Large-diameter pipe fitting plastic coating equipment and plastic coating method

A large-diameter pipe and large-diameter technology, which is applied in the field of plastic coating equipment for large-diameter pipe fittings, can solve problems such as uneven spraying, poor plastic coating effect, and dust residue, and achieve uniform spraying, high efficiency, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

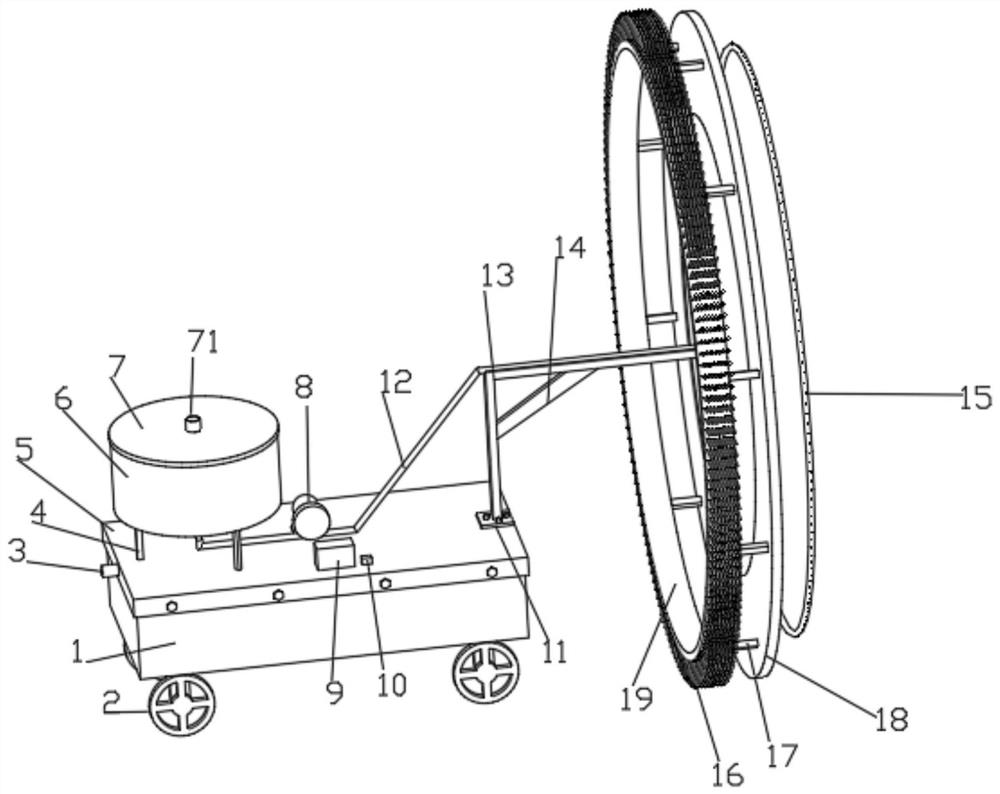

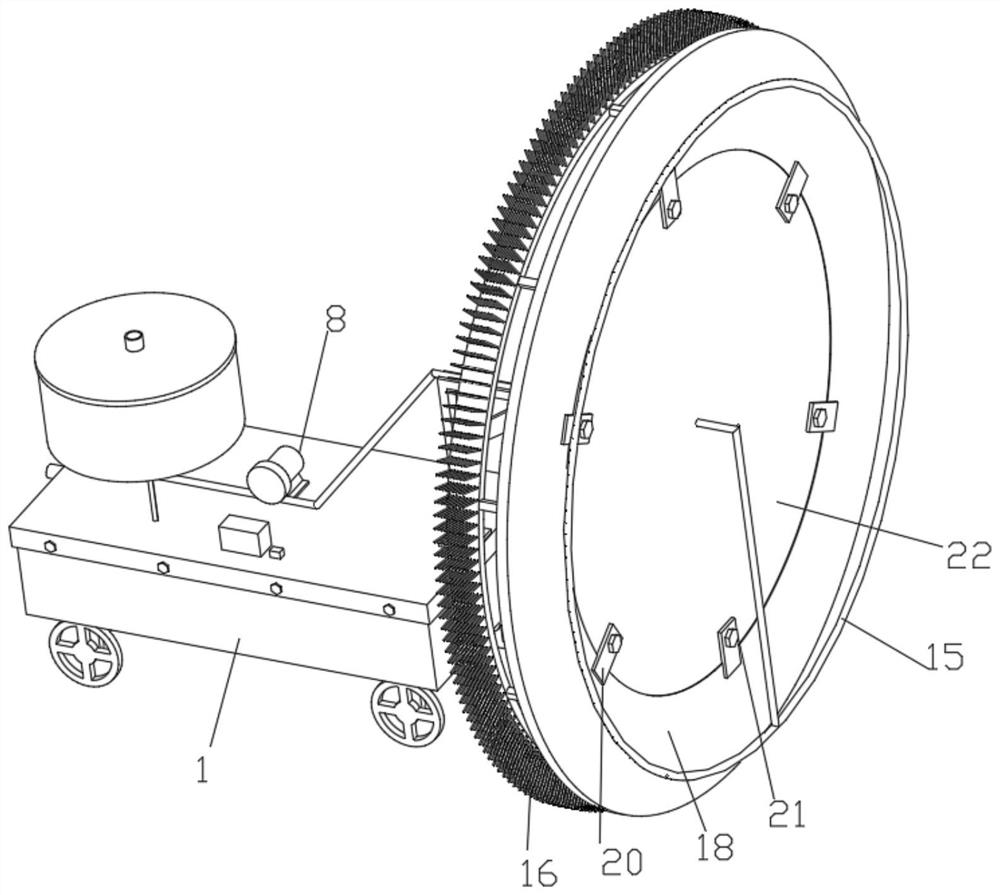

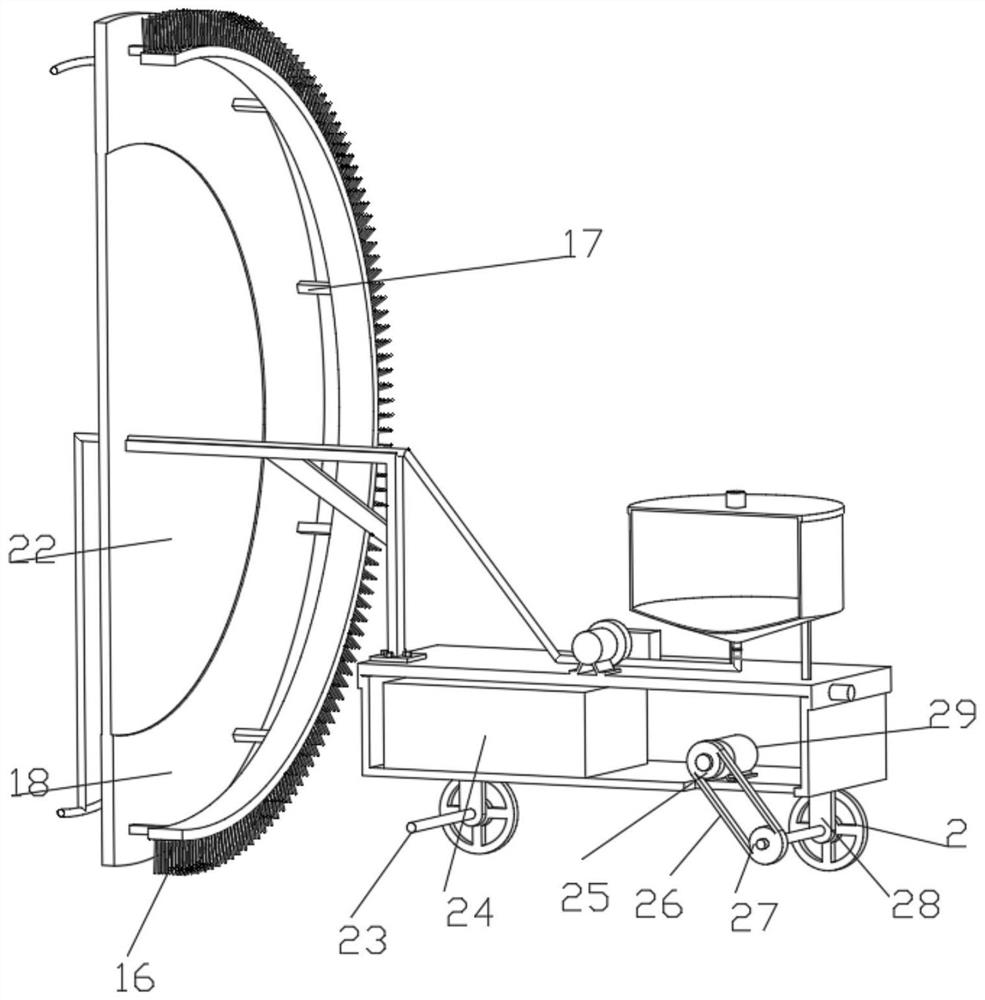

[0033] A kind of plastic coating equipment for large-diameter pipe fittings in this embodiment includes a car body 1, a camera 3, a liquid pump 8, a controller 9, a signal receiver 10 and a drive motor 29, and the bottom of the car body 1 is symmetrically fixedly connected with legs 28, Support leg 28 is connected with rotating shaft 23 by the bearing that is fixedly connected, and the outer end of rotating shaft 23 is fixedly connected with roller 2, and left end rotating shaft 23 is fixedly connected with driven pulley 27, and driven pulley 27 is movably connected with belt 26, and belt 26 is on the car. Rotate in the through hole provided at the bottom of the body 1, the battery 24 and the drive motor 29 are fixedly connected in the car body 1, the output end of the drive motor 29 is fixedly connected with the driving pulley 25, the driving pulley 25 is movably connected with the belt 26, and the top of the car body 1 A car cover 5 is fixedly connected, the left side wall of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap