Perforated metamaterial and perforated plate broadband sound absorption and insulation structure

A technology of perforated plates and metamaterials, applied in the direction of sound-producing equipment, instruments, etc., can solve problems such as poor sound absorption performance, and achieve the effects of improved sound insulation performance, good sound absorption performance, and excellent sound insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

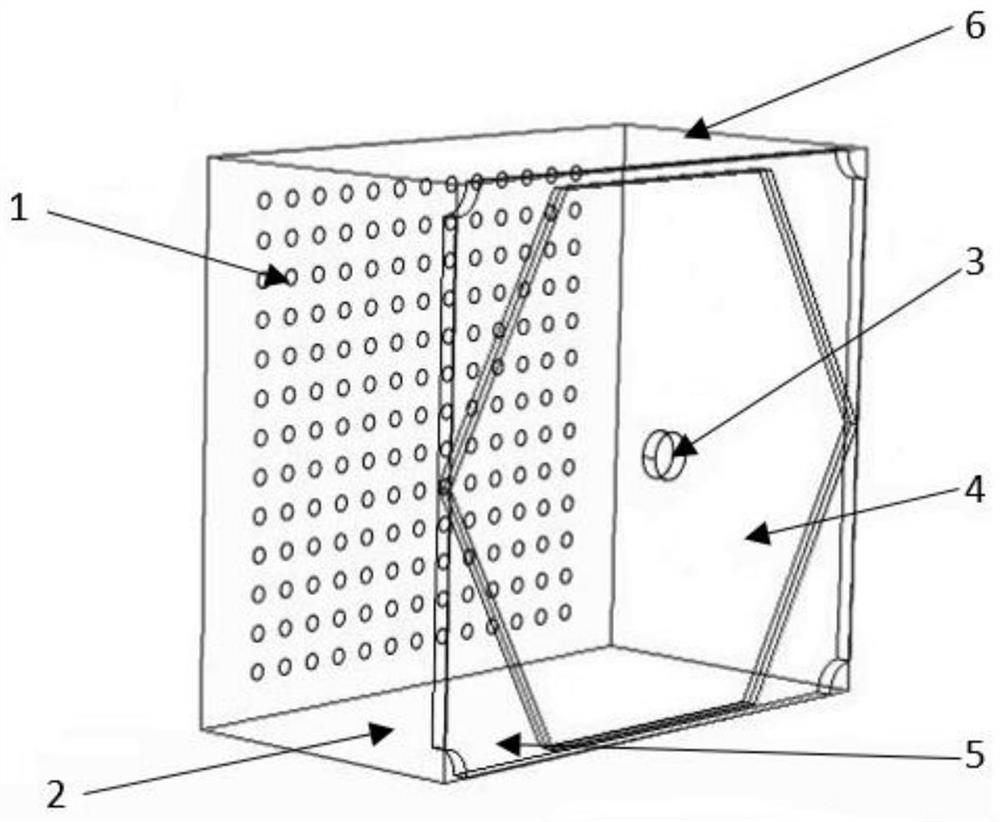

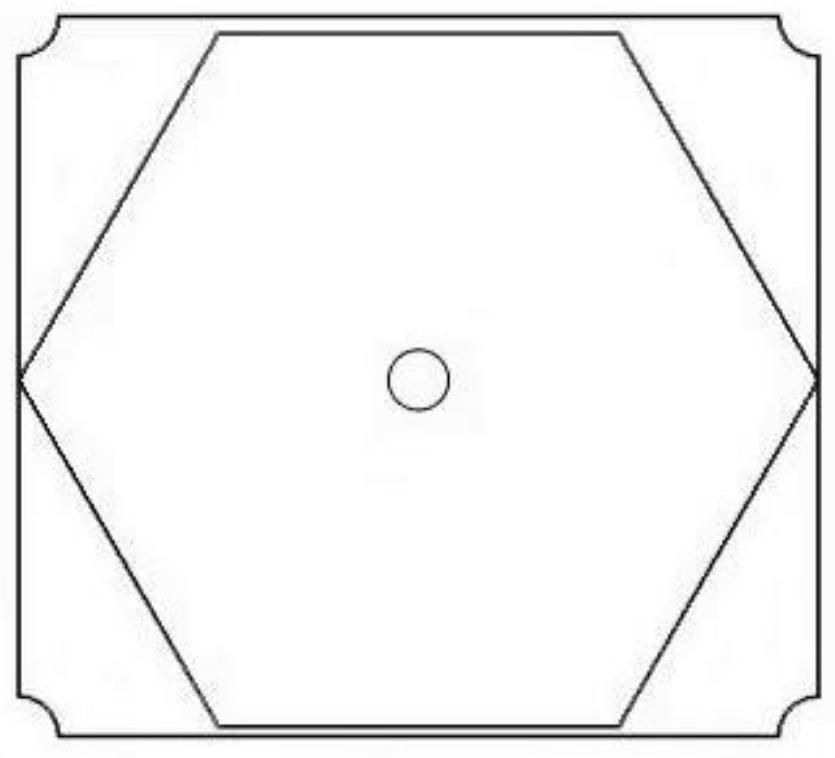

[0026] Specific implementation mode one: see Figure 1-4 This embodiment will be described. The wide-band sound-absorbing and insulating structure of perforated metamaterial and perforated plate described in this embodiment includes perforated plate 1, mass block 3, film 4, perforated frame 5 and four chamber walls 6, which are surrounded by four chamber walls. A frame wall with a square cross section, a perforated plate 1 is installed at the rear of the frame wall, a perforated frame 5 is installed at the front, and a cavity 2 is formed in the middle, a film 4 is fixed inside the perforated frame 5, and the center of the film 4 A mass block 3 is pasted, the film 4 is a regular hexagon, the mass block 3 is a solid cylindrical structure, and the four corners of the perforated frame 5 are opened with quarter circular holes.

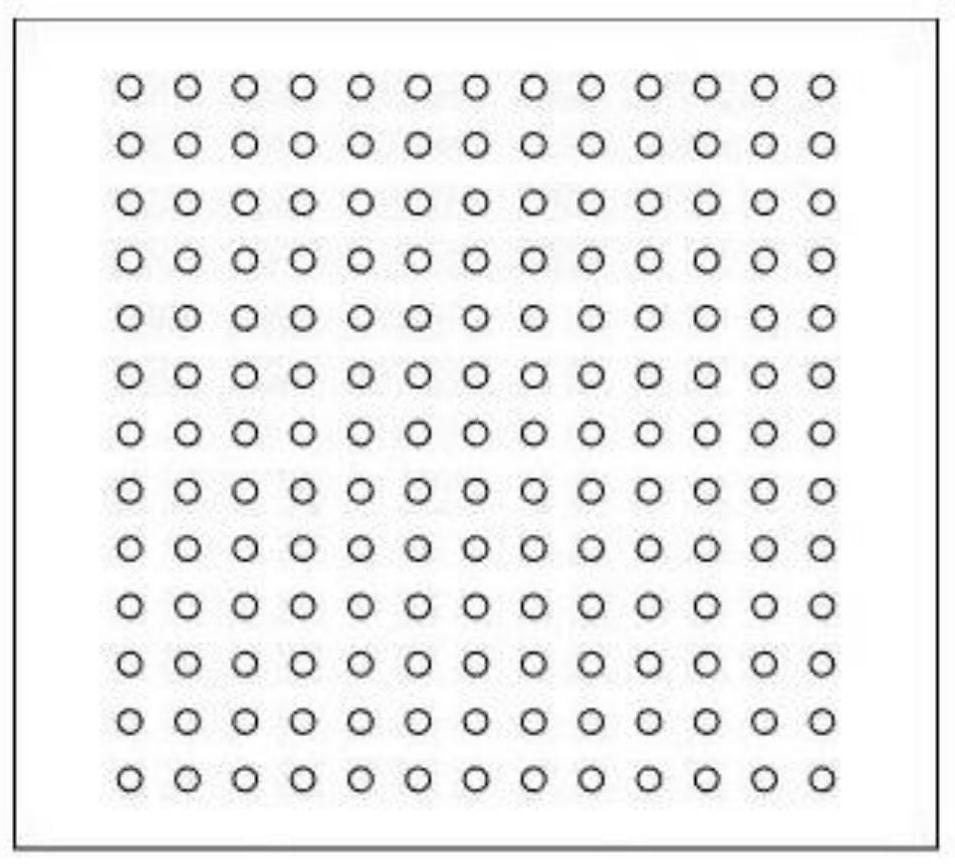

[0027] The perforated plate 1 is square, with a thickness of 0.9mm-2mm, a porosity of 5%-25%, and a perforation diameter of 2-5mm.

[0028] The cavity 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Perforation diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap