Liquid-repellent plastic molded body and production method therefor

A production method and technology of shaped bodies, applied in the direction of chemical instruments and methods, pollution prevention methods, cleaning methods and appliances, etc., can solve the problems of unsuitable packaging materials, etc., and achieve the effect of stable maintenance and stable liquid repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

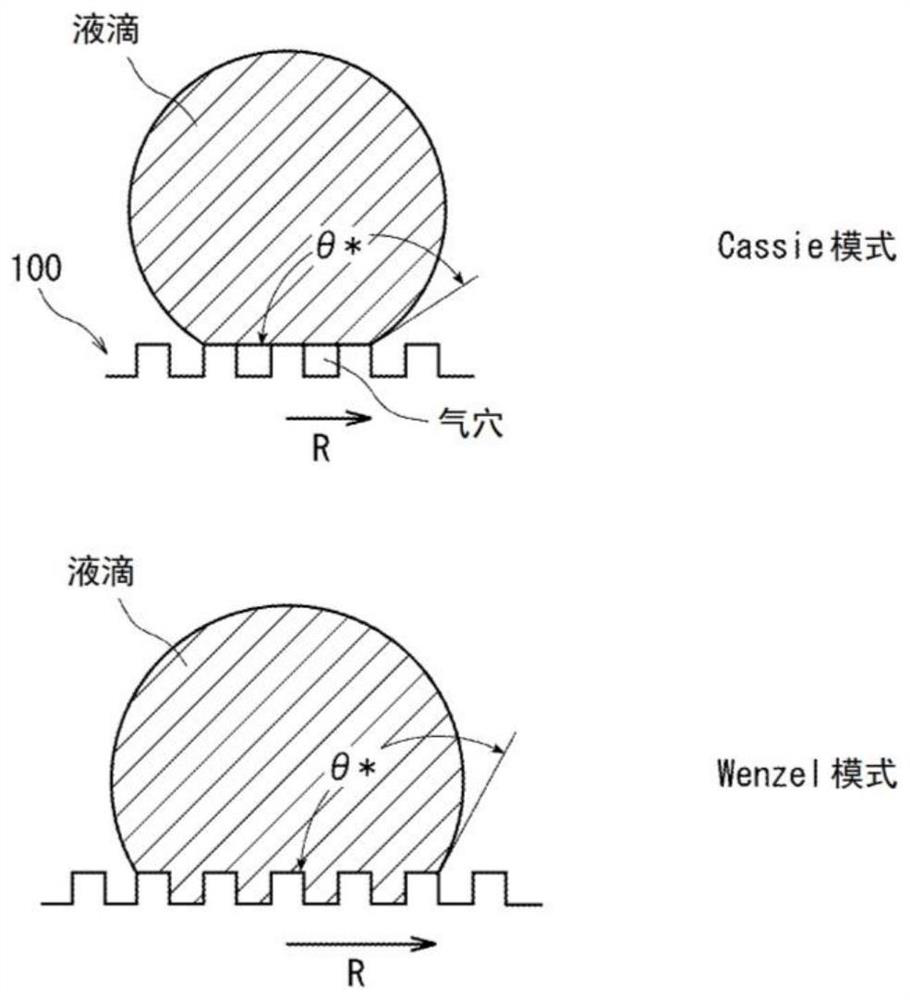

[0062] will refer to figure 1 A description is given of the principle of liquid repellency by means of a rough surface (concave-convex surface). In the Cassie mode where a droplet is placed on the rough surface 100, the recesses in the rough surface 100 act as air pockets so that the droplet is in recombined contact with the solid and gas (air). It is known that composite contacts achieve high liquid repellency because the radius R of the liquid droplet on the contact interface is small, and the liquid is in contact with air, which is the most hydrophobic substance. Specifically, the apparent contact angle θ* is close to 180°.

[0063] On the other hand, in the case of a droplet intruding into a recess in the rough surface 100 shown as a Wenzel mode, the droplet is not in recombination contact, but only in contact with the solid. In the Wenzel mode, the contact radius R of the droplet on the contact interface is large, and the apparent contact angle θ* is similarly close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com