Folding length difference compensation mechanism of multi-folding device

A technology of folding length and compensation mechanism, which is applied to the structural components of portable computers, instruments, electrical digital data processing, etc., and can solve the problems affecting the overall thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

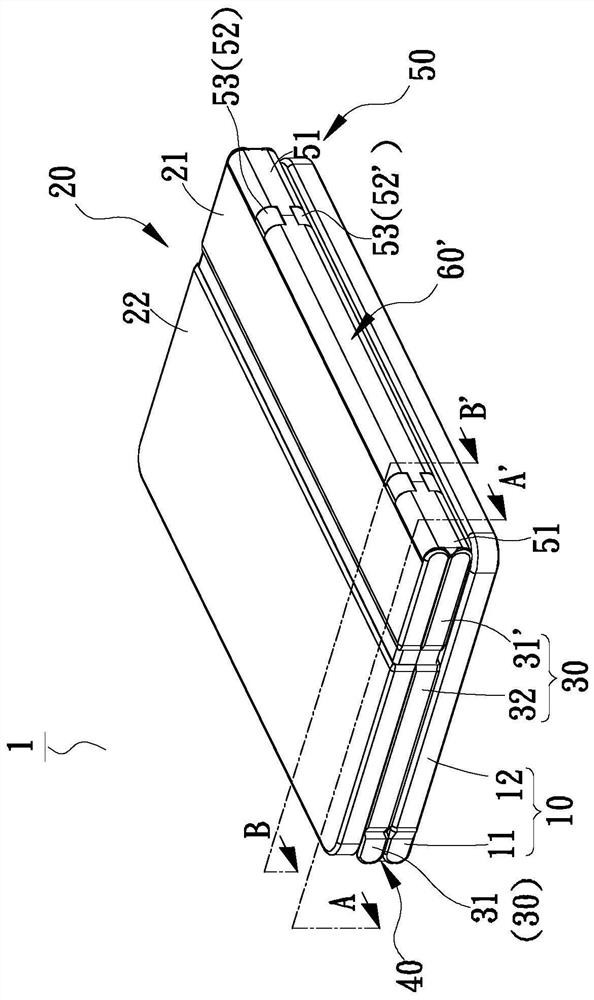

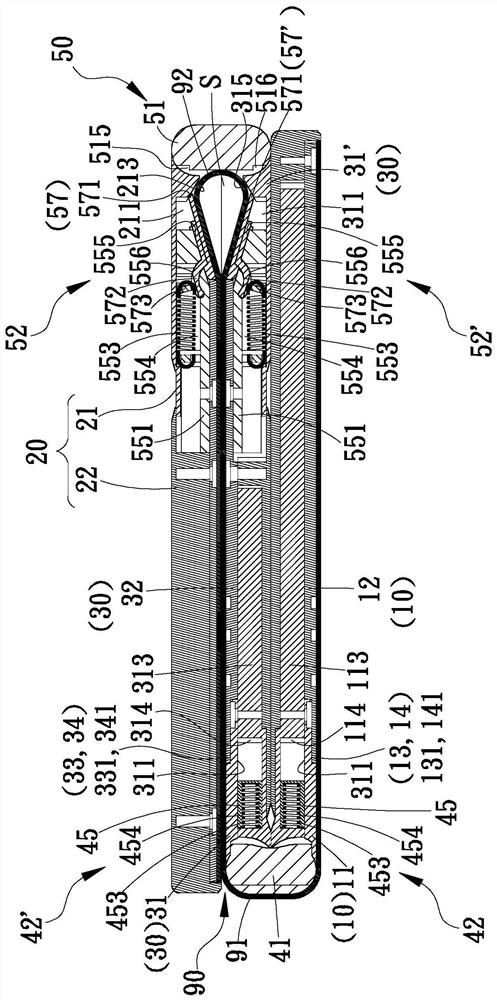

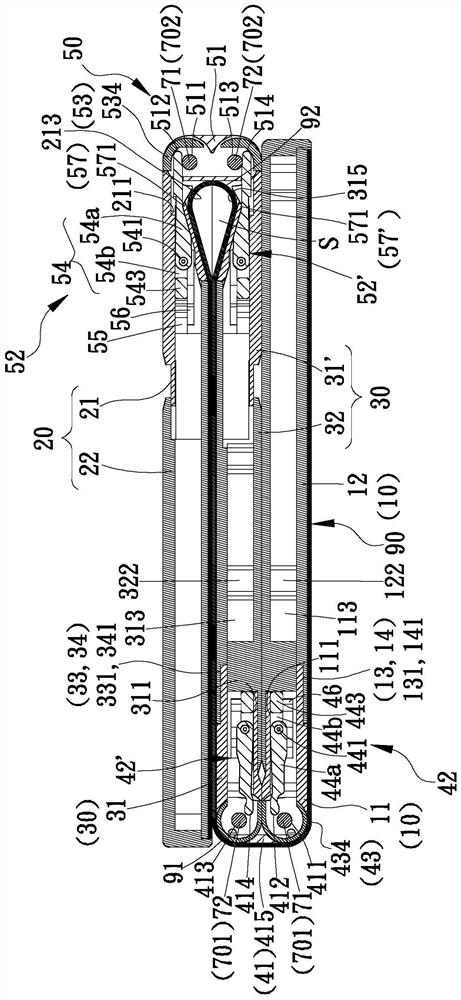

[0104] see Figure 1 to Figure 26 As shown, the present invention is a folding length difference compensation mechanism of a multi-folding device, wherein the state after the whole is completely folded is as follows Figure 1 to Figure 7 As shown, it is presented in the form of inner folding and outer folding. When the outer folding part is unfolded into a flat state, it will be as follows Figure 8 to Figure 12 As shown, when the infolding part is turned into a flattened state, it is as follows Figure 13 to Figure 16 As shown, when the whole is fully flattened, the state is as Figure 17 to Figure 20 As shown, when the whole adopts the double outer folding scheme, it presents a flattened shape and a folded shape such as Figure 21 and Figure 22 As shown, when the whole adopts the double inward folding scheme, it presents a flattened shape and a folded shape such as Figure 23 and Figure 24 As shown, before and after laying the adhesive layer are as follows Figure 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com