A gas-liquid coupling power conversion system for gas drilling

A gas-liquid coupling and gas drilling technology, which is applied to the driving device for drilling in the wellbore, drilling equipment, earthwork drilling and production, etc., can solve the problems of trajectory control lag, easy motor speed, short life, etc., to eliminate flow and pressure Pulsation, the effect of avoiding pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the gas-liquid coupling power conversion system for gas drilling of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

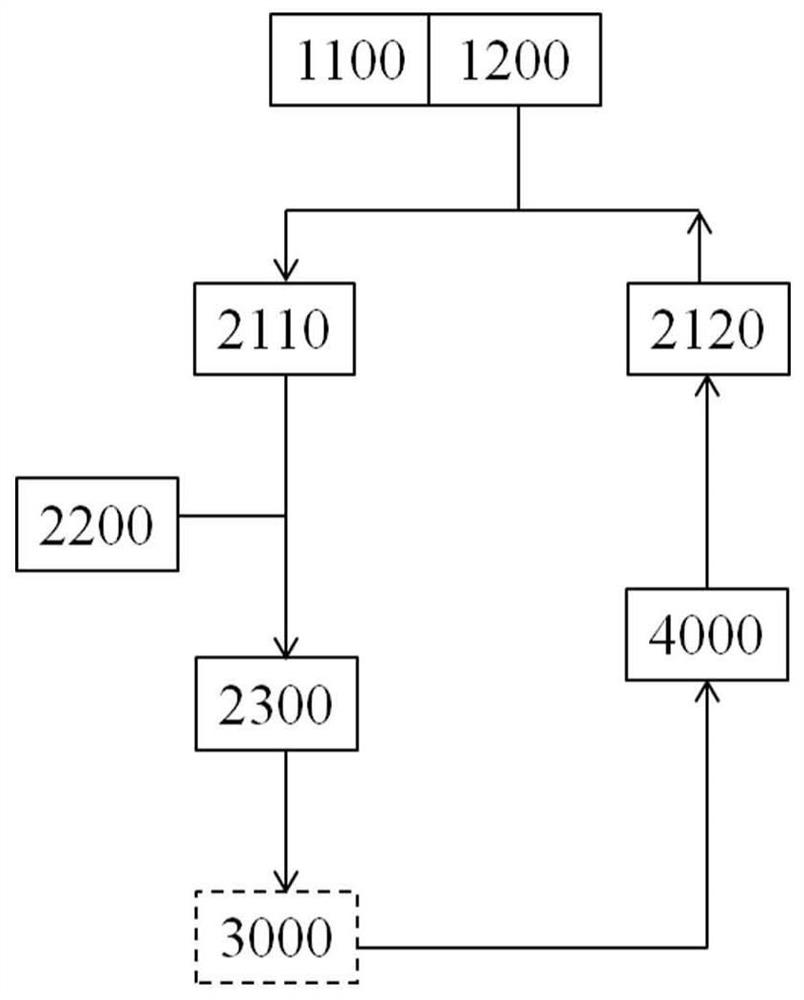

[0043] figure 1 A schematic structural view of a gas-liquid coupling power conversion system for gas drilling in an exemplary embodiment of the present invention is shown.

[0044] In an exemplary embodiment of the present invention, the gas-hydraulic coupling power conversion system for gas drilling can provide stable hydraulic driving force to the downhole hydraulic actuator, and the system may include a gas-hydraulic coupling stamping device, a hydraulic oil control device and Fuel tank assembly.

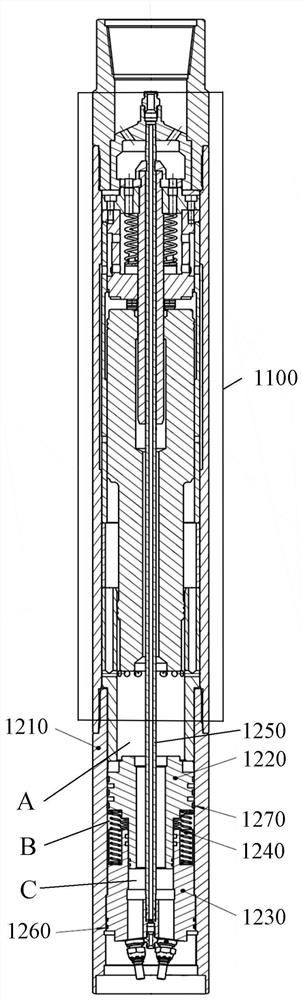

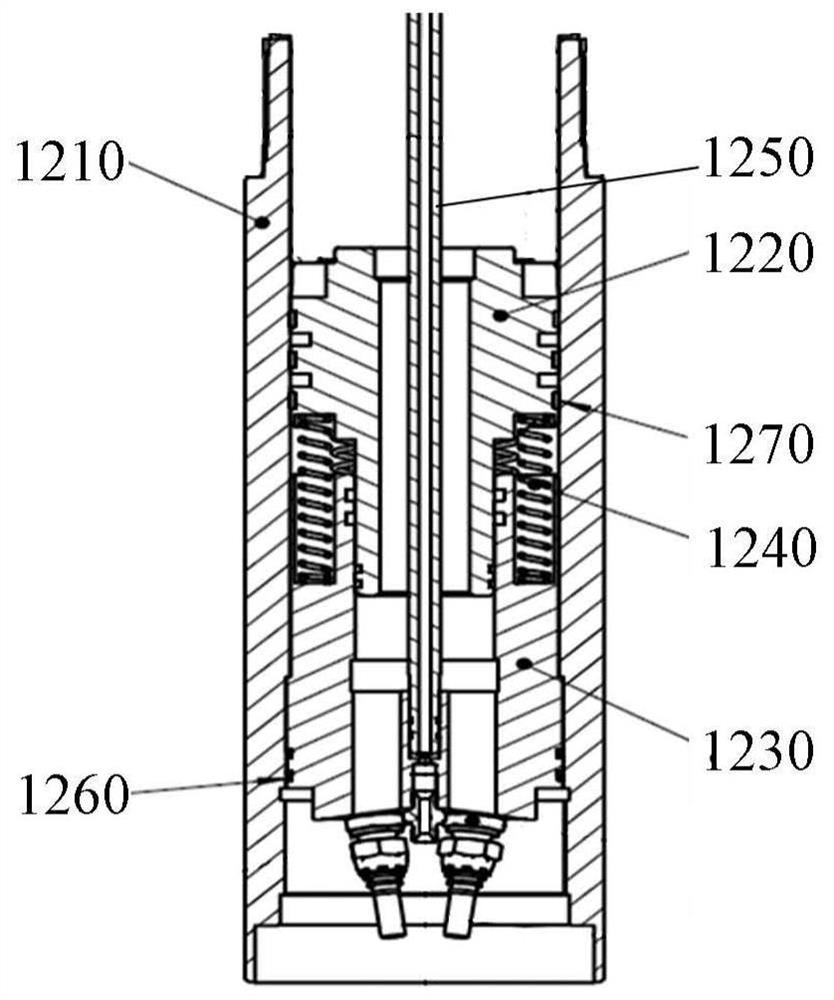

[0045] Among them, the gas-hydraulic coupling stamping device may include such as figure 1 A pneumatic impactor 1100 and a reciprocating pump 1200 are shown. The pneumatic impactor 1100 can convert the pressure energy of the gas into the mechanical energy of the piston....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com