Packaging member having surface with excellent liquid repellency

A liquid repellency and component technology, applied in special packaging objects, packaging, wrapping paper, etc., can solve the problem of inability to evaluate the water repellency or liquid repellency of multi-layer films, and achieve excellent liquid repellency and cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

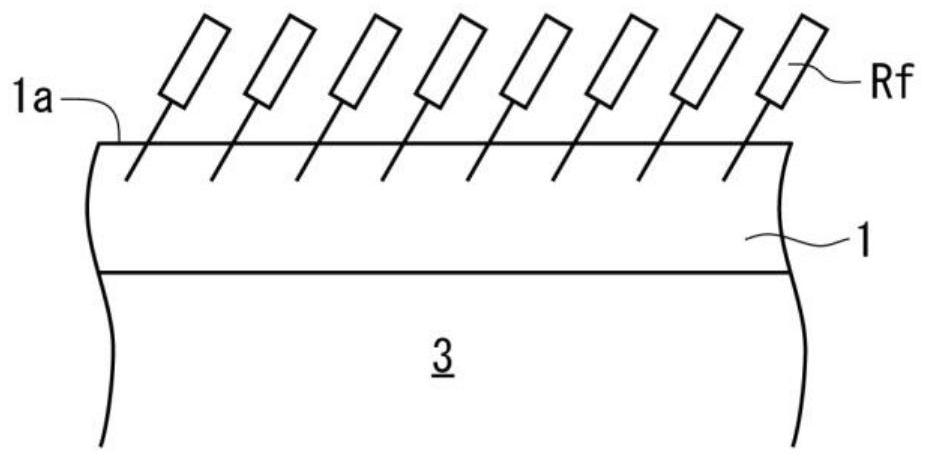

Image

Examples

Embodiment 1

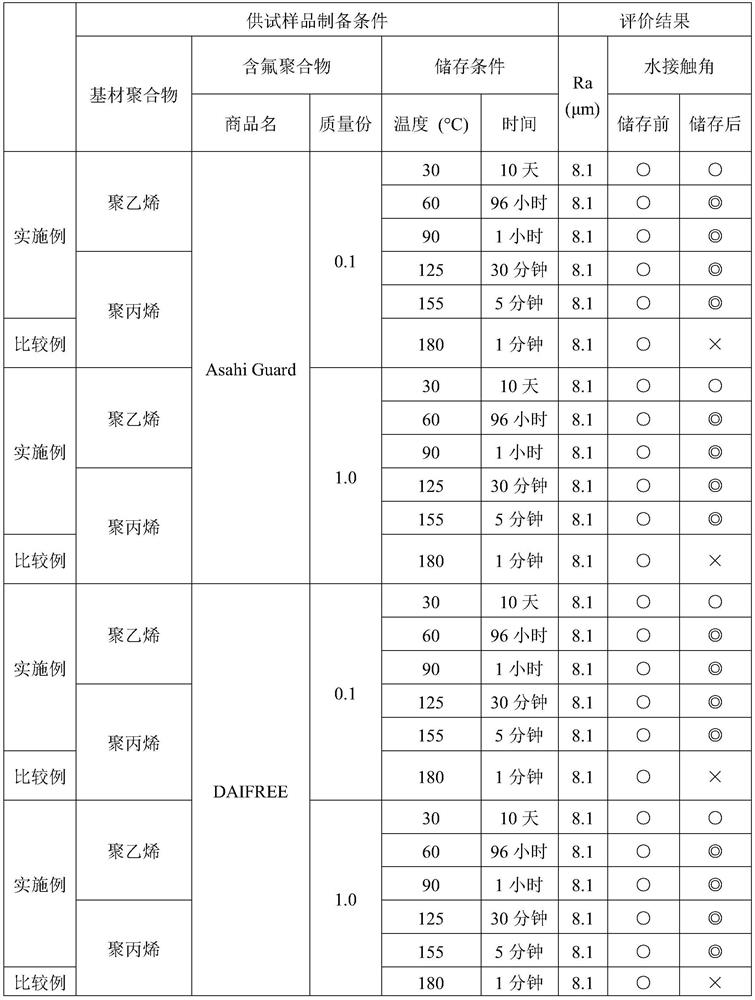

[0088] (Preparation method of test sample)

[0089]A low-density polyethylene resin (manufactured by Japan Polyethylene Co. LJ8041) or polypropylene (J246M manufactured by Prime Polymer Co.) was melt-kneaded by using a kneader at a temperature higher than the melting point of the low-density polyethylene resin or polypropylene.

[0090] The kneaded product was pulverized by using an electric mill and shaped into a granular shape.

[0091] The pellets were heated and pressed by using an electric heat press, and formed into a film having a thickness of 100 μm.

[0092] The film thus formed was dry-laminated on a biaxially stretched PET film having a thickness of 12 μm via an adhesive to obtain a test sample, which was then stored in an electric oven set at a predetermined temperature within a predetermined time to allow the fluoropolymer to migrate.

[0093] (Evaluation method)

[0094] The water contact angles of the test samples before and after storage in an electric oven...

Embodiment 2

[0117] (Preparation method of test sample)

[0118] A low-density polyethylene resin (LJ8041) blended with 0.1 parts by mass of a fluoropolymer (AG-E060) was melt-kneaded at a temperature higher than the melting point of the polyethylene resin by using a kneader.

[0119] The kneaded product was pulverized by using an electric mill and shaped into a granular shape.

[0120] Install the cap mold on the injection molding machine. The pellets were charged into the hopper of the injection molding machine and injection molded into test sample caps at a barrel temperature set at 180°C.

[0121] Next, the test samples were stored capped in an electric oven set at 90° C. for 1 minute to allow migration of the fluoropolymer.

[0122] A test sample cap was fitted to a PET bottle prefilled with 300 mL of sauce (Delicious Sauce Tonkatsu manufactured by Kikkoman Co.) to obtain a test sample bottle.

[0123] (Evaluation method and result)

[0124] Tilt the test bottle to pour off the sa...

Embodiment 3

[0128] (Preparation method of test sample)

[0129] A low-density polyethylene resin (LJ8041) blended with 1.0 parts by mass of a fluoropolymer (AG-E060) was melt-kneaded at a temperature higher than the melting point of the polyethylene resin by using a kneader.

[0130] The kneaded product was pulverized by using an electric mill and shaped into a granular shape.

[0131] Install the nozzle mold for eye medicine on the injection molding machine. The pellets were charged into the hopper of the injection molding machine and injection molded into test nozzle samples at a barrel temperature set at 180°C.

[0132] Next, the test nozzle samples were stored for 1 minute in an electric oven set at 90°C to allow migration of the fluoropolymer.

[0133] The test nozzle sample was assembled into a PET eye drop container pre-filled with eye drops to obtain a test eye drop sample.

[0134] (Evaluation method and result)

[0135] A test eye drop sample is held in such a manner that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com