Test tube cleaning device

A technology for cleaning devices and test tubes, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as low safety, poor cleaning effect, time-consuming and laborious, etc., and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

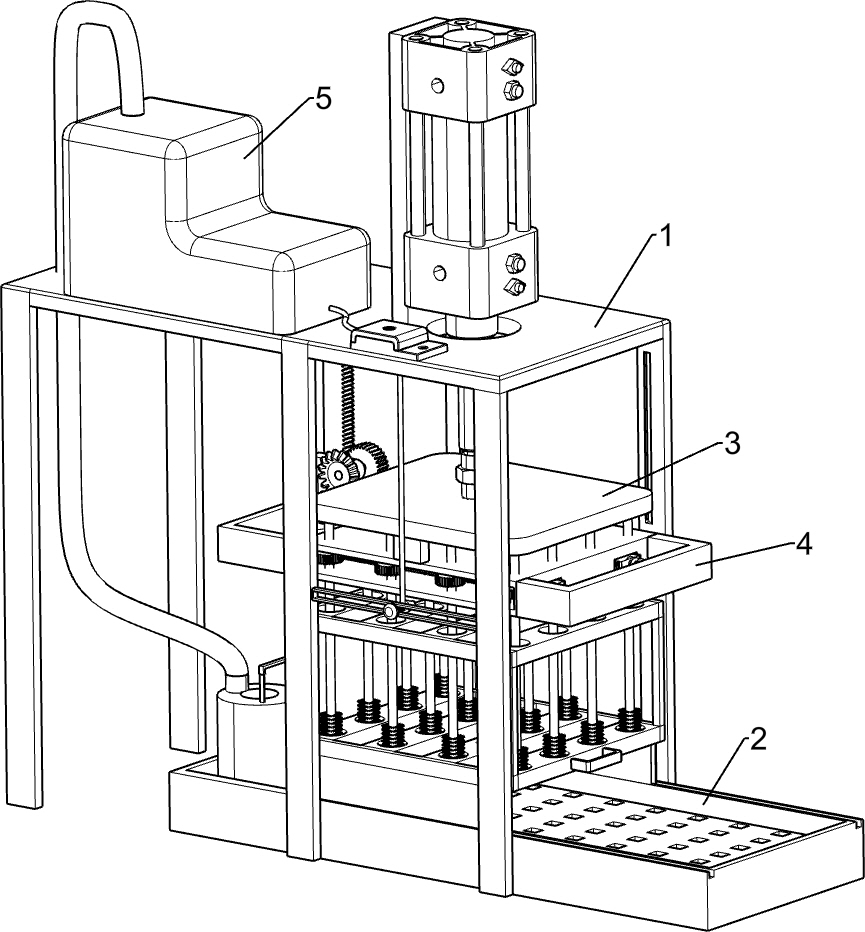

[0022] A test tube cleaning device, such as figure 1 As shown, it includes a mounting frame 1, a placement mechanism 2, a lifting cleaning mechanism 3, and a rotating mechanism 4. A placement mechanism 2 is provided between the lower right part of the mounting frame 1, and a lifting cleaning mechanism 3 is connected to the upper right side of the mounting frame 1. , The lower side of the lifting and cleaning mechanism 3 is provided with a rotating mechanism 4, and the rotating mechanism 4 is connected with the inner top wall of the mounting frame 1.

[0023] When the device needs to be used, people can start the parts of the lifting and cleaning mechanism 3, drive the parts of the lifting and cleaning mechanism 3 to move upward to the top of the placement mechanism 2, close the parts of the lifting and cleaning mechanism 3, and slide the parts of the placement mechanism 2 to the right, Place the test tube in the placement mechanism 2, slide the parts of the placement mechanism...

Embodiment 2

[0025] On the basis of Example 1, such as Figure 1-3 As shown, the placement mechanism 2 includes a placement frame 21 and a test tube rack 22. The placement frame 21 is arranged between the lower right part of the installation frame 1, and the test tube rack 22 is slidably connected between the front and rear sides of the top of the placement frame 21.

[0026] When the test tube needs to be placed, people can start the parts of the lifting and cleaning mechanism 3, drive the parts of the lifting and cleaning mechanism 3 to move upwards to the top of the test tube rack 22, close the parts of the lifting and cleaning mechanism 3, slide the test tube rack 22 to the right, and place the test tube In the test tube rack 22, slide the test tube rack 22 to the left to reset.

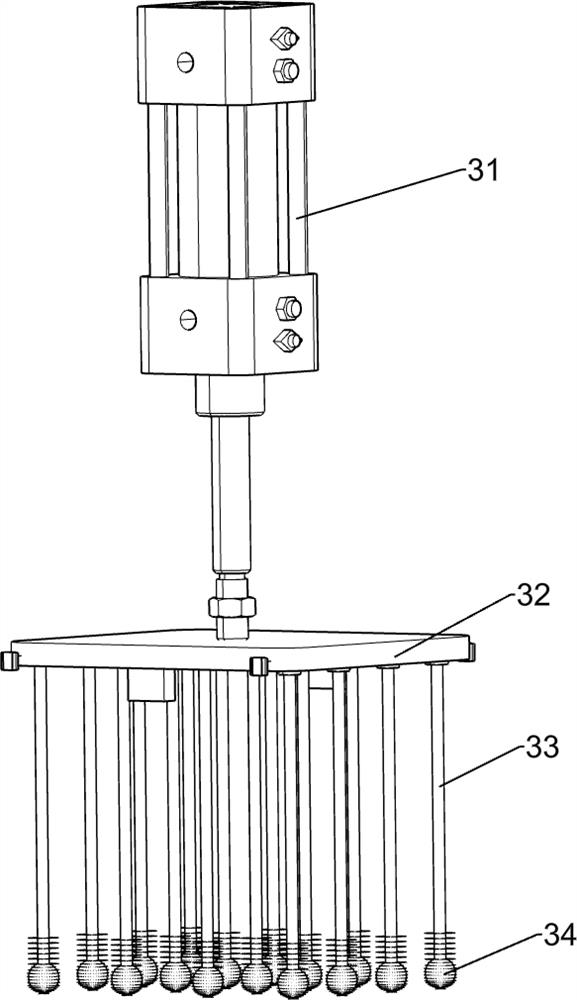

[0027] The lifting and cleaning mechanism 3 includes a cylinder 31, a lifting plate 32, a connecting rod 33 and a hairbrush 34, the upper side of the right side of the mounting frame 1 is provided with a cyli...

Embodiment 3

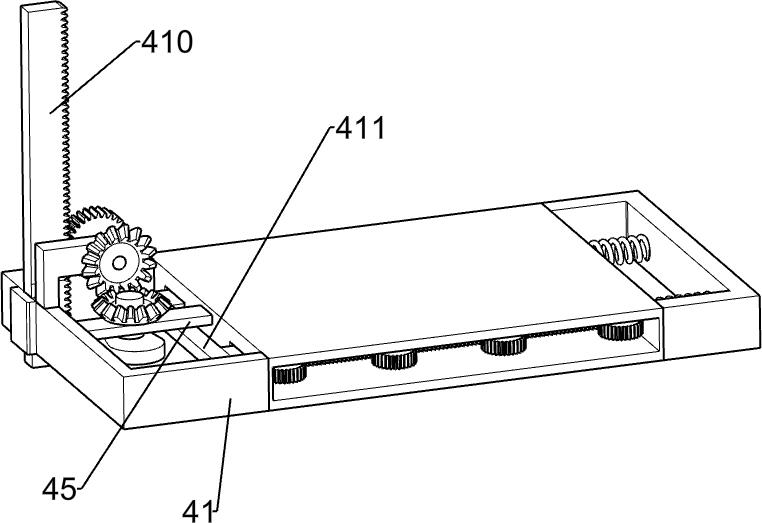

[0030] On the basis of Example 2, such as figure 1 with Figure 4-6 As shown, the rotating mechanism 4 includes a mounting frame 41, a double-sided rack 42, an elastic member 43, a first gear 44, a connecting plate 45, a first bevel gear 46, a cam 47, a second bevel gear 48, and a second gear 49 , a single-sided rack 410, a slider 411, a first shaft 412 and a second shaft 413, an installation frame 41 is connected between the front and rear sides of the bottom of the lifting plate 32, the connecting rods 33 pass through the installation frame 41, and inside the installation frame 41 Slide block 411 is connected to the left sliding type, and double-sided rack 42 is provided on the front and rear sides of the right part of slide block 411, and elastic member 43 is connected between the right side of double-sided rack 42 and the inner right wall of installation frame 41, The upper part of the connecting rod 33 is equipped with a first gear 44, and the first gear 44 is meshed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com