Optical system capable of performing grouping focusing, imaging device and lens

An optical system and light technology, applied in the optical field, can solve the problems of reduced imaging quality, reduced imaging quality, and optical lenses cannot meet the requirements of machine vision recognition for lenses, and achieve high resolution, wide working distance, and low distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1 Group focusing optical system

[0075] In this embodiment 1, parameter conditions: f=35mm, f A =40.2mm, f B =107.6mm, ΔL=9.7mm, TTHI=40.3mm.

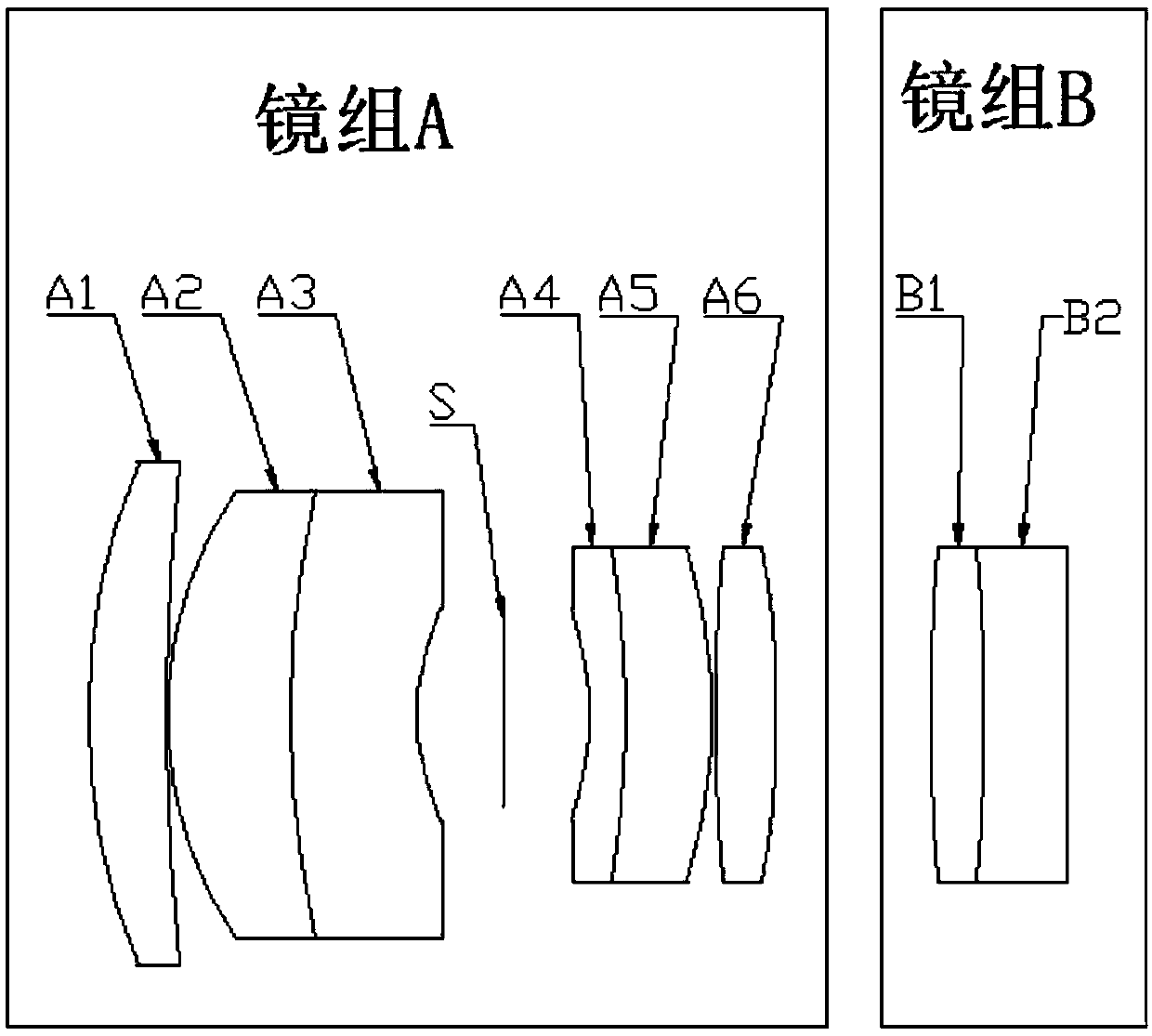

[0076] see figure 1 , in this embodiment 1, the optical system for group focusing includes:

[0077] The first lens group A, meniscus positive lens A1, meniscus positive lens A2, meniscus negative lens A3, variable diaphragm S, meniscus negative lens A4, Meniscus positive lens A5 and biconvex positive lens A6. Wherein the meniscus positive lens A2 and the meniscus negative lens A3 are glued together. The meniscus negative lens A4 and the meniscus positive lens A5 are glued together.

[0078] The second lens group B is a biconvex positive lens B1 and a meniscus negative lens B2 arranged in sequence from the object side to the image side along the incident direction of the light. The cemented surface of the negative lens B2 faces the object side.

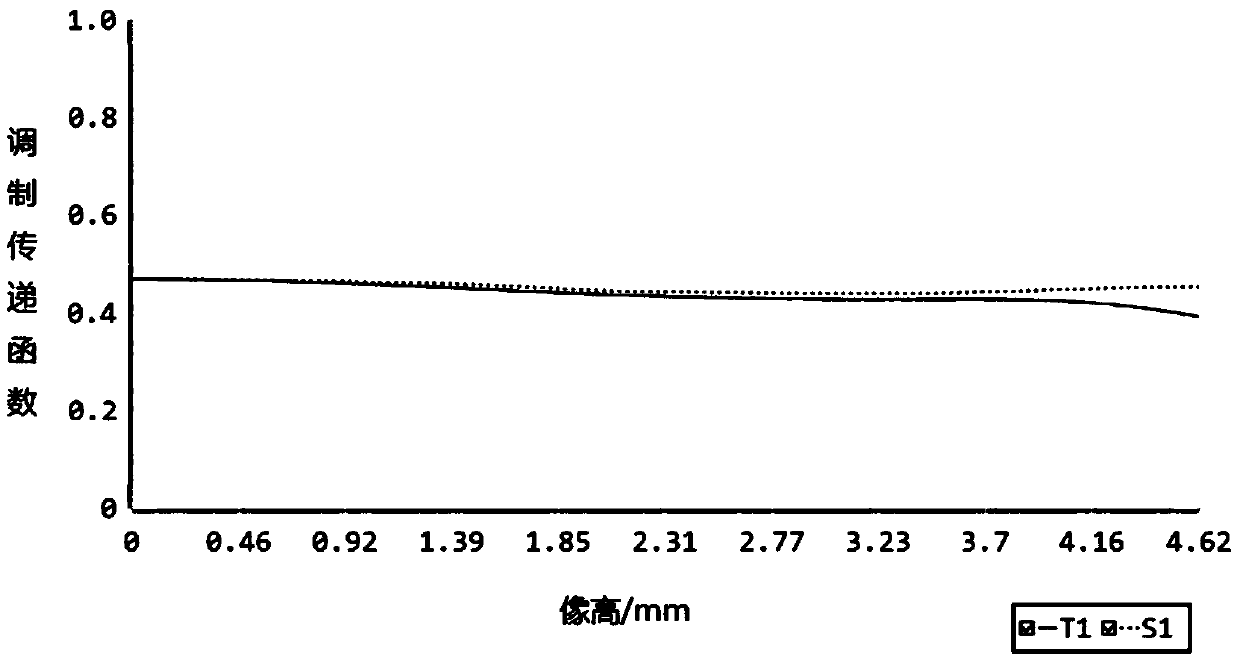

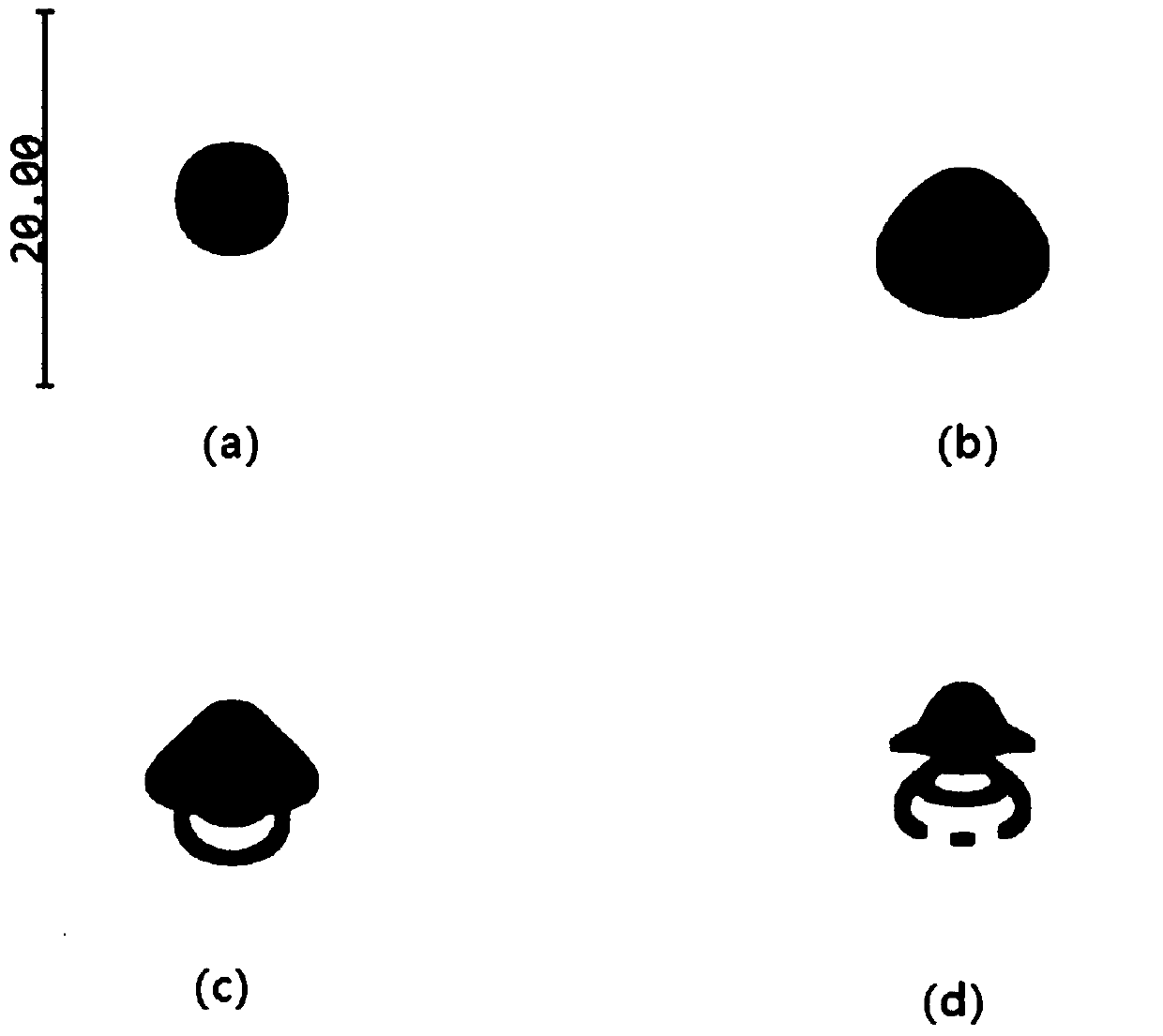

[0079] In the present embodiment 1, the technical indicators ac...

Embodiment 2

[0099] Embodiment 2 Group focusing optical system

[0100] In this embodiment 2, parameter condition: f=35mm, f A =40.2mm, f B =110.6mm, ΔL=9.6mm, TTHI=40.1mm.

[0101] see Figure 8 , in this embodiment 2, the optical system for group focusing includes:

[0102] The first lens group A is arranged in sequence along the light incident direction, meniscus positive lens A1, meniscus positive lens A2, meniscus negative lens A3, variable diaphragm S, meniscus negative lens A4, meniscus positive lens A5 And meniscus positive lens A6. Wherein the meniscus negative lens A4 and the meniscus positive lens A5 are glued together.

[0103] The second lens group B is provided with a biconvex positive lens B1 and a biconcave negative lens B2, and the cemented surface of the biconvex positive lens B1 and the meniscus negative lens B2 is cemented, and the cemented surface of the meniscus negative lens B2 faces the object side.

[0104] Embodiment 2 can achieve the same technical index an...

Embodiment 3

[0107] Embodiment 3 Group focusing optical system

[0108] In this embodiment 3, parameter condition: f=35mm, f A = 39.1 mm, f B =115.2mm, ΔL=9.2mm, TTHI=38.4mm.

[0109] see Figure 9 In this embodiment 3, the optical system for group focusing includes:

[0110] The first lens group A is arranged in sequence along the light incident direction, meniscus positive lens A1, meniscus positive lens A2, meniscus negative lens A3, variable diaphragm S, meniscus negative lens A4, meniscus positive lens A5 And meniscus positive lens A6. Wherein the meniscus positive lens A2 and the meniscus negative lens A3 are glued together. The meniscus negative lens A4 and the meniscus positive lens A5 are glued together.

[0111] The second lens group B is provided with a biconvex positive lens B1.

[0112] Embodiment 3 can achieve the same technical index and image quality as Embodiment 1. The lens parameters of Example 3 are shown in Table 3.

[0113] table 3

[0114] Surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com