Optical imaging lens matched with liquid lens

An optical imaging lens and liquid lens technology, applied in the lens field, can solve problems such as resolution, depth of field, magnification, relative illuminance limitation, light far not reachable, etc., to achieve high resolution, high relative illuminance, The effect of high yield rate in mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

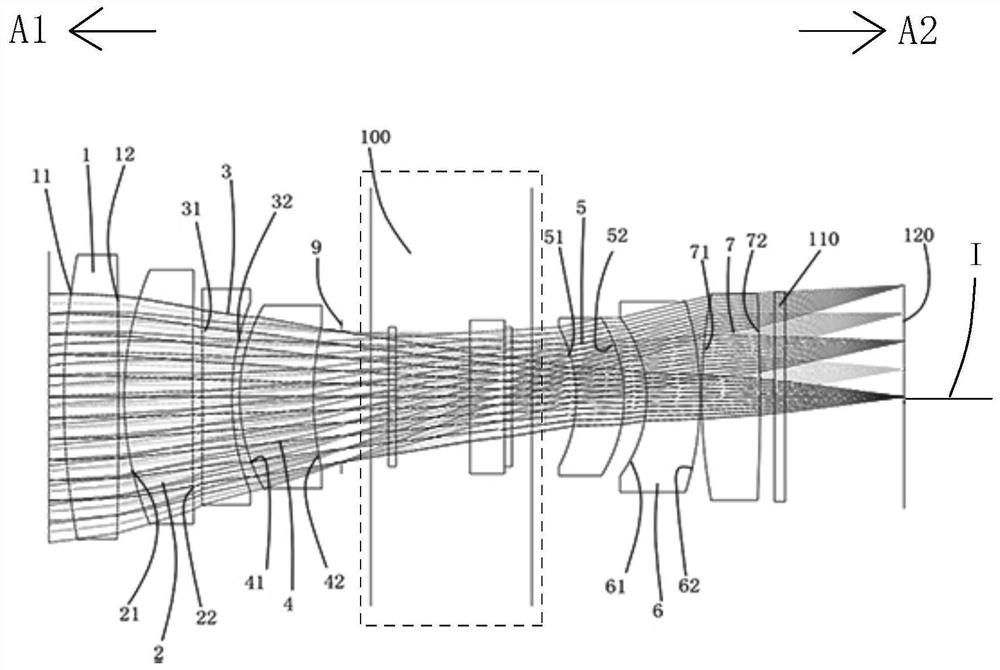

[0077] Such as figure 1 As shown, an optical imaging lens with a liquid lens includes a first lens 1, a second lens 2, a third lens 3, a fourth lens 4, and a diaphragm in sequence along an optical axis I from the object side A1 to the image side A2 9. The liquid lens 100, the fifth lens 5, the sixth lens 6, the seventh lens 7, the protective glass 110 and the imaging surface 120; the first lens 1 to the seventh lens 7 each include a lens facing the object side A1 and allowing the imaging light to pass through The object side and an image side facing the image side A2 through which the imaging light passes.

[0078] The first lens 1 has a positive refractive power, the object side 11 of the first lens 1 is a convex surface, and the image side 12 of the first lens 1 is a convex surface. Of course, in other embodiments, the image side 12 of the first lens 1 can also be is concave or flat.

[0079] The second lens 2 has a positive refractive power, the object side 21 of the seco...

Embodiment 2

[0093] Such as Figure 7 As shown, an optical imaging lens with a liquid lens includes a first lens 1, a second lens 2, a third lens 3, a fourth lens 4, and a diaphragm in sequence along an optical axis I from the object side A1 to the image side A2 9. The liquid lens 100, the fifth lens 5, the eighth lens 8, the sixth lens 6, the seventh lens 7, the protective glass 110 and the imaging surface 120; the first lens 1 to the eighth lens 8 each include a lens facing the object side A1 And an object side through which the imaging light passes and an image side facing the image side A2 through which the imaging light passes.

[0094] The first lens 1 has a positive refractive power, the object side 11 of the first lens 1 is a convex surface, and the image side 12 of the first lens 1 is a concave surface. Of course, in other embodiments, the image side 12 of the first lens 1 can also be is convex or planar.

[0095] The second lens 2 has a positive refractive power, the object sid...

Embodiment 3

[0113] Such as Figure 13 As shown, the concave-convex surface shape and refractive index of each lens in this embodiment and the second embodiment are the same, and only the optical parameters such as the radius of curvature of the lens surface and the thickness of the lens are different. In addition, in this specific embodiment, the second lens 2 and the third lens 3 are glued together, and the third lens 3 and the fourth lens 4 are glued together.

[0114] The detailed optical data of this specific embodiment are shown in Table 3-1.

[0115] Detailed optical data of the third embodiment of table 3-1

[0116]

[0117]

[0118] Please refer to Table 6 for the values of the relevant conditional expressions in this specific embodiment.

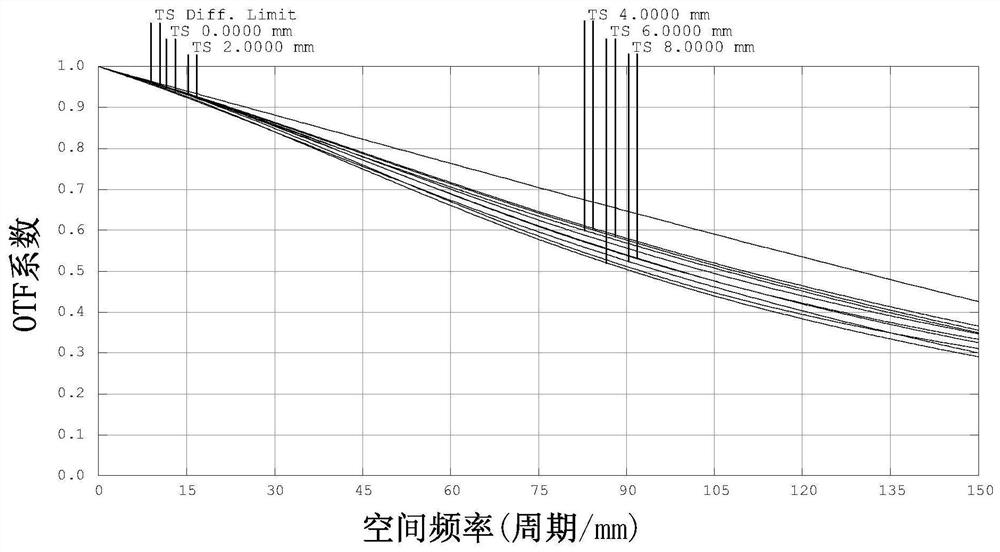

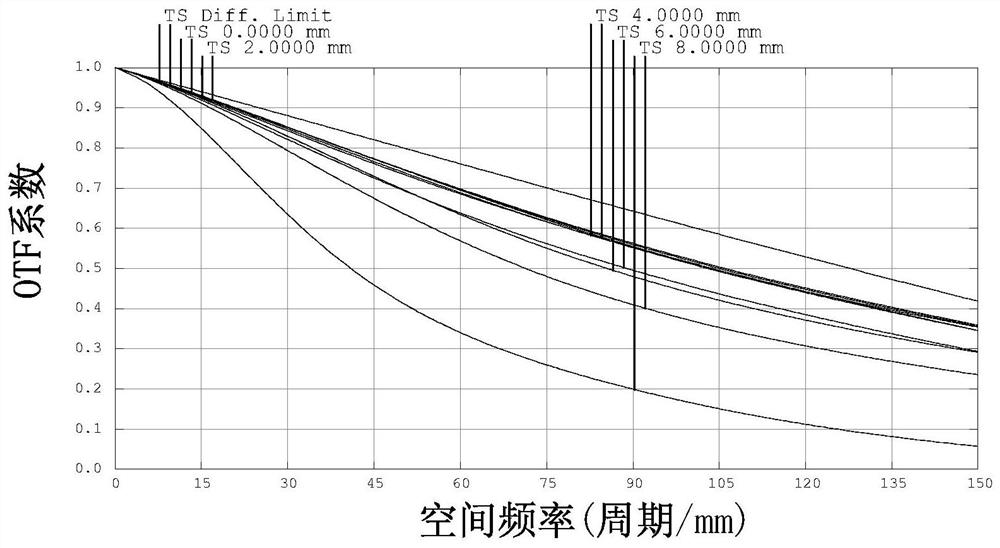

[0119] The MTF transfer function curve diagram of the different working object distances of this specific embodiment is detailed in Figure 14 , 15 and 16, it can be seen that the range of working object distance is wide, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com