Survey equipment and survey method for geological survey

A surveying equipment and geological surveying technology, applied in the field of geological surveying, can solve problems such as poor drilling effect, large engine vibration, and inability to control the feed depth well, so as to achieve less skew, enhanced firmness, convenience and accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in this application will be further described in detail below in conjunction with the accompanying drawings.

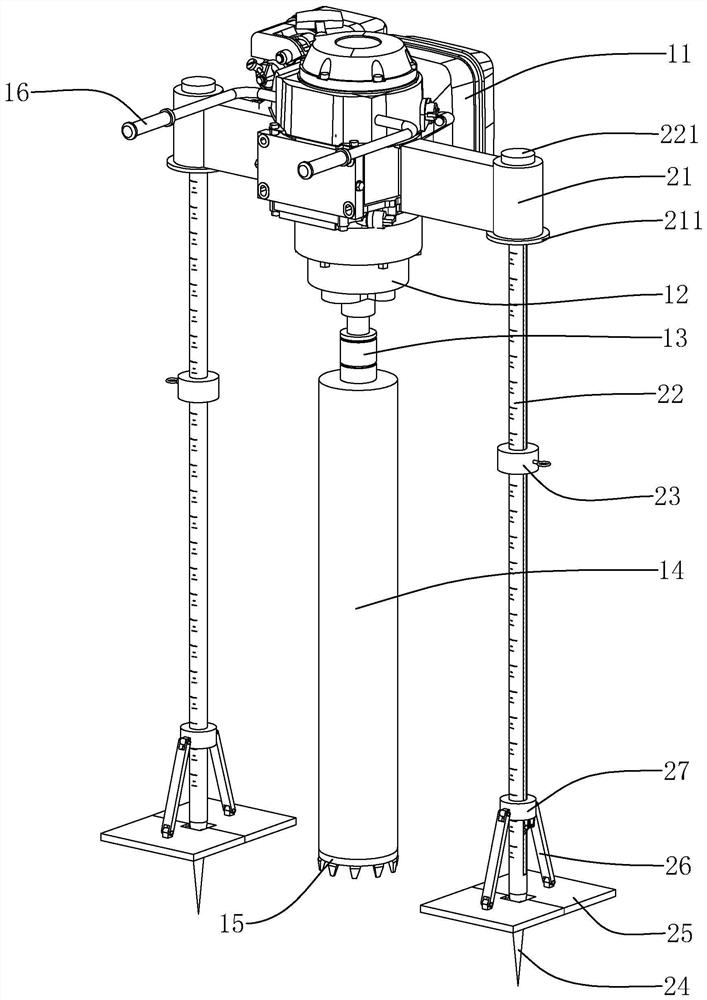

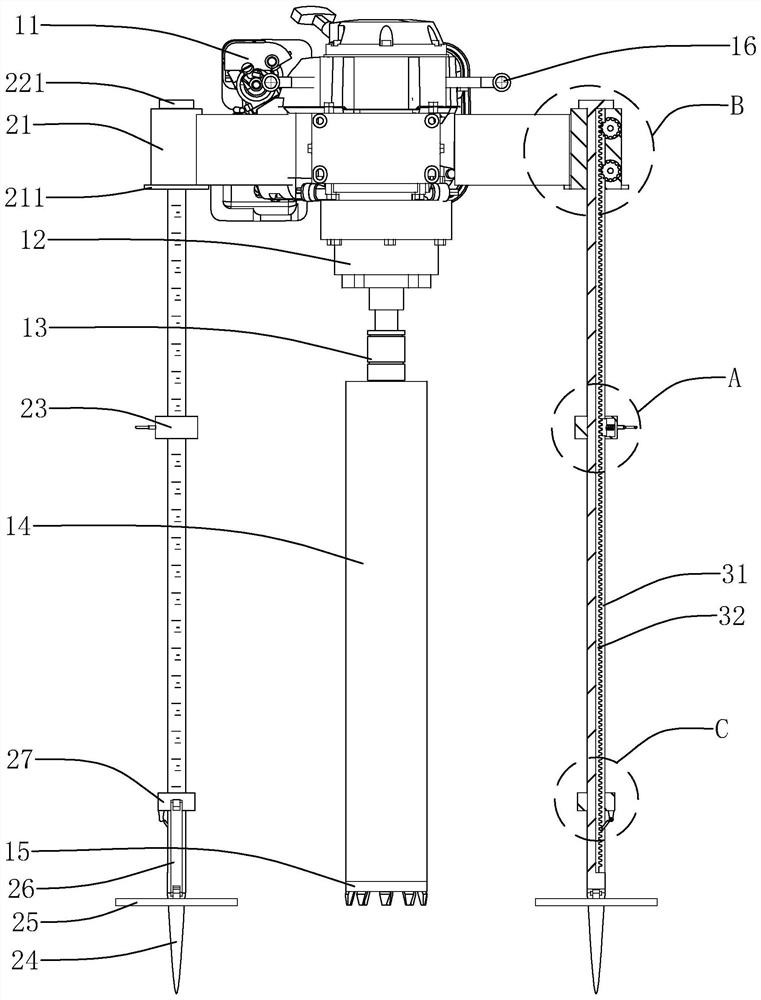

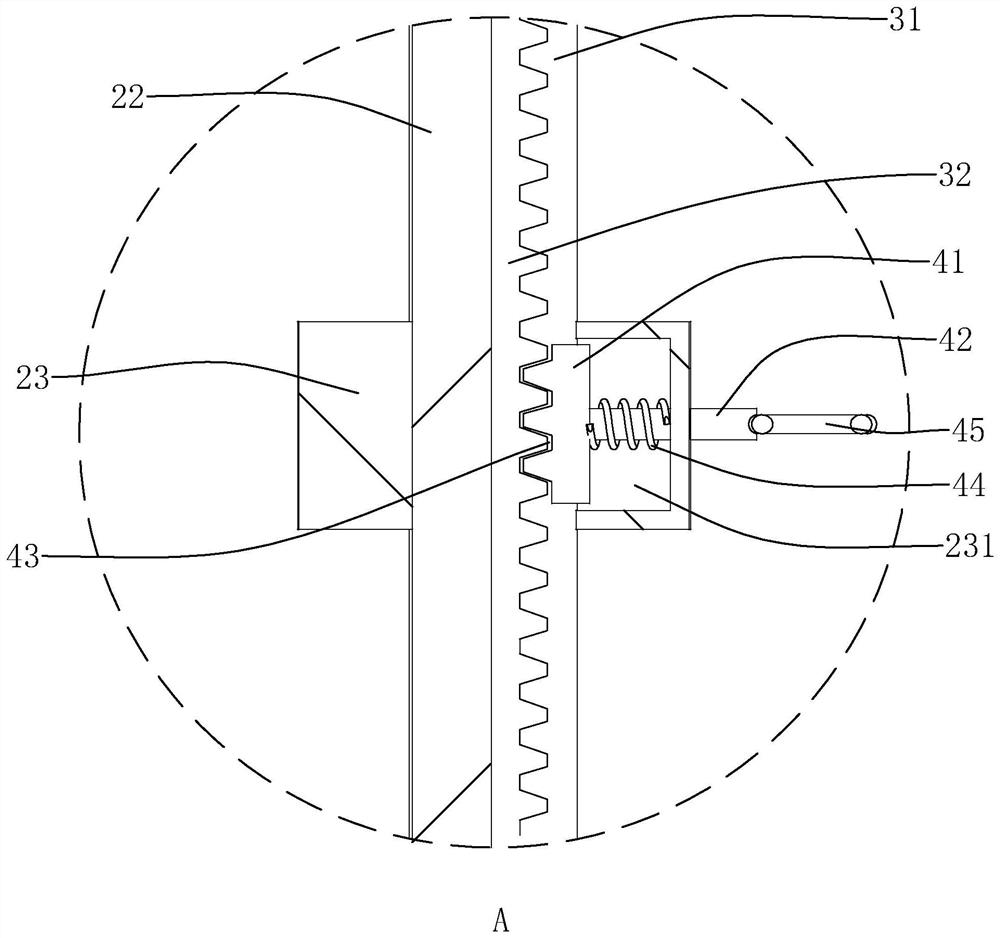

[0041] The embodiment of the present application discloses a surveying equipment for geological surveying. Please refer to figure 1 with figure 2 , a surveying equipment for geological survey comprises a motor 11, a speed reducer 12 arranged at the output end of the motor 11, a coupling 13, a core pipe 14 arranged on the coupling 13 and a drill bit threaded on the core pipe 14 15. The input end of the speed reducer 12 is connected with the engine 11 , and the output end is connected with the coupling 13 . The core pipe 14 is arranged at the end of the shaft coupling 13 away from the speed reducer 12 , and the drill bit 15 is arranged at the end of the core pipe 14 away from the shaft coupling 13 . Wherein, the engine 11 is set as a diesel engine. The axes of the coupling 13, the core barrel 14 and the drill bit 15 are collinear.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com