Spreading machine for garment processing

A cloth stretching machine and clothing technology, applied in transportation and packaging, textiles and papermaking, winding strips, etc., can solve problems such as inconvenient operation, affecting cutting, and dust-proof treatment of the device, so as to achieve simple and convenient operation and ensure normal operation The effect of cutting and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

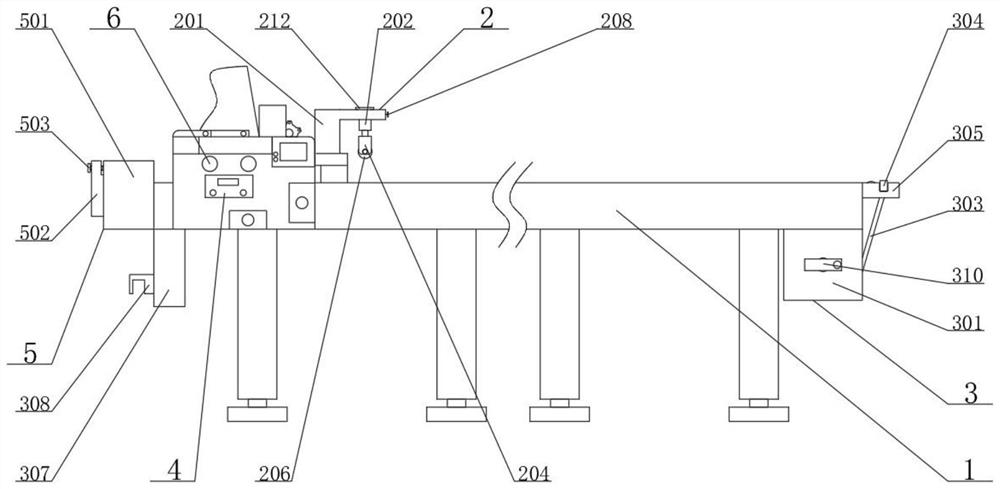

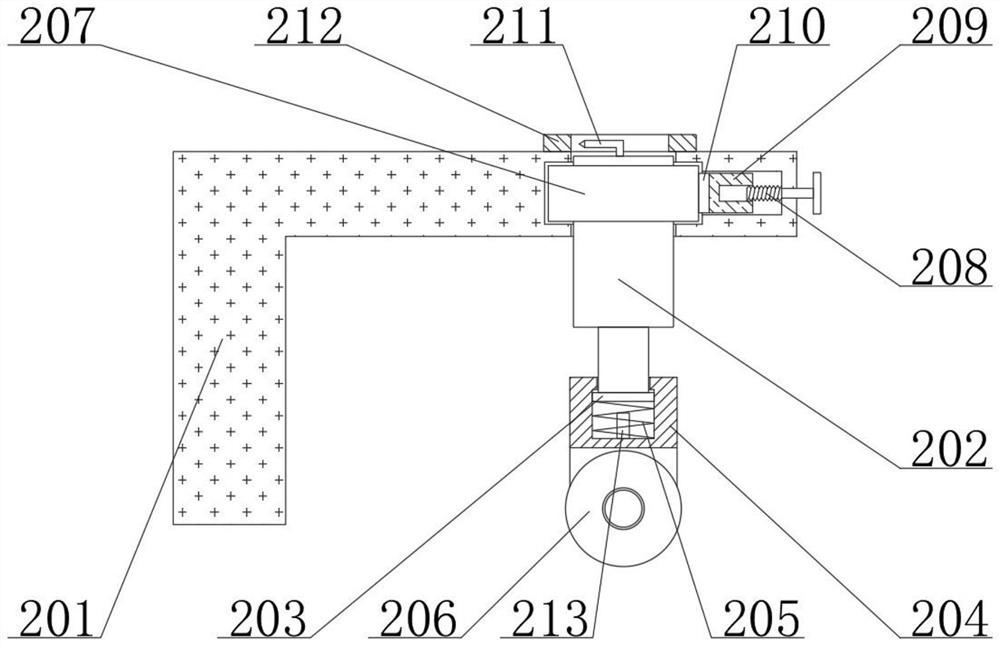

[0027] see figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 , the present invention provides a technical solution:

[0028]A cloth stretching machine for garment processing, comprising a fixed frame 1, a leveling device 2, a dustproof device 3 and a retractable device 5, the front and rear sides of the right end of the cloth pulling mechanism of the fixed frame 1 are fixedly connected with the leveling device 2, the whole The flat device 2 includes a support 201, an electric telescopic rod 202, a pressing plate 203, a support frame 204, a first spring 205, an electric rubber roller 206, a rubber sleeve 207, a first threaded shaft 208, a slide block 209, a rubber sheet 210, a pointer 211, The dial 212 and the first control switch 213, the front and rear sides of the right end of the pulling mechanism of the fixed frame 1 are fixedly connected with a support 201, the inner right end of the support 201 is rotatably connected with an electric telescopic r...

Embodiment 2

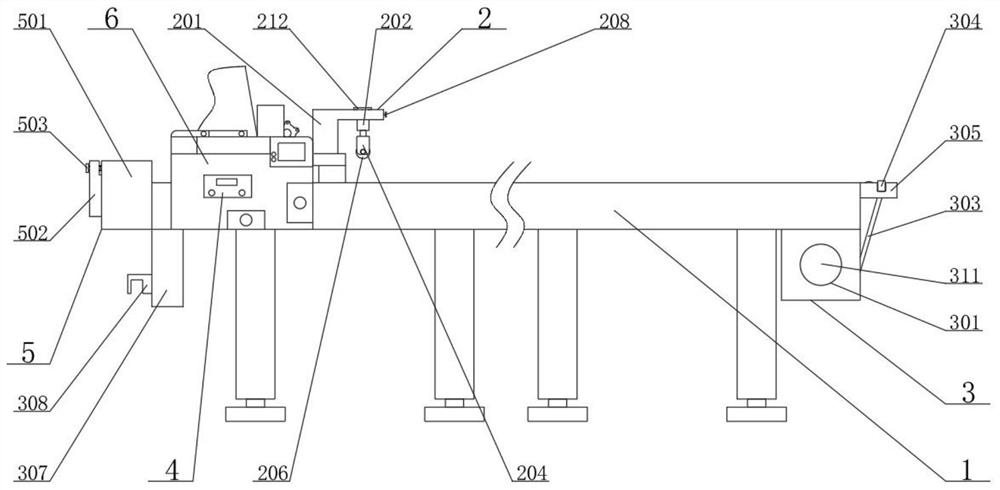

[0031] see figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 , the present invention provides a technical solution:

[0032] A cloth stretching machine for garment processing, comprising a fixed frame 1, a leveling device 2, a dustproof device 3 and a retractable device 5, the front and rear sides of the right end of the cloth pulling mechanism of the fixed frame 1 are fixedly connected with the leveling device 2, the whole The flat device 2 includes a support 201, an electric telescopic rod 202, a pressing plate 203, a support frame 204, a first spring 205, an electric rubber roller 206, a rubber sleeve 207, a first threaded shaft 208, a slide block 209, a rubber sheet 210, a pointer 211, The dial 212 and the first control switch 213, the front and rear sides of the right end of the pulling mechanism of the fixed frame 1 are fixedly connected with a support 201, the inner right end of the support 201 is rotatably connected with an electric telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com