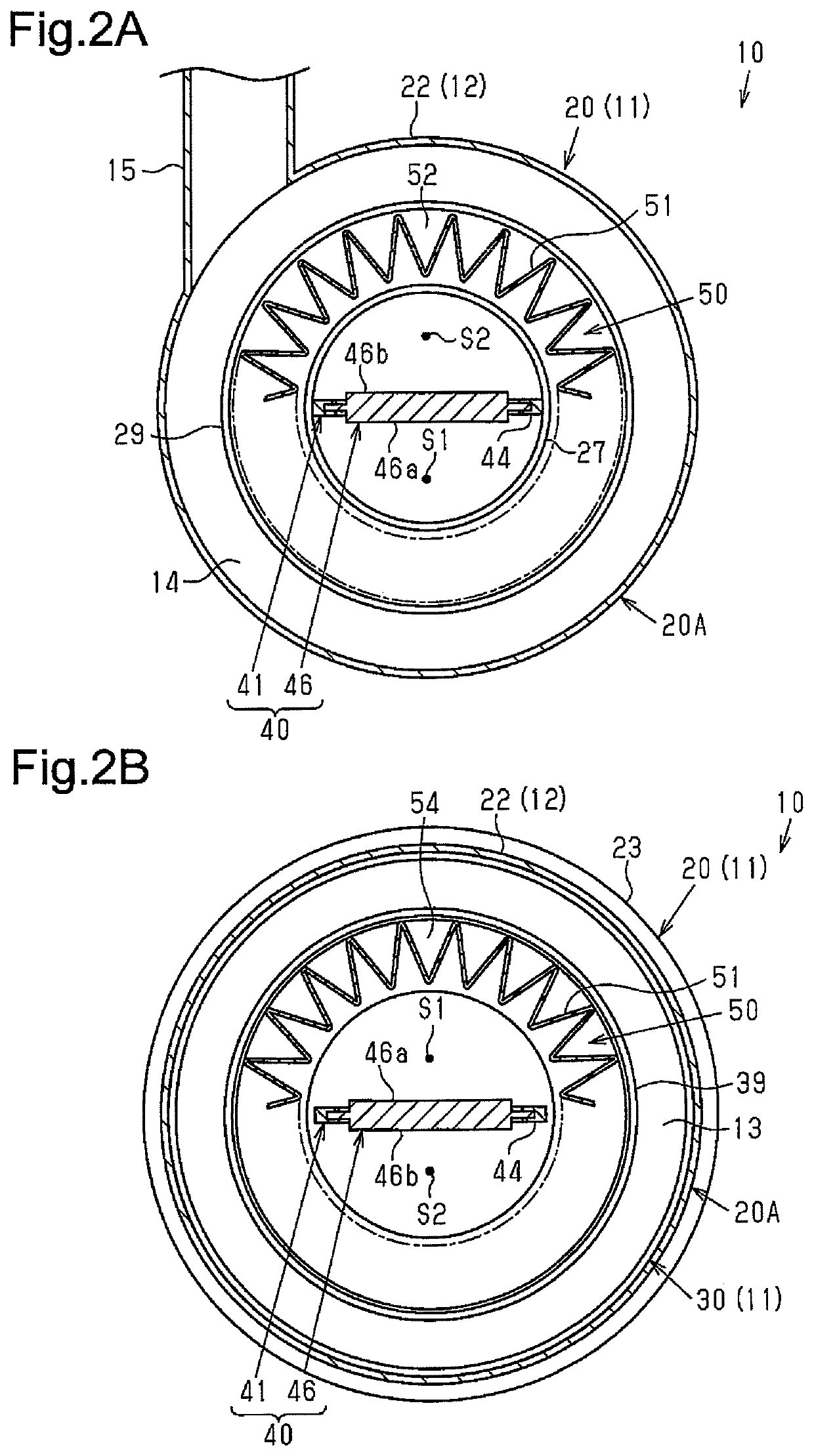

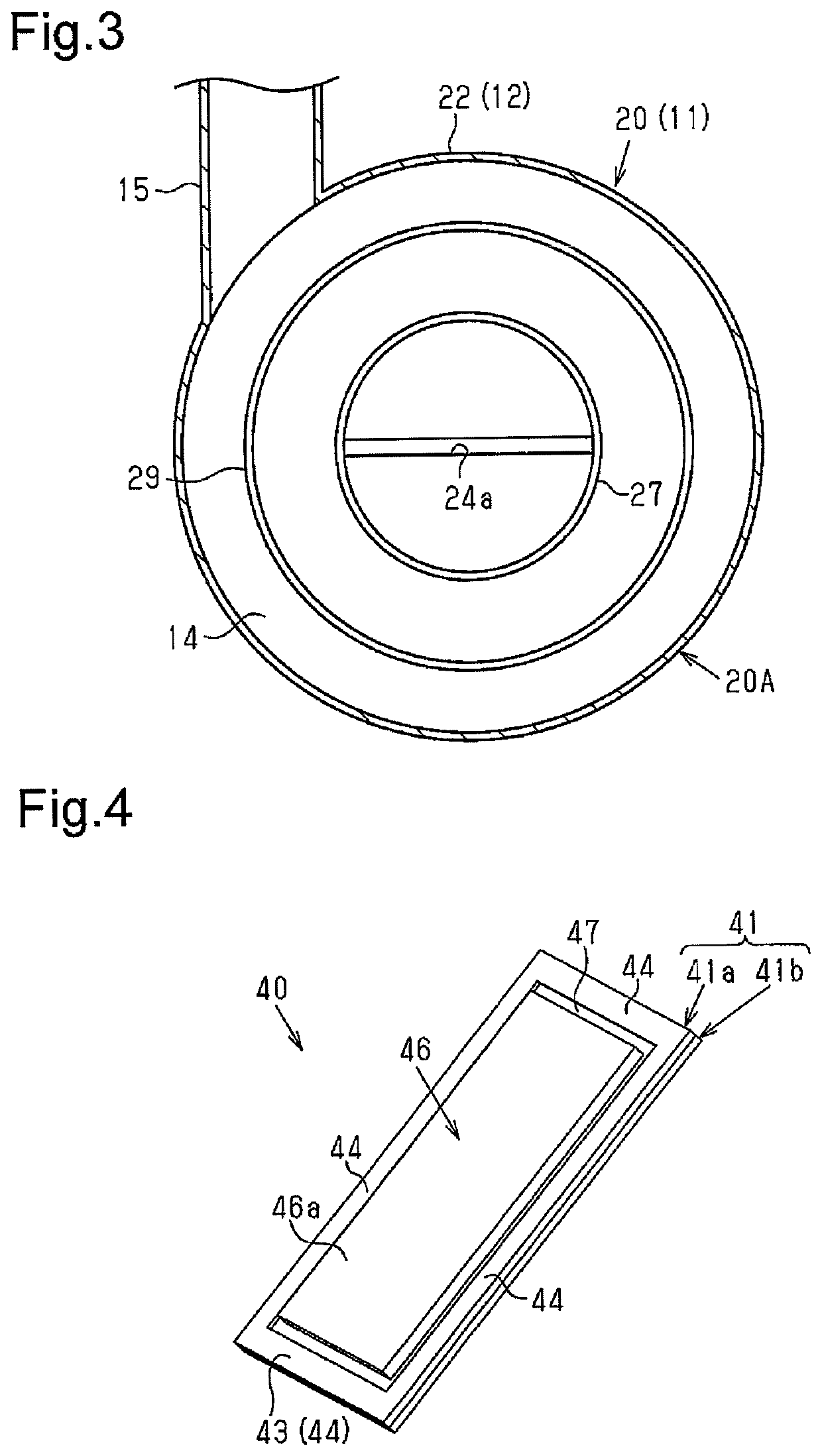

Tubular air cleaner

InactiveUS20180119653A1Reduce air pressure lossCombination devicesDispersed particle filtrationFiltrationEngineering

A tubular air cleaner includes a housing, which has a peripheral wall and a bottom wall, an inlet, which is formed in the peripheral wall, an outlet, which is formed in the bottom wall, a filter element, and a partition wall portion. The filter element has a filtration portion and is accommodated in the housing. The partition wall portion forms the inlet together with the peripheral wall. The filter element is arranged eccentrically with respect to the axis of the housing. An air flow path is formed between the filtration portion and the inner peripheral surfaces of the peripheral wall and the partition wall portion. The air flow path has a gradual change portion, in which the distance between the inner peripheral surface of the peripheral wall and the outer peripheral surface of the filtration portion gradually decreases toward the downstream end.

Owner:TOYOTA BOSHOKU KK

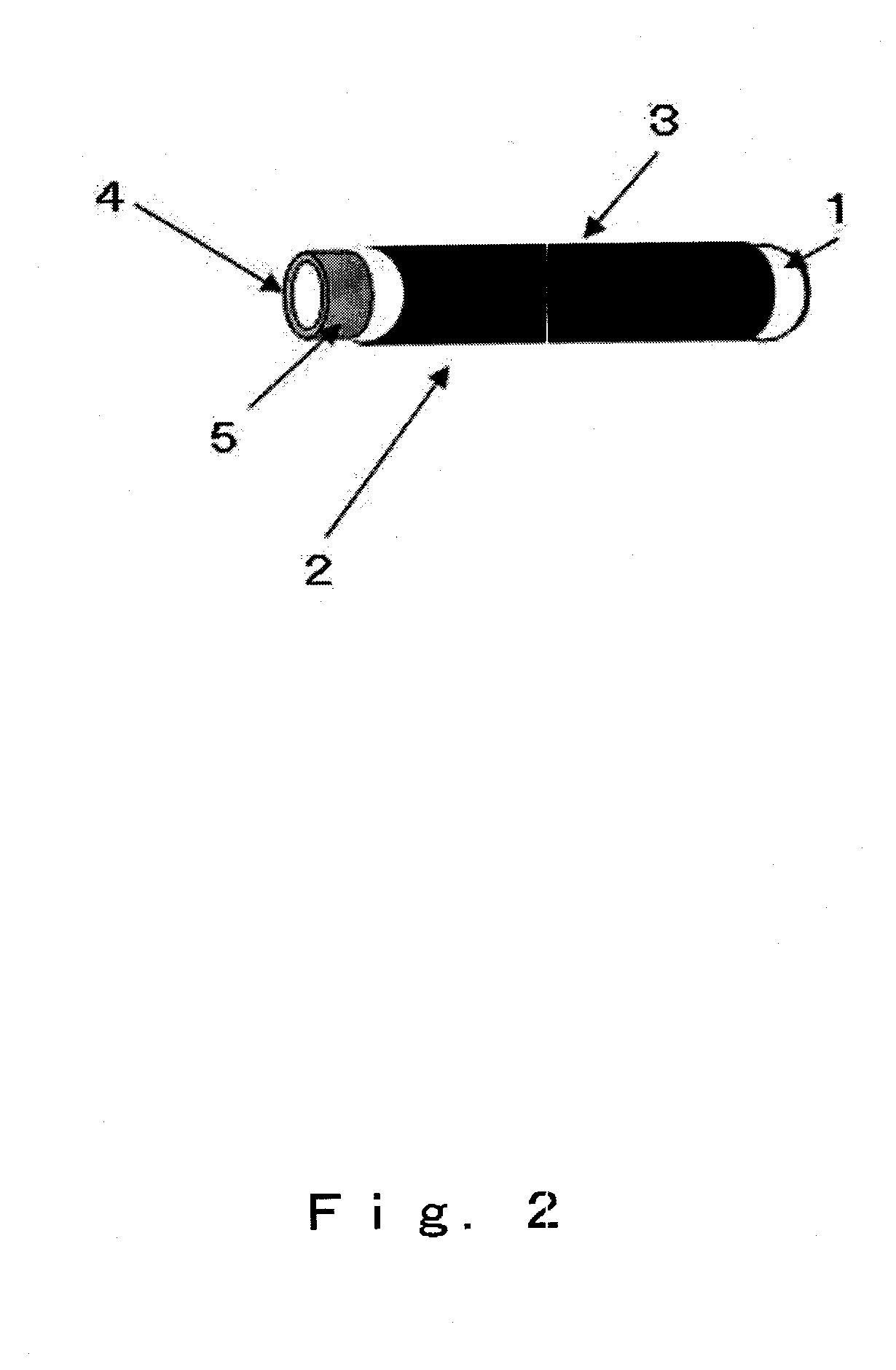

Hollow fiber tube and aeration oxygenation device formed by hollow fiber tube

InactiveCN104474912AEasy to manufactureLow costSemi-permeable membranesWater aerationHollow fibreYarn

The invention relates to a hollow fiber tube. The hollow fiber tube is woven by superfine fiber yarns with thickness of 0.001-0.01D and / or fiber bundles formed by the superfine fiber yarns; a plurality of flexible holes are formed in the tube wall of the hollow fiber tube obtained by weaving, wherein the flexible holes are formed by arranging the fiber yarn, the fiber bundle, the fiber yarn and the fiber bundle in parallel and / or crossing and superposing in a weaving process; the hole diameter of the flexible holes can be changed between 1 micro and 30 microns along with the difference of air pressure. The invention further discloses an aeration oxygenation device formed by the hollow fiber tube. The device has the remarkable advantages of high oxygen utilization rate (up to 25-40%), difficult block, high mechanical strength, long service life, convenient manufacturing, low cost and the like, and can be widely applied to the aeration oxygenation occasions of the fields such as chemical industry, environmental protection and fishery breeding.

Owner:上海众邦盛环保科技有限公司

Cylindrical air cleaner for internal combustion engine

ActiveUS20180147525A1Increase in airflow resistanceReduce air pressure lossGas treatmentDispersed particle filtrationAir cleanersInternal combustion engine

A cylindrical air cleaner for an internal combustion engine comprises: a cylindrical housing including a circumferential wall having an inlet, a top wall having an outlet, and a bottom wall opposed to the top wall; and a tubular filter element accommodated in the housing. A planar adsorbent filter to adsorb evaporated fuel of the internal combustion engine is located at an inner side of the filter element and extends in an axial direction of the filter element. The adsorbent filter includes a basal end portion fixed to an inner surface of the bottom wall. An inner surface of the filter element is spaced apart from each of opposite planes of the adsorbent filter by a gap that allows air to reach the outlet without passing through the adsorbent filter.

Owner:TOYOTA BOSHOKU KK

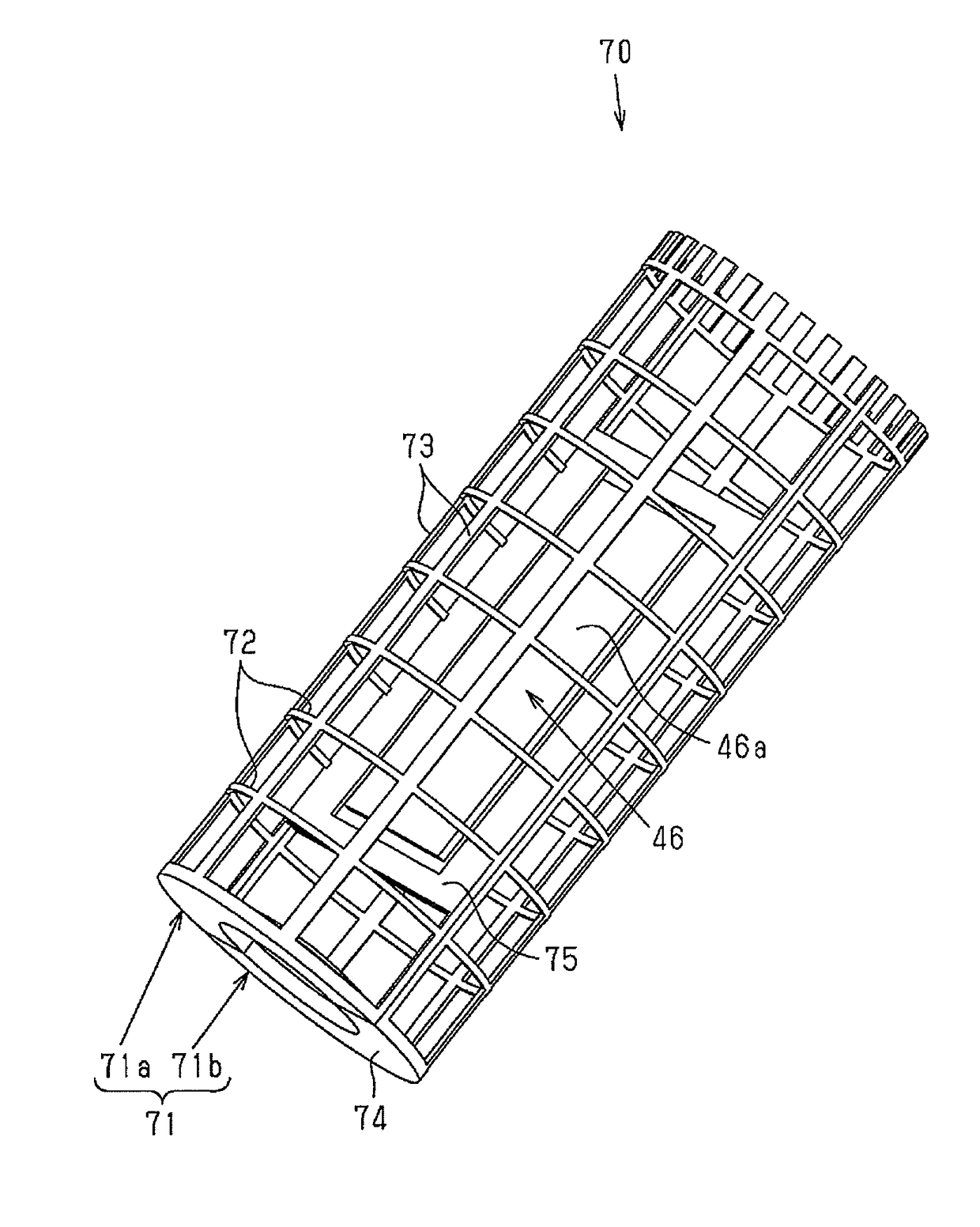

Tubular air cleaner for internal combustion engine and tubular filter element

ActiveUS20180149117A1Reduce air pressure lossIncrease freedomGas treatmentNon-fuel substance addition to fuelExternal combustion engineEngineering

A tubular air cleaner for an internal combustion engine includes a tubular housing, which includes a circumferential wall including an inlet, a top wall including an outlet, and a bottom wall opposed to the top wall, and a tubular filter element, which includes a tubular filter portion and is accommodated in the housing. A frame is arranged at an inner side of the filter portion to maintain shape of the filter portion. A planar adsorbent filter, which adsorbs evaporated fuel of the internal combustion engine, extends in an axial direction of the filter portion and is fixed to the frame. The inner surface of the filter portion is spaced apart from each of opposite planes of the adsorbent filter by a gap that allows air to reach the outlet without passing through the adsorbent filter.

Owner:TOYOTA BOSHOKU KK

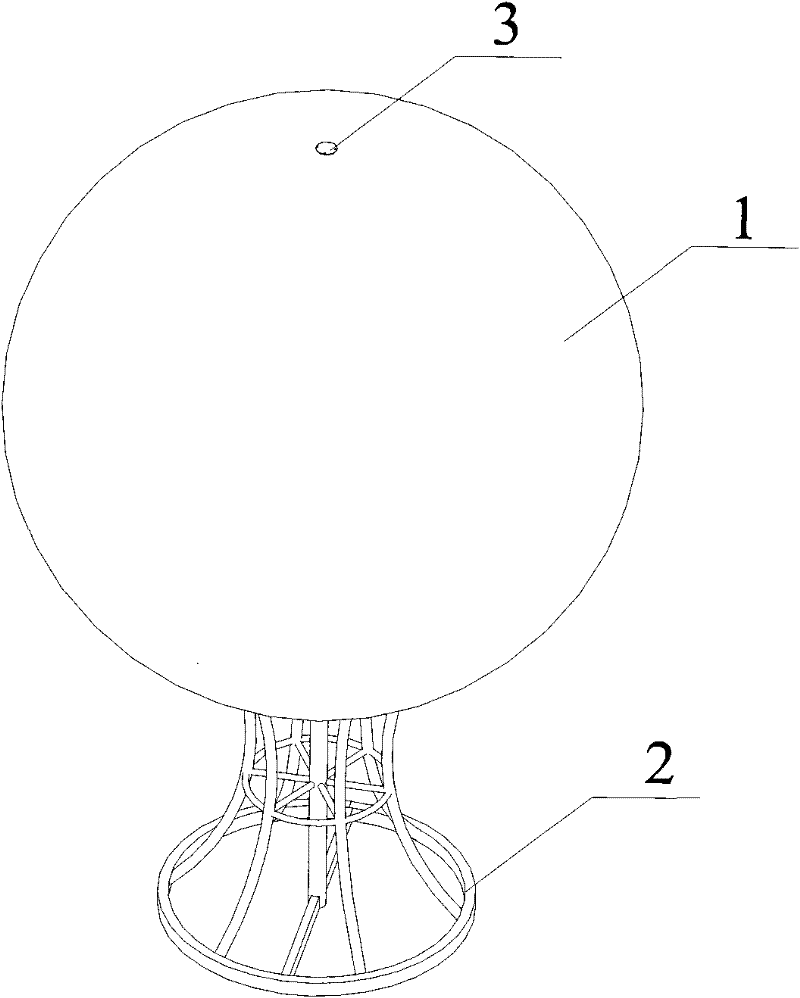

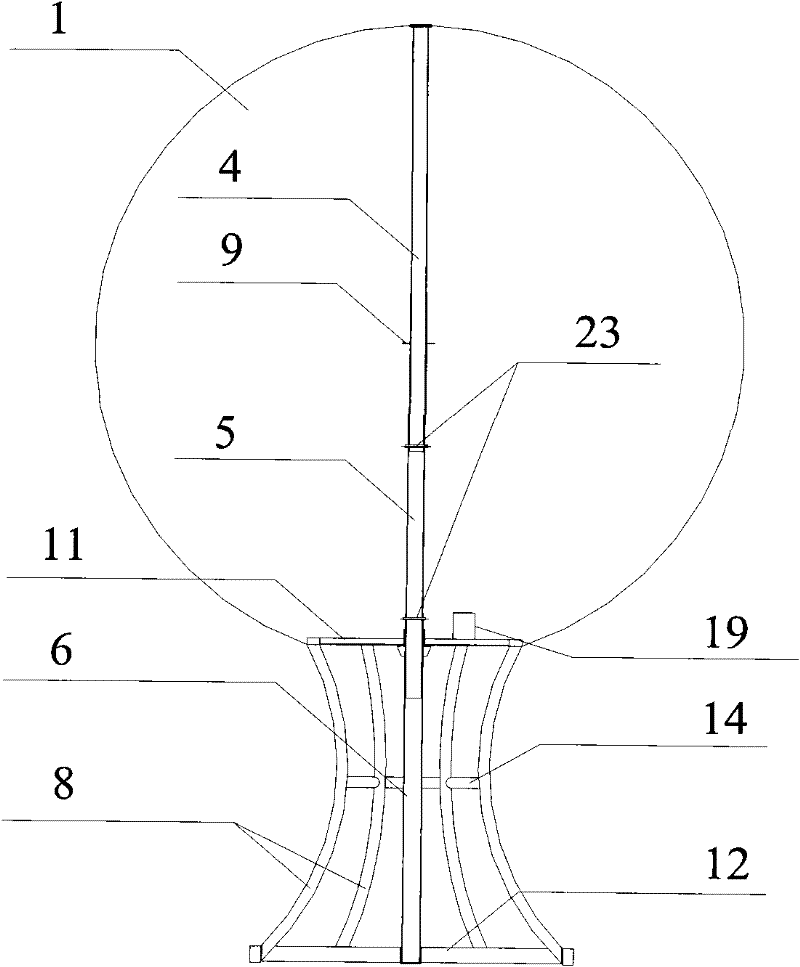

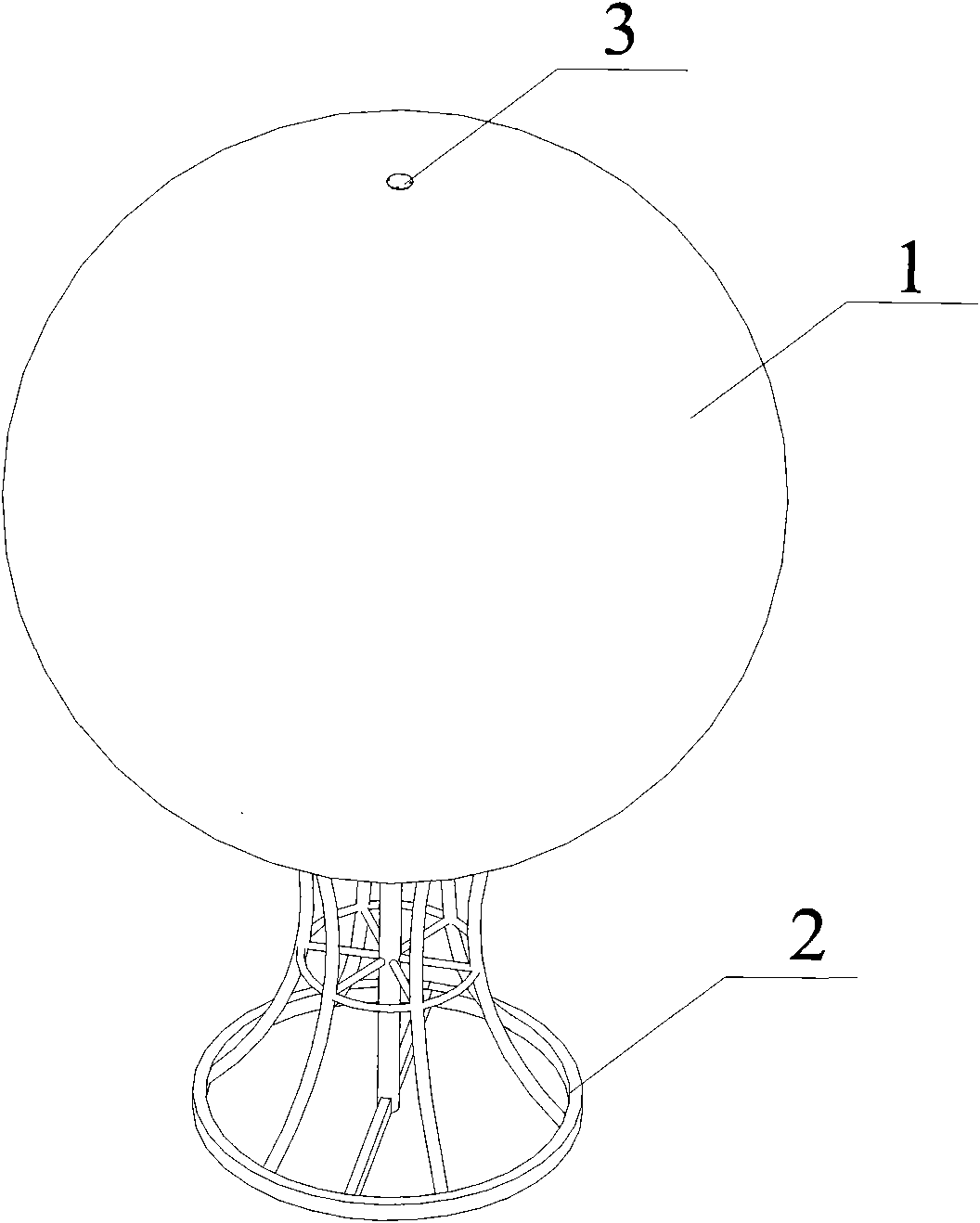

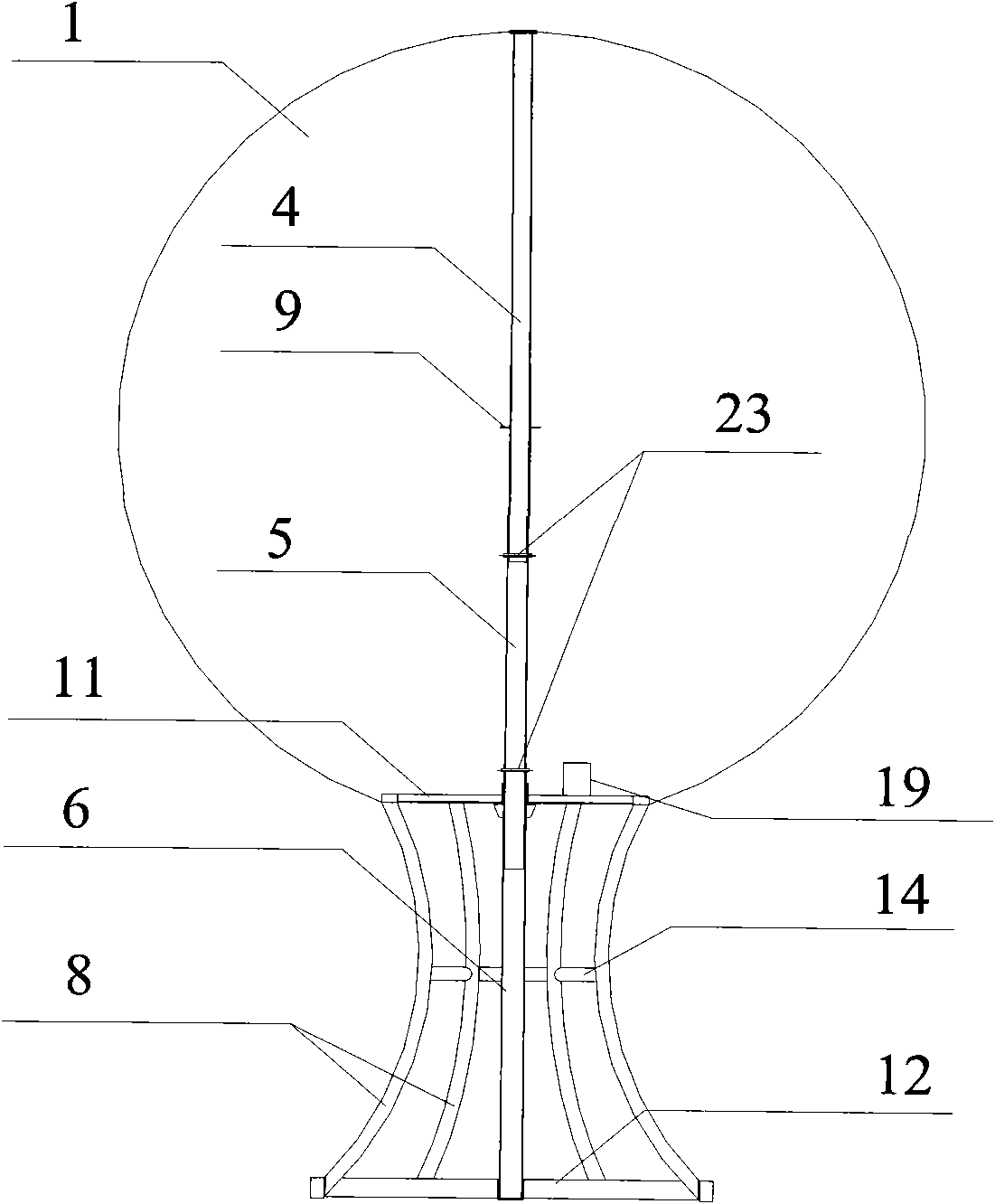

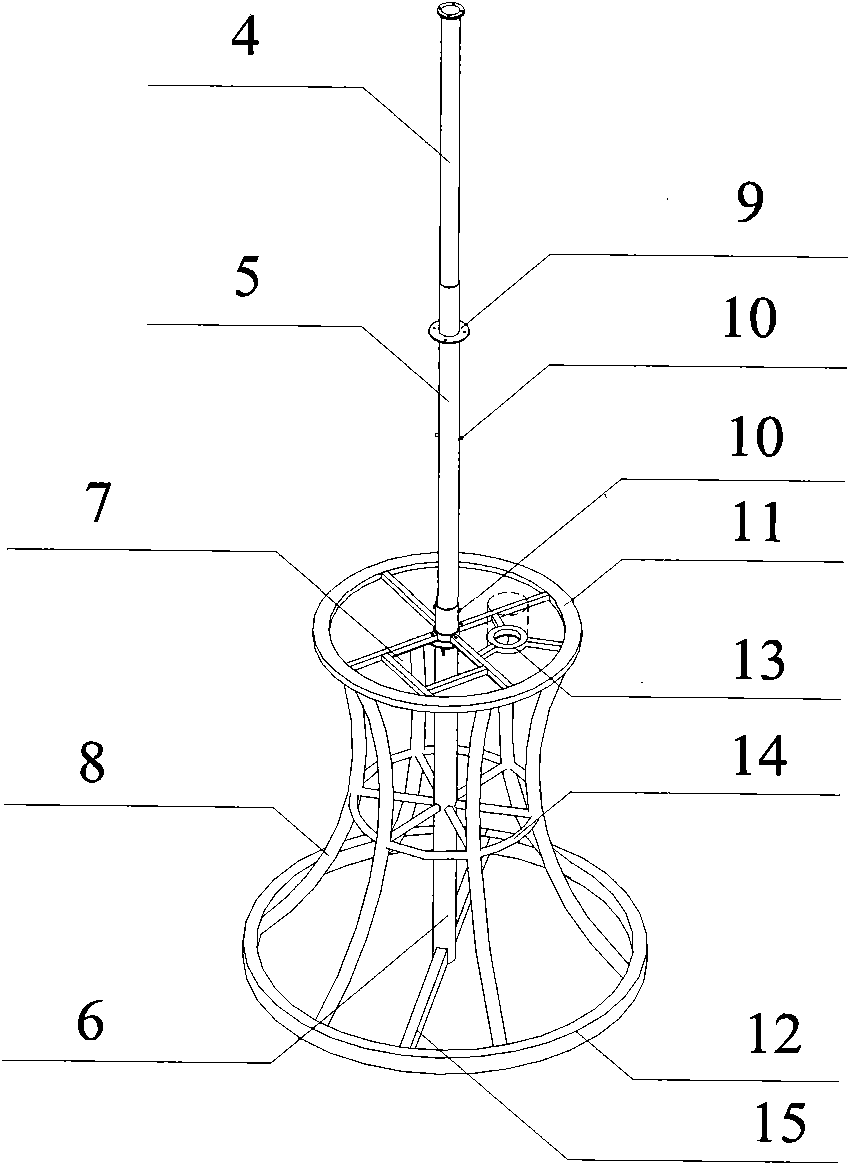

Large-size lightbox ball

ActiveCN102446468AWide spreadImprove lateral stabilityAdvertisingIlluminated signsInformation propagationSpherical angle

The invention relates to a large-size lightbox ball, comprising a ball body, a support and an inflating device, wherein the ball body is made by clipping a high-strength composite flexible material according to a special spherical surface and then splicing the clipped materials; the support is arranged at the lower part of the ball body and comprises a bottom ring, a bottom beam, a first stand column, a second stand column, a third stand column, a strut, a tying ring and a top ring; and the inflating device is arranged on the support. Compared with the prior art, the large-size lightbox ball disclosed by the invention has the advantages of large spherical angle, a wider information propagation range, high integral lateral stability and wind resistance of a ball body structure, longer service life, and capability of reducing the consumed energy for compensating air pressure losses, and the support can be designed into different shapes according to the requirements on activity styles on the premise of preserving a consistent top ring form.

Owner:SHANGHAI HIGHBIRD FABRIC STRUCTURES +1

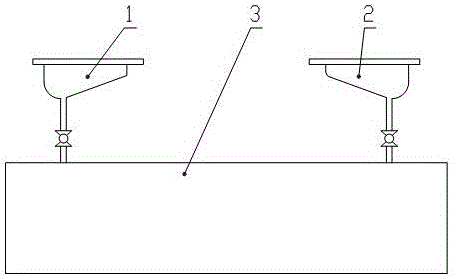

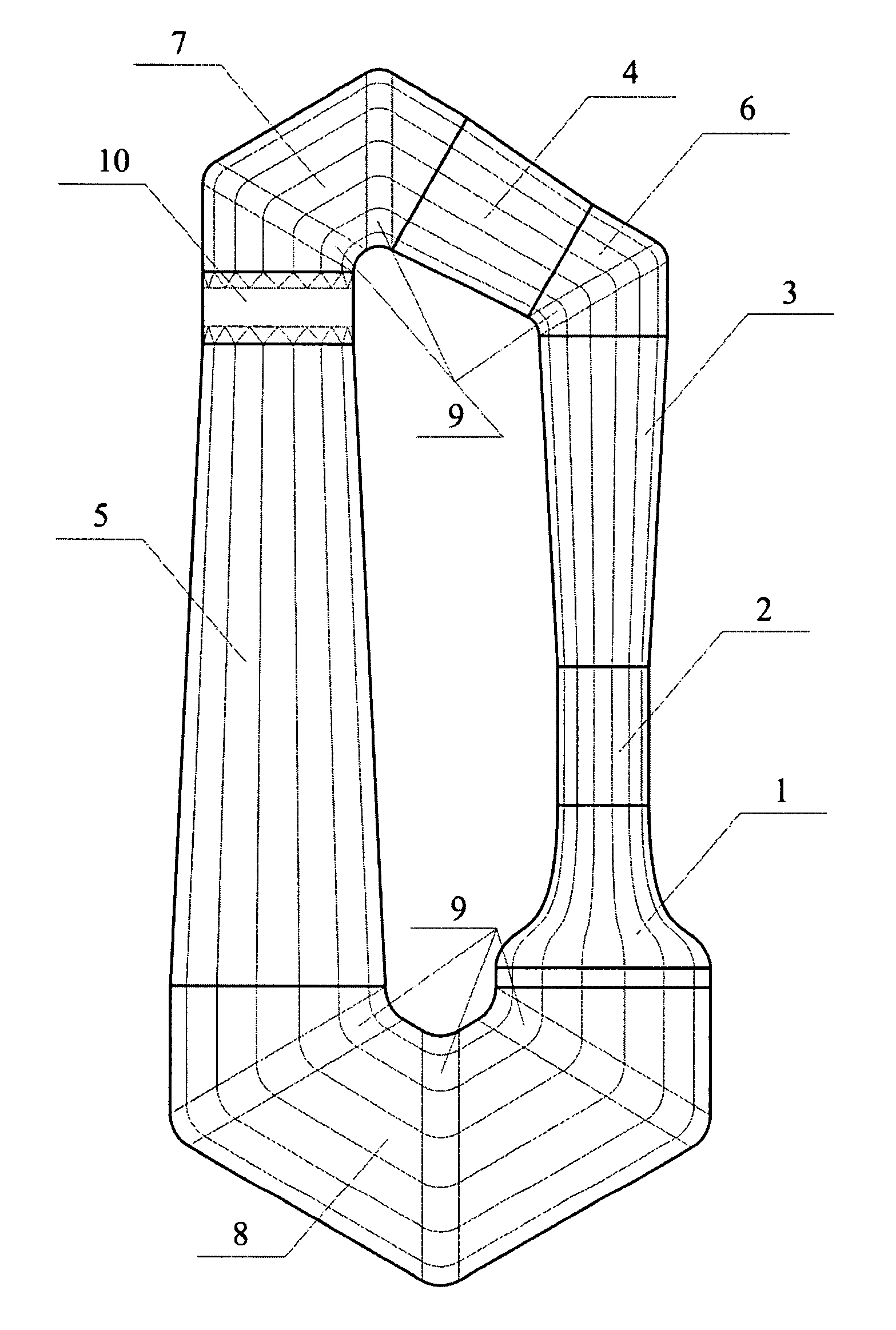

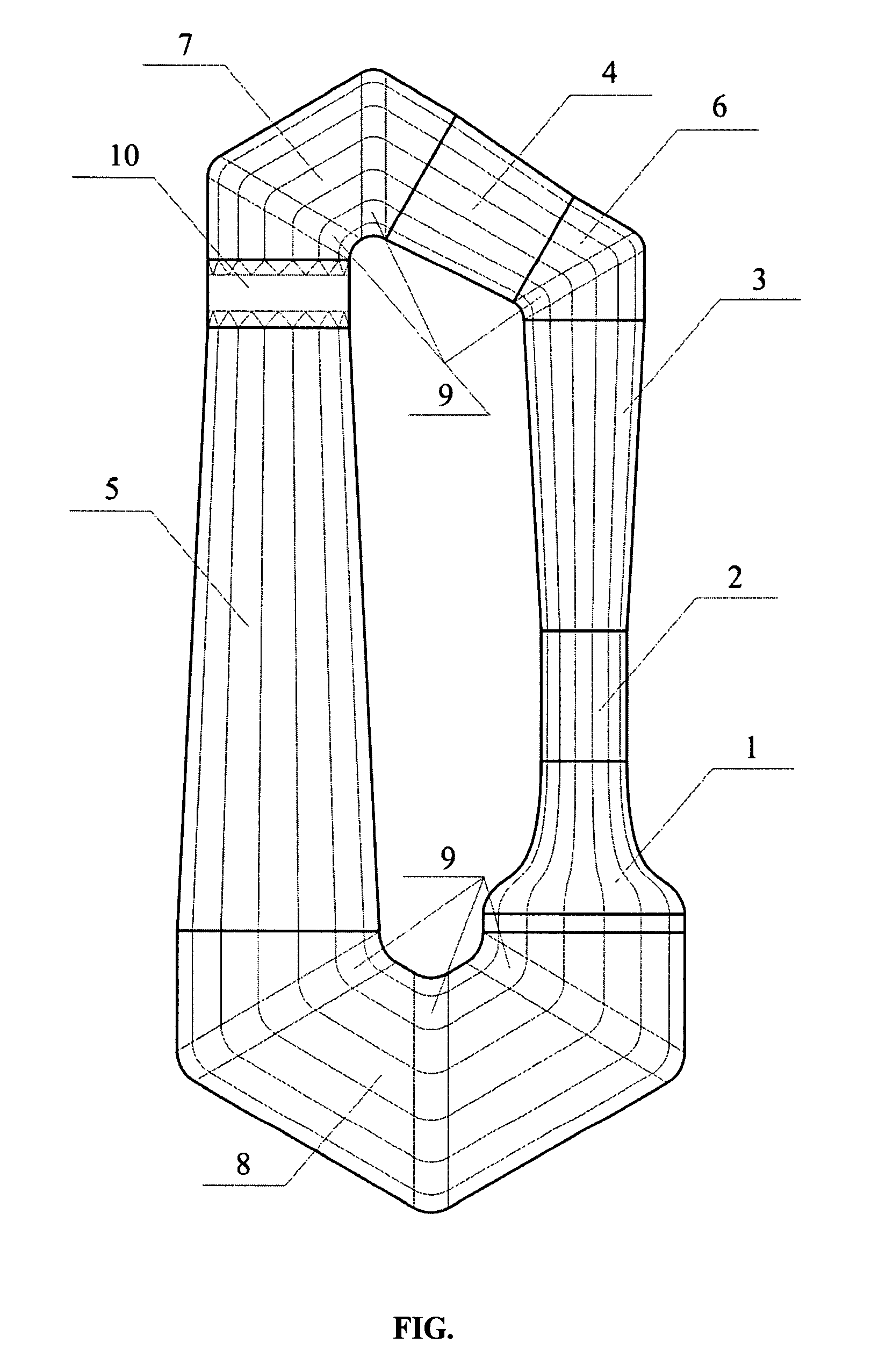

Multi-stage vacuum suction type dejecta collection system and dejecta collection method thereof

InactiveCN106184054AReduce air pressure lossShorten the suction distanceFlushing devicesLavatory sanitoryControl systemCollection system

The invention discloses a multi-stage vacuum suction type dejecta collection system and a dejecta collection method thereof, and relates to the field of feculence disposal. The system comprises a first toilet stool, a second toilet stool and a feculence box. The first toilet stool and the second toilet stool are both connected with the feculence box. A plurality of vacuum units are arranged between the first toilet stool and the feculence box. Each vacuum unit comprises a storage tank and a vacuum generation device. The first toilet stool and the second toilet stool are connected with a control system. According to the system, one or more vacuum units are additionally arranged between the toilet stools and the feculence box for conveying feculences, and direct connection of the two toilet stools and the feculence box is reduced; and when the two toilet stools are simultaneously used, one toilet stool discharges feculences, and the other toilet stool can only wait and discharge feculences after the other toilet stool which discharges feculences firstly completes feculence discharging and the feculence box establishes the vacuum state again, so that the utilization rate of the two toilet stools is increased.

Owner:长春市玺泽商贸有限公司

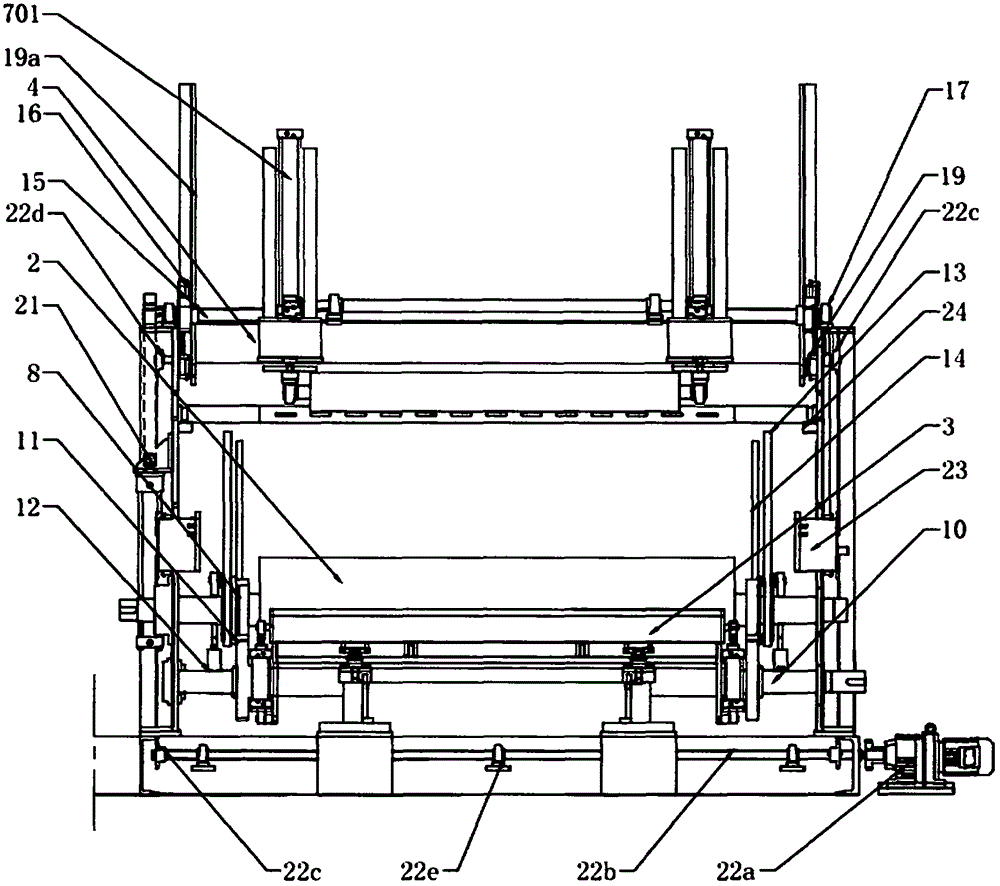

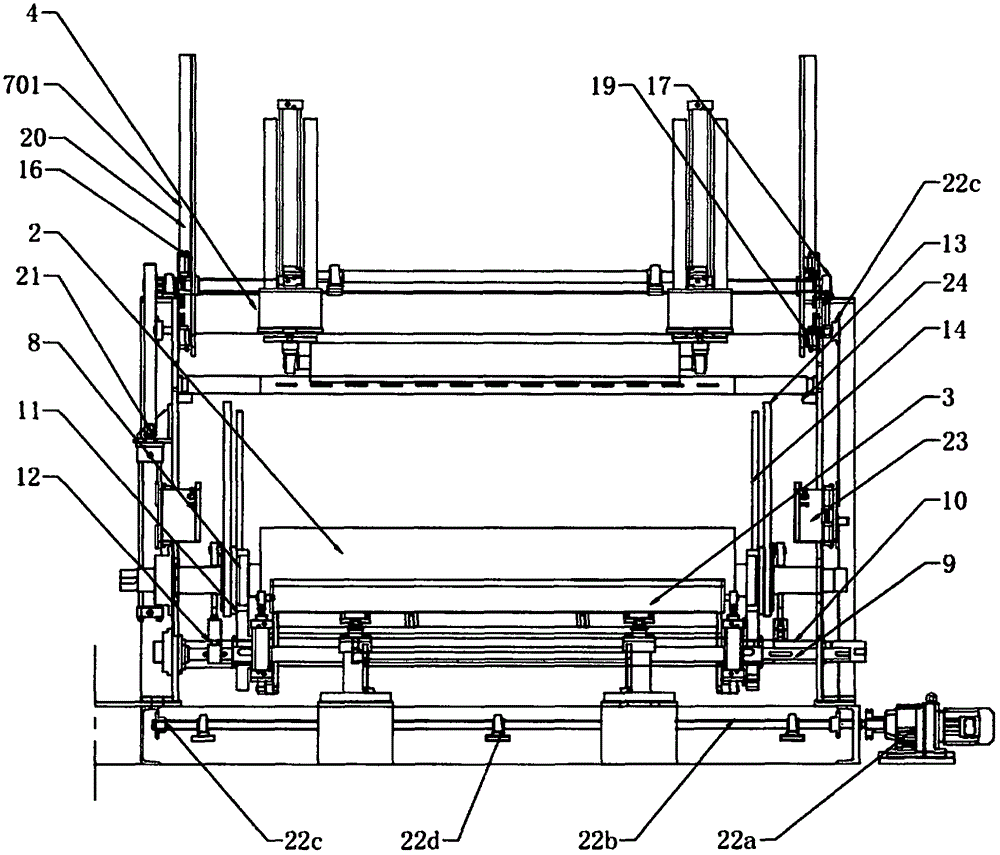

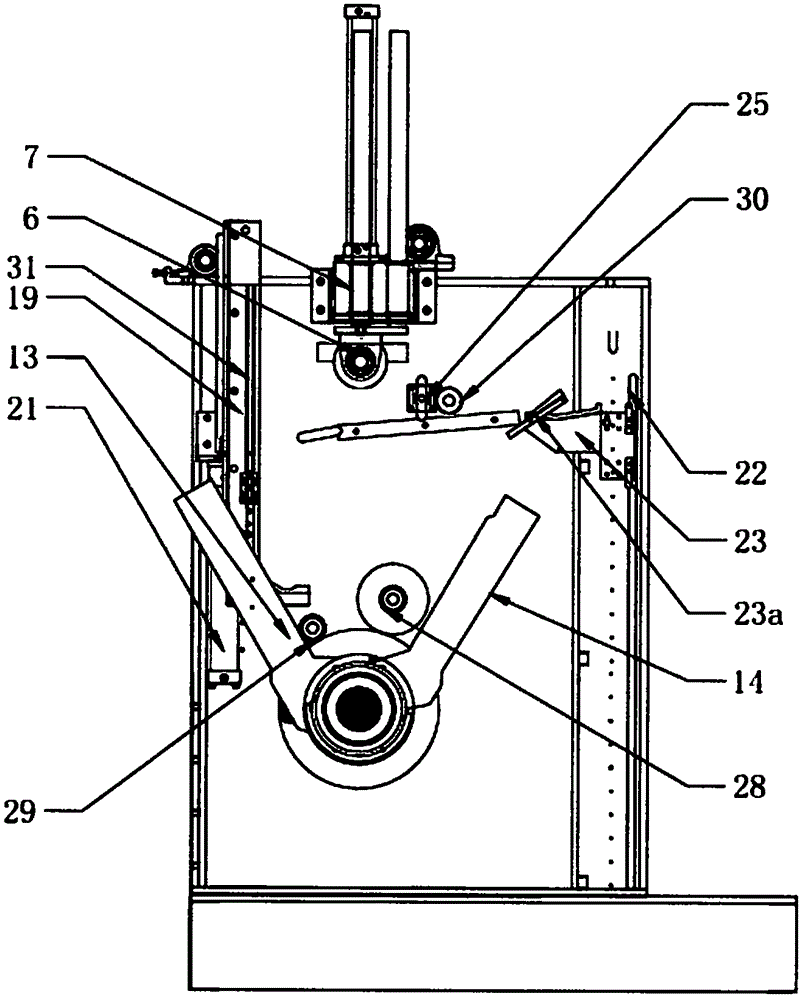

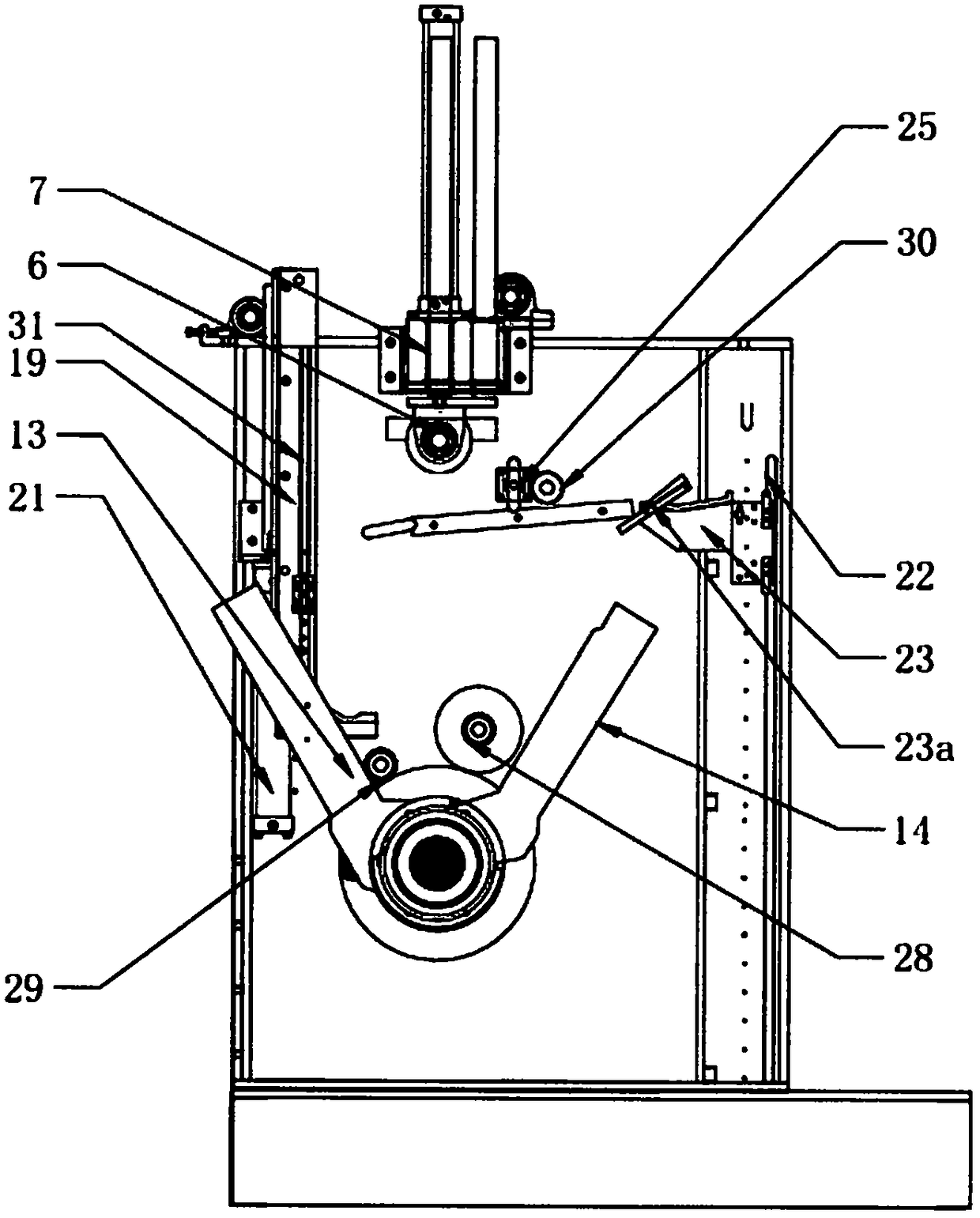

Novel PVC super-transparent thin film coiling device

The invention discloses a novel PVC super-transparent thin film coiling device. The Novel PVC super-transparent thin film coiling device comprises a rack, rollers connected to the two ends of the rack correspondingly, lifting tables symmetrically arranged on the two sides of the rollers, and cross beams located above the rollers. Pressurization rollers are arranged above the rollers. Two bearing seats are symmetrically arranged at the two ends of the rollers. A first synchronizing shaft and a second synchronizing shaft are connected to the two bearing seats correspondingly in a sleeved mode. The ends, far away from the rollers, of the two bearing seats are symmetrically provided with a first swing device and a second swing device correspondingly. A first holding frame and a second holding frame are symmetrically connected to the first synchronizing shaft and the second synchronizing shaft through the first swing device and the second swing device correspondingly. A sliding rail is arranged between a first synchronous gear and a bear and slidably connected with an L-shaped hook plate. Lifting devices are symmetrically arranged on the side, far away from the L-shaped hook plate, of the rack and are connected with pipe hook plates. One sides of the lifting devices are provided with lever mechanisms. An inclined plate with a limiting switch is arranged between the L-shaped hook plate and the pipe hook plates. A first cylinder is arranged above the inclined plate. A controller is arranged above the first cylinder.

Owner:徐立军

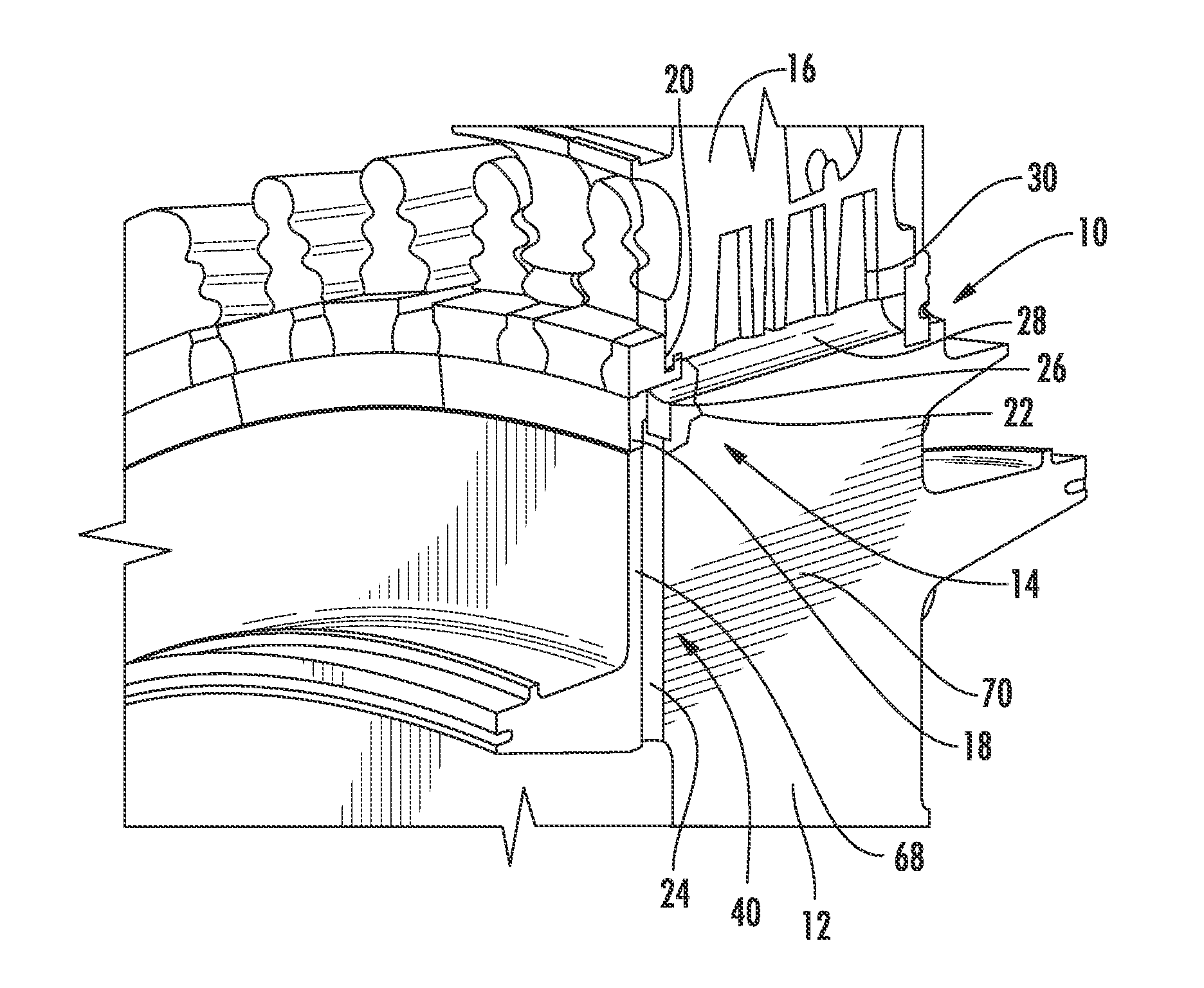

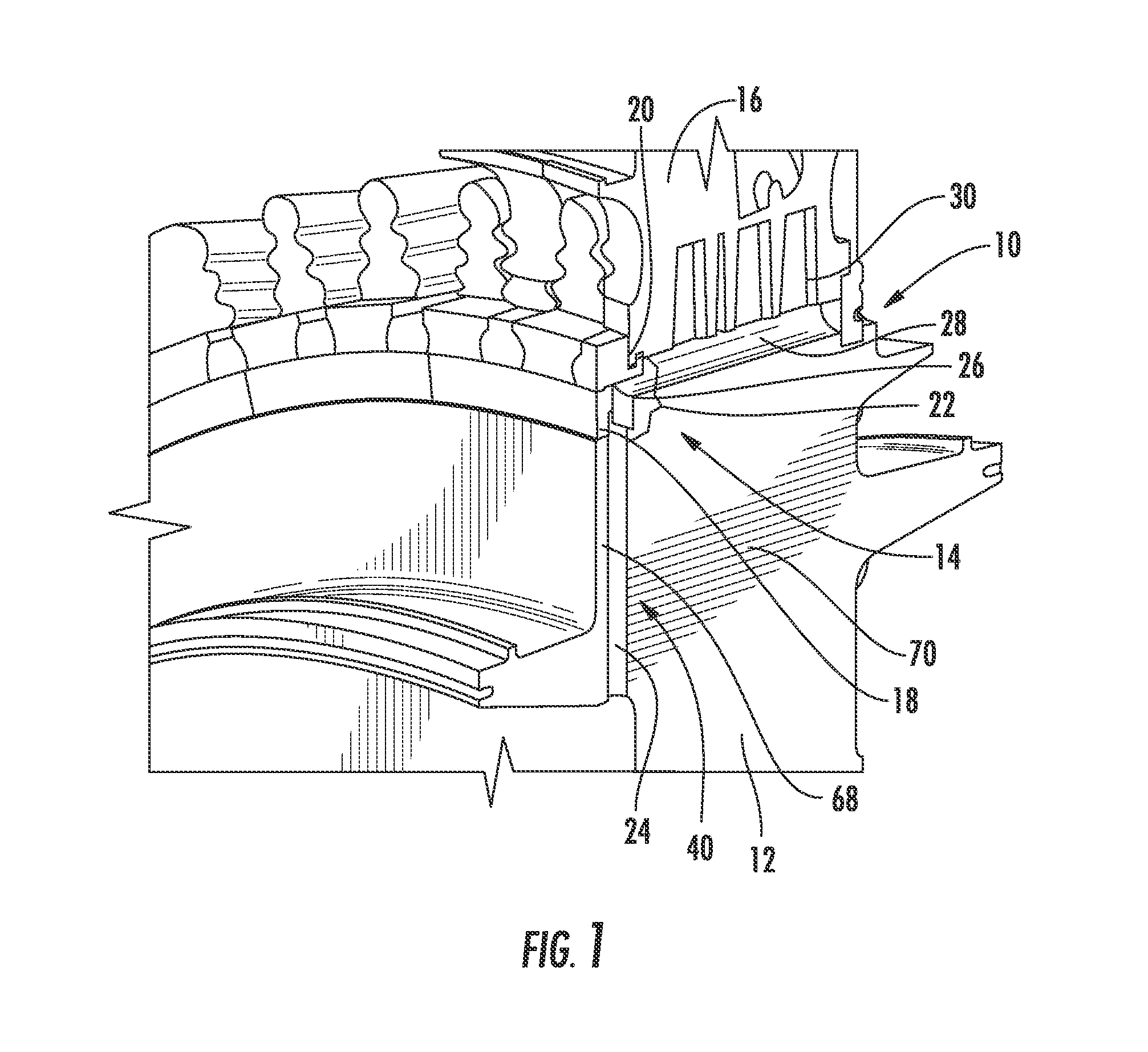

Seal system for cooling fluid flow through a rotor assembly in a gas turbine engine

InactiveUS20120183389A1Improved flow of cooling fluidHigh trafficPump componentsBlade accessoriesTurbine bladeEngineering

A sealing system for a rotor assembly in a gas turbine engine is disclosed. The sealing system may include a seal formed from a side block and an upper seal that seals a gap between a radially outward extending first rotor supply channel in a rotor assembly terminating at an inlet of an axially extending second rotor supply channel that is in fluid communication with an internal blade cooling system of a turbine blade. The seal may include components that enhance the flow of cooling fluids over conventional configurations. In another embodiment, the sealing system may include an integrated sealing block configured to seal a gap between adjacent turbine blades at an intersection between the first and second rotor supply channels. The integrated sealing block may be formed from a radially inward extending leg and central body.

Owner:SIEMENS ENERGY INC

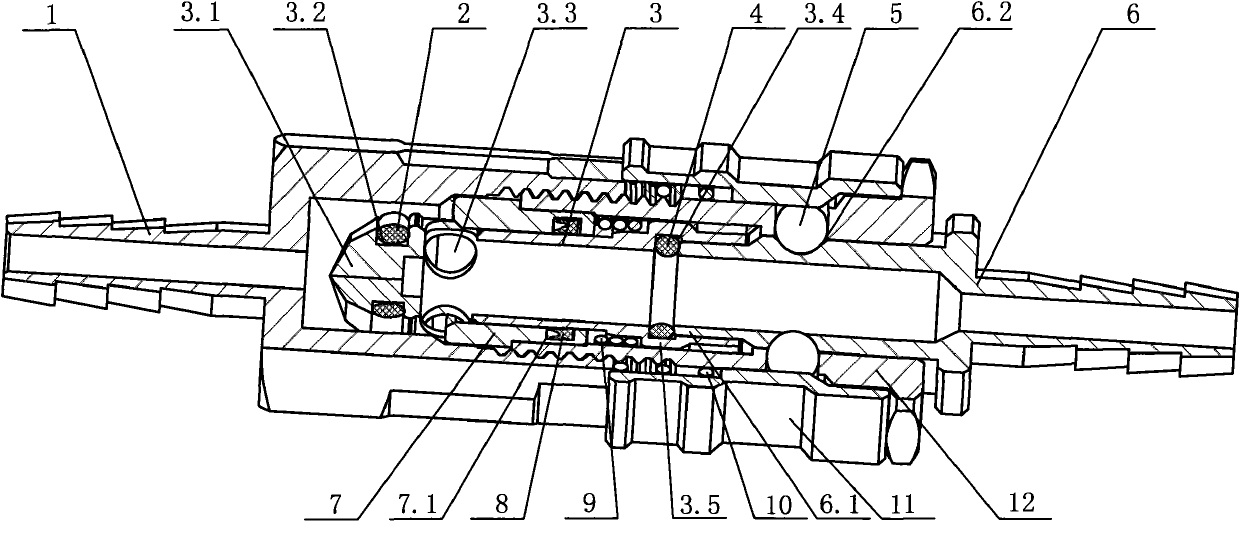

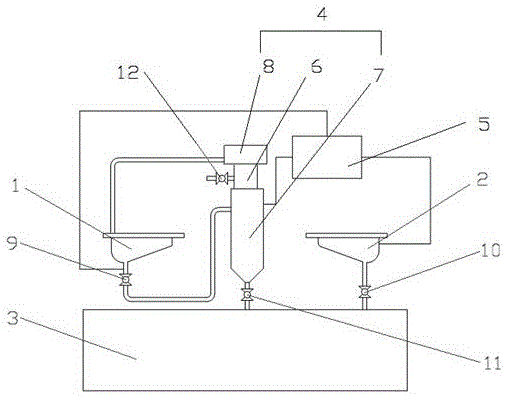

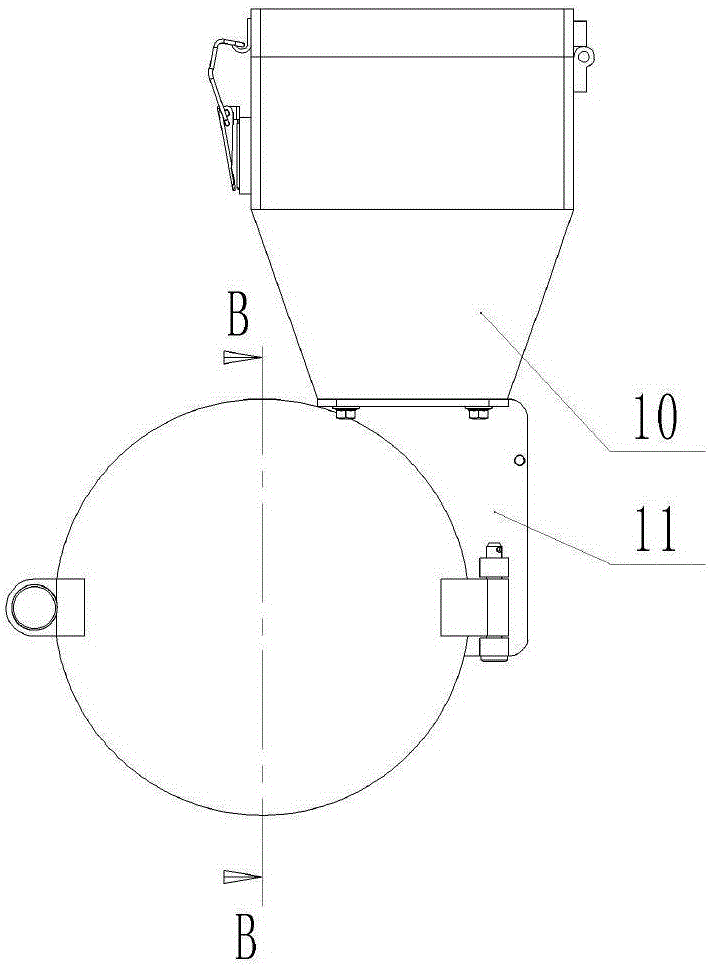

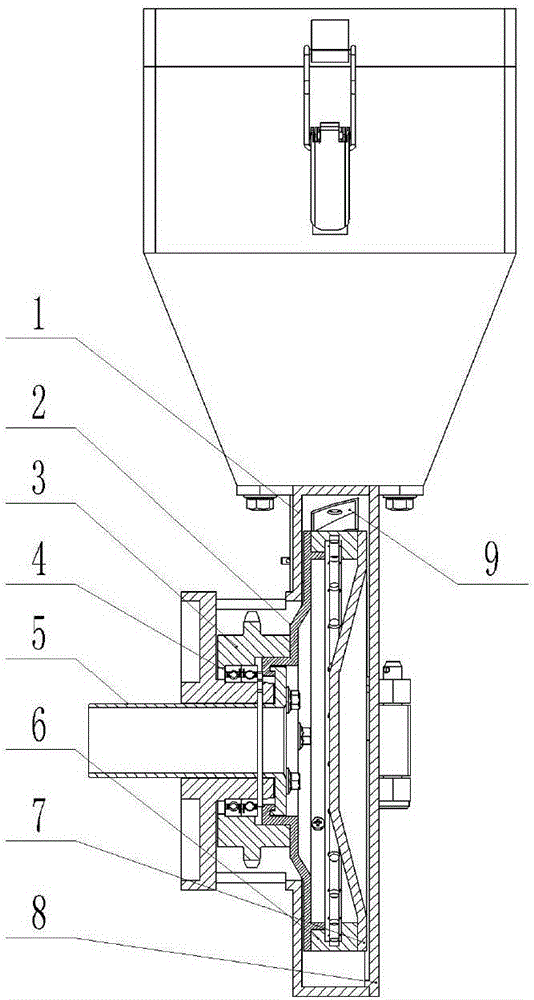

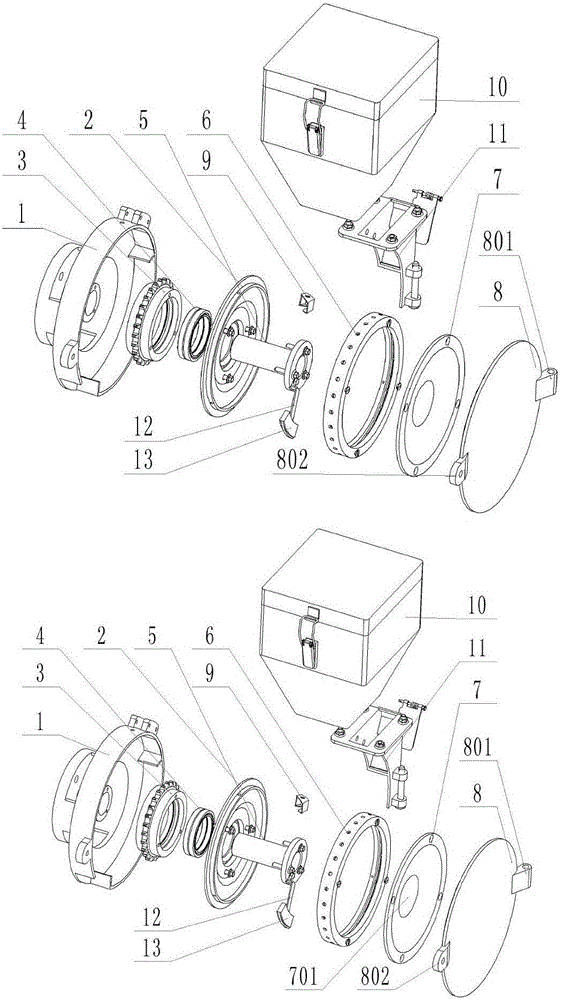

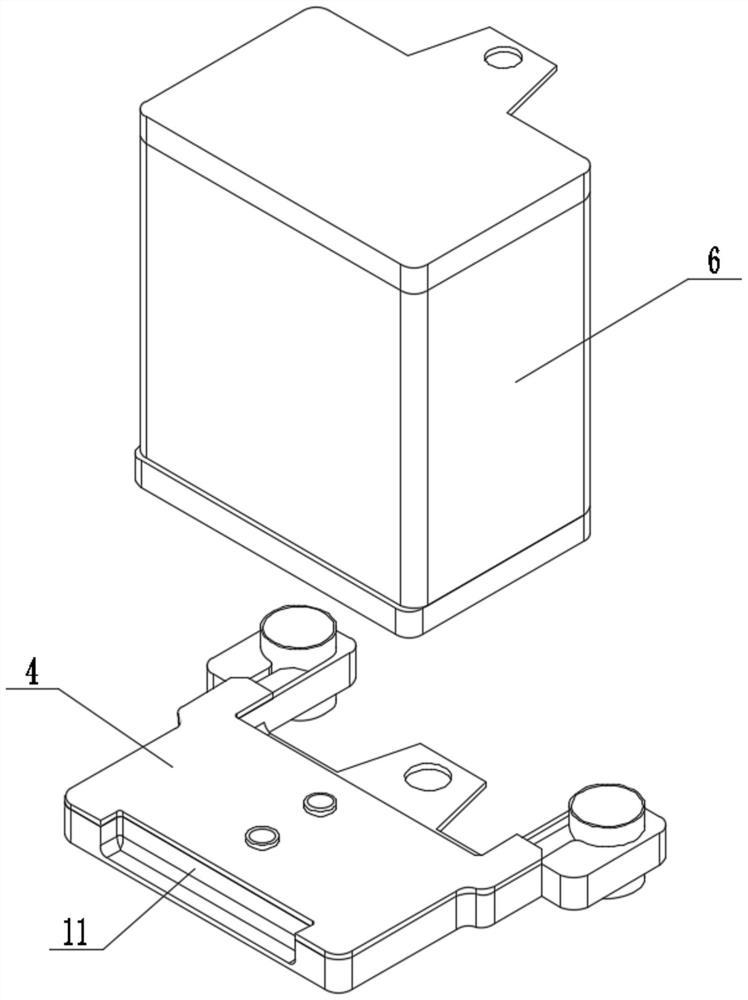

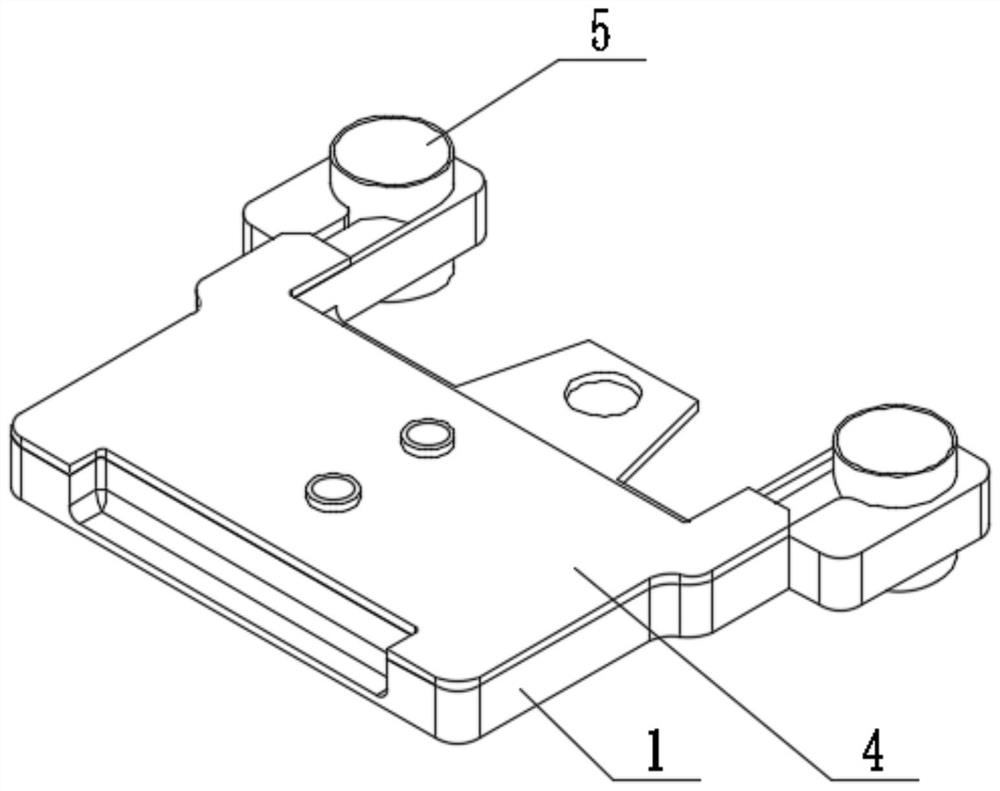

Synchronous low-pressure peripheral air-aspiration type precise seeding device

InactiveCN106211884AReduce wearReduce air pressure lossSeed depositing seeder partsSynchronous motorAgricultural engineering

The invention belongs to the technical field of agricultural machinery, and in particular relates to a synchronous low-pressure peripheral air-aspiration type precise seeding device which comprises a rear casing (1), a rear air chamber disc (2), a chain wheel (3), a bearing (4), an air inlet tube (5), a seeding disc (6), a front air chamber disc (7), a front casing (8), a seed cleaning cutter (9), a seed box (10), a seed storage box (11), a seed discharge pressing plate (12) and a seed discharge cutter (13). As the seeding disc of the synchronous low-pressure peripheral air-aspiration type precise seeding device is fixedly connected with an air chamber, pressure loss and member abrasion caused by relative rotation can be reduced; the seeding device is used for feeding seeds by virtue of seed gravities and air pressure, the seed feeding property can be improved, and the air pressure requirements can be met; as the air inlet tube is of integral design, air can be directly fed into the air chamber, and air flow loss caused by connection can be avoided to the maximum extent.

Owner:CHINA AGRI UNIV

Large-size lightbox ball

ActiveCN102446468BWide spreadImprove lateral stabilityAdvertisingIlluminated signsInformation propagationSpherical angle

The invention relates to a large-size lightbox ball, comprising a ball body, a support and an inflating device, wherein the ball body is made by clipping a high-strength composite flexible material according to a special spherical surface and then splicing the clipped materials; the support is arranged at the lower part of the ball body and comprises a bottom ring, a bottom beam, a first stand column, a second stand column, a third stand column, a strut, a tying ring and a top ring; and the inflating device is arranged on the support. Compared with the prior art, the large-size lightbox ball disclosed by the invention has the advantages of large spherical angle, a wider information propagation range, high integral lateral stability and wind resistance of a ball body structure, longer service life, and capability of reducing the consumed energy for compensating air pressure losses, and the support can be designed into different shapes according to the requirements on activity styles on the premise of preserving a consistent top ring form.

Owner:SHANGHAI HIGHBIRD FABRIC STRUCTURES +1

Fuel cell and fuel cell power generation system

The invention relates to the technical field of cathode closed type fuel cells, and provides a fuel cell and a fuel cell power generation system. The fuel cell comprises a gas distribution plate and a cathode closed type electric pile, the first end face of the gas distribution plate makes contact with the first end face of the cathode closed type electric pile, the first end plate is provided with a cathode air inlet and a cathode air outlet, the first end face is provided with a cathode air inlet groove and a cathode air outlet groove, and the cathode air inlet and the cathode air outlet are communicated with the cathode air inlet groove and the cathode air outlet groove respectively. According to the fuel cell disclosed by the invention, the cathode gas inlet groove and the cathode gas outlet groove are formed in the gas distribution plate, so that the use of a cathode gas distribution pipeline is reduced, the length of the pipeline in a power generation system is reduced, the pipeline structure is simplified, and the gas pressure loss is reduced; and risks caused by complex processes such as gas pipe out-of-phase sealing and the like which must be adopted for achieving insulation between the electric piles when multiple piles of gas circuits are connected in the system are avoided, and integration of a power generation system is facilitated.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

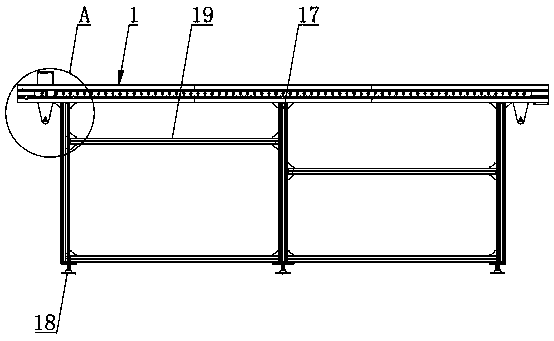

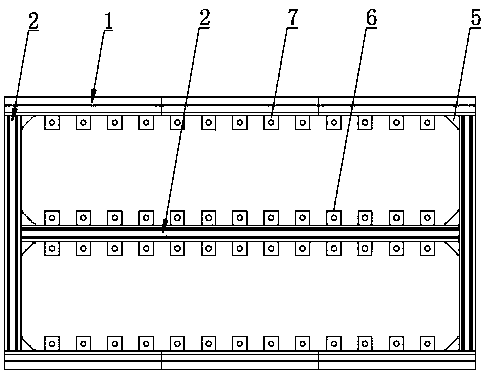

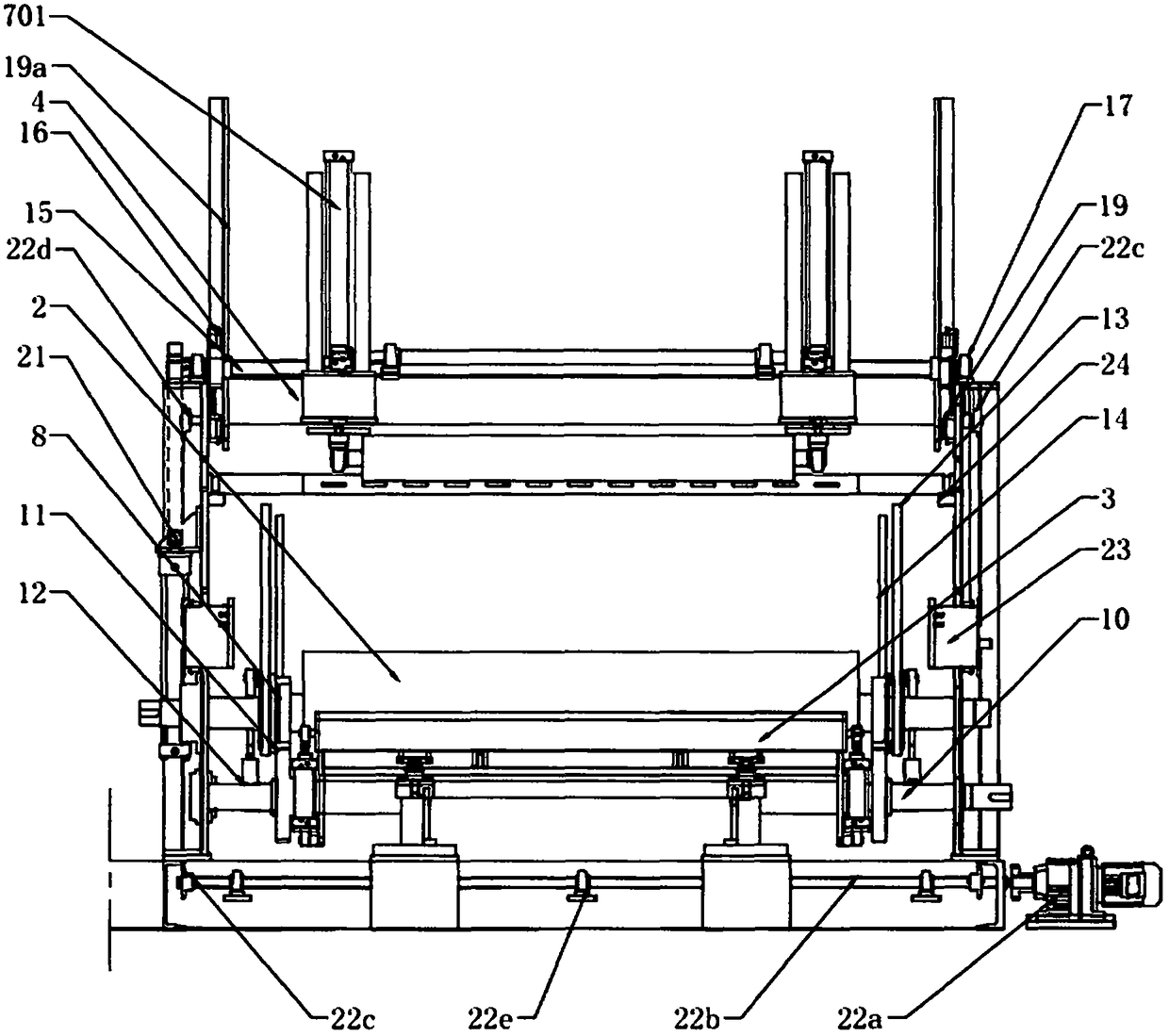

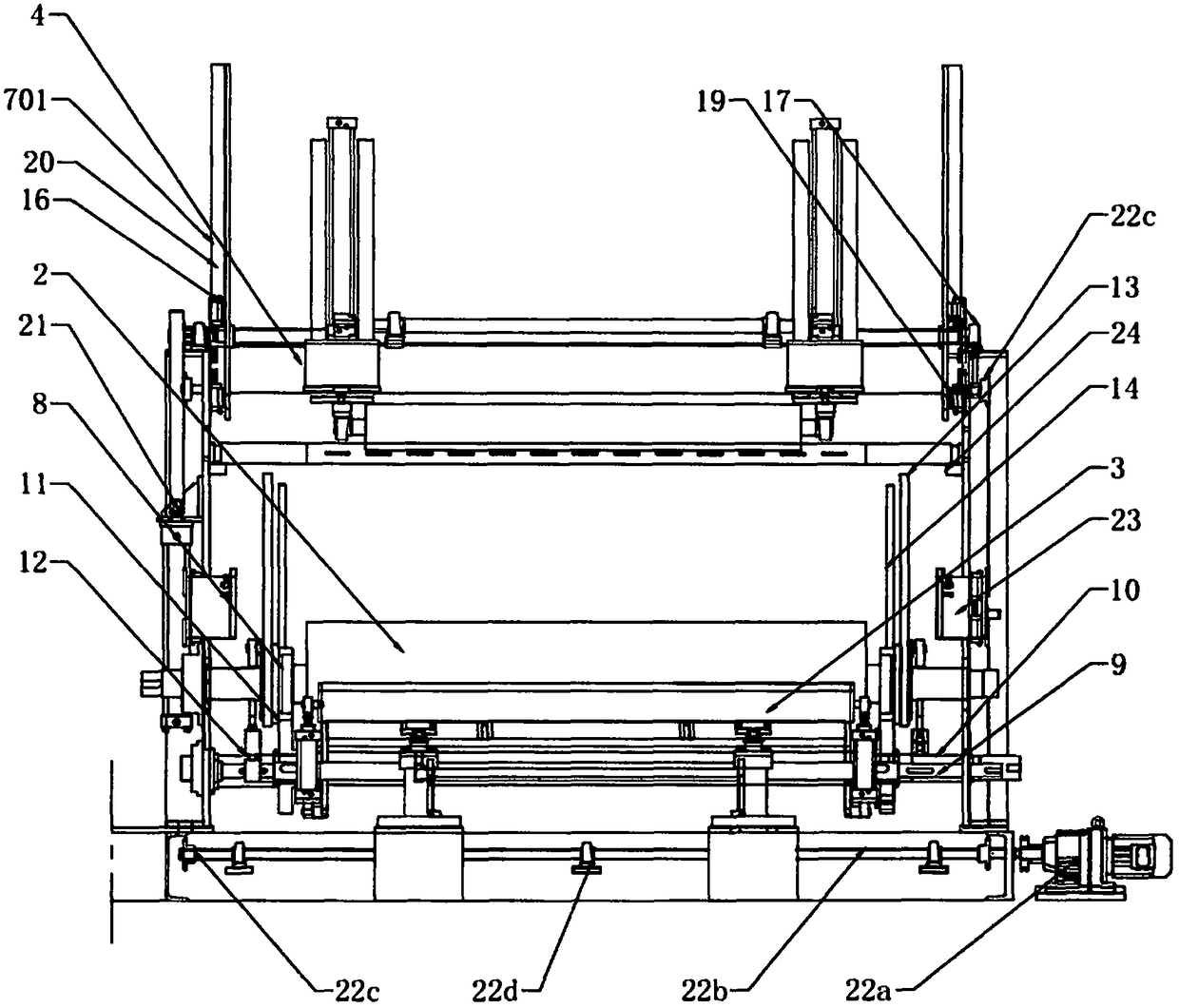

Freely spliced adsorption platform device of flexible material cutting equipment

The invention relates to the technical field of adsorption platforms, in particular to a freely spliced adsorption platform device of flexible material cutting equipment. The freely spliced adsorptionplatform device comprises a table board part and a rack part. The table board part is composed of table board frames, aluminum section bars and table board panels. The table board frames and the aluminum section bars jointly form a rectangular frame, butt joint pin holes are formed in the table board frames, steel pins are embedded into the butt joint pin holes, the table board frames are combined and spliced to form front and back frames of the rectangular frame through the steel pins, the table board frames are connected to a plurality of first angle iron through bolts, the first angle ironis connected to the aluminum section bars through bolts, an adsorption platform is placed in the rectangular frame, and the adsorption platform is formed by splicing the table board panels. The freely spliced adsorption platform device has the beneficial effects that by adopting the integrated section bars, the dimensional error is small; extremely small errors of the plane can be guaranteed without repeatedly regulating the whole plane; the freely spliced adsorption platform device can be spliced freely, and complex operations such as hoisting in high-rise building mounting are cancelled; the whole freely spliced adsorption platform device is spliced quickly and is firm, so that the efficiency is improved greatly.

Owner:WUHAN GEMEI UNITED TECH CO LTD

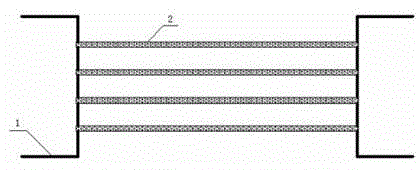

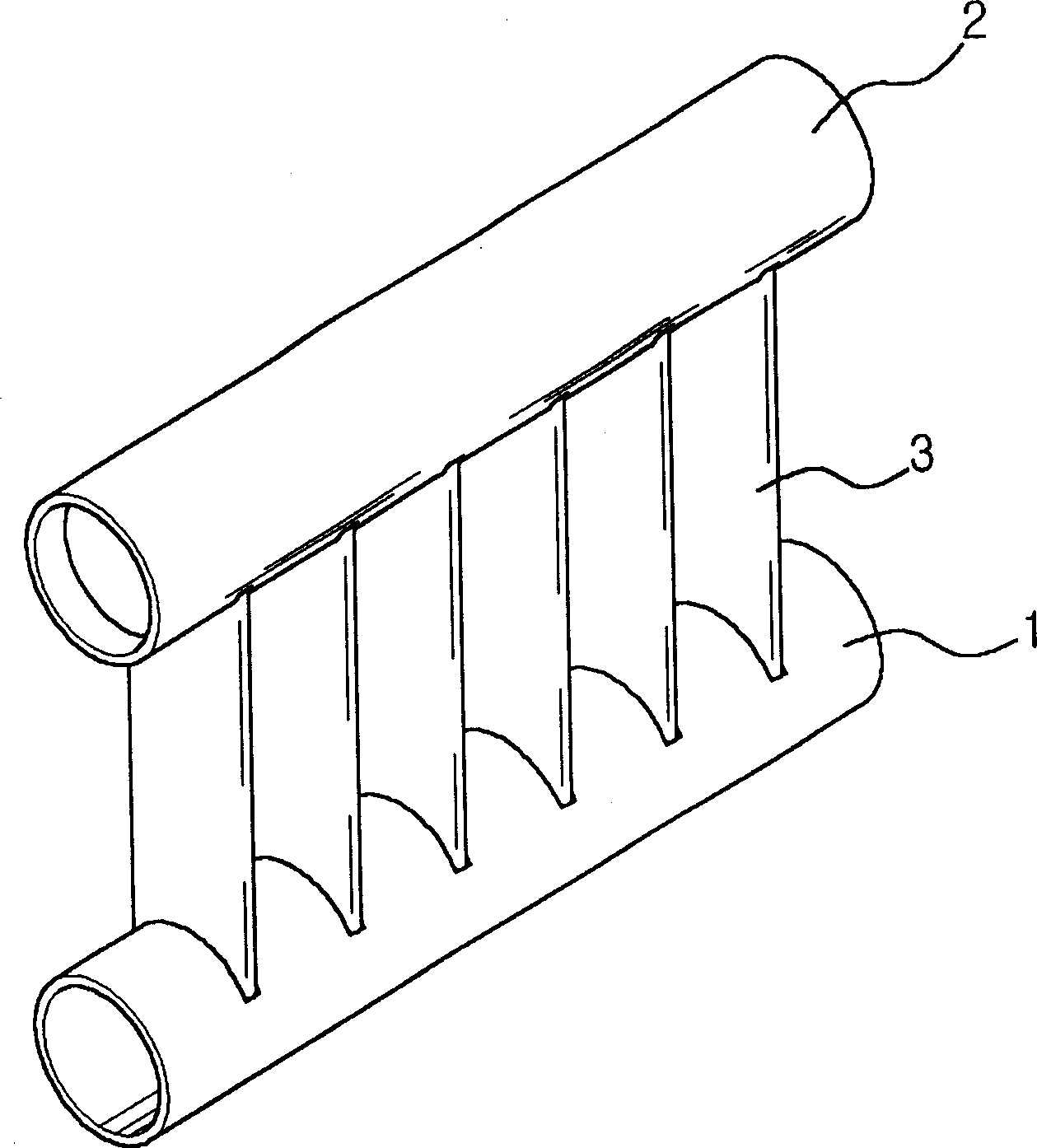

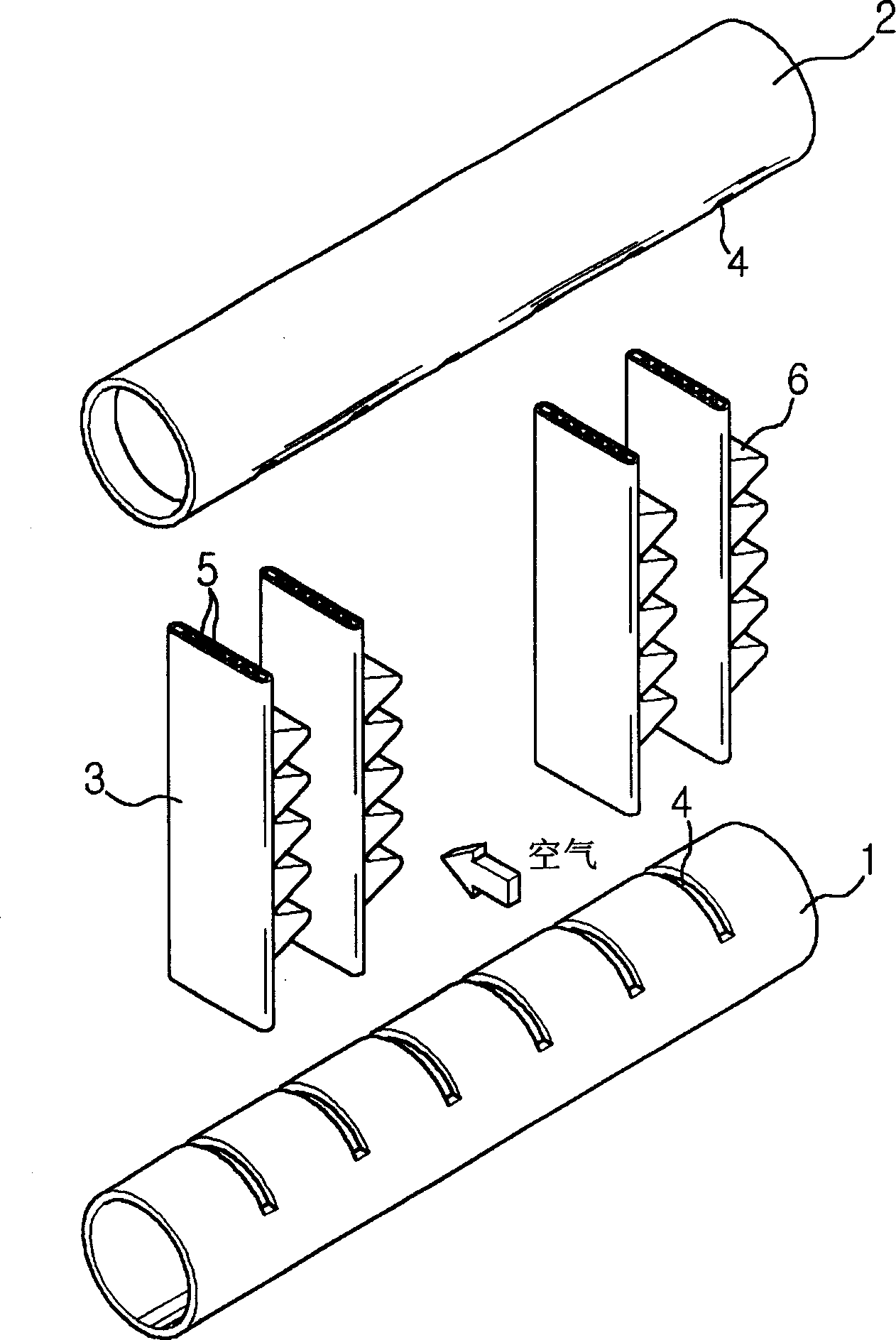

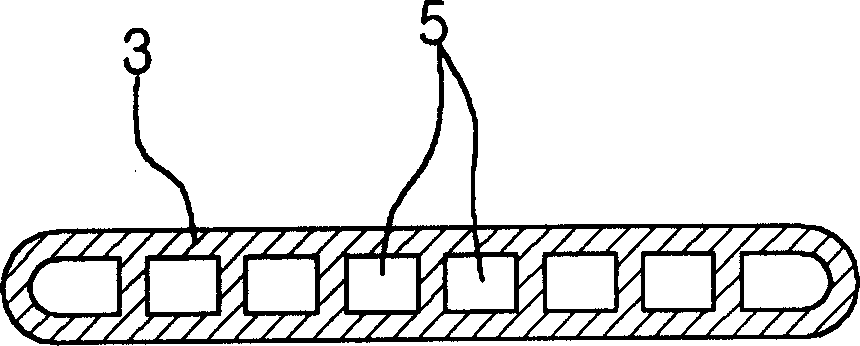

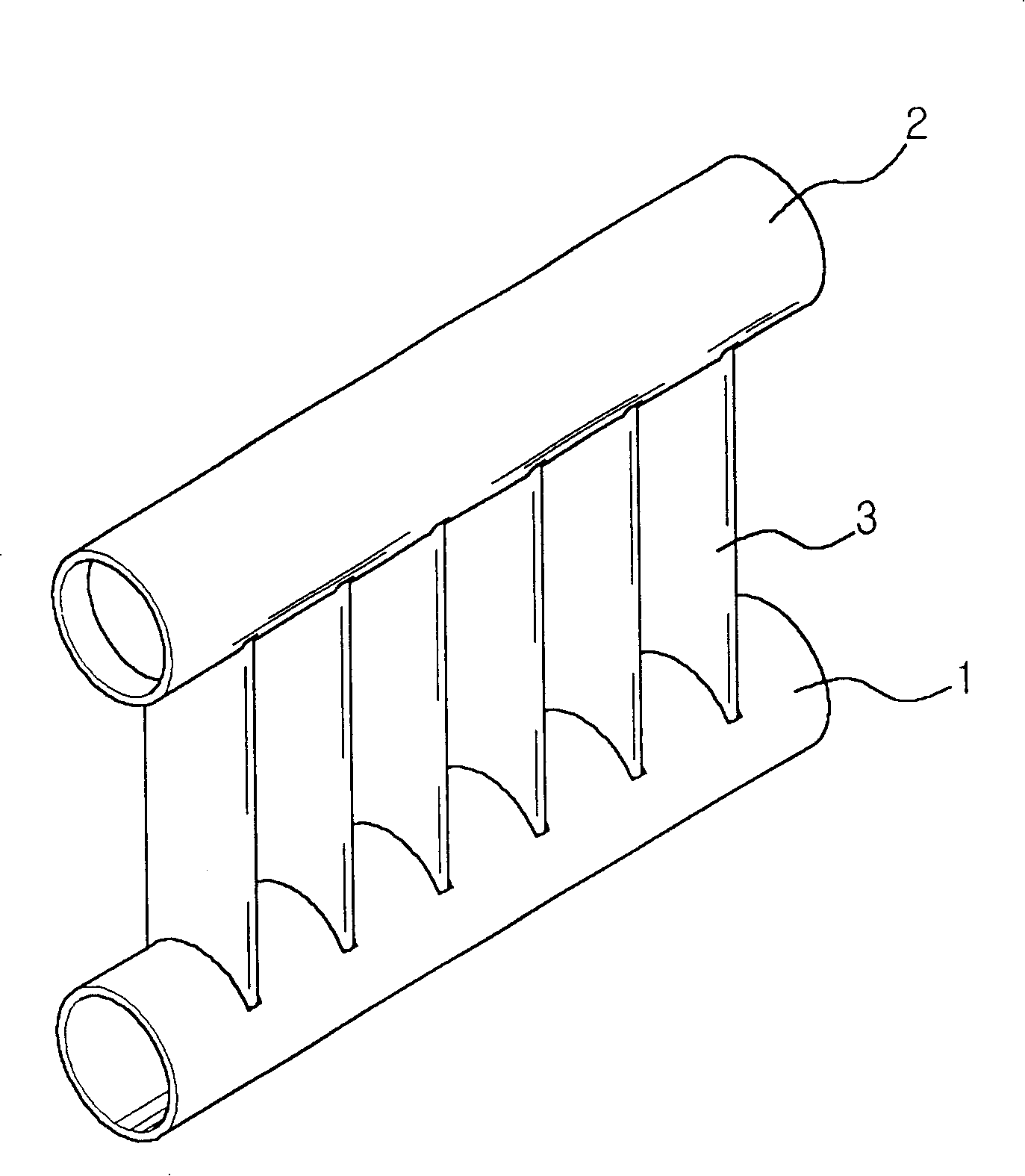

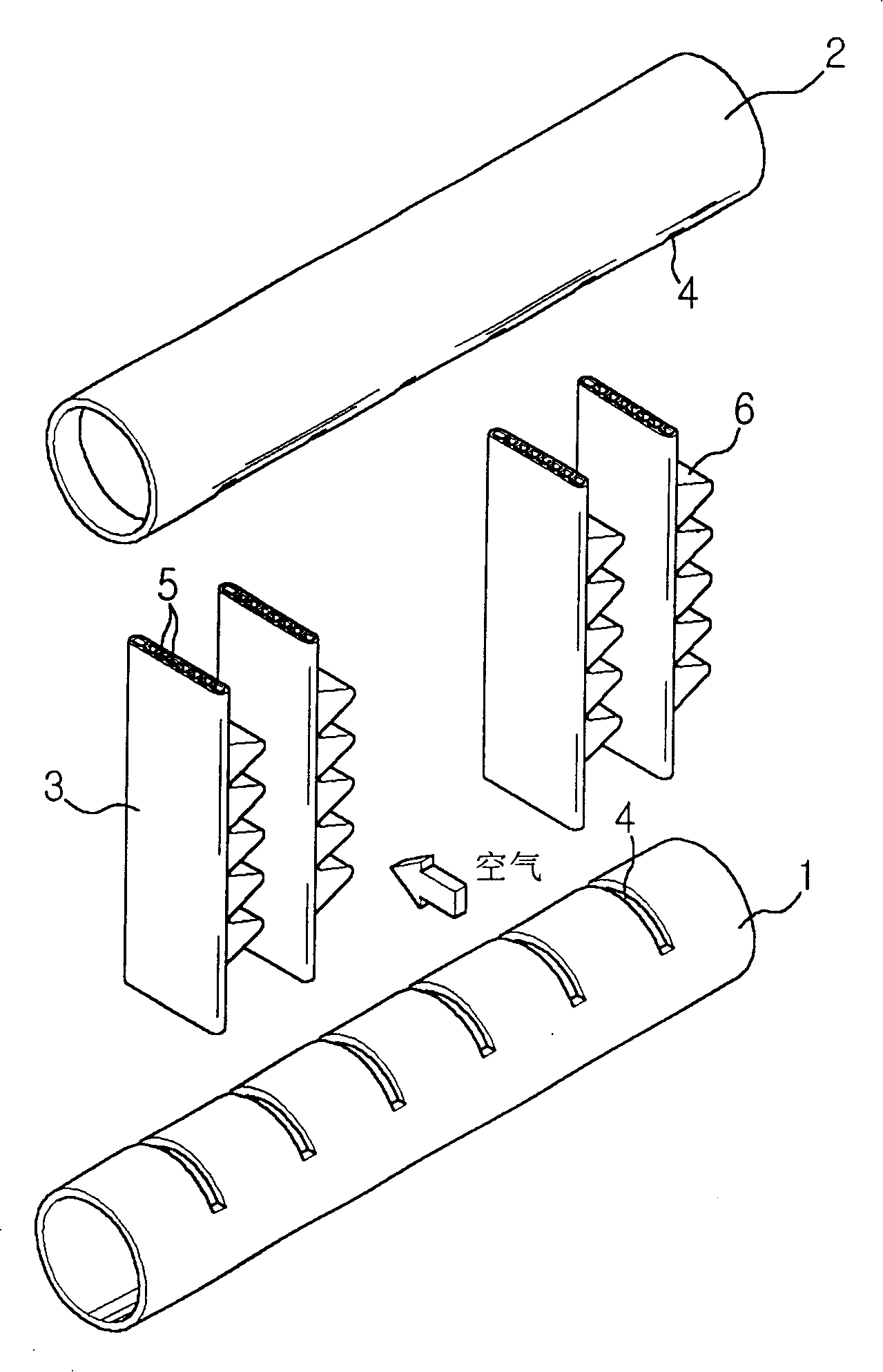

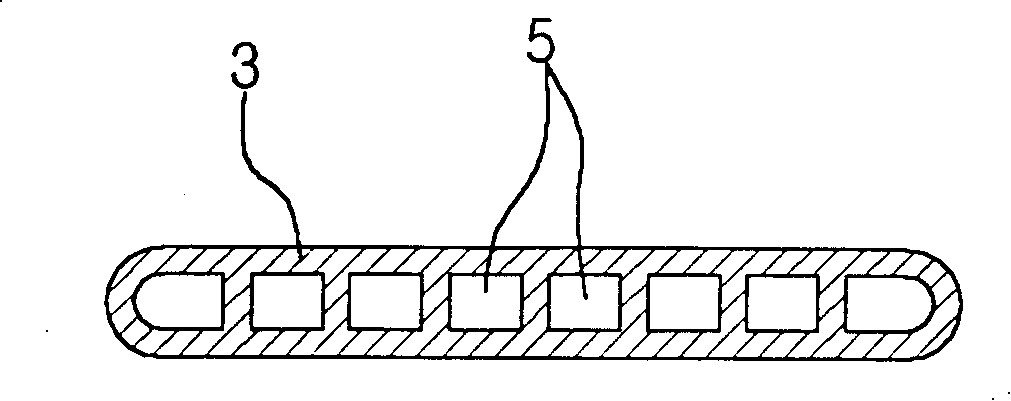

Superfine pipeline heat exchanger

InactiveCN1611902ASmooth dischargeReduce air pressure lossCondensate preventionStationary conduit assembliesEngineeringHeat sink

This invention relates to a kind of arrangement structure of cooling fin that can smoothly discharge condensed water that condense on the surface of the cooling fin. The feature of the superthin tube heat-exchanger is that hollow level header can make refrigerant flow through; several refrigerant tubes insert in the level header, so it can distribute the refrigerant that flow in the level header; cooling fin that set between the vertical refrigerant tubes said above. In this heat exchanger, several cooling fins are fixed between the above vertical refrigerant tubes with a certain distance. This invention can discharge the condensed water flow from top of the refrigerant tube more easy. This invention can achieve another effect that it can reduce the air pressure losing of the flowing air on the effect of the fan, and prevent the heat reducing.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

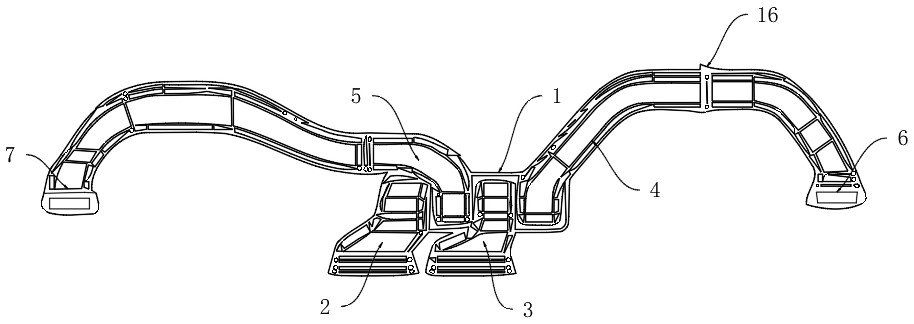

Wind tunnel

The invention relates to closed-circuit tunnels used for aerodynamic researches, sportsmen-parachutists training and other purposes. The inventive closed-circuit tunnel comprises a confuser, a working area, a diffuser, one or several return channels, a blower unit and turning bends having different flow deflection angle, wherein the bend having the smaller flow deflection angle is placed in a high-speed flow cross-section, whereas the bend having the greater flow deflection angle is arranged in a low flow speed cross-section. In a preferred embodiment, the tunnel comprises a first turning bend containing one turning gut for turning the airflow at 60 degrees, a second turning bend containing two turning guts for turning the airflow at 120 degrees, and a third turning bend containing three turning guts for turning the airflow at 180 degrees. The invention makes it possible to reduce air pressure losses, the drive power and a specific amount of metal per structure.

Owner:PETRUK VICTOR

A PVC ultra-permeable film calendering and winding device

The invention discloses a novel PVC super-transparent thin film coiling device. The Novel PVC super-transparent thin film coiling device comprises a rack, rollers connected to the two ends of the rack correspondingly, lifting tables symmetrically arranged on the two sides of the rollers, and cross beams located above the rollers. Pressurization rollers are arranged above the rollers. Two bearing seats are symmetrically arranged at the two ends of the rollers. A first synchronizing shaft and a second synchronizing shaft are connected to the two bearing seats correspondingly in a sleeved mode. The ends, far away from the rollers, of the two bearing seats are symmetrically provided with a first swing device and a second swing device correspondingly. A first holding frame and a second holding frame are symmetrically connected to the first synchronizing shaft and the second synchronizing shaft through the first swing device and the second swing device correspondingly. A sliding rail is arranged between a first synchronous gear and a bear and slidably connected with an L-shaped hook plate. Lifting devices are symmetrically arranged on the side, far away from the L-shaped hook plate, of the rack and are connected with pipe hook plates. One sides of the lifting devices are provided with lever mechanisms. An inclined plate with a limiting switch is arranged between the L-shaped hook plate and the pipe hook plates. A first cylinder is arranged above the inclined plate. A controller is arranged above the first cylinder.

Owner:徐立军

Regenerative air dryer

ActiveUS8999045B2Simplified air pathsReduces external pipingGas treatmentIsotope separationDesiccantAir dryer

A regenerative air drying system including at least one dryer module including a housing having a inlet air passage, an outlet air passage, and a wash air passage. The air dryer system further includes a desiccant canister mounted to the housing and in communication with the inlet, outlet, and exhaust air passages, and a single controllable valve selectively moveable between a first position and a second position, wherein the single controllable valve, when in the first position, forms a supply air flow path from the inlet air passage, through the desiccant canister in a first direction, and to the outlet air passage, and when in the second position, forms a wash air path from the outlet air passage, through the desiccant canister in a direction opposite the first direction, and to the exhaust air passage.

Owner:SUBURBAN MFG

Tubular air cleaner for internal combustion engine

ActiveUS10753319B2Increase resistanceReduce air pressure lossGas treatmentNon-fuel substance addition to fuelEngineeringInternal combustion engine

A tubular air cleaner for an internal combustion engine includes a housing and a filter element. The housing includes a case and a cap coupled to the case in a removable manner. The cap includes a cap body and an adsorbent filter assembly. The adsorbent filter assembly includes a planar adsorbent filter, which adsorbs evaporated fuel of the internal combustion engine, and a fixing portion. The adsorbent filter is located at an inner side of the filter element and extends in an axial direction of the filter element. The inner surface of the filter element is spaced apart from each of opposite planes of the adsorbent filter by a gap that allows air to reach an outlet without passing through the adsorbent filter.

Owner:TOYOTA BOSHOKU KK

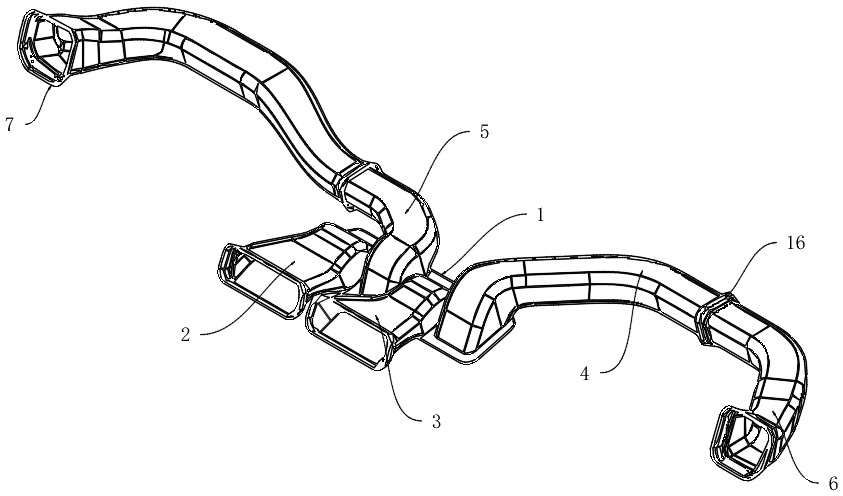

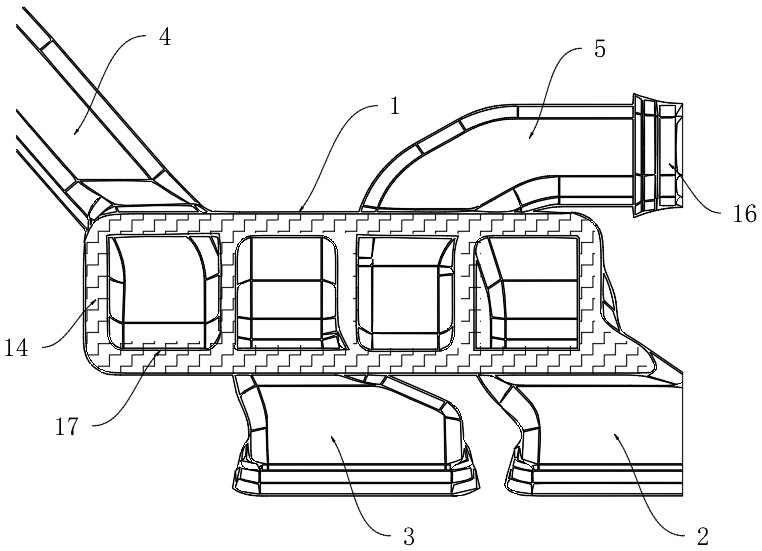

Air conditioner face blowing air pipe for pickup truck

PendingCN113682111AReduce design difficultyImprove design efficiencyAir-treating devicesVehicle heating/cooling devicesAir volumeEngineering

The invention discloses an air conditioner face blowing air pipe for a pickup truck, relates to the technical field of automobile refrigeration, and aims to solve problems that in the actual use of an existing air conditioner face blowing air pipe, a mixed flow transition section is generally connected to an outlet of an air conditioner box, air blown by an air conditioner is sent to different air outlets in four positions through different branches. Therefore, in the design process, in order to balance air volume distribution, a large amount of design optimization work needs to be conducted on different branch results and pipe type thicknesses, and large design errors always exist when the design target of air volume distribution is achieved. A first face blowing air pipe and a second face blowing air pipe are arranged at the upper end of an air pipe connecting piece, a first side face blowing air pipe is arranged on one side of the second face blowing air pipe, and a second side face blowing air pipe is arranged between the first face blowing air pipe and the second face blowing air pipe. A first side face blowing air pipe opening is formed in one end of the first side face blowing air pipe.

Owner:JIANGLING MOTORS

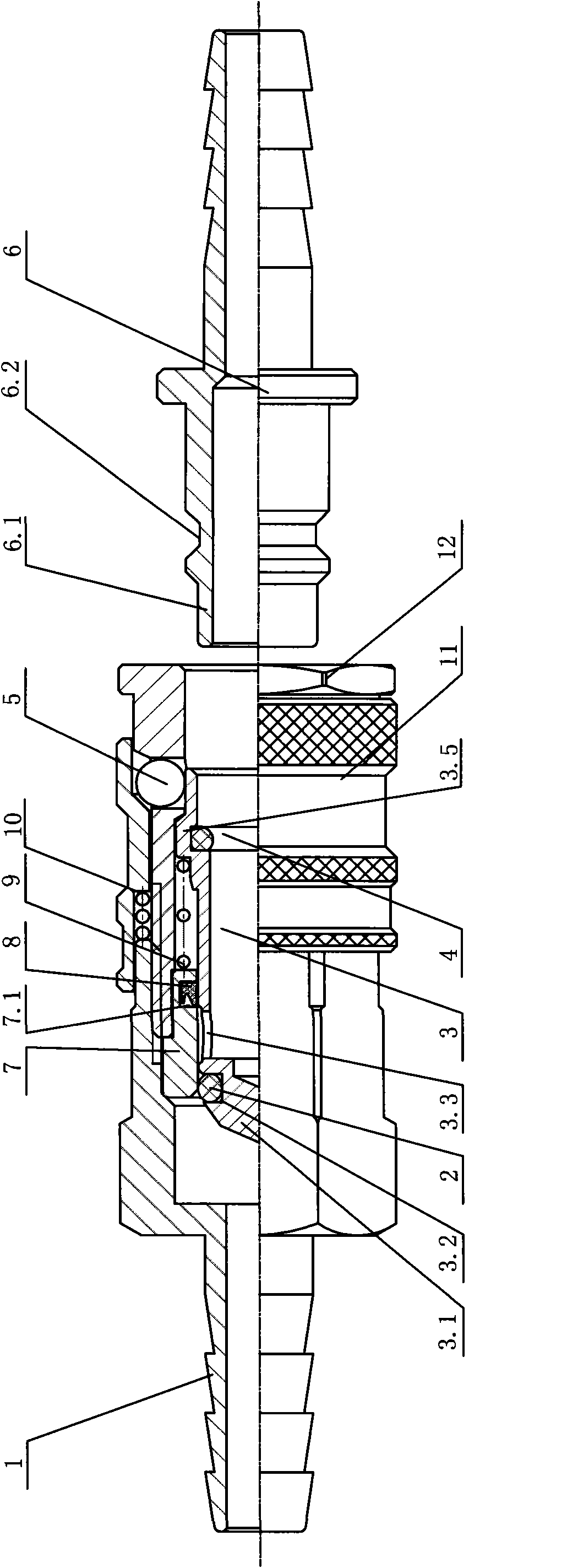

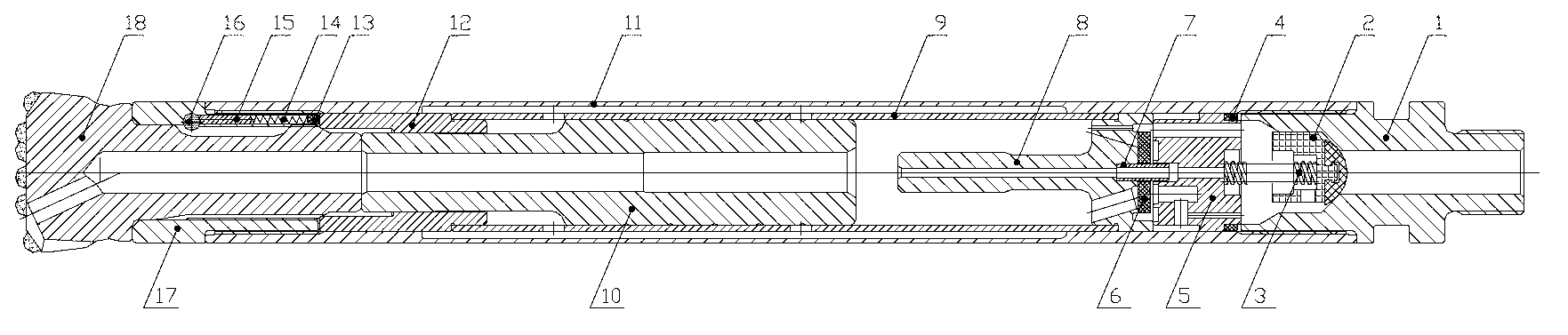

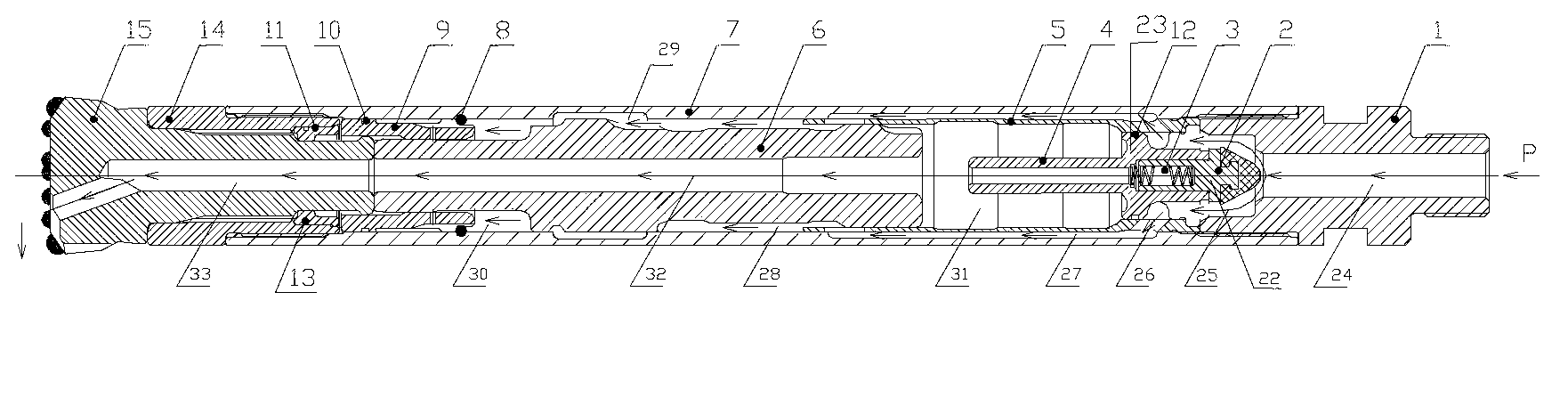

Middle-low air pressure down-hole hammer

Provided is a middle-low air pressure down-hole hammer. The middle-low air pressure down-hole hammer comprises a back joint, a check valve, an air-distribution rod, a piston, an internal cylinder, an outer casing pipe, a clamping ring, a guide sleeve, a plug, a first spring, a rubber stick, a lateral pin, a pin-hanging type drill and a pin-hanging type front joint. The check valve is a one-way valve and provided with a valve seat and a second spring. The piston is a long-and-thin-shaped piston with a hole path. The air-distribution rod and an air inlet seat at the back end of the check valve are of an integrated structure. The internal cylinder is placed outside the air-distribution rod and the piston. In the process of piston motion, the matched end of the piston and the air-distribution rod is in the internal cylinder all the time, a cavity is formed between part of the piston and the outer casing pipe, and other parts of the piston are matched with the internal cylinder. According to the middle-low air pressure down-hole hammer, the air distribution rod and the valve seat of the check valve are integrated, the structure is simple, the functions of locating, vibration damping and air suction can be achieved, and stability and reliability are achieved in the process of work. Contact portions of the piston and the internal cylinder are reduced, and therefore the internal cylinder is wear-resisting, and working pressure ranges of the hammer are wide.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Cylindrical air cleaner for internal combustion engine

ActiveUS10589211B2Increase resistanceReduce air pressure lossGas treatmentDispersed particle filtrationEngineeringInternal combustion engine

A cylindrical air cleaner for an internal combustion engine includes a cylindrical housing including a circumferential wall having an inlet, a top wall having an outlet, and a bottom wall opposed to the top wall. There is a tubular filter element accommodated in the housing. A planar adsorbent filter to adsorb evaporated fuel of the internal combustion engine is located at an inner side of the filter element and extends in an axial direction of the filter element. The adsorbent filter includes a basal end portion fixed to an inner surface of the bottom wall. An inner surface of the filter element is spaced apart from each of opposite planes of the adsorbent filter by a gap that allows air to reach the outlet without passing through the adsorbent filter.

Owner:TOYOTA BOSHOKU KK

Superfine pipeline heat exchanger

InactiveCN100398971CSmooth dischargeReduce air pressure lossCondensate preventionStationary conduit assembliesEngineeringHeat sink

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com