Lifting type building steel pipe inner wall derusting and polishing device

A steel pipe inner wall, lifting technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of limited grinding range of steel pipe, grinding block can not realize the axial movement of steel pipe, etc., and achieve flexible adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

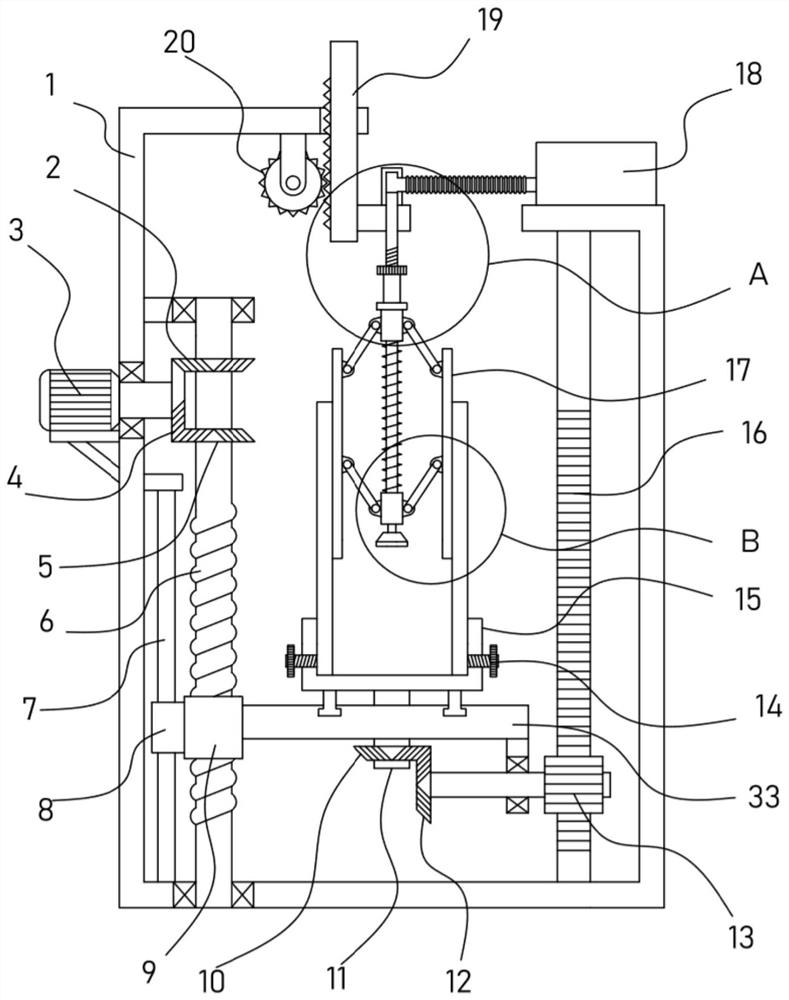

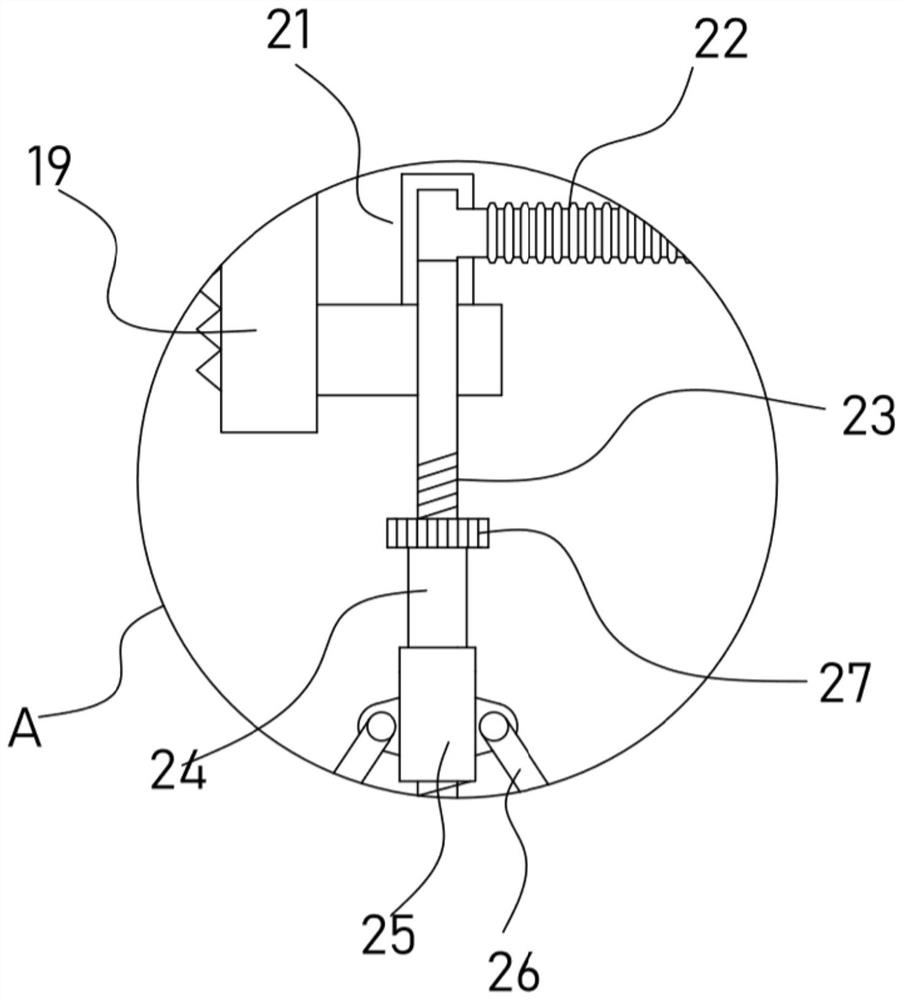

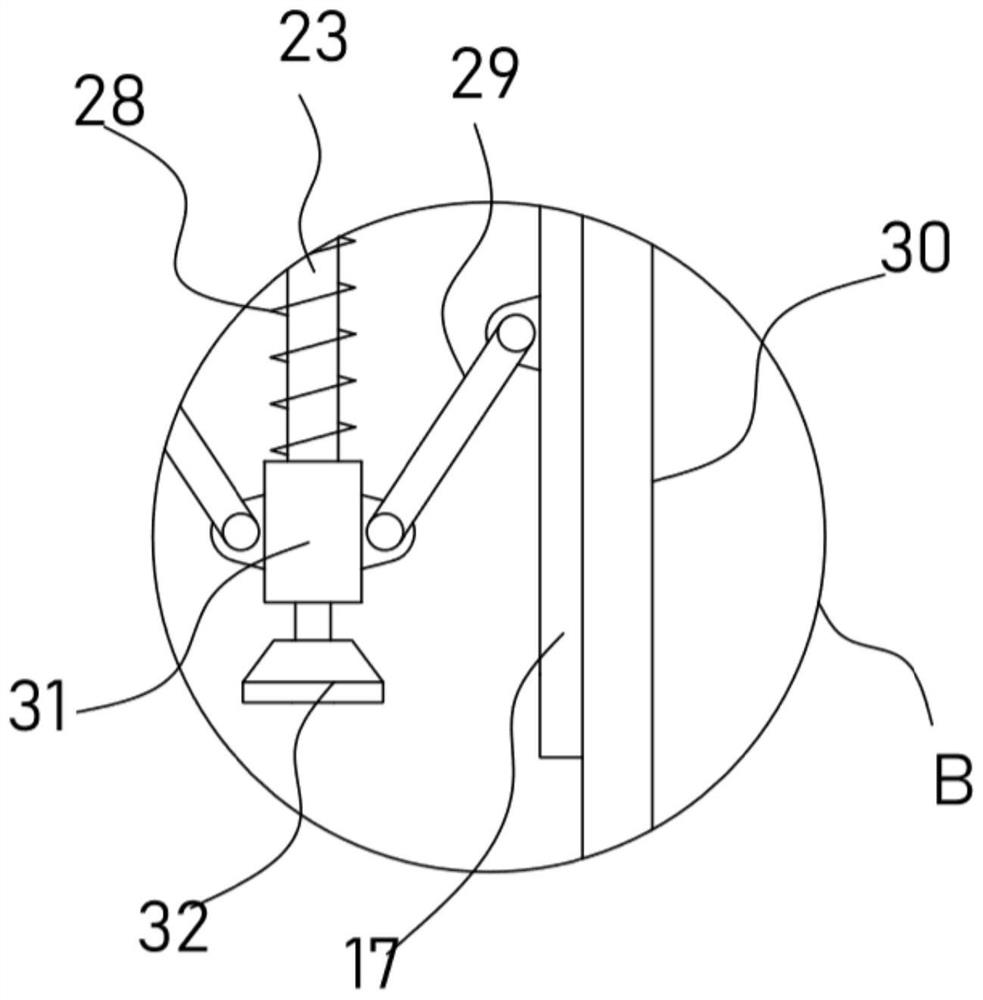

[0023] see Figure 1-4 , a lifting type building steel pipe inner wall derusting and polishing device, comprising a fixed frame 1, a motor 3 is fixed on the fixed frame 1, a support plate 33 is horizontally provided on the fixed frame 1, and a support plate 33 is provided on the support plate 33 for fixing the steel pipe 30 The clamping mechanism, the lifting gear 20 is rotatably installed on the fixed frame 1, and the lifting gear 20 is meshed with a vertically arranged spur rack II19, and the spur rack II19 is provided with a grinding wheel for derusting the inner wall of the steel pipe 30. mechanism, the motor 3 is driven and connected with a lifting mechanism for driving the support plate 33 to lift vertically, and the bottom of the support plate 33 is provided with a rotating mechanism for driving the support seat 15 to rotate.

[0024] The device clamps and limits the steel pipe 30 through the clamping mechanism provided. Specifically, the clamping mechanism includes a v...

Embodiment 2

[0028] On the basis of Embodiment 1, in addition, the lifting mechanism of the device includes a vertically arranged threaded rod 6 rotatably mounted on the fixed frame 1, and the threaded rod 6 is threaded with a threaded sleeve 9 fixed to the support plate 33 The threaded rod 6 is sleeved with a bevel gear I2 and a bevel gear II5, and the motor 3 is driven and connected with an incomplete bevel gear 4 that alternately meshes with the bevel gear I2 and the bevel gear II5. The lifting mechanism also includes a bevel gear that is fixed on The cover block 8 of the side wall of the threaded cover block 9 is provided with a guide rod 7 vertically on the cover block 8 .

[0029] The motor 3 drives the incomplete bevel gear 4 to rotate, and the incomplete bevel gear 4 alternately meshes with the bevel gear I2 and the bevel gear II5. At this time, the threaded rod 6 rotates clockwise and counterclockwise, and then the threaded sleeve block 9 drives the support plate 33 to realize Ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com