A cutting and tensioning device for textile fabric production

A textile fabric and tensioning device technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve problems such as inability to cut quickly and efficiently, easy damage, and easy shaking of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

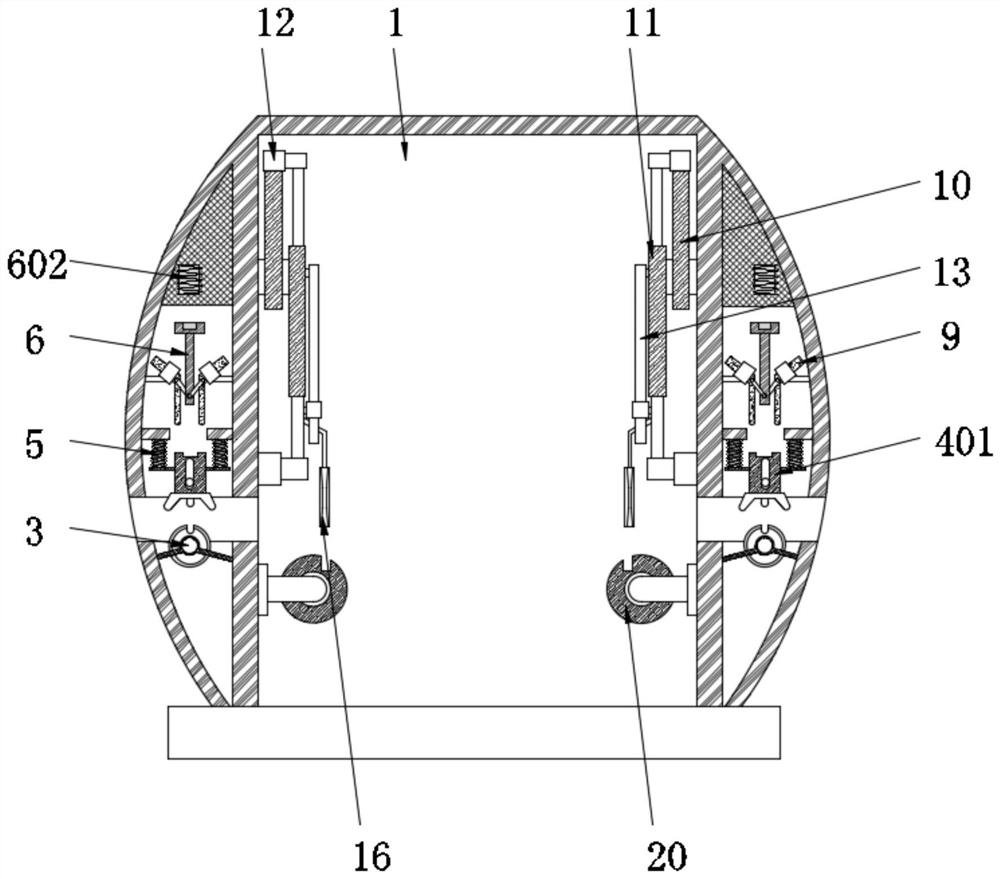

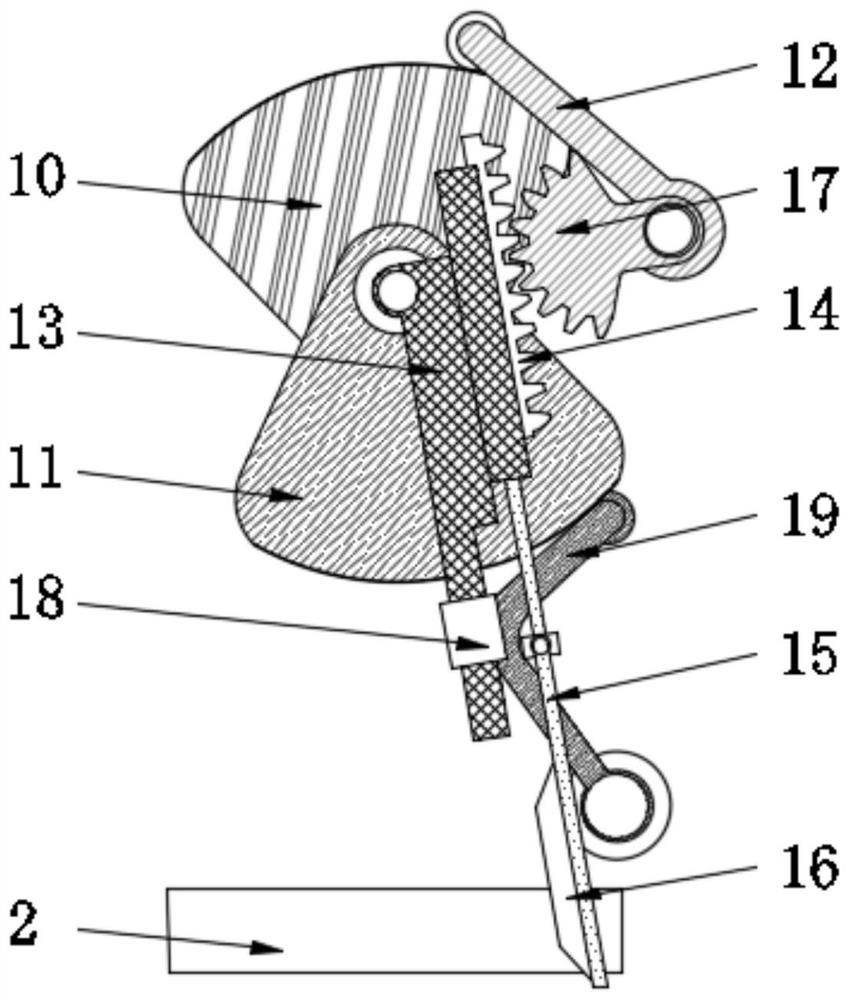

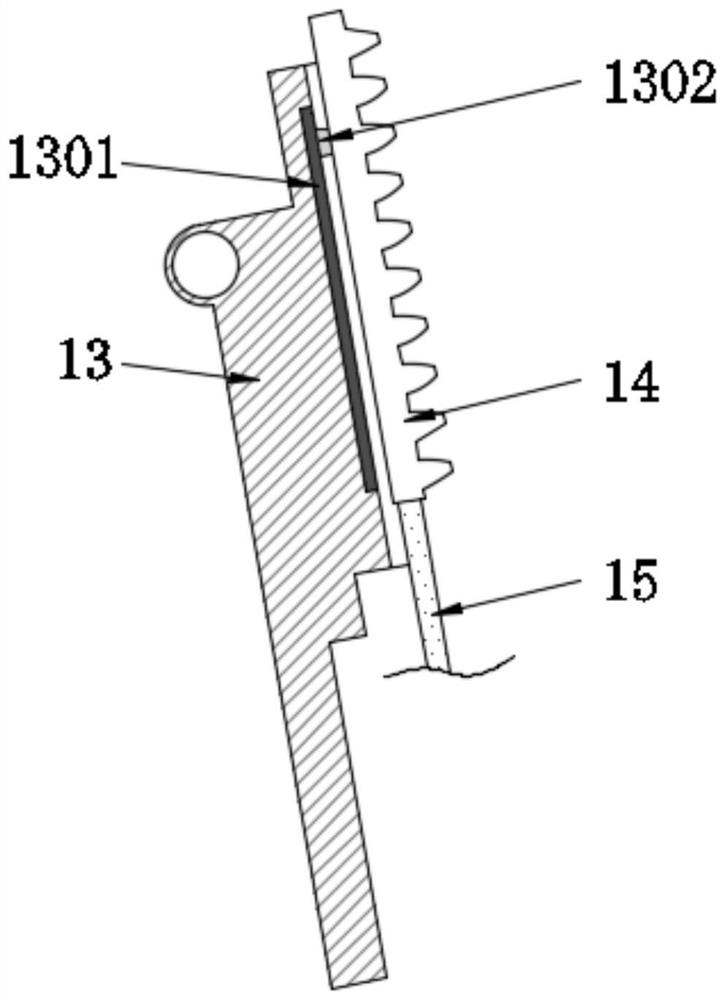

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The invention provides a cutting and tensioning device in the production of textile cloth, as attached figure 1 to attach Figure 5 Shown: Including processing chamber 1, both sides of the left end of processing chamber 1 are provided with entrance and exit 2, inside of entrance and exit 2 is fixedly installed with pasting roller 3, above the pasting roller 3 and inside of entrance and exit 2 is provided with a corresponding The card joint 4 is an inverted U-shaped structure, and the lower surface of the card joint 4 and the upper surface of the sticking roller 3 are respectively provided with corresponding bumps and concave holes, and the upper surface of the card joint 4 is fixedly installed with a bottom The block 401, the bottom block 401 and the clip joint 4 are integrally formed. The connection between the surface of the bottom block 401 and the clip joint 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com