Pneumatic quick connector

A fast, female joint technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of cumbersome on and off operations, large air pressure loss, and small gas flow area, so as to solve the problems of more pressure loss and reduced air pressure Loss, the effect of preventing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

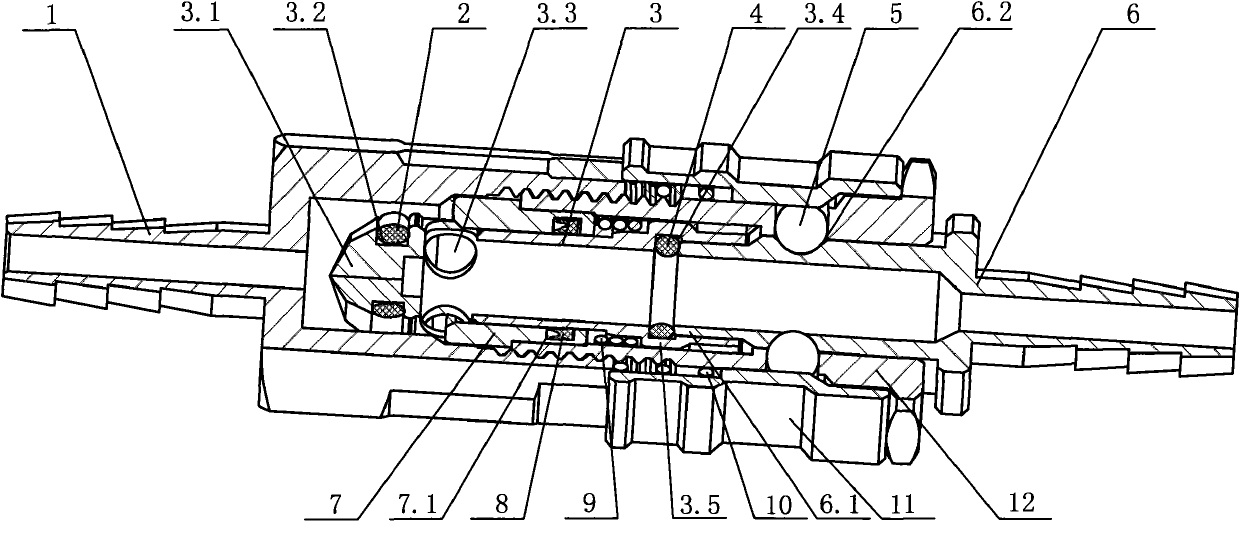

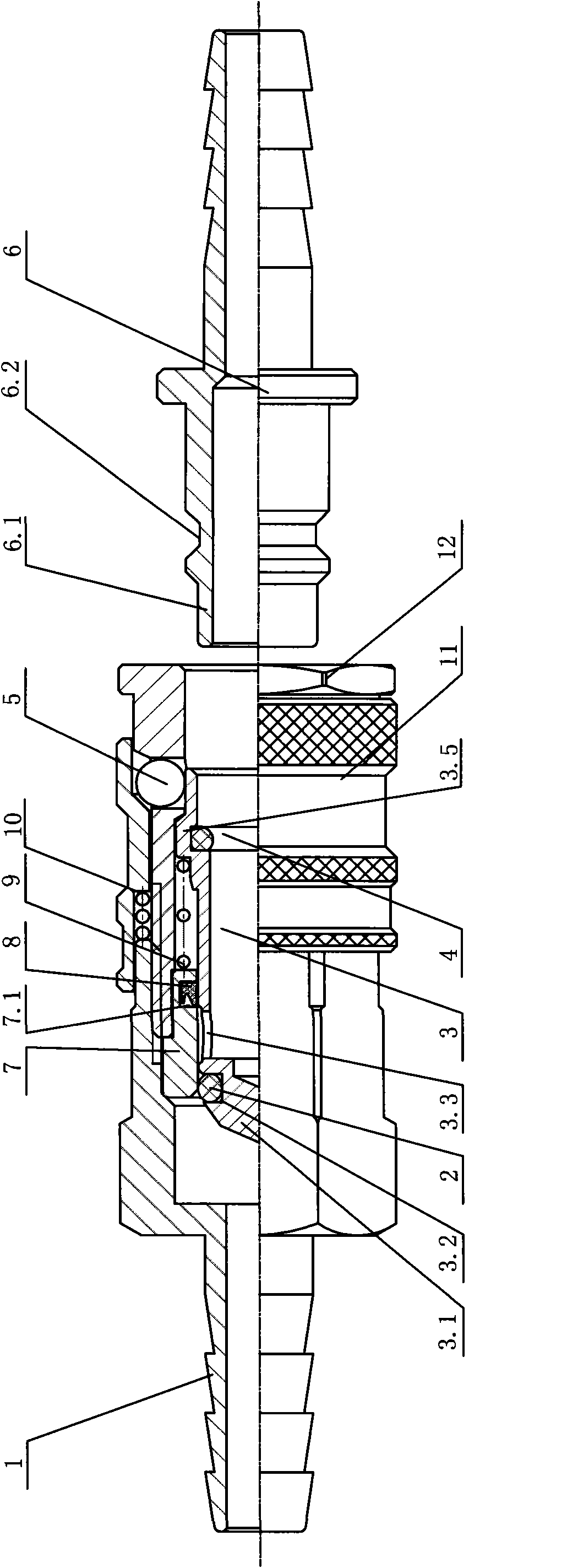

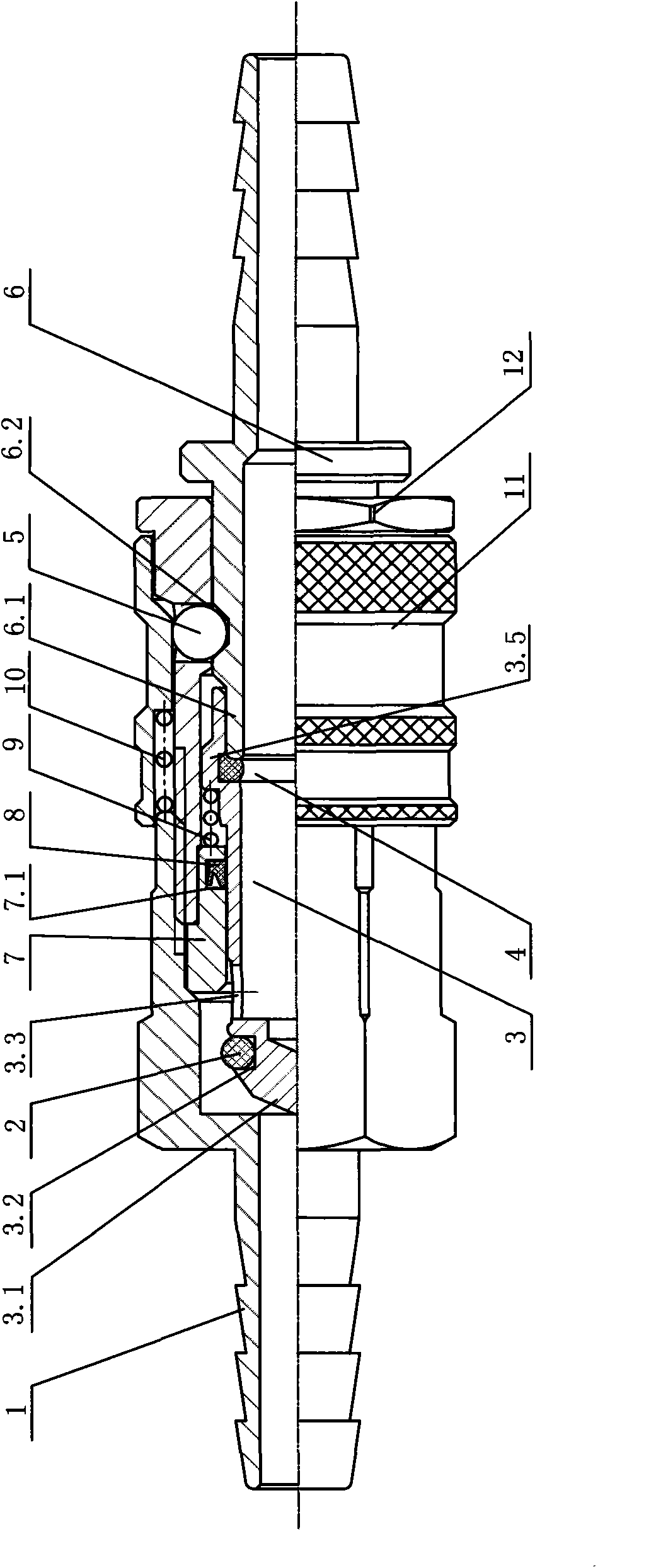

[0014] Such as figure 1 , figure 2 As shown, the present invention is a pneumatic quick joint, which includes a female joint 1 connected to the air inlet pipe and a male joint 6 connected to the air outlet pipe, and a locking sleeve 12 is fixedly installed on the air outlet end of the female joint 1. The locking sleeve 12 is connected with the female joint 1 through threads. A guide sleeve 7 is interposed between the locking sleeve 12 and the inner wall of the female joint 1 , and a check valve core 3 that can move back and forth is movably interspersed in the inner hole of the guide sleeve 7 . The inner wall of the guide sleeve 7 is provided with a groove 7.1, and a Y-shaped sealing ring 8 is embedded in it. When the check valve core 3 is inserted into the inner hole of the guide sleeve 7, the Y-shaped sealing ring 8 is more stable than other sealing rings. The frictional force is smaller, and it is not easy to damage or fall off, which facilitates the installation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com