A kind of paint film thickness tester and realization method

An implementation method and tester technology, which are applied in electrical/magnetic thickness measurement, instruments, measurement devices, etc., can solve the problems affecting the test stability and accuracy of the instrument, difficult to filter out ripple signals, and interfere with the reference voltage, and achieve measurement results. Low error, extended use range, reduced measurement frequency jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

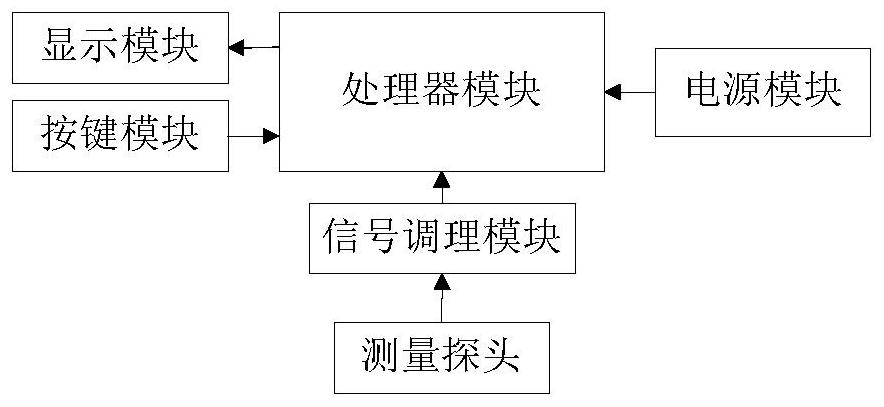

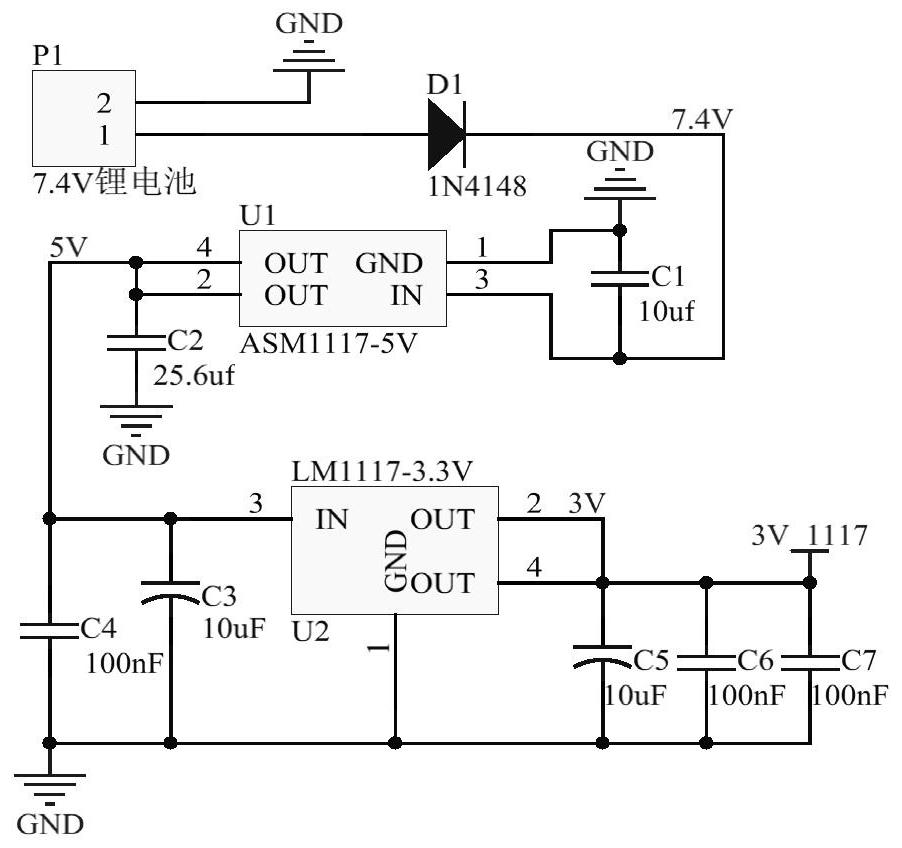

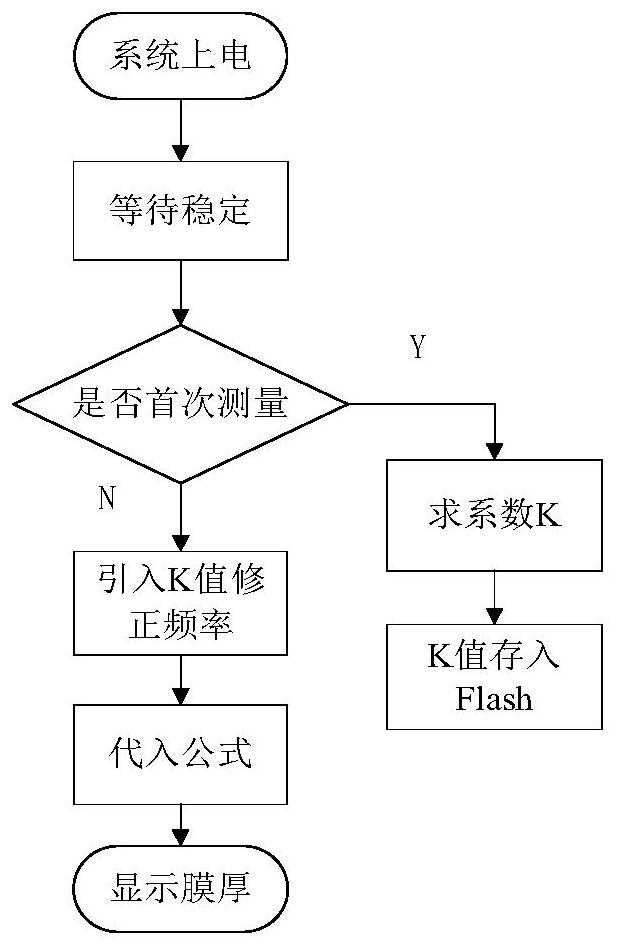

[0018] like figure 1 Shown is the schematic diagram of the module structure of the present invention. The GD32-based paint film thickness tester suitable for iron and aluminum bases includes a processor module, a signal conditioning module, a measurement probe, a power module, a button module and a display module. The processor module adopts GD32F350CBT6 as the main chip, the operating frequency is up to 108MHz, and the built-in 12-bit AD conversion has the advantages of low cost, low power consumption and high performance. When the processor module responds to the command input by the key, it controls the change of the capture frequency of the timer input. The signal conditioning circuit uses a 14-bit binary asynchronous counter SN74HC4020 and a four-way precision single-power low-power operational amplifier TLE2024 to generate a stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com