Multi-stage vacuum suction type dejecta collection system and dejecta collection method thereof

A technology of vacuum suction and defecation, which is applied in waterway systems, flushing equipment with water tanks, sanitary equipment for toilets, etc. It can solve problems such as waiting or delaying work, inconvenience for users, and long sewage pipelines, etc. Efficiency, reducing air pressure loss, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

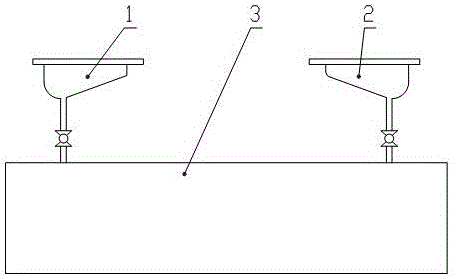

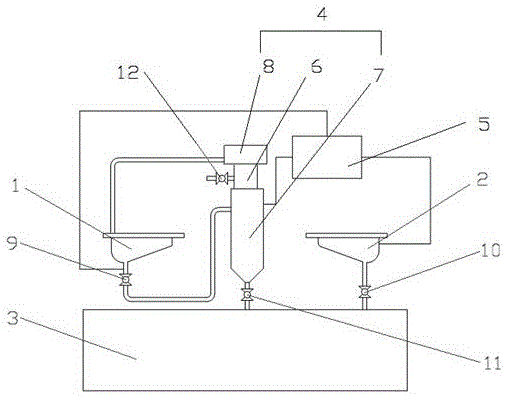

[0016] figure 2 Show a specific embodiment of a multi-stage vacuum suction type feces collection system of the present invention: a multi-stage vacuum suction type feces collection system, including a first toilet 1, a second toilet 2 and a dirt box 3, the first toilet 1 and the second toilet 2 are connected with the dirt tank 3, and the connection between the first toilet 1 and the second toilet 2 and the dirt tank 3 is respectively provided with a first drain valve 9 and a second drain valve 10, wherein the first drain valve At least one vacuum unit 4 is arranged between a closet 1 and the dirt tank 3, and the vacuum unit 4 includes a storage tank 7 and a vacuum generator, wherein the vacuum generator 6 is connected to the storage tank 7, and the storage tank 7 is connected to the sewage tank 3 , the first toilet 1 is connected, the connection between the storage tank 7 and the dirt tank 3 is provided with a third drain valve 11, the first toilet 1 and the second toilet 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com