Material mixing method for improving ingredient uniformity of formula milk powder

A technology of formula milk powder and uniformity, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of uneven mixing, unqualified sampling, etc., and achieve the effect of solving uneven mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

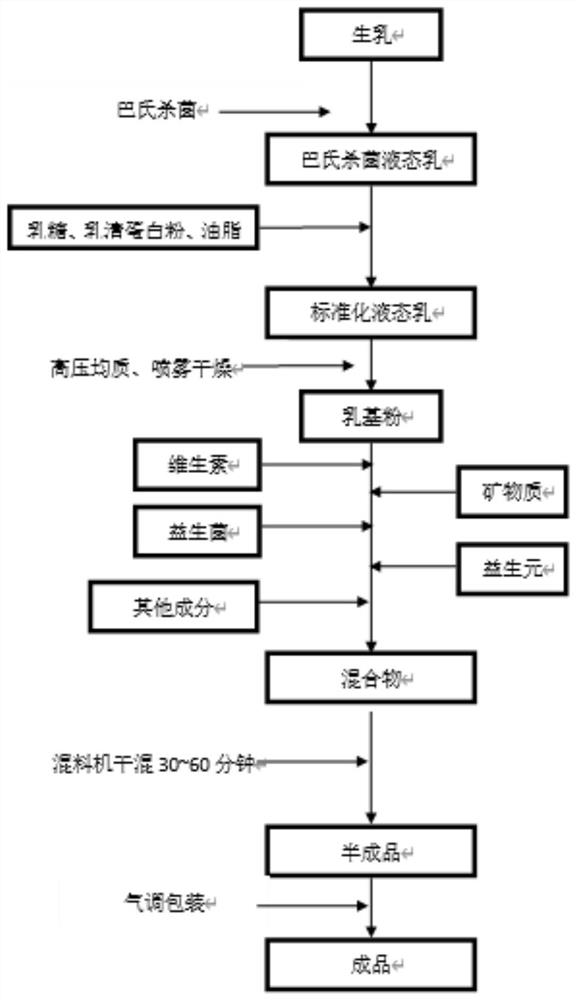

Method used

Image

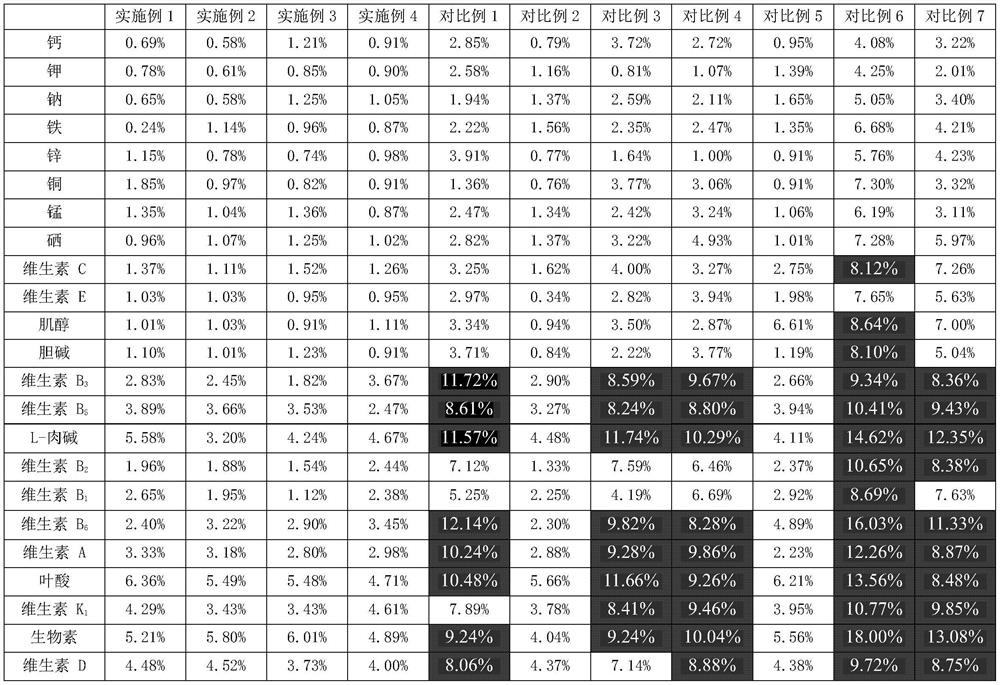

Examples

Embodiment 1

[0024] 1. Mixing batch confirmation

[0025] Carry out the batch number for each batch of raw and auxiliary materials. After confirming the formula, proceed to the follow-up process.

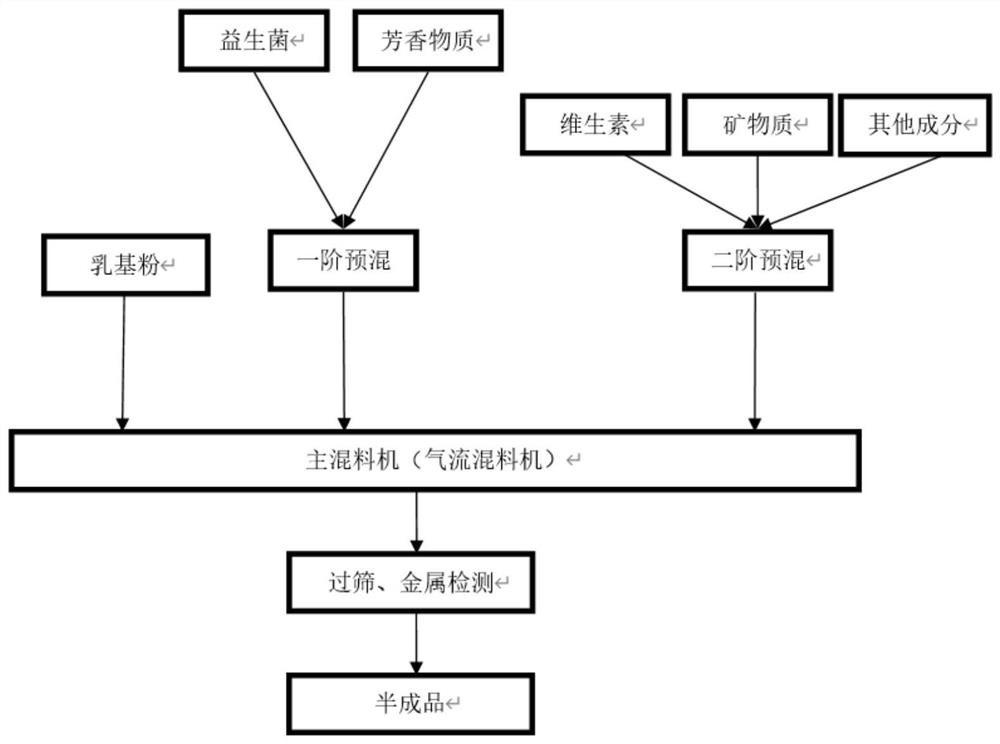

[0026] 2. First-order premix

[0027] 2.1 Premixed substances

[0028] Probiotics / aroma ingredients;

[0029] 2.2 Outer packaging sterilization

[0030] Use ultraviolet light to sterilize the surface of the auxiliary material packaging material;

[0031] 2.3 Weighing

[0032] Manual weighing;

[0033] 2.4 Premix

[0034] 2.4.1 Equipment selection

[0035] The mixing equipment adopts three-dimensional motion mixer or drum mixer;

[0036] 2.4.2 Mixing time

[0037] Mix for 3 minutes;

[0038] 3. Second-order premix

[0039] 3.1 Premixed substances

[0040] Ingredients such as vitamins / minerals / prebiotics;

[0041] 3.2 Outer packaging sterilization

[0042] Use ultraviolet light to sterilize the surface of the auxiliary material packaging material;

[0043] 3.3 Weighing

[0044] Ma...

Embodiment 2

[0064] 1. Mixing batch confirmation

[0065] Carry out the batch number for each batch of raw and auxiliary materials. After confirming the formula, proceed to the follow-up process.

[0066] 2. First-order premix

[0067] 2.1 Premixed substances

[0068] Probiotics / aroma ingredients;

[0069] 2.2 Outer packaging sterilization

[0070] Use ultraviolet light to sterilize the surface of the auxiliary material packaging material;

[0071] 2.3 Weighing

[0072] Manual weighing;

[0073] 2.4 Premix

[0074] 2.4.1 Equipment selection

[0075] The mixing equipment adopts three-dimensional motion mixer or drum mixer;

[0076] 2.4.2 Mixing time

[0077] Mix for 10 minutes;

[0078] 3. Second-order premix

[0079] 3.1 Premixed substances

[0080] Ingredients such as vitamins / minerals / prebiotics;

[0081] 3.2 Outer packaging sterilization

[0082] Use ultraviolet light to sterilize the surface of the auxiliary material packaging material;

[0083] 3.3 Weighing

[0084] Man...

Embodiment 3

[0104] 1. Mixing batch confirmation

[0105] Carry out the batch number for each batch of raw and auxiliary materials. After confirming the formula, proceed to the follow-up process.

[0106] 2. First-order premix

[0107] 2.1 Premixed substances

[0108] Probiotics / aroma ingredients;

[0109] 2.2 Outer packaging sterilization

[0110] Use ultraviolet light to sterilize the surface of the auxiliary material packaging material;

[0111] 2.3 Weighing

[0112] Manual weighing;

[0113] 2.4 Premix

[0114] 2.4.1 Equipment selection

[0115] The mixing equipment adopts three-dimensional motion mixer or drum mixer;

[0116] 2.4.2 Mixing time

[0117] Mix for 7 minutes;

[0118] 3. Second-order premix

[0119] 3.1 Premixed substances

[0120] Ingredients such as vitamins / minerals / prebiotics;

[0121] 3.2 Outer packaging sterilization

[0122] Use ultraviolet light to sterilize the surface of the auxiliary material packaging material;

[0123] 3.3 Weighing

[0124] Ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap