A calibration method for scara manipulator dispensing system

A calibration method and manipulator technology, which are applied to manipulators, program-controlled manipulators, and devices for coating liquid on surfaces, etc., can solve the problems of heavy workload and inconvenient operation, and achieve the requirements of less operation time, convenient operation and satisfying production requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

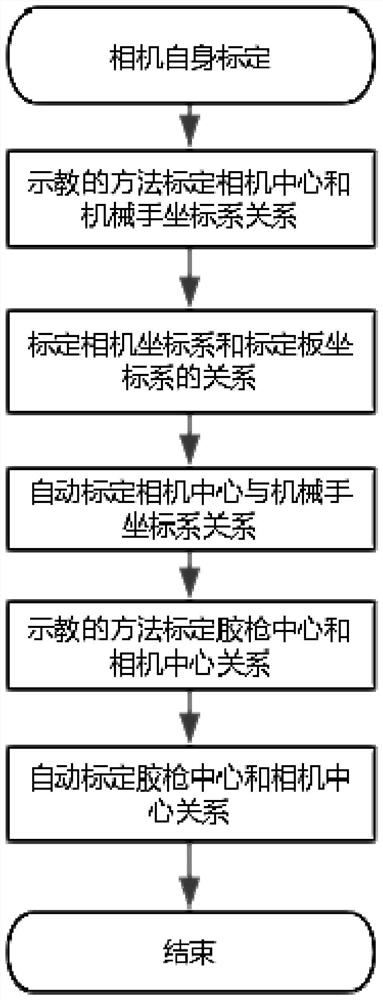

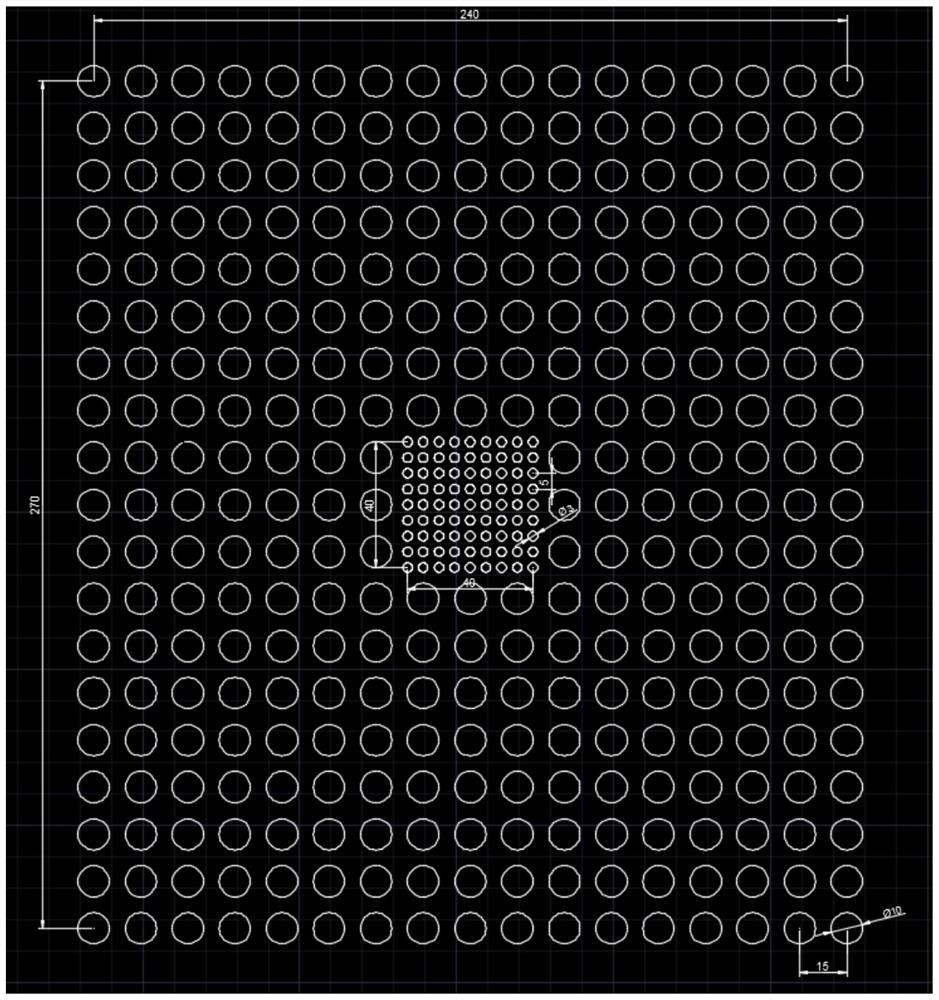

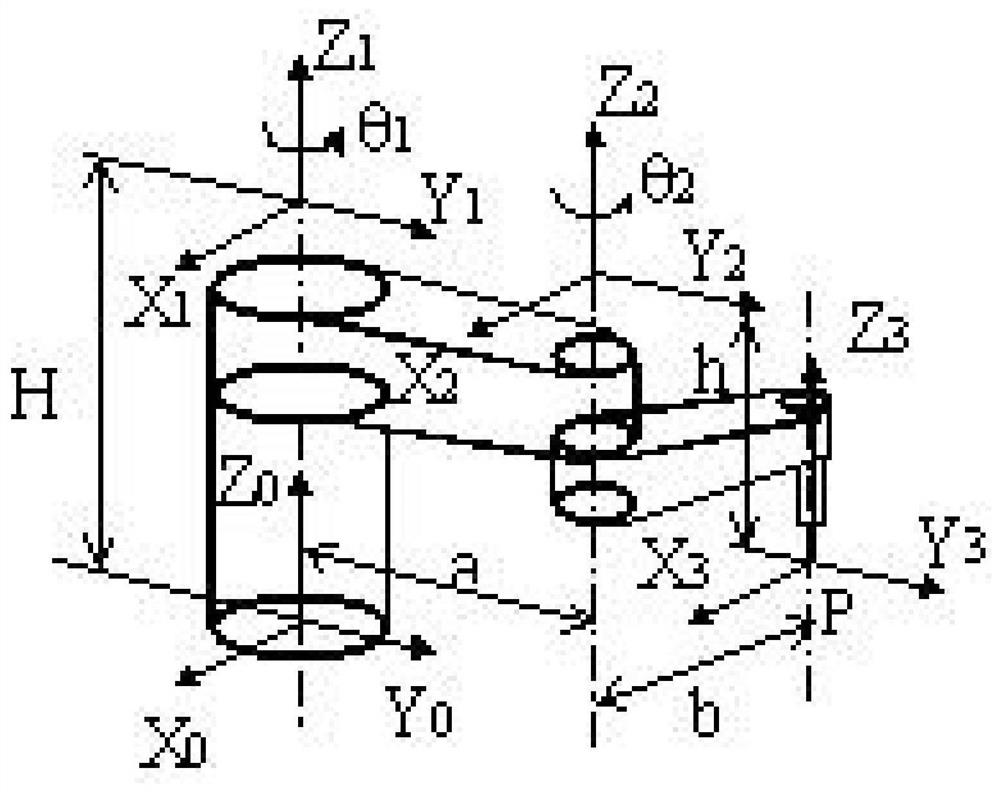

[0020] The invention discloses a calibration method of a SCARA manipulator dispensing system, which establishes a coordinate system W with the camera center as the TCP point on a large calibration board cam , the motion mechanism is a SCARA manipulator, and it is necessary to establish W cam and manipulator coordinates W Robot The relationship between the actuator is the dispensing valve, and the relative relationship matrix between the dispensing valve and the camera center needs to be established

[0021] to combine Figure 1 to Figure 3 As shown, the dispensing system includes a SCARA-type manipulator, a camera and a dispensing valve, the camera is installed on the arm of the manipulator, the dispensing valve is installed on the execution end of the manipulator, the The calibration method is realized based on a preset calibration program,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com