A Piezoelectric Motor Driven by Sawtooth Wave

A piezoelectric motor and sawtooth wave technology, applied in the field of precision drive and positioning, can solve the problems of high cost, low moving speed, difficult miniaturization, etc., and achieve the effect of high price, large working step distance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

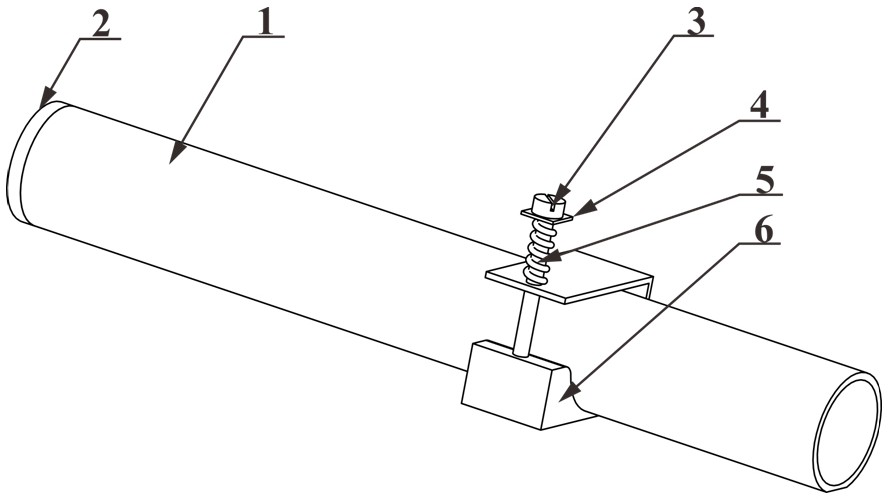

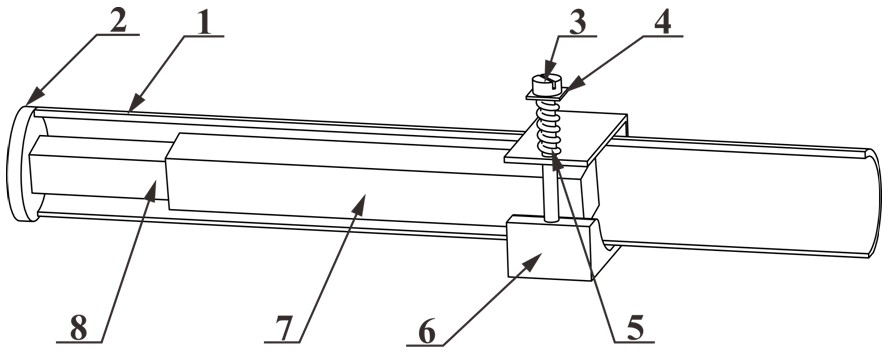

[0031] see figure 1 with figure 2 , a piezoelectric motor driven by a sawtooth wave includes a drive mechanism and a pretension mechanism.

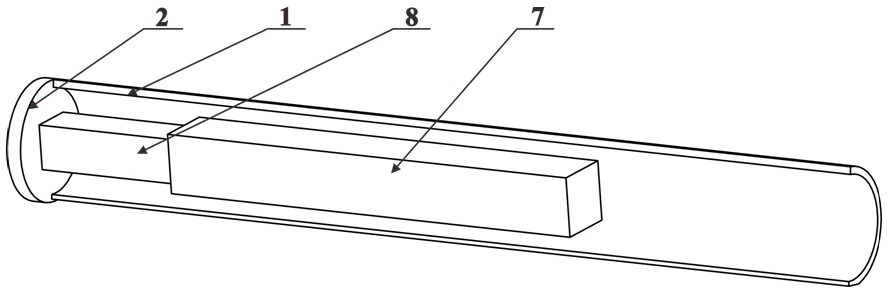

[0032] see image 3 , the driving mechanism includes a body 1 , a piezoelectric stack 8 and a mass 7 . The body 1 is tubular, with an end cap 2 fixedly installed at one end and an open end at the other end. The piezoelectric stack 8 and the mass block 7 are columnar, and one end is connected to each other; the other end of the piezoelectric stack 8 is fixedly connected to the end cover 2 , and the piezoelectric stack 8 and the mass block 7 are located in the body 1 in a cantilever shape.

[0033] see figure 1 , The pre-tightening mechanism includes a clamping block 6 , a pre-tightening bolt 3 and a spring 5 . see Figure 4 , the clamping block 6 is a U-shaped clamping block; one side of the opening end of the clamping block 6 is provided with a through hole 61, and the other side is provided with a threaded hole 62, and the pre-tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com