Power head damper and rotary drilling rig

A shock absorber and power head technology, applied in rotary drilling rigs, springs/shock absorbers, rotary drilling, etc. The thickness of the limit block 10 and other issues can reduce the impact of the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0035] [First Embodiment]

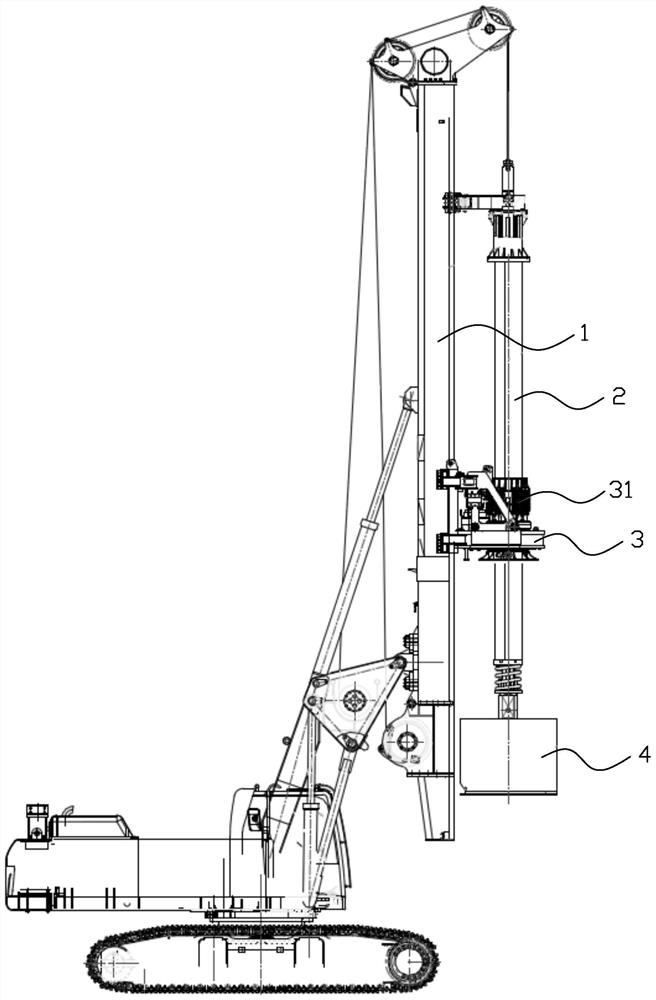

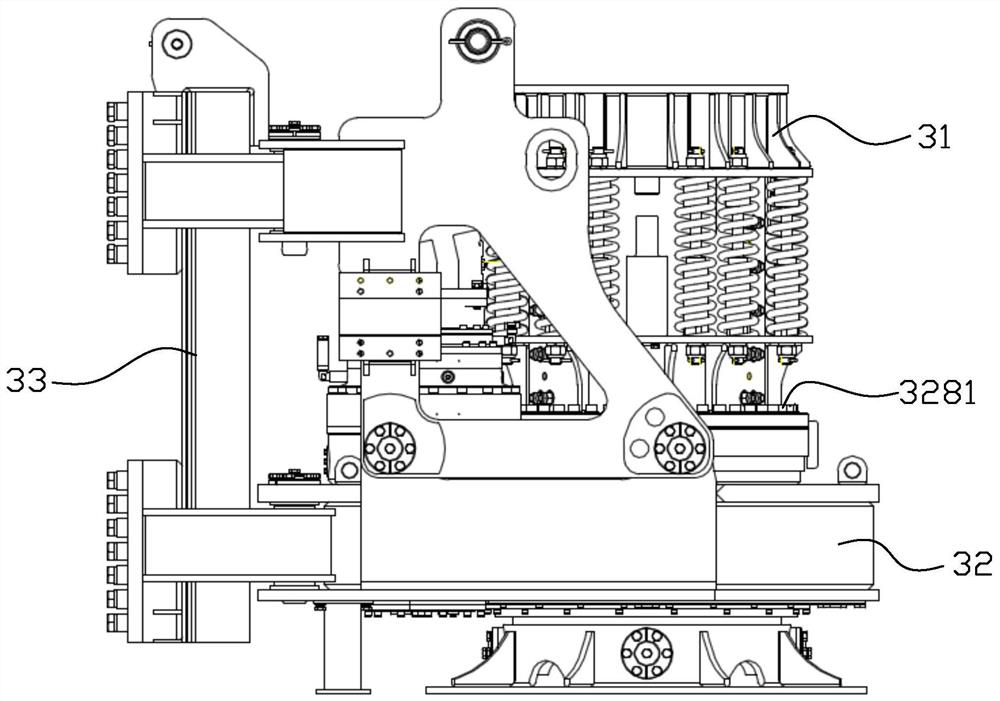

[0036] like figure 1 As shown, the rotary drilling rig includes a main engine and a mast 1, a drill pipe 2, a power head assembly 3 and a drilling tool 4 arranged on the main engine. The bottom of the mast 1 is pivotally connected to the main engine, so that the mast 1 can be opened to a substantially vertical state during construction of the rotary drilling rig, or folded to the main engine during shutdown. The power head assembly 3 is arranged on the mast, and is connected with the main engine through a pressurized oil cylinder or a pressurized hoisting wire rope. The drill rod 2 is connected with the power head assembly 3 to rotate under the driving of the power head assembly 3 . The drilling tool 4 is installed at the bottom of the drill rod 2 and can be driven by the drill rod 2 to perform drilling operations. The main engine is also provided with a cab, a main hoisting device, etc., which are well known to those skilled in the art and will ...

Example

[0055] [Second Embodiment]

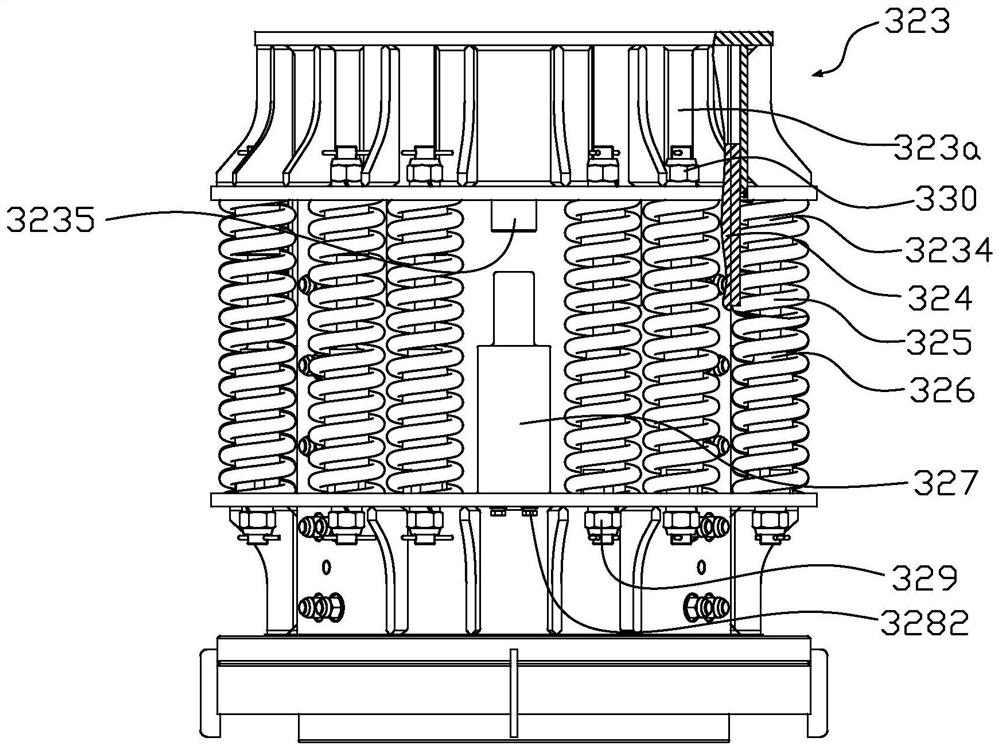

[0056] Please also refer to Figure 13 and Figure 14 , the power head shock absorber 31 of this embodiment is substantially the same as the power head shock absorber 31 of the first embodiment, the difference is that the first guide portion 3231 only has two limiting portions 3231b, and the two limiting portions 3231b are respectively fixed on both sides of the installation port 3232, each limiting portion 3231b and the bracket body 323a of the shock absorber bracket 323 connected to it are roughly “T” shaped, and the space between the two limiting portions 3231b A guide groove 3231c is formed.

[0057] For other structures of this embodiment, please refer to the above-mentioned first embodiment, which will not be repeated here.

[0058] The beneficial effect of the power head shock absorber of the present invention is that the power head shock absorber includes a shock absorber bracket and a drive sleeve, and the shock absorber bracket is slee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap