Tobacco sheet dip-coating method capable of controlling coating rate

A tobacco sheet and coating method technology, applied to the device for coating liquid on the surface, tobacco, preparing tobacco, etc., can solve the problem that there is no controllable area of coating rate, and it is impossible to accurately realize the adjustment of coating rate and controllable adjustment , complex control methods and other issues, to achieve the effect of simple operation, easy operation, and overcoming difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

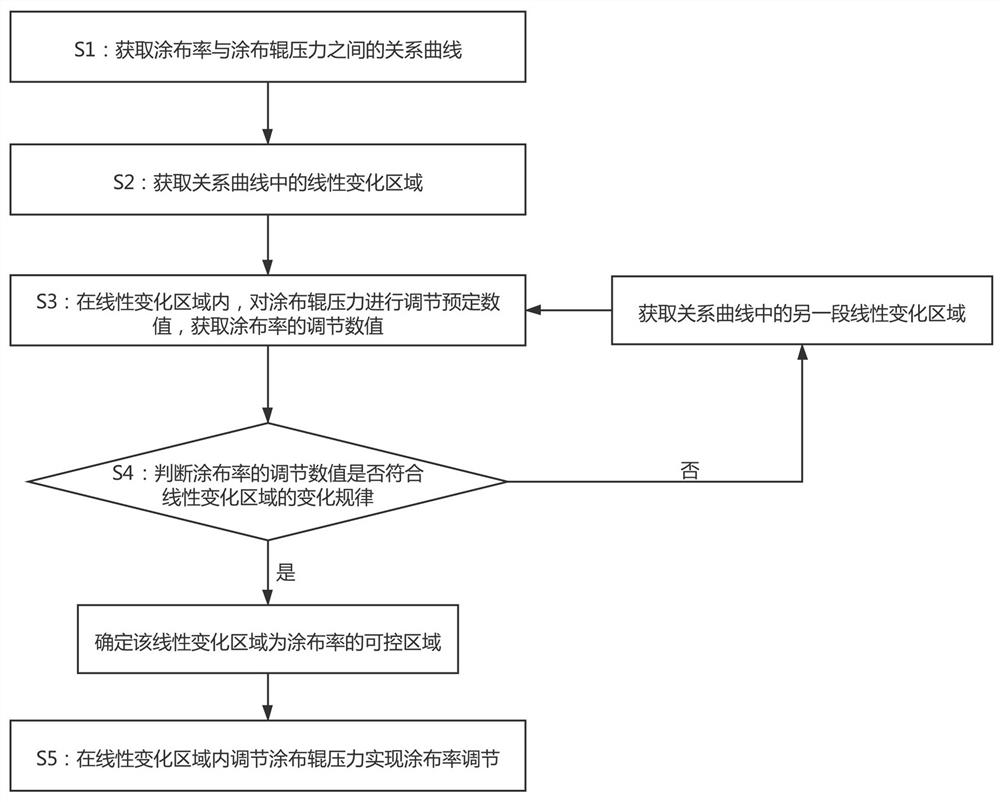

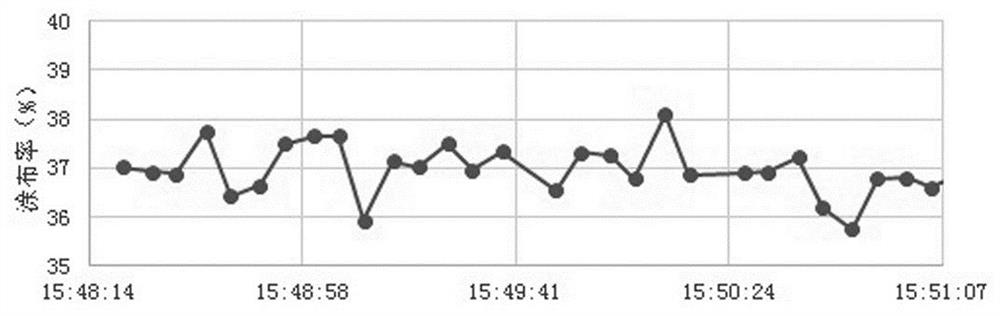

[0035] Example: such as Figures 1 to 3 Shown, be only wherein one embodiment of the present invention, a kind of tobacco sheet dip coating method of controllable coating rate, comprises the following steps:

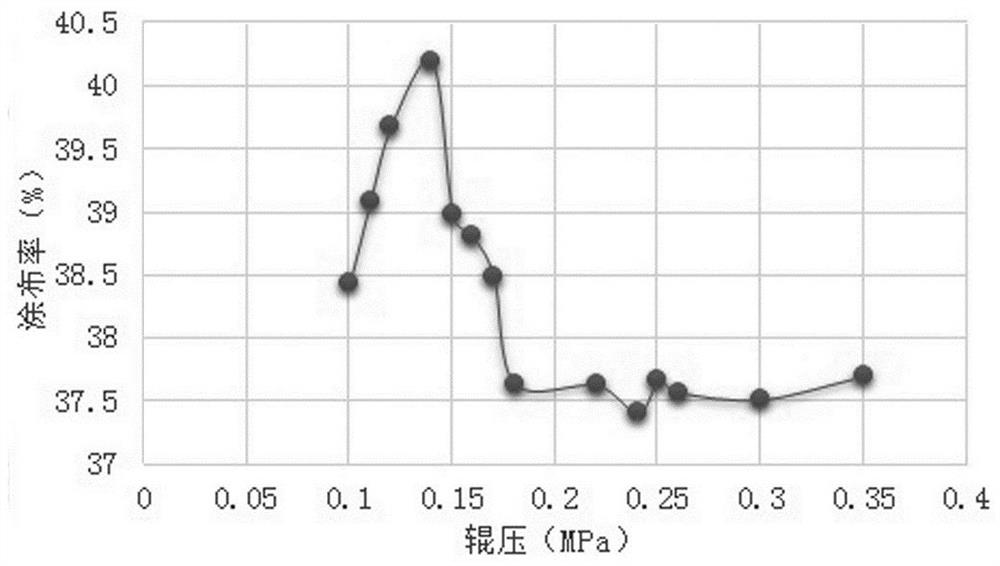

[0036] S1: Obtain the relationship curve between the coating rate and the coating roller pressure;

[0037] Before performing step S1, it is necessary to set up a coating device, the coating moving roller and the coating fixed roller are installed on the frame, the coating liquid tank is arranged above the coating moving roller and the coating fixed roller, and the receiving tank It is installed under the coating moving roller and the coating fixed roller to collect the leaked coating liquid, and the sheet to be coated passes from top to bottom, passes between the coating moving roller and the coating fixed roller, and is coated, and then is coated Horizontal output below the fabric roller.

[0038] Coating roller pressure device: connected with the coating moving roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com