LED vehicle lamp module

A technology of LED car lights and LED chips, which is applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of interference from oncoming vehicles, difficult to match the luminous effect of car lights, etc., to avoid glare, improve assembly firmness, The effect of tight installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

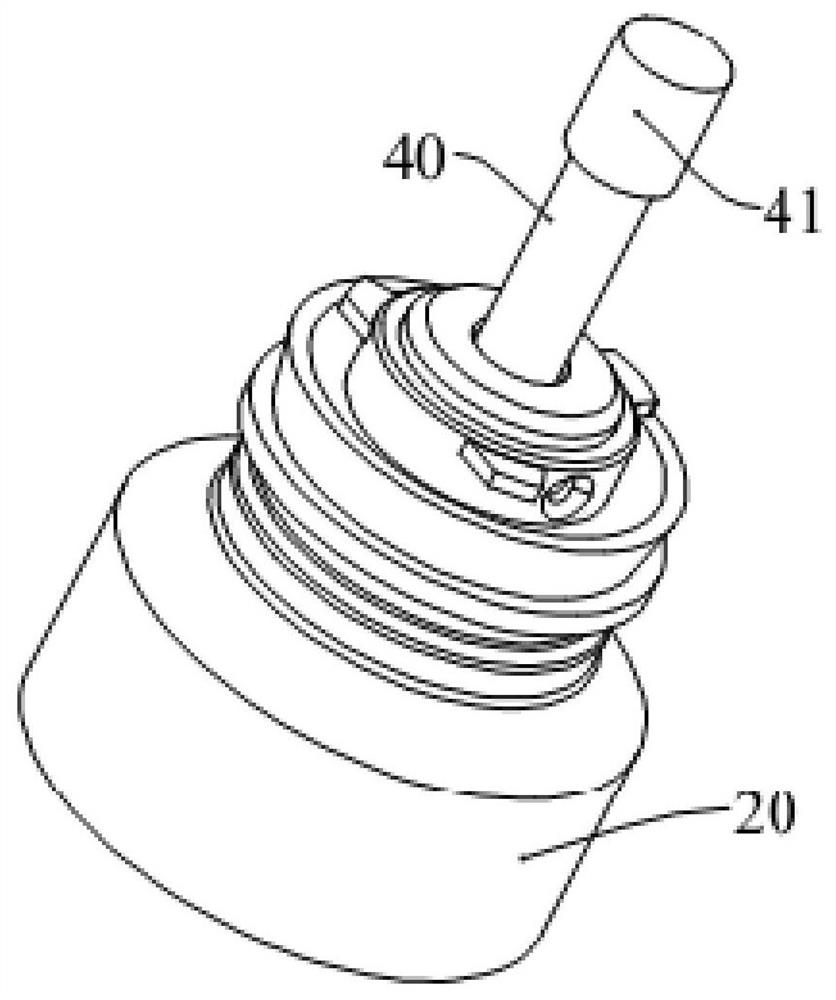

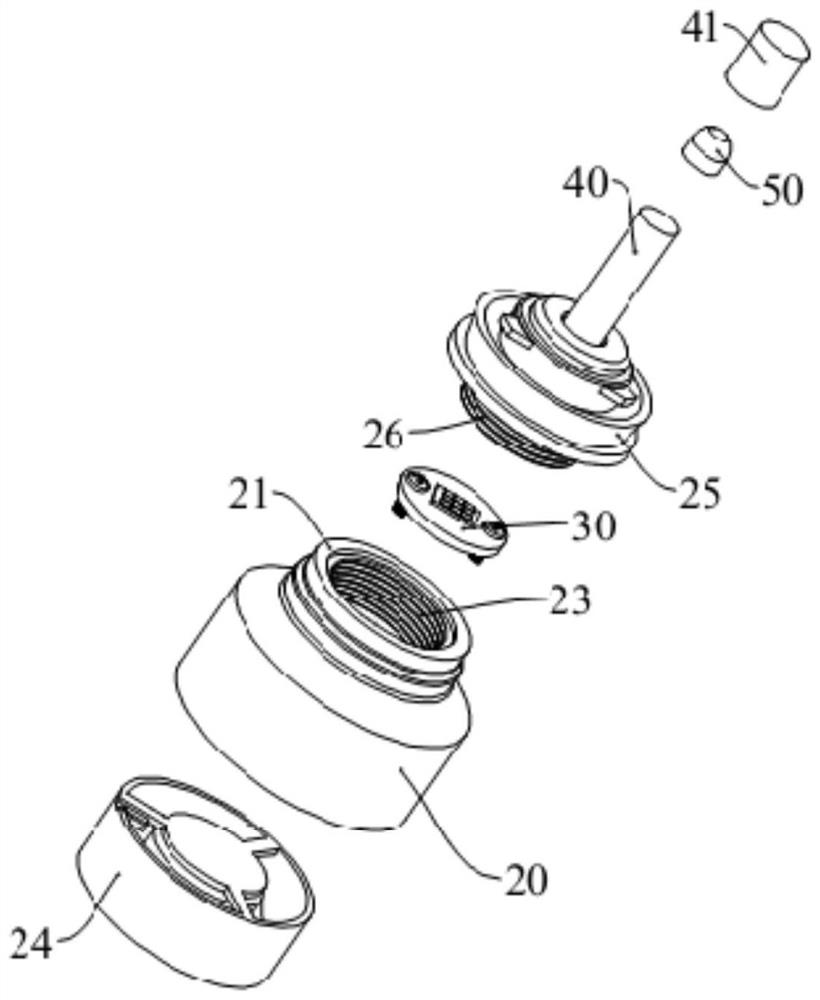

[0037] see figure 2 and image 3 , the present embodiment has a base 20, the bottom of the base 20 is provided with a cooling fan 24, for example, the bottom of the base 20 is provided with an accommodation chamber, and the cooling fan 24 is installed in the accommodation chamber. The cooling fan 24 is used to blow out the heat generated by the LED chip, thereby rapidly reducing the temperature of the LED chip. The substrate 30 is installed in the base 20, and the upper end of the base 20 is provided with a raised portion 21, and the raised portion 21 extends from the upper surface of the base 20, and the raised portion 21 is a circular columnar structure, and the The inner wall of the portion 21 is provided with an internal thread 23 .

[0038] The upper end of the base 20 is provided with a mounting base 25, and the inside of the mounting base 25 is provided with a mounting assembly. The mounting assembly is used to fix the light guide 40 in the mounting base 25. One sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com