Hollow fiber tube and aeration oxygenation device formed by hollow fiber tube

A fiber tube and hollow technology, which is applied in the field of aeration and oxygenation devices, can solve the problems of shortening the service life of aeration and oxygenation devices, aging of the operating time, and easy breeding of microorganisms, etc. Strong air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A hollow fiber tube, which is woven from ultra-fine fiber filaments with a fineness of 0.008D; the hollow fiber tube wall obtained by weaving has a number of flexible holes, and the flexible holes are arranged in parallel between the fiber filaments during the weaving process. / or formed by crossing and overlapping, and the diameter of the flexible hole can vary between 1-10 μm with the difference of wind pressure. The hollow fiber tube has an outer diameter of 1.2 mm, an inner diameter of 0.6 mm, and a wall thickness of 0.3 mm. The superfine fiber is made of polyethylene and polypropylene with elastic modulus less than 1000MPa.

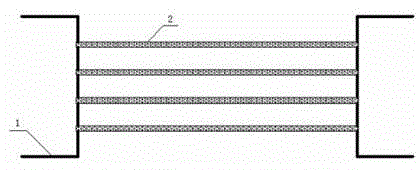

[0028] Such as figure 1 As shown, an aeration and oxygenation device composed of the above-mentioned hollow fiber tubes includes two air intake pipes 1 and four hollow fiber pipes 2 arranged in parallel between the two air intake pipes 1, and the two air intake pipes 1 The tube wall of the tube is provided with holes, and the two ends of the...

Embodiment 2

[0031] A hollow fiber tube, which is woven from a fiber bundle composed of 280 superfine fiber filaments with a fineness of 0.002D; the hollow fiber tube wall obtained by weaving has a number of flexible holes, flexible holes It is formed by the parallel arrangement and / or cross-overlapping of fiber bundles during the weaving process, and the diameter of the flexible hole can vary between 15-25 μm with the wind pressure. The hollow fiber tube has an outer diameter of 1.6 mm, an inner diameter of 1.0 mm, and a wall thickness of 0.3 mm. The superfine fiber is made of cellulose acetate and polyvinyl chloride with elastic modulus less than 1000MPa.

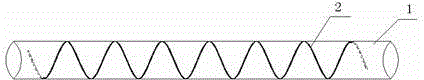

[0032] Such as figure 2 Shown, a kind of aeration and oxygenation device that is made of above-mentioned hollow fiber tube, it comprises an air inlet pipe 1 and a hollow fiber pipe 2, has a hole on the pipe wall at one end of air inlet pipe 1, and one end of hollow fiber pipe 2 is from air inlet pipe 1 passes through the hole from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com