Spring end face grinding device

A face grinding and grinding technology, applied in the direction of grinding workpiece supports, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of low grinding efficiency, high labor intensity of operators, hidden safety hazards, etc. Achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is:

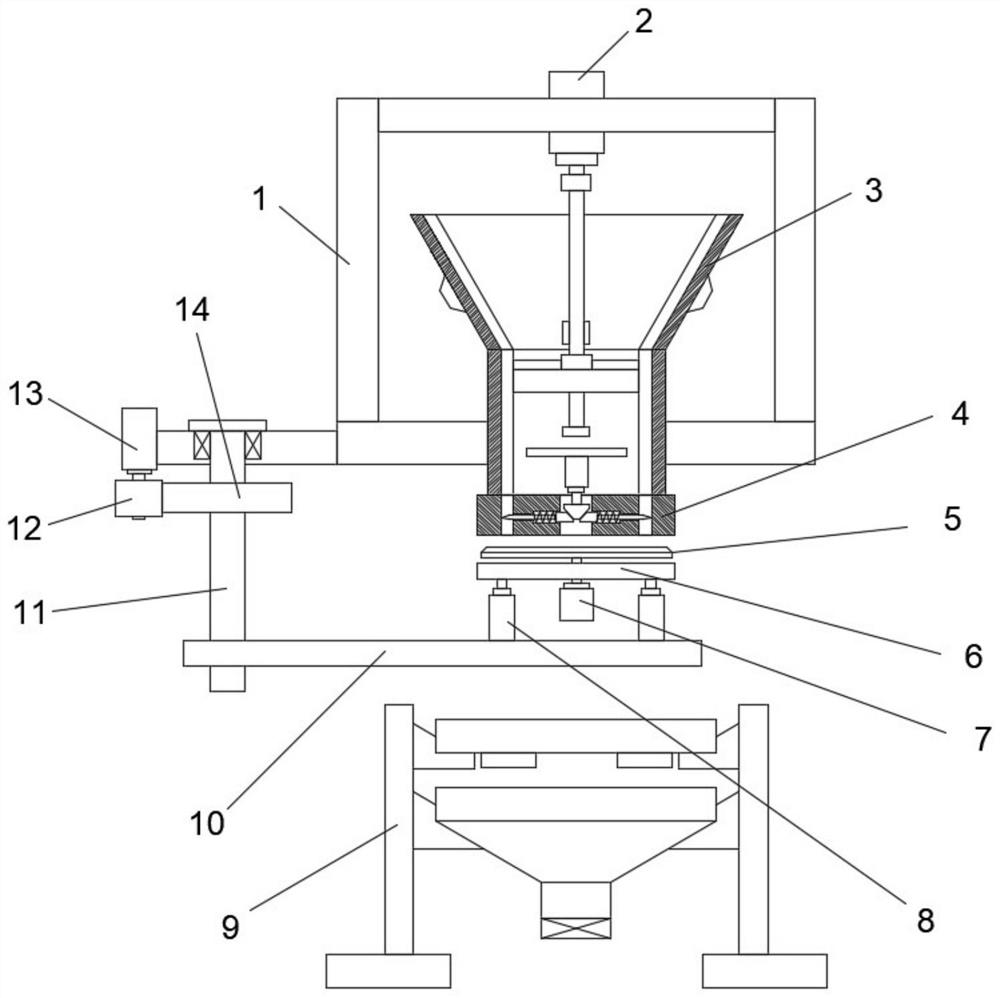

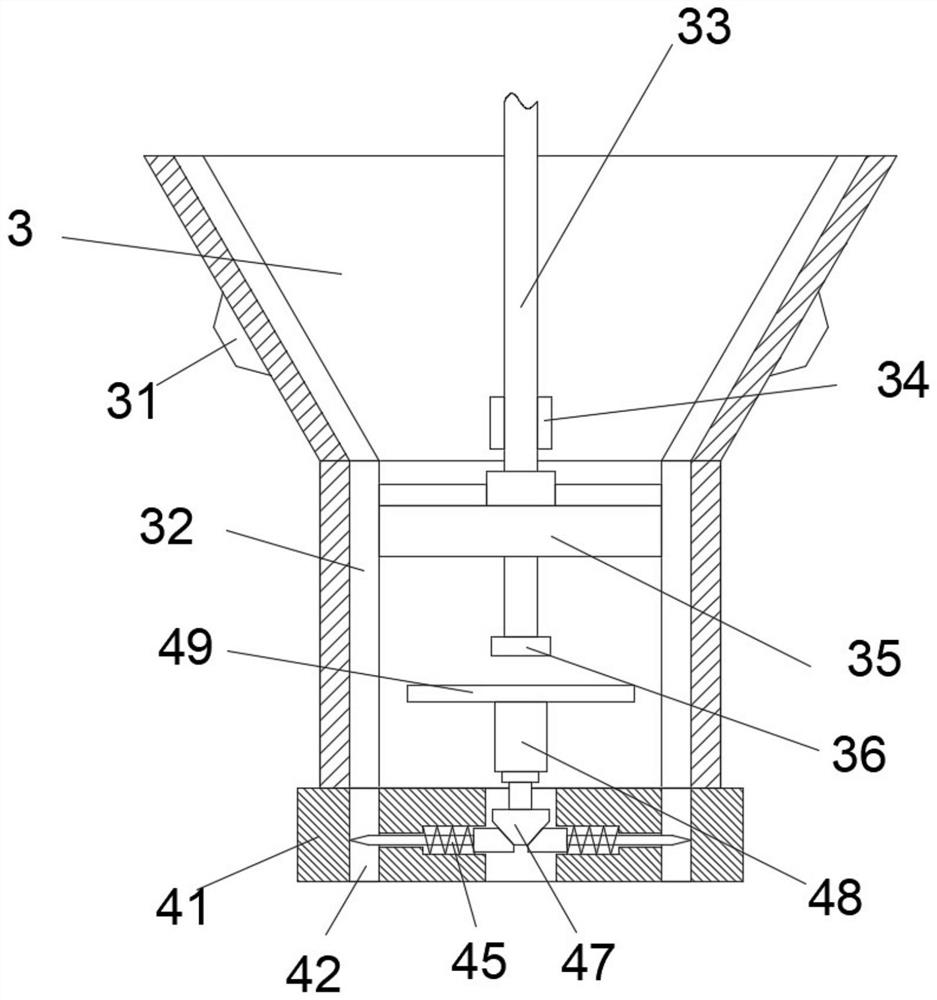

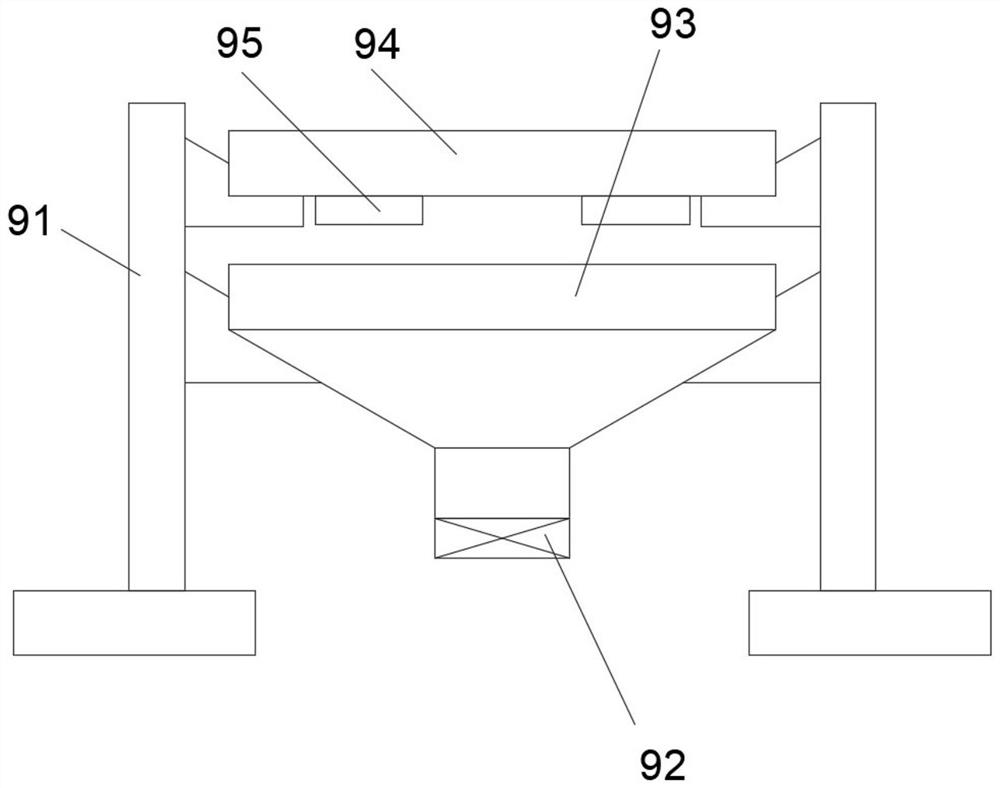

[0026] see Figure 1-6 Shown, a kind of spring end surface grinding device comprises feeding barrel 3, spring fixing mechanism 4, grinding device, material receiving device 9; Described feeding barrel 3 below is provided with spring fixing mechanism 4; Said spring fixing mechanism 4 below is provided with a receiving device 9; the grinding device grinds the spring end face fixed by the spring fixing mechanism 4; the feeding barrel 3 is vertically arranged; the upper side of the feeding barrel 3 is arranged in a funnel shape, and A second vibrator 31 is provided to facilitate feeding of the spring; the inner wall of the feeding cylinder 3 is vertically provided with a plurality of guide grooves 32; the spring enters the spring fixing mechanism 4 through the guide grooves 32; the feeding cylinder 3 A stirring block 35 is arranged inside; the stirring block 35 fits with the feeding cylinder 3; a plurality of stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com