Electronic product supporting frame

A technology for electronic products and support frames, applied in the field of support frames, can solve the problems of numerous parts, cumbersome structure, no blocking force, etc., and achieve the effect of simplifying parts, easy to use, and optimizing assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

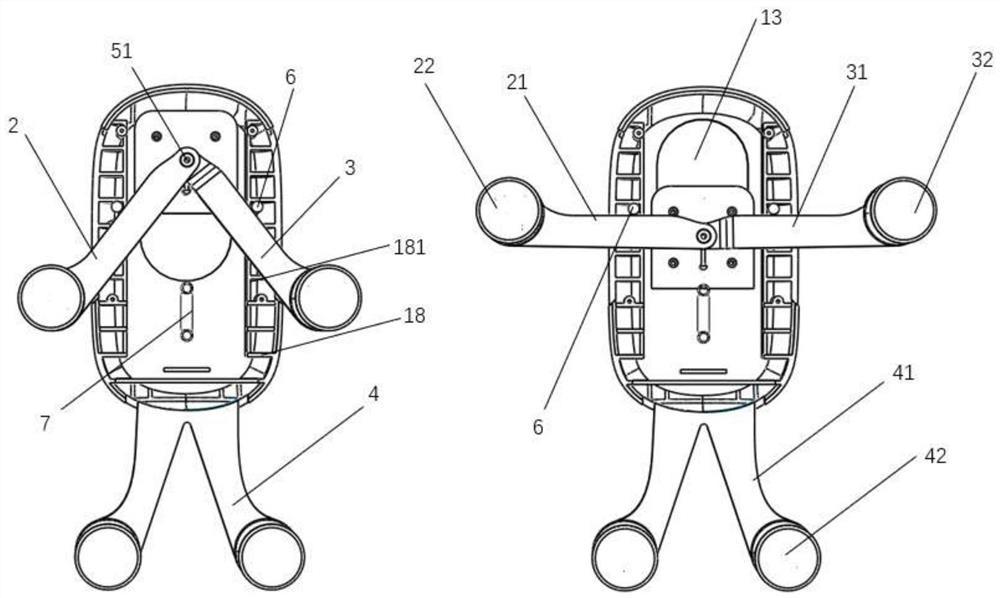

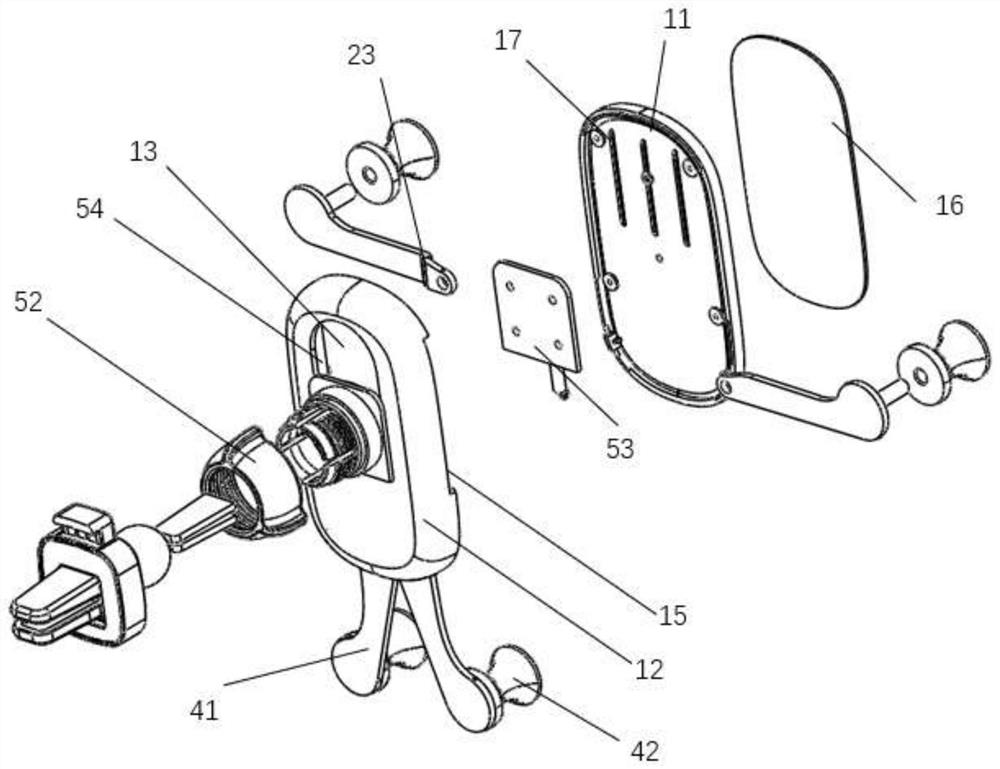

[0067] see Figure 1-3 , a support frame for electronic products, comprising: a housing 1, the housing 1 includes a front housing 11 and a rear housing 12, the rear housing 12 is provided with an opening 13, and the front and rear housings (11, 12) are connected Then the cavity 14 is formed. The cavity 14 is movable and partially accommodates the inner ends of the left and right clamping parts ( 2 , 3 ) for clamping the electronic product from the top and the side, and the inner end of the driving rod 51 .

[0068] The front housing 11 is in the shape of a cover plate, and the front surface is set as a concave surface, so as to facilitate the external attachment of the decorative shell 16 to cover the mounting structures on the surface of the front housing 11 such as threaded holes and screw ends. The rear housing 12 is in the shape of a concave cavity to form a receiving space for installing linkage components.

[0069] The front and rear housings (11, 12) are fastened and ...

Embodiment 2

[0090] The structure and principle of this embodiment are basically the same as those of Embodiment 1, the main difference lies in: the sliding part and the sliding structure.

[0091] see Figure 4-7 , the fixing assembly 5 is connected with the casing 1 through a sliding structure to realize the above-mentioned activities. The sliding structure includes a slider and a slideway, and the slider can slide along the slideway.

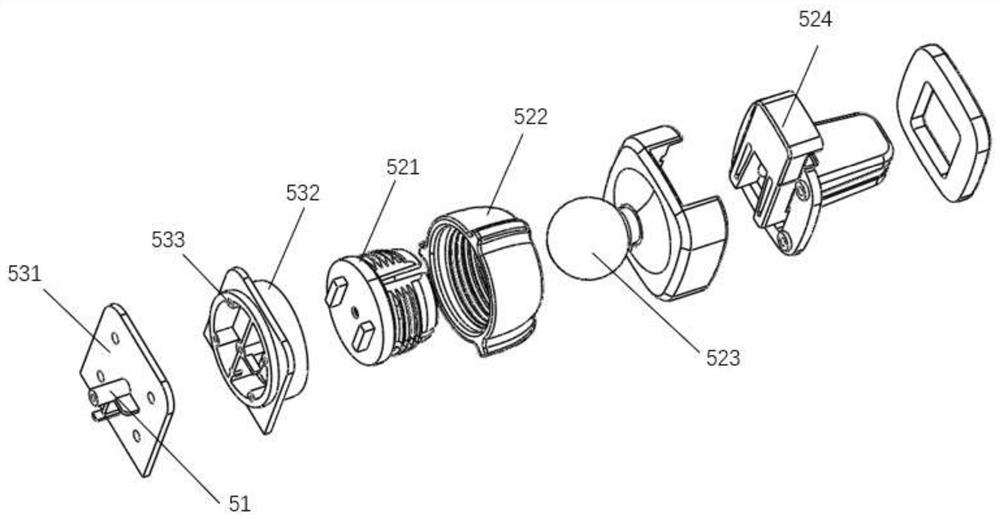

[0092] Specifically, the fixing assembly 5 includes a fixing part 52 and a sliding part 53, the driving rod 51 is arranged on the sliding part 53, and the fixing part 52 is adapted to be connected with the carrier. The sliding portion 53 includes a third sliding portion 535 provided with a drive rod 51, the edge of the third sliding portion 535 is formed with a projection 5351 that can slide on the mouth edge 54 of the opening 53, the projection 5351 is a slider, and the opening 13 The mouth edge 54 forms a slideway, and the opening 13 is also provided ...

Embodiment 3

[0096] The structure and principle of this embodiment are basically the same as those of Embodiment 1, the main difference lies in: the sliding part and the sliding structure.

[0097] see Figure 8 , the fixing assembly 5 is connected with the casing 1 through a sliding structure to realize the above-mentioned activities. The sliding structure includes a slider and a slideway, and the slider can slide along the slideway.

[0098]Specifically, the fixing assembly 5 includes a fixing part 52 and a sliding part 53, the driving rod 51 is arranged on the sliding part 53, and the fixing part 52 is adapted to be connected with the carrier. The sliding part 53 includes a fourth sliding part 537 provided with a drive rod 51. The two sides of the mouth edge 54 of the opening 13 are respectively provided with slide rails 5371. The slide rails 5371 are strip-shaped protrusions formed on the inner side of the mouth edge 54. The gap between the riser and the mouth edge 54 forms a slidewa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap