Superfine pipeline heat exchanger

A heat exchanger and pipeline technology, applied in the field of branch pipe structure, can solve the problems of poor heat exchange performance, large flow resistance, ineffective heat exchange between flowing air and heat sink 6, etc., so as to reduce air pressure loss and prevent heat conduction. volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

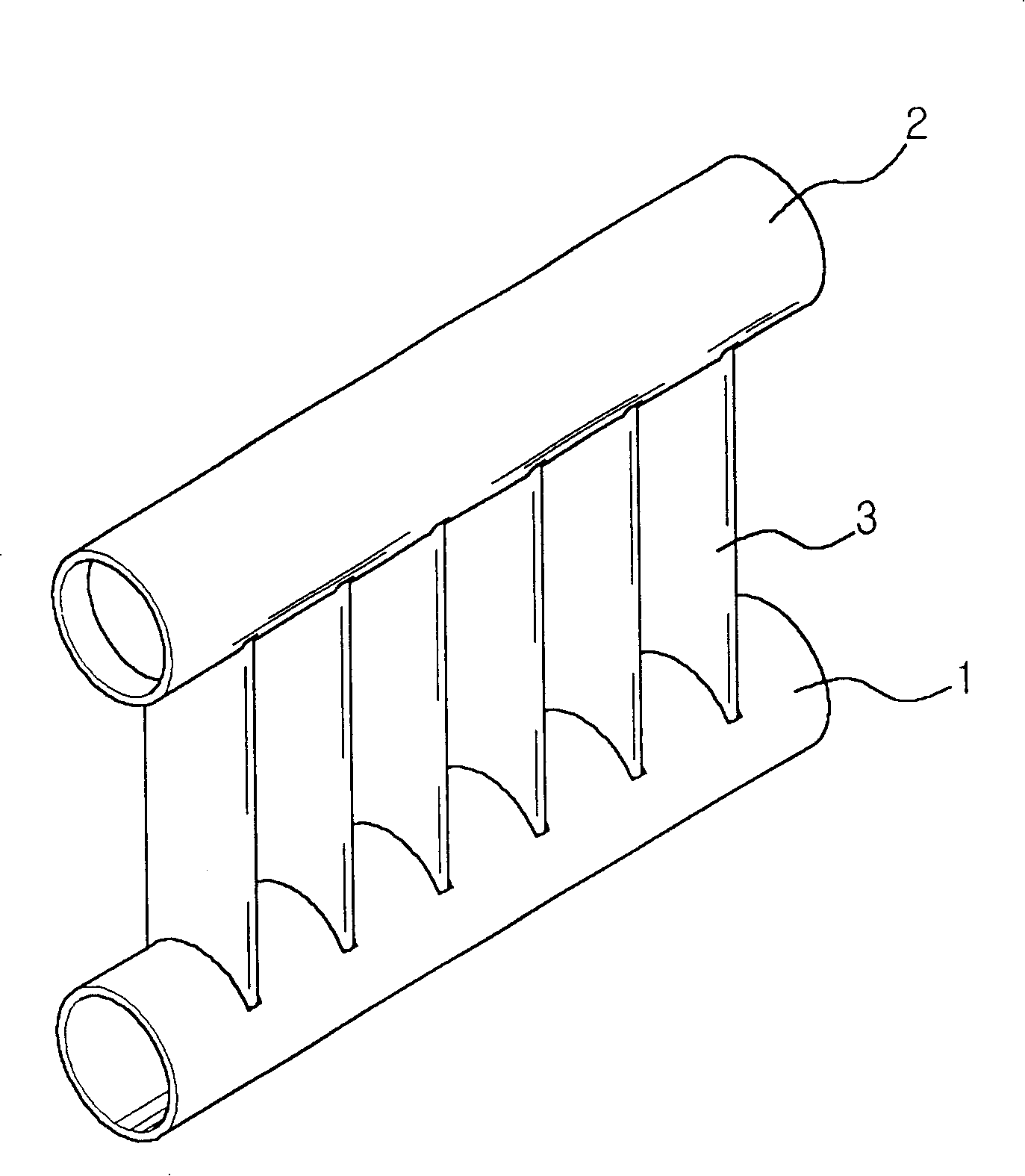

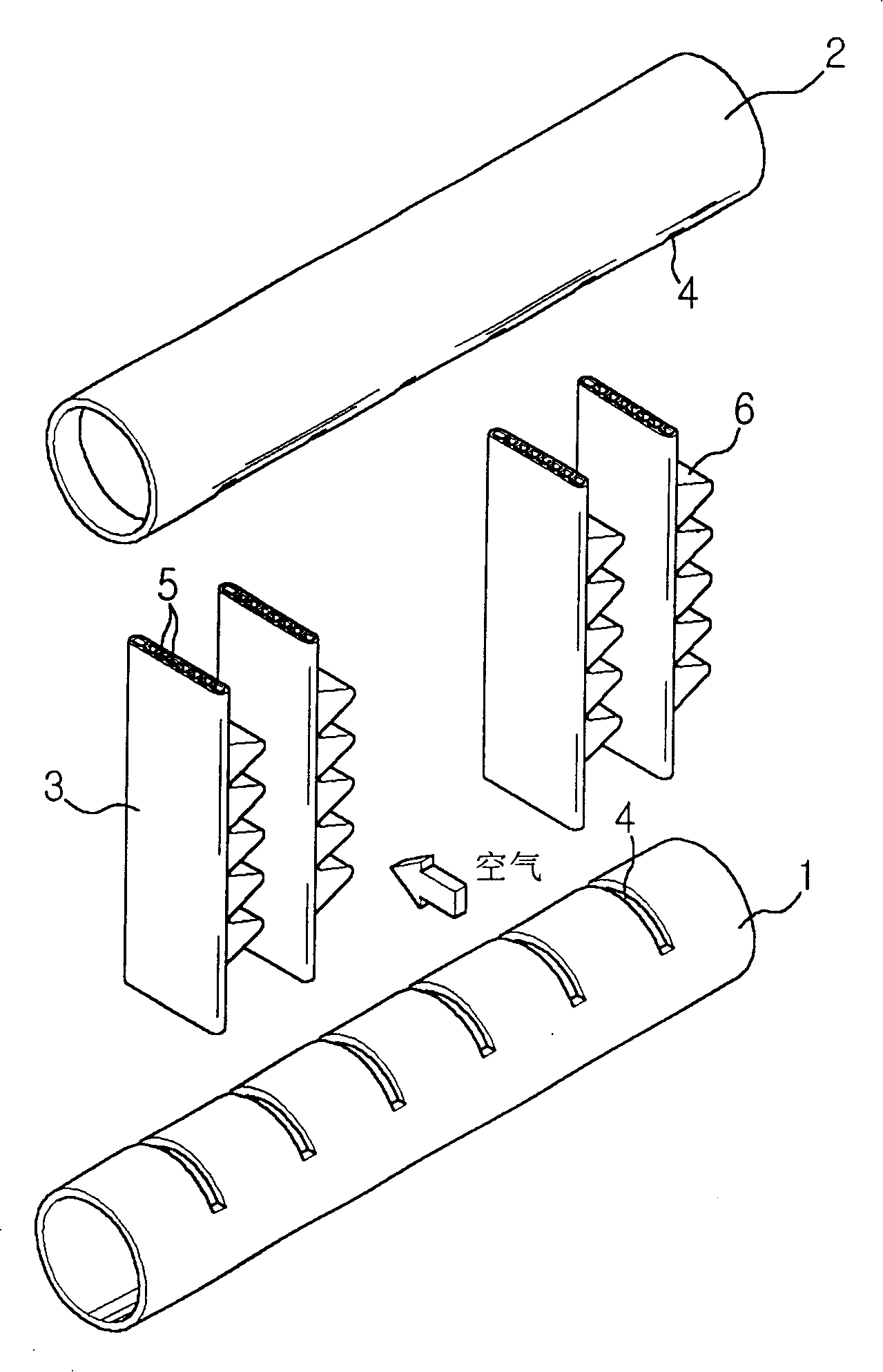

[0028] Embodiments of the ultra-fine tube heat exchanger of the present invention will be described in more detail below with reference to the accompanying drawings.

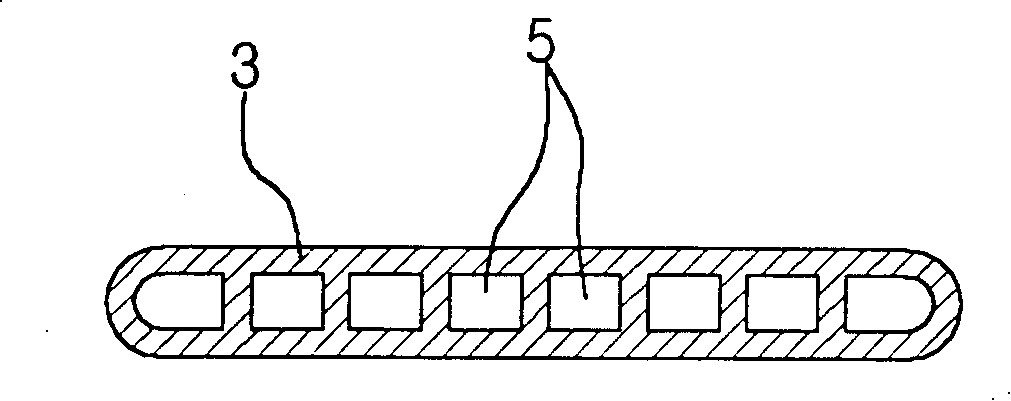

[0029] Figure 5a It is a side view of the state in which several cooling fins are installed on the branch pipe in the present invention; Figure 5b is a cross-sectional view of a branch pipe of the present invention; Figure 6 It is a view of the discharge condition of condensed water in the present invention.

[0030] With reference to the accompanying drawings, it can be known that, unlike the prior art structure in which only a single cooling fin is installed on the branch pipe 3, in the present invention, several cooling fins 6a, 6b are installed on the branch pipe 3 at certain intervals. , 6c. The condensed water generated on the surface of each cooling fin will flow down along the direction of gravity, and the condensed water 7 will gather at the lowermost end of each cooling fin, and then under the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com